Chartered application Presentation

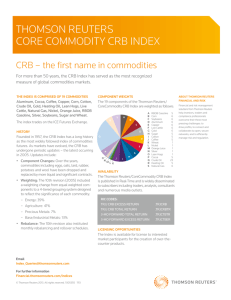

advertisement

Chartered Application Presentation (Brisbane EA office, 15th November 2012, 1.00 pm) S. VIGNAESWARAN B. Eng (MONASH, AUSTRALIA) MSC. BIS (KEELE, UNITED KINGDOM) MIE(Aust) EA NO: 3393786 This presentation is based maximally on the Brisbane experience, and has been supplemented with Malaysian experience where it is unavoidable. Agenda for today’s presentation GENERAL INTRODUCTION COMPLIANCE TO EA REQUIREMENTS MACRO VIEW OF PROJECTS DONE K E Y V E R I F I C AT I O N A R E A S C A B L E S I Z I N G S O F T WA R E C O N V E Y O R B E LT D E S I G N A U S T R A L I A N S TA N D A R D S S U S TA I N A B I L I T Y ENGINEERING ETHICS My electrical (electrical automation) engineering experience. Project Location Category Details Role University campus Saudi Arabia Building Services AUD 2.2 billion Consultant Coal Seam Gas India Oil & Gas upstream AUD 10 million ++ EPM / Designer Power plant Malaysia Utility AUD 700,000 ++ DPM /Site Engineer Renewable / Energy audit Malaysia Utility AUD $20,000 Design Consultant Wilson Transformer Victoria, Australia OEM Transformer design Designer / Trainee ELCOM Sydney, Australia Quasi-Govt Power station EIA Designer / Trainee Bitumen plant Malaysia Private sector AUD 100 million ++ EPM / Designer 100 ++ tenders (international) Malaysia All segments Up to AUD 130 million Designer / Estimator Distribution SCADA Malaysia Utility Automation $100 million ++ Specialist vendor Mineral Mining plant Brisbane, Australia Mining AUD 100 million ++ E&I Designer currently Malaysia Utility On-going Utility designer Points to note: Varied projects International Multi-market segment Large scale projects Multiple roles & scope 22 years of experience 20 0 Submission reference: item A- K 5 years 10 years Design Site work 6 years Management 1 years others Compliance reference: C1.1 – C1.3 What I have done to maximize my chances of being a chartered engineer …. Shared values My practices to date Ethical behavior I have indirectly fulfilled this with my signed CV and by the comments in the ethical slides Competent performance I have published 3 international and numerous career related papers and have fulfilled the CPD requirements in 1 year Innovative practices This will be elaborated later in the standards, conveyor design and cable sizing slides Equality of opportunity I have worked with employers from all background and under varied circumstances in Saudi, India and elsewhere, like EWB. Social justices I have supported and made a difference by undertaking work in developing and needed areas like CSG and renewable energy Sustainable development This will be elaborated later under the sustainability slide The learning process is as important as the knowledge which is acquired Compliance reference: C1.1 – C1.3 Projects that I have been involved (in Australia) MAK – copper/molybdenum project E&I specifications Velta – Arc furnace plant electrical (green field) design Ernest Henry, Mt. Isa Magnetite plant – E&I expansion / upgrade (brown field) design Covered areas: Greenfield, Brownfield, Standards, Design and Engineering Office Practices Compliance reference: C2.1 – C2.6, C3.1 – C3.6, E1B.1 – E1B.8, E4B.1 – E4B.4 MAK project Three areas of concern: COMPREHENSIBLE list of applicable standards for CB, Tx, cables etc? Can the common and specific standards be referenced separately? Can I sign the specification documentation prior to being a chartered? Specifications referring Australian standards 080-I610-0001_0 AS / NZS 3000 AS ISO 15745 Project Specification for Process Control Systems.pdf Electrical installations Industrial Automation Systems and Integration - Open Systems Application Integration Framework Industrial Automation Systems and Integration - Integration of Industrial Data for Exchange, Access and Sharing Degrees of protection provided by enclosures (IP Code) Electromagnetic compatibility (EMC) Functional Safety of Electrical/Electronic/Programmable Electronic Safety Related Systems Programmable Controllers Functional Safety - Safety Instrumented Systems for the Process Industry Sector AS ISO 18876 AS 60529 AS 61000, AS 61508, AS IEC 61131, AS IEC 61511, 080-I610-0002_0 AS 2381 AS 3000 AS 60529 Project Specification for Nucleonic Instruments.pdf (All parts) – Electrical equipment for explosive gas atmospheres – Selection, installation and maintenance Electrical installations Degrees of protection provided by enclosures (IP Code) 080-I610-0003_2 AS/NZS 3000 AS/NZS 60079 AS/NZS 60529 AS/NZS 61000 AS/NZS 61241 IEC 60534 ISA 5.1 ISA S75.01.01 Project Specification for Control Valves.pdf Electrical installations Electrical apparatus for explosive gas atmospheres Degrees of protection provided by enclosures (IP code) Electromagnetic compatibility (EMC) Electrical apparatus for use in the presence of combustible dust Industrial-process control valves Instrument Symbols and Identification Flow Equations for Sizing Control Valves Compliance reference: C2.1, C2.4, E1B.8 Velta arc furnace design Detail of electrical design logistics; ● reliability of source ● redundancy for S/S ● cable routing logistics ● power harmonics and dips Gaining confidence in the transferred knowledge is as important, if not more than the transfer of knowledge itself = technology absorption Greenfield design Compliance reference: C1.4 Xstrata Mt. Isa Magnetite plant capacity expansion project Existing drawing Client standards highlighted to Client Inconsistency check Client approval Internal design process Electrical (conveyor) design process Operations & maintenance Existing design guidelines Component failure Contingency consideration Power failure Australian standards Cable design process Automation failure Client approval Brownfield design New drawings Applicable standards Revised guidelines Compliance reference: C2.1 – C2.6 Electrical design software challenges ( standardize electrical design activities) No flexibility / traceability in its use Electrical cable design No guidelines in its design usage PowerPac Pro Software issues (slides) Constraint in time and resources PowerCAD design software Costly to purchase / no vendor support Use demo version for initial design Verify the output Sample test calculations Field side verification Electrical design office administration AS 3000 guidelines Submit for Client approval Use Excel spreadsheet Format cable design presentation in Excel Finalize cable size calculation Compliance reference: C3.1 – C3.6 PowerPac software issues - 1 An upstream breaker of 16 Amps was chosen with a specific let through energy. Cable size : 25 mm2 Compliance reference: E4B.1 – E4B.4 PowerPac software issues - 2 A larger upstream breaker was chosen with its corresponding let through energy Cable size : 35 mm2 Compliance reference: E4B.1 – E4B.4 PowerPac software issues - 3 A much larger breaker size with a comparatively smaller let through energy Cable size : 25 mm2 Do we accept this on the basis that a RELIABLE 100% fast trip will be required to limit the let through energy? Does this software address copper clad aluminum (CCA) cables? Does the standards address copper clad aluminum (CCA) cables? Why do cable short circuit calculations? Worst case = costly cable size Does the software establish the boundary of design accuracy? kV? Compliance reference: E4B.1 – E4B.4 CONVEYOR BELT PULL WIRE SWITCH DESIGN Pullwire This active logic circuit carries continuous current at 110Vac which is energy inefficient. The contacts can weld under continuous current at 110Vac The pullwire logic can be implemented by ‘negative logic’ circuits as in the Oil & Gas field. Compliance reference: E4B.1 – E4B.4 Australian standards This compliance flowchart refers to electronic switches while the prior one refers to electro-mechanical switches. Standards referenced determine application or visa versa? Need to search compliance at Clause level to introduce cross segment good practices. Do we introduce SIL and redundancy of power supply? Compliance reference: E4B.1 – E4B.4 Sustainability - The need to fulfill current needs without adversely impacting future options or needs. Non-sustainability Sustainability Using a cable one size larger to cater for future loads Placing plant equipment and building with a contiguous future growth space Using electrical design software with systematic design approaches Considering environmental issues and co-ordinating with the other disciplines for a holistic design approach Energy saving approaches as in the conveyor design issues Sizing the cable exactly for the current load capacity Placing plant equipment randomly and/or with no usable space Doing design calculations on paper without traceability and/or verifiability. Consider only E&I issues and set design responsibility battery limits Accept current practices and not consider possible improvements or enhancements To have the same privileges or close to the same benefits in the future as a result of our present action Compliance reference: E1B.1 – E1B.4 Engineering ethics This can be summarized into 2 key words; Judgment Judgment is making an informed decision as what is contextually right and wrong. (why) Ethically wrong but legally right circumstances in engineering practices … Charging Client for research work while doing Client’s project Not highlighting possible operational and maintenance impact of design decisions Not requesting for additional resources to carry out a comprehensive plant design Not finding international jobs when the local jobs are limited or to gain exposure Not changing specialization or moving out of comfort zone when the circumstances require to do so. Transparency Transparency involves disclosure of the whole issue over the period in concern, to all the stakeholders. Stakeholders involves all those affect by the issue now and in the future. Disclosure involves discretion (or it is whistle blowing) “ The world needs more smart, intelligent and tech savvy engineers and less of cunning, devious and legally savvy practitioners ” Compliance reference: C3.1 – C3.6 Chartered Application Presentation (Brisbane EA office, 15th November 2012, 1.00 pm) The End Why I Should be a Chartered Engineer Outcomes Activities I have been a professional in my field My EA submission is based on 1 year in Australia I had limited opportunities to fully comply I have adopted continuous learning process I am sharing my knowledge with my peers I need to share my knowledge with my juniors in a recognized manner I need to legally contribute to the Australian engineering arena I intend to work and live in Australia permanently Completed CPD and Stage I requirements I have had no adversities throughout my career The focus was on my Australian experience only A full project life cycle was not possible due to current global economic circumstances Learning flow chart highlighted in the slides EA project management presentation and international papers presented I have 22 years of validated international engineering experiences to share CPEng is required to practice in QLD and a valued asset elsewhere in Australia CPEng is a necessary recognition to provide designer services, increase job and career opportunities Currently working in Malaysia as an Electrical Utility Designer