Cells & Batteries

NE 139 6029G

Assessments

Why Study Cells & Batteries Increasing reliance on batteries

Alternative power supplies

Solar cells Wind Turbine Diesel Generator Batteries Inverter Low Voltage

Why Study Cells & Batteries Increasing reliance on batteries

Alternative power supplies

Cordless Drills

Hybrid cars

Supply back-up

Can the batteries be fully discharged?

Can the battery be left flat?

Can you use a car battery for a solar power system?

Chemical Effect of Current Electrical current causing chemical change

Electro-plating (electro-deposition) Splitting water into Hydrogen & Oxygen Lightning thought to have made the basic building blocks of life on earth.

Used to stop corrosion (Cathodic protection) Refining of metals (Copper)

CHARGING OF BATTERIES

BACKGROUND Periodic Table

Page 437 Every element has a symbol Lead= Sulphur = Oxygen = Hydrogen = Pb S O H When “Compounds” are made the elements symbols are grouped together Water= H 2 O Hydrogen x2 Oxygen

BACKGROUND

When compounds are made the electrons may be liberated creating: Positive Ions Free Electrons Compounds lacking electrons Negative Ions Compounds with excessive electrons

BACKGROUND

Processes that produce electric charge from a chemical reaction are: Batteries Fuel Cells Cells connected together Developed to a usable form by NASA for Mercury, Apollo, and Skylab missions Fuel cell acts as a “combustion” chamber. Converting high energy fuel ( Hydrogen) with Oxygen to electric current.

OXYGEN

FUEL CELLS

ELECTRIC CURRENT WATER HYDROGEN

Efficiency

HEAT

45%

Can be any fuel(gas) provided the electrode and membrane are correctly chosen

ELECTRIC CELLS

An electric cell contains three parts, namely:

Electrolyte

Acid Alkali (Base) Salt

Anode Cathode

Discharging Known as a Voltaic Cell Negative electrode or Plate Positive electrode or Plate

ELECTRIC CELLS

An electric cell contains three parts, namely:

Electrolyte

Acid Alkali (Base) Salt

Anode Cathode

Charging Known as a Electrolytic Cell Negative electrode or Plate Positive electrode or Plate

ELECTRIC CELLS

Anode Cathode

+ -

Electrolyte

+ +

ELECTRIC CELLS

Chemical reaction between two electrodes and the electrolyte they are in contact with

Primary Cell

Chemical reaction is irreversible One electrode is “eaten” away When cell is constructed, all cell’s energy is present

Secondary Cell

Chemical reaction is reversible Chemical change does not destroy electrode Once made, has to be charged

LUIGI GALVANI

1737 - 1798

PRIMARY CELLS 1780

Luigi Galvani discovered that when two different metals were connected together and then both touched to different parts of a nerve of a frog leg at the same time, they made the leg contract. He called this "animal electricity" .

ALESSANDRO GIUSEPPE ANTONIO ANASTASIO VOLTA

1745 - 1827

PRIMARY CELLS 1800

Voltaic Pile (Copper, Zinc, Sulphuric acid

PRIMARY CELLS Cell Voltage:

Dependant on electrode type See Table 3.1 Page62 What voltage will the cell’s voltage be if Copper & Zinc is used?

Zinc = -0.76 V Copper = +0.34 V Voltage difference = +0.34 (-0.76) = 1.1 V Copper electrode = Positive terminal

PRIMARY CELLS Cell Voltage:

Dependant on electrode type See Table 3.1 Page62 What voltage will the cell’s voltage be if Gold & Aluminium is used?

Aluminium = -1.76 V Gold = +1.42 V Voltage difference = +1.42 (-1.76) = 3.18 V Gold electrode = Positive terminal

PRIMARY CELLS Cell Voltage:

Dependant on electrode type See Table 3.1 Page62

Cell Current:

Dependant surface area of electrode (Plate)

Copper

ZINC COPPER CELL

Hydrochloric Acid Zinc + + H H + HCl Cl H + HCl Cl ZnCl Zn ++ -

ZINC COPPER CELL Problems with this type of cell

Hydrogen gas bubbles stick to the copper electrode Reduces surface area of electrode Effect known as “Polarisation” Chemicals (Depolarisers) are added to reduce this effect

ZINC COPPER CELL Problems with this type of cell

Any impurities in Zinc electrode will act as a small cell and eat the electrode away even if the cell is not connected Effect known as “Local Action” Causes the cell to go flat or have a “shelf life”

JOHN FREDERIC DANIEL

1790 - 1845

THE DANIELL CELL 1836

First attempt to remove the problem of Polarisation Used second electrolyte to consume the hydrogen

GEORGES LECLANCHE

1839 - 1882

THE LECLANCHE CELL 1866

Positive electrode = Carbon Negative electrode = Zinc Electrolyte = Ammonium Chloride Depolariser = Manganese Dioxide Zn(s) + 2 MnO 2 (s) + 2 NH 4 Cl(aq) → ZnCl 2 + Mn 2 O 3 (s) + 2 NH 3 (aq) + H 2 O

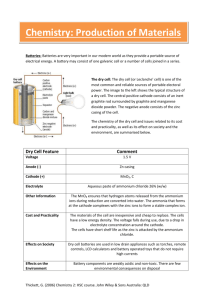

THE ZINC CARBON CELL 1866

THE ZINC CARBON CELL 1866

Positive electrode = Carbon Negative electrode = Zinc Electrolyte = Ammonium Chloride Depolariser = Manganese Oxide Zn( s ) + 2MnO 2 ( s ) + 2NH 4 + ( aq ) → Mn 2 O 3 ( s ) + Zn(NH 3 ) 2 2+ ( aq ) + H 2 O( l )

THE ZINC CHLORIDE CELL

Electrolyte = Zinc Chloride Zn( s ) + 2 MnO 2 ( s ) + ZnCl 2 ( aq ) + 2 H 2 O( l ) → 2 MnO(OH)( s ) + 2 Zn(OH)Cl( aq )

THE ALKALINE CELL

Alkaline Cells Alkaline watch batteries are primarily used where cost is a factor. Construction is similar to Lithium cells. Voltage rated at 1.5 volts. Next time you find a free watch in your pack of breakfast cereal, chances are it will be powered by a Zinc Alkaline cell. Advantages Cheap to make. Environmentally safe. Good for low and intermittent high drain applications. Will keep that el-cheapo quartz watch going for months!

Disadvantages Only about half the capacity of a silver oxide cell. Voltage not very constant during its life. Relatively short shelf life, similar to carbon zinc cells in its characteristics, but with about double the stored energy capacity.

Uses Suitable for applications where a cheap alternative is required. Wouldn't risk putting one in my Accutron even if I could find one to fit.

A) Cell top (-ve electrode) B) Anode of Zinc + Electrolyte gel C) Nylon seal D) Electrolyte in Separator, Anode and Cathode Material.

E) Cathode of Manganese Dioxide F) Absorbent separators containing electrolyte G) Cell Can (+ve electrode)

Cylindrical alkaline batteries are produced with a high surface area zinc anode, a high density manganese dioxide cathode, and a potassium hydroxide electrolyte. A cutaway (fig. 4) of a typical cylindrical alkaline battery is illustrated in the following diagram: Cathode is a mixture of high purity electrolytic manganese dioxide and carbon conductor.

Anode is a gelled mixture of zinc powder and electrolyte.

Separators of specially selected materials prevent migration of any solid particles in the battery.

Steel can confines active materials and serves as the cathode collector.

Brass collector serves as the anode collector.

Positive and negative covers provide contact surfaces of nickel-plated steel.

Non-conductive plastic film label electrically insulates the battery.

Nylon seal provides a safety venting mechanism

THE MERCURY CELL

Mercury batteries have been the mainstay of watch batteries for almost 50 years. These cells are rated at 1.36 volts. Due to increasing concerns over waste mercury finding its way into our food, the manufacturing of these batteries has virtually stopped.

Advantages Extremely constant voltage over its useful life. Suitable for low drain and intermittent high drain applications. Long shelf life - up to 3 years.

Disadvantages Contains mercury, which in certain forms is highly toxic to humans and animals.

Uses Excellent for Accutrons, as they were designed originally to operate with these cells. Were used in nearly all applications requiring small constant voltage cells, ie, watches, hearing aids, portable scientific instruments etc.

A) Cell top (-ve electrode) B) Anode of powdered zinc + electrolyte gel C) Nylon seal D) Electrolyte E) Cathode of Mercuric Oxide and Graphite F) Absorbent separator of fabric and electrolyte G) Barrier separator membrane.

H) Cell Can (+ve electrode) I) Metal sleeve to support the nylon case seal

THE SILVER OXIDE CELL

A silver oxide battery (IEC code: S), also known as a silver–zinc battery, is a primary cell (although it may be used as a secondary cell with an open circuit potential Silver oxide batteries have a long life and very high energy/weight ratio, but a prohibitive cost for most applications due to the high price of silver of 1.86 volts). . They are available in either very small sizes as for example in button cells where the amount of silver used is small and not a significant contributor to the overall product costs, or in large custom design batteries where the superior performance characteristics of the silver oxide outweigh cost considerations. The large cells found some applications with the military, Mark 37 torpedoes or on Alfa class submarines chemistry The silver oxide/zinc alkaline primary battery is the predominate system of the miniature battery product line. It typically can be used in watches, calculators, photoelectric exposure devices, hearing aids, and electronic instruments. Its general characteristics include: Higher voltage than comparable mercury batteries Flatter discharge curve than alkaline manganese dioxide batteries Good low temperature characteristics Good resistance to shock, vibration, and acceleration Low and essentially constant internal resistance Excellent service maintenance; in excess of 90% after storage at 21°C(70°F) for five years Available in voltages ranging from 1.5 to 6.0 volts and a variety of sizes.

Cathodes are a mixture of Ag battery.

electrical contact.

2 O and conductor.

Anodes are a gelled mixture of amalgamated zinc powder and electrolyte.

Separators of specially selected materials prevent migration of any solid particles in the Insulating and sealing gaskets are moulded of nylon.

Exterior battery surfaces of nickel are used to resist corrosion and to insure good Silver oxide batteries contain a cathode of silver oxide with a low percentage of manganese dioxide and graphite, an anode of high surface area zinc, and a highly alkaline electrolyte consisting of either sodium hydroxide or potassium hydroxide. The open circuit voltage of silver oxide batteries is 1.6 volts. The operating voltage at typical current drains is 1.55 volts or more. Silver oxide batteries offer a higher flat operating voltage characteristic than mercuric oxide batteries as illustrated in the following diagram: The type of electrolyte used with silver oxide batteries determines their rate or current carrying capability.

Under heavy drains, potassium hydroxide (KOH) electrolyte offers less resistance to the current flow and allows the battery to operate at higher efficiency than a sodium hydroxide (NaOH) electrolyte. At low drains both electrolytes operate with equal efficiency. This relationship is shown in the following diagram:

Silver oxide batteries containing a KOH electrolyte are more difficult to seal than those containing at NaOH electrolyte. As a result, NaOH batteries are typically more salt resistant than similar sized KOH batteries. Both batteries however, exhibit excellent long term salt resistance.

Temperature: Silver oxide batteries have good performance characteristics at temperature extremes. They can be used up to 55°C(131°F). Silver oxide batteries utilizing KOH as an electrolyte will operate with less loss of efficiency at lower temperatures than comparable NaOH batteries. Batteries with KOH electrolyte will operate down to -28°C (-20°F) and NaOH batteries down to -10°C(14°F) with some service reduction in both types.

It provides up to 40 percent more run time than lithium-ion batteries and also feature a water-based chemistry that is free from the thermal runaway and flammability problems that have plagued the lithium-ion alternatives This once attractive technology had the highest energy density (prior to lithium technologies), and was primarily developed for aircraft use. The worldwide rise in silver prices seemed to spell its demise. It was the power source in all of the Apollo spacecraft: the command module re-entry batteries, the lunar module and the lunar rover . (The Apollo Service Module used fuel cells as a primary power source.) More recently, the company ZPower has introduced a new line of rechargeable silver Applications: Eveready silver oxide batteries are specially designed to meet the varying power requirements of a wide variety of applications.

Watch and Calculator - Silver oxide watch batteries using a sodium hydroxide (NaOH) electrolyte system are primarily designed for low drain continuous use over long periods of time, typically up to five years. This is commonly found in analog watch applications.

Silver oxide watch batteries using a potassium hydroxide (KOH) electrolyte system are principally designed for continuous low drains with periodic high drain pulse demands for periods of approximately one to two years. This is typical of applications such as LCD watches with backlight, analog watches with alarms and calculators.

Hearing Aid and Electronic - Silver oxide hearing aid and electronic batteries are designed to produce greater volumetric energy density at higher continuous discharge rates than silver oxide watch or photographic batteries. Hearing aid and electronic batteries use potassium hydroxide electrolyte in combination with the separator system designed to match the required application.

Photographic - Silver oxide photo batteries are designed to provide constant voltage or periodic high drain pulses with or without a low drain background current.

zinc batteries to compete with lithium-ion batteries. The claims include an energy density of 200Wh/kg, complete non-flammability, and no toxic chemicals. To offset the high price of silver, the company plans to offer a trade-in policy to recycle all of it.

[2][3] Intel 's venture arm, Intel Capital , has provided the company with financial backing.

[4] ZPower claims that an undisclosed "major manufacturer" of laptop computers will introduce its silver-zinc battery in a new line of laptops in 2009.

Silver Oxide Cells The silver oxide cell is really the ideal successor to mercury batteries, and is superior in a number of ways. It has a higher capacity than mercury cells for a given size. These cells are rated at 1.62 volts. Their construction is very similar to mercury cells, the cathode material being the main difference.

Advantages Constant voltage over its useful life. Contains no chemicals harmful to the environment. Basically superior in all ways over mercury cells.

Disadvantages About half the shelf life of mercury cells. Uses Main applications are in watches. Great for Accutrons, which will perform equally well with these cells as mercury cells.

A) Cell top (-ve electrode) B) Anode of powdered zinc + electrolyte gel C) Nylon seal D) Electrolyte E) Cathode of Silver Oxide and Graphite F) Absorbent separator of fabric and electrolyte G) Barrier separator membrane.

H) Cell Can (+ve electrode) I) Metal sleeve to support the nylon case seal

THE LITHIUM CELL

Lithium Cells Lithium cells are often called "coin cells" due to their shape. The lithium cells used in watches are Lithium-Manganese Dioxide, and are rated at 3.0 volts. The other type of lithium cells commonly seen are Lithium-Thionyl Chloride, which are rated at 3.6 or 3.7 volts. These are not used in watches.

Advantages Fairly constant voltage over most of its useful life. Contains no chemicals harmful to the environment. Very long shelf life, up to 10 years. Disadvantages Suitable for low drain or only intermittent high drain applications.

Uses Excellent for quartz watches that draw very low current, and only intermittent current when the stepper motor is driven. Can last 5 years or more in the correct application. Not suitable for Accutrons as the voltage is too high.

A) Cell top (-ve electrode) B) Anode of lithium C) Nylon seal D) Electrolyte in Separator, Anode and Cathode Material.

E) Cathode of Manganese Dioxide F) Absorbent separators containing electrolyte G) Cell Can (+ve electrode)

Zinc-Air Cells Note: Not to be used in watches!

Zinc-Air cells are not watch batteries, and are included in this list because they seem at first glance to be a good alternative to Mercury cells for our Accutrons. Read on and find out why not. Zinc-Air cells have the highest capacity of all button cells due to the fact that most of the cell volume can be taken up with anode material (zinc), because the cathode material used is oxygen obtained from the atmosphere. Their rated voltage is 1.4 volts. They are activated by peeling off an adhesive layer, allowing air to enter the cell through small vent holes.

Advantages Very high capacity for their size. Very constant voltage ouptut for most of their life. Able to be used in medium current applications. Slightly shorter shelf-life than Mercury cells when not activated, but longer than Alkaline and Silver Oxide. Environmentally safe.

Disadvantages Must be used in applications where the battery compartment is vented to the atmosphere. The cells are hygroscopic, and therefore may store and release water to and from the atmosphere. Actual performance of the cell can depend on the relative humidity.

Uses The main use for Zinc Air button cells is in hearing aids. They must not be used in watches, as they require atmospheric oxygen to function, and they may emit water which can be corrosive to metal parts. Under extremes of temperature, or if the cell is shorted out, the internal membranes may rupture, and vent liquids and gas to the atmosphere. Do not use in watches!!!

Type Chemical Reaction Operating Temperature Recommended for Initial Voltage Capacity Discharge Rate Internal Resistance Impedance Storage Life Storage Temperature

THE ALKALINE CELL

Primary 2Zn + 3MnO 2 KOH --> 2ZnO + MN 3 O 4 -20º F to 130º F ( -28º C to 54º C). Good range of operating temperatures.

High-discharge devices, which include (but are not limited to): Digital cameras, RC cars, portable power tools, heavy-use flashlights, CB walkie-talkies, FRS radios, portable televisions, handheld video games, portable audio systems (such as boomboxes), CD players, MP3 players, appliances, shavers, and toothbrushes.

1.5 volts or 9.0 volts.

•When used in a device with a high discharge rate, the service life is up to 38% higher than standard alkalines. •At low to moderate discharge rates, performance is similar to standard alkalines. •Alkaline batteries do not have a standard capacity rating; see the Capacity heading for a full explanation.

Sloping. Products with a high current drain are particularly hard on batteries; the higher the current drain is, the steeper the discharge slope will be.

Very low. It remains almost constant until the end of its life when it will increase rapidly.

Chemical Reaction Very low (much less than that of carbon zinc batteries).

Operating Temperature Loses 5% of performance after one year, and 2.5% each year after. We recommend that Initial Voltage -40º F to 120º F ( -40º C to 48º C).

Capacity Discharge Rate Internal Resistance Impedance Storage Life Storage Temperature Disposal 2Zn + 3MnO 2 KOH --> 2ZnO + MN 3 O 4 See each type.

1.5 volts or 9.0 volts.

Alkaline batteries do not have a standard capacity rating; see the Capacity heading for a full explanation.

Sloping. Products with a high current drain are particularly hard on batteries; the higher the current drain is, the steeper the discharge slope will be.

Very low. It remains almost constant until the end of its life when it will increase rapidly.

Very low (much less than that of carbon zinc batteries).

See below.

See below.

Not recyclable; can be safely thrown away.

Positive cap: Formed protrusion at one end of the battery can which identifies it as the positive terminal.

Steel can: Nickel-plated steel which is formed into a container to hold chemicals and serves as the positive collector.

Outer Jacket: A plastic sleeve which contains decorative printing identifying the cell type and size.

Separator: Porous non-woven fibrous material which separates electrodes; holds electrolyte between electrodes.

Electrolyte: A solution of potassium hydroxide in water which carries the ionic current inside the battery.

Cathode: Manganese dioxide and graphite which take up electrons from the external circuits.

Anode: Powdered zinc metal which serves as the source of electrons.

Anode Collector: Tin-plated brass which serves as a path for the electrons from the anode to the external circuit.

Seal/Vent: Molded plastic disc which holds internal components inside the cell and releases internal pressure when battery is abused.

THE LITHIUM IRON DISULFIDE CELL

Lithium-Iron: A recent addition in the marketplace, the Lithium Anode, Iron Sulfide (or Iron Disulfide) Cathode battery stands out from the rest of the Lithium based Primary batteries in that its voltage output is typically 1.5 volts and comes in standard AA size. It also has for a Primary Lithium based battery uncommonly high capacity and high drain characteristics, typically higher than normal Zinc Manganese Dioxide Alkaline batteries. However their cost, when compared with normal Alkaline batteries has to be taken into consideration, especially when a lot of the simpler silent Super 8 cameras tend to have low to moderate drain characteristics.

BUTTON Lithium-Manganese Dioxide: The most commonly available Lithium based button cell type battery, it consists of a Lithium Anode, Manganese Dioxide cathode and typically an organic electrolyte. It, however, cannot be used for replacing a Mercury Oxide battery because of its size, voltage (typically 3 volts) and its sloping output voltage characteristic under mid to high drain applications.