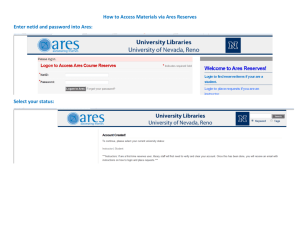

ARES Overview forSFT..

advertisement

DARPA ARES Program Ken Dorsett 25October 2014 What is ARES? Transformer Phases I and II • Modular Concept • Roadable VTOL Multi-Mission VTOL Transport UAS • Compact Landing Zone – Half of Typical Helo • Higher Speed Than Helos • Embedded with Infantry • Closed Rotor for Safety • Field-Changeable Payload ARES Aerial Reconfigurable Embedded System User Defined Payload Modules Modular Cargo UAS VTOL ISR KMAX • Pioneering Unmanned Cargo • Gets Trucks Off IED Roads AACUS • Autonomous Aerial Cargo Utility System CASEVAC • Highly Autonomous VTOL, Navigation, Obstacle Avoidance, Autoland • Fly-By-Wire Flight Controls with Redundancy Autonomous Control • Intuitive Human / Machine Controls for Non-Aviator Operators Separable UAV 2 ARES Operational Vehicle Vision • Next Generation Modular VTOL Unmanned System • • • • Field-Changeable Payloads – Multi-Mission with Single Type of Lifter Compact Landing Zone – Half of Typical Helo Tilting Ducted Fans - Closed Rotor for Safety and Speed Highly Autonomous – Usable by Non-Aviator Troops in the Field Deliver Light Vehicles • SOF Support Unmanned Cargo • Food, Fuel, Water, Ammo • Palletized loads CASEVC • Dedicated Medical Lift • Humanitarian Aid • Disaster Relief Small Unit Transport / Utility • Armed Scout • SOF Infil/Exfil VTOL ISR • Purpose Built Sensor Pod and BLOS Comms • Longer Loiter w/ Added Fuel 3 What is the Role for ARES? Point to Point Delivery of Right Sized Loads for Users = • • • • Door to Door Delivery at Point of Need Multiple Units Operating Simultaneously Each Modular Vehicle is Lower Cost than Heavy Lifter Autonomous Delivery – Not Tied to GCS vs. Mass Transportation of Bulk = • • • • Emphasizes Design for Max Lift Weight Speed Secondary Needed for Outsize Cargo or Heavy Items Larger and more Expensive Lifter 4 ARES –Modular UAS Concept Integrates Existing Tech Twin OTS Turboshaft Engines • Reliability and Redundancy • Geared to Cross Drive Shaft • Scalable Systems Fly By Wire Controls • Triplex for Safety and Redundancy • Sensors for Automated Navigation and Landing • iPad style mission programming Payload Pods Sized for User Needs • Low Cost – Interchangeable Pods • Payload Protected from Wind and Weather Twin Tilting Ducted Fans • Tailored Duct Shape for Rapid Transition to/from VTOL • Mono-Cyclic plus Aero Controls • Scalable Closed Rotor for Small Takeoff and Landing Area • Improved Safety for Ground Operations • Half the Landing Area of Conventional Helo • Folding Outer Wing Panels 5 Demonstration Program • Build and Fly Demonstrator in 2015. Show Design is Traceable to the Field Vehicle – Full Scale Flight Module – Maximum Use of COTS Hardware – COTS Engines, OTS Actuators, Gears, Flight Control Hardware, etc for Low Cost – Ground Control Station for Remote Pilot UAV Demo • Demonstrate Core Capabilities of Modular VTOL UAV Flight – – – – – Measure Thrust on Ground Test Stand Demonstrate VTOL and Hover Demonstrate Transition to Forward Flight and Back to Hover Demonstrate Basic Handling and Performance in Flight Demo Modular Payload Delivery and Separable Flight 6 DUCT CHORD 2.57 FT ARES Demonstrator General Arrangement 41 ft SPAN OVERALL HEIGHT 9.87 FT 16.2 FT 7 Phase III Demo Flight Test Plan Build-up to full graduation flight test with cargo delivery Test Build-up Hover • IGE controllability • OGE controllability • Maneuver • Translation Handling Qualities Evaluation Climb to 10,000’ Altitude Transition to Forward Flight Vertical Landing Return to Test Site VTO Transition • Controllability • High speed Cruise Fuel Burn Measurement Cruise Flight • Low altitude • Fuel flow • At altitude FM Returns to Start Point VTO Repeat tests with Cargo Pod And Payload Handling Qualities Evaluation Vertical Landing Manually detach cargo pod Test site: Yuma Test Center (YTC), UAS & Aviation Test Facilities 8 Wind Tunnel Test - Oct 2013 and July 2014 Cruise Transition Hover 9 Demonstrator Fabrication in Process Duct Fabrication in Progress Airframe Parts Machined Control Actuators in Test 10 Demonstrator Fabrication in Process Gearboxes in Machining Right Angle Gears from CH-53 Prop Hubs Machined; Tension Straps Built Final Machined Prop Blade Mold 11 Summary • Next Generation of VTOL UAS – ARES = Aerial Reconfigurable Embedded System – Modular VTOL Payload Delivery – Cargo, ISR, other – Designed for Operation by Non-Aviators (Infantry) • Working toward Demonstrator Build and Test in 2015 – Fast Paced DARPA Demonstration Program – Hardware Being Built Now for Demonstrator – Demonstrator will be Remote Piloted • Working Transition to Operational System – Talking to USMC, US Army, SOCOM, other users – Gathering User Input for Operational Requirements – Incorporate Technologies for Autonomy 12