Self test paper 3M and 5S

advertisement

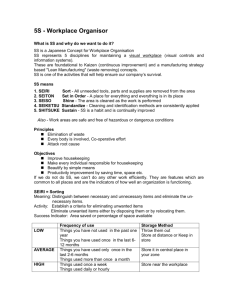

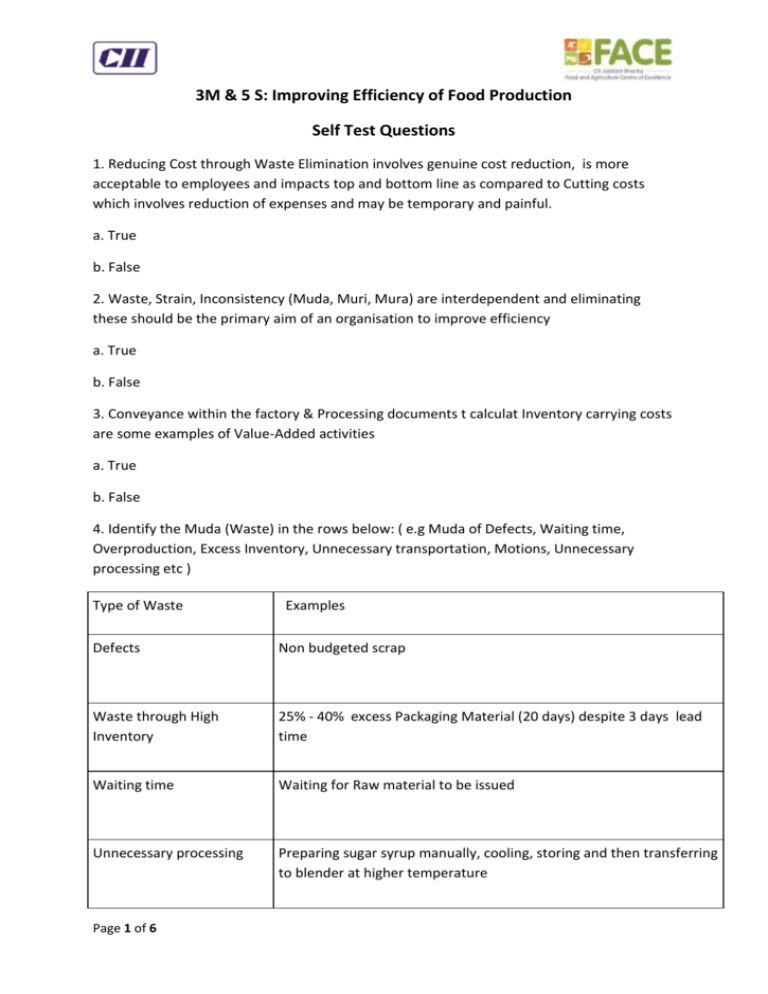

3M & 5 S: Improving Efficiency of Food Production Self Test Questions 1. Reducing Cost through Waste Elimination involves genuine cost reduction, is more acceptable to employees and impacts top and bottom line as compared to Cutting costs which involves reduction of expenses and may be temporary and painful. a. True b. False 2. Waste, Strain, Inconsistency (Muda, Muri, Mura) are interdependent and eliminating these should be the primary aim of an organisation to improve efficiency a. True b. False 3. Conveyance within the factory & Processing documents t calculat Inventory carrying costs are some examples of Value-Added activities a. True b. False 4. Identify the Muda (Waste) in the rows below: ( e.g Muda of Defects, Waiting time, Overproduction, Excess Inventory, Unnecessary transportation, Motions, Unnecessary processing etc ) Type of Waste Examples Defects Non budgeted scrap Waste through High Inventory 25% - 40% excess Packaging Material (20 days) despite 3 days lead time Waiting time Waiting for Raw material to be issued Unnecessary processing Preparing sugar syrup manually, cooling, storing and then transferring to blender at higher temperature Page 1 of 6 Unnecessary transportation Transferring material in 1 tier instead of 2 tier trolley Excess Inventory Transactions not processed, Data which is not organized or fully Utilized. Motions Repeated to and fro movement of the worker 5. 5S is an effective way of reducing Muda of Waiting a. True b. False 6. High Quantities of Work - In - Process may be a symptom of Line Inconsistency/ Line Imbalance (Mura) a. True b. False 7. Zone wise identification of Waste, Strain, Inconsistency (3 M), followed by prioritisation and team allocation is an effective practice to start eliminating 3 M a. True b. False 8. Transportation Waste may be caused by a. Poor Plant Layout b. Use of Batch Process c. Long Lead times d. Large storage areas e. Scheduling Problems f. All of The above (a-e) Page 2 of 6 g. None of the above (a-e) 9. Some causes of Muda of Waiting may be: a. Machine downtime b. Lack of parts c. Line stoppages d. Long changeover time e. Batch flow of material f. All of The above (a-e) g. None of the above (a-e) 10. The key purpose of workplace organisation through 5S is a. reducing manual labour b. reducing energy consumption c. reducing environment pollution d. to reduce waste 11. Sorting (1S) involves a. Identifying a place for everything and keeping everything in place. In other words, Prefixed quantities in prefixed locations with identifications, labels, directional signs resulting in a ' Visual' factory. b. Training, 5 S Audit, Sustaining c. Segregating necessary from unnecessary, disposing what is not required and doing it at stipulated frequency d. Cleaning sorted items at stipulated frequencies as per cleaning schedules, responsibilities and standardised methodologies. 12. Systematic Arrangement (2 S) involves a. Training, 5 S Audit, Sustaining b. Segregating necessary from unnecessary, disposing what is not required, doing it at stipulated frequency Page 3 of 6 c. Cleaning sorted items at stipulated frequencies as per cleaning schedules, responsibilities and standardised methodologies. d. Identifying a place for everything and keeping everything in place. In other words, Prefixed quantities in prefixed locations with identifications, labels, directional signs thus resulting in a ' Visual' factory/ workplace. 13. Self Discipline (5S) involves a. Cleaning sorted items at stipulated frequencies as per cleaning schedules, responsibilities and standardised methodologies. b. Identifying a place for everything and keeping everything in place. In other words, Prefixed quantities in prefixed locations with identifications, labels, directional signs resulting in a ' Visual' factory. c. Training, 5 S Audit, Sustaining by following standards d. Segregating necessary from unnecessary, disposing what is not required, doing it at stipulated frequency 14. Spic and Span (3 S) a. Documenting and implementing Cleaning Procedures (What to clean, How, Who, When, Where) b. Identifying root causes of why things get dirty and doing the needful c. Maintaining only the required number of items d. Preventing Spillage and Leakage in the Workplace from machineries, utility lines, ceilings etc e. All of the above 15. The best way to identify 5S zones is to do it on the layout map so that every space is covered under 5S a. True b. False 16. It is not necessary to cover Scrap Yard, Toilets and Garden/ Lawns of the workplace under 5S Zones a. True Page 4 of 6 b. False 17. Fixed Point Photography and Worst Point Photography are effective ways to: a. take action on defaulters b. monitor 5S Progress and take improvement actions c. None of the above 18. You would know that 5S is working in your workplace when you find a. Visual Workplace b. Reduced Search time for tools, records, documents c. No unwanted items d. No spillage and leakage from equipments, lines, ceilings etc f. All of the above 19. Some useful tools for 5S are: a. Cleaning schedules b. Sorting frequency c. 5S Maps with zones and responsibilities d. 5S Audit schedules with checklists and allocated scores e. All of the above 20. 3S (Spic and Span) involves: a. Remove Unnecessary items b. Reducing Search time of items c. Cleaning in such a way so that flaws can be inspected d. Standardising arrangements to avoid misplacing e. Self Discipline f. All of the above 21. Sorting means a. Removing all items from the workplace that are not needed for current production Page 5 of 6 b. Removing all items from the workplace that are not needed at all 22. What items should be covered under Red tagging? a. Inventory b. Equipments and Spare parts c. Shelves d. All of the above (a, b, c) e. None of the above (a, b, c) 23. Best way to do Red tagging: a. Do whole target area quickly b. Do whole target area slowly 24. Practical Training on 5S in the Workplace is helpful to understand that 5S is not Housekeeping but a tool to organise the workplace in such a way so that wastes are reduced. a. True b. False 25. Redesigning the workplace layout to take advantage of ergonomics, may reduce Waste of Motion a. True b. False ............................................................................................................................................................... . Page 6 of 6