Set Based Design - Rose

advertisement

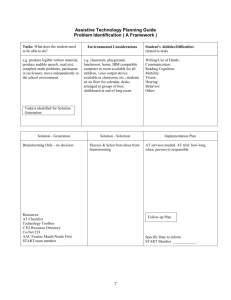

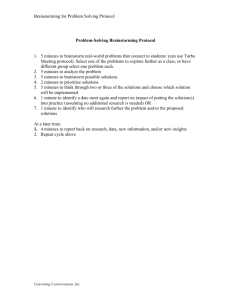

Set-Based Design Our operating assumption is that we want to be better designers and we are looking for ways to improve our techniques. Review Creativity/Brainstorming Creativity is a divergent thinking skill in which we postpone judgment and try to see a situation from as many different perspectives as possible. Brainstorming is a term used for the creative generation of many ideas. What Do We Do With Brainstorming? • How quickly did you select an idea for your device? • How many ideas did you generate before you got there? • With brainstorming the idea is to go back and look at all of the ideas that you generated and generate many feasible ideas. (not to decide on an idea and then make a brainstorming list) Now what? • Typically, use a concept selection technique to select one or two ideas for continuation. • Selecting the “best” solution at this stage is challenging. • Maintaining several concepts for longer times in the design cycle may be better • We will compare “set-based design” to “pointbased design” Courtesy Durward Sobek, Montana State University Rather than pick the best! Was the design of the radiator for the Harley V-Rod more Point-Based or more Set-Based? Explain Sobek and Ward define principles that provide the framework for set-based design Map the Design Space – Define the feasible regions – Explore trade-offs by designing multiple alternatives – Communicate the sets of possibilities Integrate by Intersection – Look for intersections – Impose minimum constraint – Seek conceptual robustness Establish feasibility before commitment 1. 2. 3. Narrow sets gradually, balancing the need to learn and the need to decide Stay within set once committed Control by managing uncertainty at process gates Pursue radical and known solutions in parallel “Toyota’s Principles of Set-Based Concurrent Engineering” Sobek, Ward, and Liker, Sloan Management Review, Winter 1999 Define the feasible regions • Decompose the overall design into functional elements • Develop feasible regions for performance and constraints • Engineering checklists – Manufacturing may have: acceptable design radii, material thickness ranges, ... – Design may have material property ranges (strength, conductivity, …) – Design may have Regulatory constraints (safety, environmental impact, ...) • Question: – What would be on the engineering checklists for the V-Rod Radiator? – How did your company maintain design standards Explore trade-offs by designing multiple alternatives • Develop alternative solutions • Develop a solid understanding of alternatives using the method that makes most sense: – prototyping – Analysis Question: For the Harley prototype radiators, did they”converge on a best guess” (p.74 Sobek) then test and iterate, or did they test several prototypes in parallel? Communicate the sets of possibilities • Describes communication between functional groups (and with Chief Engineer) • Attempt to develop a full understanding of each others capabilities and needs • Don’t communicate your best idea (or your best idea at one operation state)... Provide description of several options over a wide operation range Look for intersections • Find regions where feasible designs from the different functions overlap • Negotiated between functional groups with the CE • Attempt to optimize total system, not individual parts Question: How would you as the engineer define the feasible design space for the radiator? (e.g. Cooling Rate = f(?)) Impose minimum constraint • “Make each decision in its time” • Know the difference between constraints and goals. Seek Conceptual Robustness • We will discuss Robustness in some detail later in the course. • Conceptual Robustness relates to “system level” performance. • In general a “robust” design is less sensitive to changes (changes can come from redesign of other components, manufacturing, consumer use, environmental conditions, …) Narrow sets gradually, balancing the need to learn and the need to decide Develop understanding before making a decision Recognizes that design is a decision based process: determine preferences generate alternatives generate expectations Stay within set once committed • Always have a fallback design. • Maintaining a range of designs from aggressive to conservative helps stay with in the set. Question: Did Harley have fallback designs? Control by managing uncertainty at process gates • This is best understood once you are in the process Pursue radical and known solutions in parallel • • Pursue unproven high pay-off solutions along with low risk backup solutions This gives market flexibility. Toyota’s Prius was a high risk design that hit the market at a good time while the Camry continued their more conservative design alternative in the same size category.