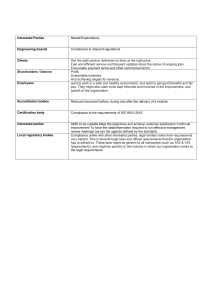

How to write a Quality Manual for ISO 9001? With Examples Updated: Apr 14 To be certified under ISO 9001, you'll need to have a Quality Manual that includes all of the necessary information and procedures. This will help demonstrate your organization's compliance with these requirements so it can get approved by an auditor. qualitymanual Your business needs a clear, comprehensive and understandable way of presenting its operations. We understand that making a quality manual is an involved process, which can be difficult for some businesses. Luckily we’ve put together this step by step guide on how to complete your very own ISO certification so you don't have any more worries! Before going ahead you must know what PDCA is. It stands for Plan, Do, Check & Act which must be your approach when preparing your Quality manual. First, let's look at the clauses in ISO 9001 standard: Clauses 0 to 3: Introduction, Scope, References, Terms and Definitions Clause 4: Context of the organization Clause 5: Leadership and commitment Clause 6: Planning for the QMS Clause 7: Support & resource management Clause 8: Operational planning and control Clause 9: Performance evaluation Clause 10: Improvement actions Apply for ISO 9001 Now, with the understanding of the above items, we are going to prepare a quality manual document that get you certified for ISO 9001:2015. Clauses 4, 5, 6 & 7 are under the "plan" phase. To cover section 4 of your standard, you must start your document with your organisation description, what you do, your scope of work, all the stakeholders, your customers, and any other general information about running and operating your business. Some of the headings here could include: Company overview & Context Scopes and Exclusions Office & Site locations Interested parties In Clause 5 of the quality manual is where we should identify leadership, their roles and responsibilities as well as commitment to quality. Leaders must be customer-focused in order for them provide adequate resources needed by everyone else on staff who has tasks associated with this area or project at hand--and ensuring there are sufficient numbers so that no one gets left behind! This can include anything from management's personal involvement all way down through detail work such like measuring progress against goals monthly etc... The Managing Director is committed to the development and implementation of the quality management system and continually improving its effectiveness by; Communicating to the organization the importance of meeting customer as well as statutory and regulatory requirements, Ensuring the quality policy is current and relevant, Ensuring the KPIs are established and relevant, Conducting the Management Review annually, and Ensuring the availably of resources detrimental to the company. This sections should also mention the roles and responsibilities, authority and decision making, policies, frameworks and compliance requirements established by management. Management should also indicate how information, decisions and news are communicated with staff and interested parties. Clause 6 of ISO 9001:2015 can be addressed in your quality manual by adding the actions to address risks and opportunities. Perhaps a Risk matrix or chart is a good idea to prioritise all the internal & external risks. Risks are the results of uncertainties and your business must have a "Risk-based approach/thinking". To cover this section identify all the internal and external issues (risks), and develop plans and actions to address them. Then set some SMART objectives to address, control and mitigate these risks under this section. Recommended headings for this sections are: - Risk Matrix - Actions to address risks and opportunities - Objectives and Planning The next part of your quality manual is about Support which covers Clause 7 of ISO 9001:2015. Hereunder this section, you must provide information about how to provide resources, how to ensure they are competent, how to communicate with stakeholders and how to document all the required information. Resources include qualified people, infrastructure (IT, equipment) and all other physical & intellectual resources. Your resources must demonstrate being fit for purpose, valid and reliable and also traceable. Your business resources must show they are competent and have all required qualifications and experiences. They must be identified, recorded and monitored which must be mentioned under this section of your Quality manual. It also needs to include a plan to ensure staff, visitors and subcontractors are aware of the quality policy which can be achieved by an induction course for example. These are the headings you can have under this section: Resources including Monitoring & Measuring Devices Competence Awareness Communication Documented information You should also include information about documents of resources such as: Technical Data Sheets (TDS) Material Safety Data Sheets (MSDS) Product Specifications Certificates of Analysis General/Technical documentation on products. Under clause 8 of your quality manual which is the "Do" part of PDCA, you must discuss the operation method of your business on a day to day basis. This is a chunky part of your Quality manual with lots of links to other processes and procedures to validate their point. You should start by explaining your organisations work in brief, steps taken to receive, process and deliver the job, and methods to guarantee meeting customers needs. This section start as the extension of section 4.4 and 6 of ISO 9001:2015 standard which is "Quality Management System And Its Processes" and "Risk assessment schedule". You must clearly mention under this section what happens if changes are required, for any reason, such as customer requests or legislations etc. You must also clearly mention your steps to communicate with customers, understand their requirements, review them and how keep them safe. What about if you keep some of their properties, what's your method to keep them protected? Add a section to explain how you ensure externally provided processes, products and services (suppliers etc.) conform to requirements. Complete product/service provision must be written under this section which describes all the steps from order to delivery and customer care. These are other sub-clauses you must address: Products and services are not to be released until planned arrangements are completed Nonconforming outputs are to be identified and controlled Identification and Traceability Objects, Outputs, Products and Services As mentioned above, this section can be quite heavy and deep, but as an operating business you have most of this information already and you only need to sort them out and prepare some procedures for each. In order to get your ISO 9001, you must develop procedures and policies for your business activities such as Supplier selection Control of production and service provision Identification and traceability Purchasing process Customer communication Determination of requirements related to the product Review of requirements related to the products Customer property ... Clause 9 of ISO 9001 is "Performance evaluation". This section must show how you measure and analyse the performance of your business. Don't forget the main purpose of this standard is to have continual improvement, meaning you should do and perform better than before every day. What are your KPIs? How do you measure customer satisfaction? How often do you check/monitor these performance indicators? Who is responsible for this etc. This section must include the Internal Audit schedule and its purpose. It also needs the Management review section. You must mention what will be covered in your management review meetings. Here are some examples of the Management review agenda: Actions from prior management reviews Review the external and internal issues from the Context Customer satisfaction and feedback Review quality objectives have been met Review process performance and conformity of products and services Check nonconformities and corrective actions Review audit results Review suppliers Check you have enough resources Review risk (and opportunities) register Review improvements The headings for this part of your Quality manual could include: Monitoring & measurements Customer satisfaction Monitoring and measurement of processes Monitoring and measurement of product(s) Internal Audit Management Review The last section of your Quality Manual is the "Improvement" (clause 10) which is Check part of PDCA. Here you must demonstrate how you are going to drive improvement and implement actions, find out the root cause of problems and execute the continual improvement. Here you must write about your commitment to continuous improvement and achieving your quality objectives. You must also demonstrate your plan for taking corrective actions and improving your organisation day after day. The headings for this section are: General Non-conformity and corrective actions (Root cause analysis) Continual improvement