Gas Turbine

advertisement

Applied

Thermodynamics

3. GAS TURBINES AND JET PROPULSION

Introduction:

Gas turbines are prime movers

producing mechanical power

from the heat generated by the

combustion of fuels.

They are used in aircraft, some

automobile units, industrial

installations and small – sized

electrical power generating

units.

A schematic diagram of a

simple gas turbine power plant

is shown below.

This is the open cycle gas

turbine plant.

Working:

Air from atmosphere is

compressed

adiabatically

(idealized) in a compressor

(usually rotary) i.e., Process

1–2.

This compressed air enters the

combustion chamber, where

fuel is injected and undergoes

combustion

at

constant

pressure in process 2–3.

The hot products of

combustion expand in the

turbine

to

the

ambient

pressure in process 3–4 and

the used up exhaust gases are

let out into the surroundings.

The compressor

is usually

coupled to the turbine, so that the

work input required by the

compressor comes from the

turbine.

The turbine produces more work

than what is required by the

compressor, so that there is net

work output available from the

turbine.

Since the products of combustion

cannot be re–used, real gas

turbines work essentially in open

cycles. The p–v and T–s diagrams

of such a plant are shown above.

The compressor

is usually

coupled to the turbine, so that the

work input required by the

compressor comes from the

turbine.

The turbine produces more work

than what is required by the

compressor, so that there is net

work output available from the

turbine.

Since the products of combustion

cannot be re–used, real gas

turbines work essentially in open

cycles. The p–v and T–s diagrams

of such a plant are shown above.

Brayton Cycle:

This is the air–

standard cycle for

the gas turbine plant.

It consists of

two

reversible

adiabatic processes

and two reversible

isobars

(constant

pressure processes).

The p–v and T–s

diagrams

of

a

Brayton Cycle are as

shown.

Process 1 - 2: Reversible

adiabatic compression.

2 – 3: Reversible constant

pressure heat addition.

3 – 4: Reversible adiabatic

expansion.

4 – 1: Reversible constant

pressure heat rejection.

A schematic flow diagram of

this somewhat hypothetical

gas turbine plant is shown

below.

Though this plant works on a closed cycle, each of the four

devices in the plant is a steady–flow device, in the sense that

there is a continuous flow of the working fluid (air) through

each device.

Hence, the steady–flow energy equation is the basis for

analysis, and can be applied to each of the four processes.

Neglecting changes in kinetic and potential energies, the

steady flow energy equation takes the from

Q – W = ∆h = Cp.∆T (Since air is assumed to be an ideal

gas)

Process 1 – 2 is reversible adiabatic, hence Q1-2 = 0

W1-2 = - Cp.∆T = - Cp (T2 – T1): - ve, work input

Work of compression

Wc = |W1 – 2| = Cp (T2-T1)

Process 2–3 is a constant pressure

process

Heat added,

Process 3-4 is again reversible

adiabatic,

+ve work output.

Process 4-1 is also a constant

pressure process

: -ve, i.e., heat is rejected

Heat rejected,

Q2 = |Q4-1| = Cp (T4-T1)

Therefore the cycle efficiency,

Therefore the cycle efficiency,

For isentropic process 1-2,

& for process 3-4,

Since p3 = p2 and p4 = p1

Compression ratio,

Therefore,

Pressure ratio,

Thus it can be seen that, for the same compression ratio,

A closed cycle turbine plant is used in a gas–cooled nuclear

reactor plant, where the source is a high temperature gas

cooled reactor supplying heat from nuclear fission directly

to the working fluid (gas/air).

Comparison between Brayton Cycle and

Otto cycle:For the same

compression

ratio,

and nearly same net

work

output

(represented by the

area inside the p–v

diagram), the Brayton

cycle handles larger

range of volume and

smaller

range

of

pressure than does

the Otto cycle.

A Brayton cycle is not

suitable as the basis for

the working of reciprocating

type of devices (Piston–

Cylinder arrangements).

A reciprocating engine

cannot efficiently handle a

large volume flow of low

pressure gas.

The engine (Cylinder) size

becomes very large and

friction losses become

excessive.

Otto cycle therefore is more

suitable in reciprocating

engines.

However, a Brayton cycle is

more suitable than an Otto

cycle, as a basis for a

turbine plant.

An I.C. engine is exposed to

the highest temperature only

intermittently (for short way

during each cycle), so that

there is time enough for it to

cool.

On the other hand, a gas

turbine, being a steady flow

device,

is

continuously

exposed to the highest

temperature.

Metallurgical considerations,

therefore limit the maximum

temperature that can be

used.

Moreover, in steady flow

machines, it is easier to

transfer heat at constant

pressure than at constant

volume.

Besides, turbines can be

efficiently

handle

large

volume of gas flow.

In view of all these, the

Brayton cycle more suitable

as the basis for the working

of gas turbine plants.

Effect of irreversibility’s in turbine/compressor:

In the ideal Brayton cycle,

compression and expansion of

air are assumed to be reversible

and adiabatic.

In

reality,

however,

irreversibility’s do exist in the

machine

operations,

even

though they may be adiabatic.

Hence the compression and

expansion processes are not

really

constant

entropy

processes.

Entropy tends to be increase (as

per the principle of increase of

entropy).

Effect of irreversibility’s in turbine/compressor:

The T–s diagram of a Brayton

cycle subject to irreversibility’s will

be as shown.

Irreversibility’s result in a reduction

in turbine output by (h4-h4S) and in

an increase in the compressor

input by (h2 – h2S).

Hence the output reduces by the

amount (h4–h4S )+ (h2–h2s).

Though heat input is also reduced

by (h2-h2s), the cycle efficiency is

less than that of an ideal cycle.

The extent of losses due to

irreversibility’s can be expressed

in terms of the turbine and

compressor efficiencies.

Turbine efficiency,

Compressor efficiency,

Methods of improving the efficiency of Brayton

cycle:

Use of regeneration:

The efficiency of the Brayton cycle can be increased by

utilizing part of the energy of exhaust air from the

turbine to preheat the air leaving the compressor, in a

heat exchanger called regenerator.

This reduces the amount of heat supplied Q1 from an

external source, and also the amount of heat rejected

Q2 to an external sink, by an equal amount.

Since Wnet = Q1 - Q2 and both Q1 and Q2 reduce by

equal amounts, there will be no change in the work

output of the cycle.

Heat added

Heat rejected

Turbine output

Compressor input

Q1 = h3 –h2’ = Cp (T3 – T2’)

Q2 = h4’ – h1 = Cp (T4’ – T1)

WT = h3 – h4 = Cp (T3 – T4)

WC = h2 – h1 = Cp (T2 – T1)

Regeneration can be used only if the temperature of air

leaving the turbine at 4 is greater than that of air leaving

the compressor at 2.

In the regenerator, heat is transferred from air leaving the

turbine to air leaving the compressor, thereby raising the

temperature of the latter.

The maximum temperature to which compressed air at 2

can be heated is equal to the temperature of turbine

exhaust at 4.

This, however, is

possible only in an

ideal regenerator.

In reality, T2’<T4.

The ratio of the

actual temperature

rise of compressed

air to the maximum

possible rise is called

effectiveness of the

regenerator.

With a regenerator, since Wnet

remains unchanged, but Q1

reduces, efficiency

η = Wnet/Q1 increases.

This is also evident from the

fact that the mean temperature

of heat addition increases and

the mean temperature of heat

rejection reduces with the use

of the regenerator, and

efficiency is also given by

With regenerator,

In the regenerator,

Heat lost by hot air = Heat gained by cold air

i.e.,

With an ideal regenerator,

therefore,

For a fixed ratio

, the cycle efficiency decreases

with increasing pressure ratio.

In practice, a regenerator is expensive, heavy

and bulky and causes pressure losses, which may

even decrease the cycle efficiency, instead of

increasing it.

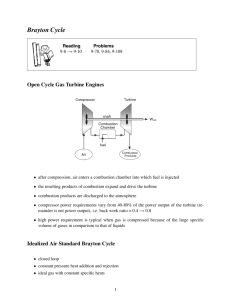

2.Multistage compression with inter cooling:

In this arrangement,

compression of air is carried

out in two or more stages with

cooling of the air in between

the stages.

The cooling takes place in a

heat exchanger using some

external

cooling

medium

(water, air etc).

Shown above is a schematic

flow diagram of a gas turbine

plant

with

two-stage

compression

with

inter

cooling.

1-2: first stage compression

(isentropic)

2-3: inter cooling

(heat rejection at

constant pressure)

3-4: second stage

compression (isentropic)

4-3: constant pressure heat

addition

5-6: isentropic expansion

6-1: constant pressure heat

rejection.

Air, after the first stage compression is cooled before it

enters the second stage compressor.

If air is cooled to a temperature equal to the initial

temperature (i.e., if T3=T1), inter cooling is said to be

perfect.

In practice, usually T3 is greater than T1.

Multistage compressor with inter cooling actually

decreases the cycle efficiency.

This is because the average temperature of heat addition

Tadd is less for this cycle 1-2-3-4-5-6 as compared to the

simple Brayton cycle 1-4’-5-6 with the initial state 1. (refer

fig).

Average temperature of heat rejection Trej also reduces,

but only marginally.

Hence efficiency is less for the modified cycle.

However, if a regenerator is also used the heat

added at lower temperature range (4 to 4’) comes

from exhaust gases from the turbine.

So there may be an increase in efficiency

(compared to a simple Brayton cycle) when multi–

stage compression with inter cooling is used in

conjunction with a regenerator.

For a gas turbine plant using 2–stage compression

without a generator,

Q1 = h5 - h4 = Cp(T5 - T4)

WT = h5 - h6 = Cp(T5-T6)

WC = (h2 - h1) + (h4 - h3) = Cp [(T2 - T1) + (T4 - T3)]

WC = (h2 - h1) + (h4 - h3) = Cp [(T2 - T1) + (T4 - T3)]

Wnet = WT – WC

= Cp [(T5 - T6) – {(T 2- T1) + (T4 - T3)}]

3) Multi-Stage expansion with reheating:

Here expansion of working fluid (air) is carried out in 2 or

more stages with heating (called reheating) in between

stages.

The reheating is done in heat exchangers called

Reheaters.

In an idealized cycle, the air is reheated, after each stage

of expansion, to the temperature at the beginning of

expansion.

The schematic flow diagram as well as T-s diagram for a

gas turbine plant where in expansion takes place in two

turbine stages, with reheating in between, are shown.

Multi-Stage expansion with reheating, by itself, does not

lead to any improvement in cycle efficiency. In fact, it only

reduces.

However, this modification together with regeneration may

result in an increase in cycle efficiency.

It can be seen from the T-s diagram that the turbine exhaust

temperature is much higher when multi stage expansion with

reheating is used, as compared to a simple Brayton cycle.

This makes the use of a regenerator more effective and may

lead to a higher efficiency.

Heat added Q1 = (h3 - h2) + (h5 - h4)

= Cp(T3 - T2) + Cp(T5 - T4)

Turbine output WT = (h3 - h4) + (h5 - h6)

= Cp(T3 - T4) + Cp(T5 - T6)

Compressor input WC = h2 - h1 = Cp(T2 - T1)

Ideal Regenerative cycle with inter

cooling and reheat:

Considerable improvement in efficiency is possible by

incorporating all the three modifications simultaneously.

Let us consider a regenerative gas turbine cycle with two

stage compression and a single reheat.

The flow diagram and T-S diagram of such an

arrangement is shown.

Idealized Regenerative Brayton cycle with two stage

compression with inter cooling and also two stage

expansion with reheating – ideal regenerator, equal

pressure ratios for stages, no irreversibilities, perfect inter

cooling and reheating.

Heat added

Q1 = Cp(T5 - T4’) + Cp(T7 - T6)

Turbine output

WT = Cp(T5 - T6) + Cp(T7 - T8)

Compressor input

WC = Cp(T2 - T1) + Cp(T4 - T3)

If perfect inter cooling, no irreversibilities, equal pressure

ratios for stages and ideal regenerator are assumed,

T1=T3, T2=T4=T8’, T5=T7 and T6=T8=T4’

Then, Q1 = Cp(T5 - T4’) + Cp(T7 – T6)

= Cp (T5 - T6) + Cp(T5 - T6)

= (T5 - T6)

Q2 = Cp(T8’ - T1) + Cp(T2 - T3)

= Cp(T2 - T1) + Cp(T2 - T1)

=2 Cp(T2 - T1)

.

It can be seen from this expression that the efficiency

decreases with increasing pressure ratio rp.

Effect of pressure Ratio rp on simple Brayton

Cycle:That means, the more the pressure ratio, the more will

be the efficiency. Temperature T1 (=Tmin) is dependent

on the temperature of surroundings.

Temperature T3 (=Tmax) is limited by metallurgical

considerations and heat resistant characteristics of the

turbine blade material.

For fixed values of Tmin and Tmax, the variation in net

work output, heat added and efficiency with increasing

pressure ratio rp can be explained with the help of a

T-s diagram as shown.

For low pressure ratio, the net work output is small and

the efficiency is also small (Cycle 1 – 2 – 3 - 4).

In the limit, as rp tends 1, efficiency tends to zero (net

work output is zero, but heat added is not zero).

As the pressure ratio increases, the work output

increases and so does the efficiency.

However, there is an upper limit for rp when the

compression ends at Tmax.

As rp approaches this upper limit (rp)max, both net work

output and heat added approach zero values.

However, it can be seen that the mean temperature

heat addition Tadd approaches Tmax, while the mean

temperature of heat rejection approaches Tmin, as rp

comes close to (rp)max.

Hence cycle efficiency, given

by

approaches the Carnot

efficiency i.e.,

rp - (rp)max When the

compression ends at Tmax

i.e., when state point 2 is at

Tmax.

When rp=rpmax,

The variation of net work output Wnet with pressure

ratio rp is shown below.

As rp increases from 1 to (rp)max, Wnet increases from

zero, reaches a maximum at an optimum value of rp

i.e., (rp)opt and with further increase in rp, it reduces

and becomes zero when rp = rpmax

Pressure Ratio for maximum net work output:Wnet= Cp[(T3 - T4) - (T2 - T1)]

T3 = Tmax & T1= Tmin

Condition for maximum Wnet is

i.e.,

It can be seen that,

Maximum net work output

Corresponding to rp = (rp)opt i.e., when Wnet is maximum, cycle

efficiency is

Open Cycle Gas Turbine

Plants:

In practice, a gas turbine plant works

on an open cycle.

Air from atmosphere is first

compressed to a higher pressure in

a rotary compressor, which is usually

run by the turbine itself, before it

enters the combustion chamber.

Fuel is injected into the combustion

chamber

where

it

undergoes

combustion.

The heat released is absorbed by

the products of combustion and the

resulting high temperature; high

pressure products expand in the

turbine producing work output.

The used up combustion

products (exhaust gases)

are let out into the

atmosphere.

In

the

ideal

case,

compression

and

expansion are assumed to

be

isentropic

and

combustion is assumed to

take place at constant

pressure.

The

schematic

flow

diagram and p-v and T-s

diagrams of an open cycle

gas turbine plant are as

shown.

Advantages and disadvantages of closed cycle

over open cycle

Advantages of closed cycle:

1. Higher thermal efficiency

2. Reduced size

3. No contamination

4. Improved heat transmission

5. Improved part load

6. Lesser fluid friction

7. No loss of working medium

8. Greater output and

9. Inexpensive fuel.

Disadvantages of closed cycle:

1. Complexity

2. Large amount of cooling water is required. This

limits its use of stationary installation or marine

use

3. Dependent system

4. The wt of the system pre kW developed is high

comparatively, not economical for moving

vehicles

5. Requires the use of a very large air heater.

Problems:

1. In a Gas turbine installation, the air is taken in at 1

bar and 150C and compressed to 4 bar. The

isentropic of turbine and the compressor are 82%

and 85% respectively. Determine (i) compression

work, (ii) Turbine work, (iii) work ratio, (iv) Th. .

What would be the improvement in the th. if a

regenerator with 75% effectiveness is incorporated

in the cycle. Assume the maximum cycle

temperature to be 8250K.

Solution:

P1 = 1 bar

T3 = 8250K

T1 = 2880K

C = 0.85

P2 = 4 bar

t = 0.82

Case1: Without Regeneration:

Process 1-2s is isentropic i.e.,

T2 s P2

T1 P1

T2 s 288 4

But C T2 s T1

T2 T1

0.4

1.4

r 1

r

428.14 0 K

i.e.,0.85

428.14 288

T2 452.87 0 K

T2 288

Process 3-4s is isentropic

r 1

r

But

0.4

1.4

T4 s P4

1

i.e.,

T4 s 825 554.96

T3 P3

4

T3 T4

825 T4

t

i.e., 0.82

T4 603.57 0 K

T3 T4 s

825 554.96

(i) Compressor work,

WC = CP (T2 – T1)

= 1.005 (452.87 – 288) = 165.69 kJ/kg

(ii) Turbine work,

Wt = CP (T3 – T4)

= 1.005 (825 – 603.57) = 222.54 kJ/kg

(iii) Work ratio = = 0.255

(iv) Thermal Efficiency ,

= 15.2%

Case2: With Regeneration:

We have effectiveness,

T5 T2

T5 452.87

i.e., 0.75

T4 T2

603.57 452.87

T5 = 565.890K

Heat supplied,

QH1 = Q5-3 = CP(T3 – T5)

= 1.005 (825 – 565.89)

= 260.4 kJ/kg

WT WC 56.85 = 0.218

th

1

260.4

QH

Improvement in th due to

regenerator 0.218 0.152

0.152

i.e., 43.6%

= 0.436

2.The maximum and minimum pressure and

temperatures of a gas turbine are 5 bar, 1.2

bar and 1000K and 300K respectively.

Assuming compression and expansion

processes as isentropic, determine the th

(a) when an ideal regenerator is incorporated in

the plant and (b) when the effectiveness of

the above regenerator is 75%.

Solution:

P2 = P3 = 5 bar P1 = P4 = 1.2 bar

T3 = 1000K

T1 = 300K

Process 1-2s is isentropic i.e.,

P2

T2 s

T1

P1

r 1

r

0.4

1.4

5

0

T2 s 300

451.21 K

1.2

Process 3-4s is isentropic i.e.,

T4 s P4

T3 P3

1.2

T4 s 1000

5

0.4

1.4

r 1

r

664.88 0 K

Ideal regenerator: i.e., T5 = T4

Heat supplied = CP (T3 – T5)

= 1.005 [1000 – 664.88] = 336.79 kJ/kg

Wnet = WT – WC = CP (T3 – T4) – CP (T2 – T1)

= 1.005 [1000 – 664.88 – 451.21 + 300] = 183.91

Wnet 183.91

th

QH 336.79

= 0.546 or 54.6%

Regenerator with = 0.75 i.e.,

T5 T2 actual temperature drop

i.e.,

0.75

T4 T2

ideal temperature drop

T5 451.21

0.75

T5 611.46 0 K

664.88 451.21

Heat supplied, QH = CP (T3 – T5)

= 1.005 (1000 – 611.46) = 390.48kJ/kg

Wnet 183.91

th

QH

390.48

= 0.471 or 47.1%

3.Solve the above problem when the adiabatic

efficiencies of the turbine and compressor are 90%

and 85% respectively.

4. A gas turbine plant uses 500kg of air/min, which

enters the compressor at 1 bar, 170C. The

compressor delivery pressure is 4.4 bar. The

products of combustion leaves the combustion

chamber at 6500C and is then expanded in the

turbine to 1 bar. Assuming isentropic efficiency of

compressor to be 75% and that of the turbine to be

85%, calculate (i) mass of the fuel required /min, of

the CV of fuel is 39000KJ/Kg. (ii)net power output

(iii)Overall thermal efficiency of the plant. Assume

CP=1.13KJ/Kg-K,=1.33 for both heating and

expansion.

Solution:

a 500 kg / min 8.33 kg / sec

m

P1 = 1 bar T1 = 2900K P2 = 4.4 bar T3 = 9230K

C = 0.75

t = 0.85 , WN = ? , th ? m f ?

Calorific Value = 39000 kJ/kg

Process 1-2s is isentropic compression

i.e.,

P

1

1

P1V1 P2V2 or T1V1 T2V2 or 1 C

P2

T2 s T1

P1

But

1

T2 s T1

C

T2 T1

T

2904.4

i.e.,

0.4

1.4

443.02 0 K

443.02 290

0.75

T2 494.030 K

T2 290

Process 3-4s is isentropic expansion i.e.,

T4 s P4

T3 P3

But

T

m f ?

We have

1

T4 s 923

4.4

0.32

1.33

639.18 0 K

T3 T4

T3 T4 s

i.e., 0.85

(i)

1

923 T4

T4 681.76 0 K

923 639.18

m a

CV

500

39000

i.e.,

m f C P T3 T2

m f 1.13923 494.03

f = 6.21kg/min

m

(ii) WN = ?

Compressor work, WC = CP (T2 – T1)

= 1.005 (494.03 – 290)

= 205.05 kJ/kg

Turbine work, WT = CP (T3 – T4)

= 1.13 (923 – 681.76)

= 272.6 kJ/kg

WN = WT – WC = 67.55 kJ/kg

a m

f WN

Net work output per minute = m

= (500+6.21) (67.55) = 34194.49 kJ/min

Power output = 569.91 kW

(iii) th = ?

Heat supplied, QH = CP (T3 – T2)

= 1.33 (923 – 494.03)

= 570.53 kJ/kg

WN

67.55

th

QH 570.53

= 0.118 or 11.8%

5. A gas turbine cycle having 2 stage compression

with intercooling in between stages and 2 stages

of expansion with reheating in between the

stages has an overall pressure ratio of 8.

The maximum cycle temperature is 14000K and

the compressor inlet conditions are 1 bar and

270C. The compressors have s of 80% and

turbines have s of 85%.

Assuming that the air is cooled back to its

original temperature after the first stage

compression and gas is reheated back to its

original temperature after 1st stage of expansion,

determine (i) the net work output

(ii) the cycle th.

Solution: T5 = 14000K

T1 = 3000K, P1= 1 bar

C1= 0.8 = C2, t1 = t2 = 0.85 ,T3 = T1 ,T7 = T5

For maximum work output,

P2 P4 P5 P7

P1 P3 P6 P8

P4

P1

P5

8

P8

Intermediate Pr essure ,

P2 P3 P6 P7 2.83 bar

For process 1-2,

But

P2

T2 s T1

P1

1

= 300 (2.83)0.286 = 403.950K

T2 s T1 403.95 300

c1 0.8

T2 429.9 0 K

T2 T1

T2 300

Since

T3 = T1 and P4 P2

P3

P1

We have T4s = T2s = 403.950K

Also since C1 = C2,

T4 = T2 = 429.90K

Compressor work, WC = CP (T2 – T1) + CP (T4 – T3)

= 2 CP (T2 – T1)

= 2 (1.005) (429.9 – 300)

= 261.19 kJ/kg

For process 5 – 6,

T6 s P6

T5 P5

1

1

T6 s 1400

2.83

0.286

1039.720 K

But

T5 T6

t1

T5 T6 s

1400 T6

i.e., 0.85

T6 1093.76 0 K

1400 1039.72

Since T7 = T5 and P5

P7

P6 P8

Since t1 = t2,

, then T8 = T6

T6 = T8 = 1093.760K

Turbine work, Wt = CP (T5 – T6) + CP (T7 – T8)

= 2 CP (T5 – T6)

= 2 (1.005) (1400 – 1093.76)

= 615.54 kJ/kg

WN = WT – WC = 354.35 kJ/kg

th = ?

Heat Supplied,

QH = CP (T5 – T4) + CP (T7 – T6)

= 1.005 (1400 – 429.9 + 1400 – 1093.76)

= 1282.72 kJ/kg

354.35

= 0.276 or 27.6%

th

1282.72

6. Determine the of a gas turbine having two stages

of compression with intercooling and two stages of

expansion with reheat. Given that the pressure ratio

is 4, minimum temperature of the cycle 270C and

maximum temperature of the cycle is 6000C, when t,

C and regenerator are equal to 80%.

( Home work)

7. A two stage gas turbine cycle receives air at 100 kPa

and 150C. The lower stage has a pressure ratio of 3,

while that for the upper stage is 4 for the compressor

as well as the turbine. The temperature rise of the air

compressed in the lower stage is reduced by 80% by

intercooling.

Also,

a

regenerator

of

78%

effectiveness is used. The upper temperature limit of

the cycle is 11000C. The turbine and the compressor

s are 86%. Calculate the mass flow rate required to

produce 6000kW.

Solution:

P1 = 1 bar

T1 =

2880K

P2

3,

P1

P4

4

P3

IC = 0.8

ε = reg = 0.78, T5 = 13730K,

m ? if P = 6000 kW

C1 = C2 = t1 = t2 = 0.86,

Process 1-2s is isentropic compression

T2 s P2

T1 P1

1

T2s = 288 (3)0.286

= 410.750K

But

Also,

C1

T2 s T1

T2 T1

410.75 288

i.e., 0.86

T2 430.730 K

T2 288

IC

T2 T3

T2 T1

430.73 T3

i.e., 0.8

T3 316.54 0 K

430.73 288

Process 3-4s is 2nd stage isentropic compression

1

T4 s P4

T3

P3

T4s = 316.54 (4)0.286 = 470.570K

But

C2

T4 s T3

T4 T3

470.57 316.54

i.e., 0.86

T4 495.64 0 K

T4 316.54

Process 5-6s is 1st stage isentropic expansion

1

P6

T6 s

T5

P

5

1

T6 s 1373

4

0.286

923.59 0 K

But

T5 T6

t1

T5 T6 s

1373 T6

i.e., 0.86

T6 986.510 K

1373 923.59

Process 6-7 is reheating, assume T7 = T5 = 13730K

Process 7-8s is 2nd stage isentropic expansion i.e., T8 s P8

T7 P7

1

T8 s 1373

3

But

T7 T8

t 2

T7 T8 s

1

0.286

1002.79 0 K

1373 T8

i.e., 0.86

T8 1054.630 K

1373 1002.79

Regenerator is used to utilizes the temperature of exhaust gases

i.e.,

Tx T4

Tx 495.64

0K

i

.

e

.,

0

.

78

T

=

931.65

x

T8 T4

1054.63 495.64

We have, Compressor work: WC = CP (T2 – T1) + CP (T4 – T3)

= 1.005 (430.73 – 288 + 495.64 – 316.54)

= 323.44 kJ/kg

Also, Turbine work : WT

= CP (T5 – T6) + CP (T7 – T8)

= 1.005 (1373 – 986.51 + 1373 – 1054.63)

= 708.38 kJ/kg

Net work output, WN = WT - WC

= 384.95 kJ/kg

But, power produced, P m

WN

i.e., 6000 x 1000 = 384.95 x 1000

m

= 15.59 kg/sec

We have, heat supplied, QH = CP (T5 – Tx) + CP (T7 – T6)

= 1.005 (1373 – 931.65 + 1373 – 986.51)

WN

= 831.98 kJ/kg

th

QH

0.463 or 46.3%

8. In a gas turbine plant working on Brayton

cycle, the inlet conditions are 1 bar and 270C.

The compression of air is carried out in two

stages with a pressure ratio of 2.5 for each

stage with intercooling to 270C.

The expansion is carried out in one stage with

a pressure ratio of 6.25.

The maximum temperature in the cycle is

8000C. The of turbine and both compression

stages are 80%. Determine (i) compressor

work, (ii) Turbine work, (iii) Heat supplied, (iv)

cycle , (v) cycle air rate.

Hint: P1 = 1 bar

P4 = P5 = 6.25 bar, P3 = P2 = 2.5 bar

9. The pressure ratio of an open cycle constant pressure gas

turbine is 6. The temperature range of the plant is 150C and

8000C. Calculate (i) th of the plant, (ii) Power developed by

the plant for an air circulation of 5 kg/s, (iii) Air fuel ratio, (iv)

specific fuel consumption. Neglect losses in the system. Use

the following data: for both air and gases: CP 1.005 kJ/kg0K

and = 1.4. Calorific value of the fuel is 42000 kJ/kg, C =

0.85, t = 0.9 and combustion of 0.95.

10. In a G.T. unit with two stage compression and two stage

expansion the gas temperature at entry to both the turbines

are same. The compressors have an intercooler with an

effectiveness of 83%. The working temperature limits are

250C and 10000C, while the pressure limits are 1.02 bar and 7

bar respectively. Assuming that the compression and

expansion processes in the compressors and turbine are

adiabatic with C of 84% and t of 89% for both the stages.

Calculate (i) the air-fuel ratio at the combustion chambers if

the calorific value of the fuel is 38500 kJ/kg, (ii) Power output

in kW for an air flow rate of 1kg/s and (iii) overall cycle .

11. In a reheat gas turbine cycle, comprising one

compressor and two turbine, air is compressed

from 1 bar, 270C to 6 bar. The highest

temperature in the cycle is 9000C. The

expansion in the 1st stage turbine is such that

the work from it just equals the work required

by the compressor. Air is reheated between the

two stages of expansion to 8500C. Assume that

the isentropic s of the compressor, the 1st

stage and the 2nd stage turbines are 85% each

and that the working fluid is air and calculate

the cycle .

Solution:

P1 = 1 bar

T3 = 1173K WT1 = WC

t1 = t2 = 0.85

T1 = 300K

P2 = 6 bar

T5 = 1123K C = 0.85

We have process 1-2 is isentropic i.e.,

T2 S P2

T1 P1

T2 S

1

6

300

1

0.4

1.4

500.5K

T2 S T1

500.5 300

But C

i.e., 0.85

T2 536K

T2 T1

T2 300

Compressor work, WC = CP (T2 – T1)

= 1.005 (536 – 300) = 237 kJ/kg

From data,

WT1 = WC = 237 kJ/kg

= CP (T3 – T4)

T4 = 937 kJ/kg

T3 T4

But t1

T3 T4 S

1173 937

i.e., 0.85

T4 S 895K

1173 T4 S

Process 3-4 is isentropic i.e.,

P4 T4 S 1

P3 T3

895

P4 6

1173

1.4

0.4

2.328 bar

From T-S diagram, intermediate pressure, P4 = P5 = 2.328 bar

Process 5-6s is isentropic in the 2nd stage turbine

T6 S P6

i.e.,

T5 P5

T5 T6

But t 2

T5 T6 S

1

T6 S

1

1123

2.328

0.4

1.4

882 K

1123 T6

i.e., 0.85

T6 918K

1123 882

WT2 = CP (T5 – T6)

= 1.005 (1123 – 918) = 206 kJ/kg

Net work output = WT – WC

= (WT1 + WT2) – WC = 206 kJ/kg

Net heat transfer or heat supplied, Q = QH + QR

Cycle efficiency,

cycle

= CP (T3 – T2) + CP (T5 – T4)

= 640 + 187 = 827 kJ/kg

Wnet

206

25%

Qnet

827

12. In a simple gas turbine unit, the isentropic

discharge temperature of air flowing out of

compressor is 1950C, while the actual

discharge temperature is 2400C. Conditions

of air at the beginning of compression are 1

bar and 170C. If the air-fuel ratio is 75 and net

power output from the unit is 650kW.

Compute (i) isentropic of the compressor

and the turbine and (ii) overall . Calorific

value of the fuel used is 46110 kJ/kg and the

unit consumes 312 kg/hr of fuel. Assume for

gases CP = 1.09 kJ/kg-K and = 1.32 and for

air CP = 1.005 kJ/kg-K and = 1.4.

Solution:

T2S = 195+273 = 468 K

T2 = 240+273 = 513K

T1 = 290K P1=1bar

A/F = 75,

Power output = Wnet = WT – WC = 650kW C = ? T = ?

cycle = ?

CV = 46110 kJ/kg, CPg = 1.09 kJ/kg-k,

g = 1.30, CPa = 1.005 kJ/kg-K, a = 1.4

f 312kg / hr 0.0867 kg / s

m

We have, Compressor Efficiency,

C

T2 S T1

T2 T1

i.e.,

468 290

0.79

513 290

A

Also, ma m f

F

= 75 (0.0867) = 6.503 kg/s

T2 S

Pr essure ratio R

T1

1 468

290

1.4

0.4

5.34

Applying SFEE to the constant pressure heating process 2-3,

m f

CV m a m f CPg T3 T2

0.0867 (46110) = (6.503 + 0.0867) 1.09 (T3 – 513)

T3 = 1069.6K

Also,

1

P4

T4 S

T3

P3

T4S = 712.6K.

g

g

1.321

1.32

T4 S 1069.65.34

Further,

a m

f CPg T3 T4 m

a CPa T2 T1

W net WT WC m

i.e., 650 = (6.503 + 0.0867) 1.09 (1069.6 – T4) – 6.503 (1.005) (513 – 290)

T4 = 776K

Now, Turbine Efficiency,

T3 T4

1069.6 776

T

0.822

T3 T4 S 1069.6 712.6

And,

cycle

Wnet

650

0.163

m f CV 0.086746110

Or

cycle

Wnet

650

650

0.162

m a m f C Pg T3 T2 3997.9

QH