Quality Control Tools Training

T1-OPEN

Welcome to

Implementing Security Policy as a Quality Process

Lloyd Hasche (Modern Technologies Corp)

Jim Lightfoot (The James Group)

Jim Engelkes (The James Group)

Session Objectives

1. Explain how quality practices can enhance information security implementation

2. Have fun!

Introduction and Purpose

1. Why quality practices for Internet Security

2. Background

3. Requirement – Value added

Value Added

1. Quality is a value of the information process

2. Security is an attribute of Quality ( Denning)

3. People are the key agents of the quality process

• Information Professionals need to apply quality management techniques (Stylinanio and Kuman )

Quality Information Process

Vq = f ( Content, Open, Integrity)

Quality Attributes

( Dorothy Denning )

Utility

Functionality

Effort

Speed

Cost

Reliability

Security

Security must contribute to overall quality and not degrade it

IT professional is the key

Dimensions of IS Quality

Stakeholders

Implementation Issues

• Customer focus

•

Process Approach

• Leadership

•

Culture

• Broad partnership and teamwork

• Motivating the troops

•

Measurement and Constructive Feedback

• Accountability for results & rewarding achievement

•

Self-assessment

Dimensions of IS Quality

In-Process

Stakeholders

• Management

• Process Owner

• Process Participants

End-of-Process

Stakeholders

• Internal Customers

• External Customers

Infrastructure

Quality

Administration

Quality

Software

Quality

Information

Systems

Quality

Data

Quality

Service

Quality

Information

Quality

Enterprise

Quality

Quality of

Business

Processes

Supported by

IS

Conclusion:

Quality practices are key to success in information security implementation

A Quote ...

“There is nothing more inefficient than doing efficiently that which should not be done at all.”

Peter Drucker

Quality Improvement Defined ...

“..... a strategic , integrated management system for achieving customer satisfaction which involves all managers and employees and uses quantitative methods to continuously improve an organization’s processes .”

Another Definition

Quality is what makes it possible for a customer to have a love affair with your product or service. Telling lies, decreasing the price or adding features can create a temporary infatuation. It takes quality to sustain a love affair .

Therefore it is necessary to remain close to the person whose loyalty you wish to retain. You must ever be on the alert to understand what pleases the customer, for only customers define what constitutes quality. The wooing of the customer is never done .

Myron Tribus

Two Perspectives...

Hardware vs. Software

What are the functions of leadership?

Why We Need To Change

Profit

Profit

(COPQ)

Theoretical costs i.e., Cost of

Doing the Right

Things Right the

First time

(COPQ)

Theoretical costs i.e., Cost of

Doing the Right

Things Right the

First time

“The price of gaining knowledge is nothing compared to the cost of ignorance.”

Anonymous

Some Common Reactions

“It’s common sense.”

“Good management produces good quality.”

“I know all of this.”

“I know my business; Don’t tell me how to do it.”

“No need for change. We do it just fine now.”

“Doesn’t apply to my area.”

“We don’t produce products; We don’t have customers.”

“There is no way to change.”

Traditional Management

Philosophies

Taylorism

Management by Objectives / Results (MBO /

MBR)

A Quote ...

“A high-priced man does just what he is told and with no back talk ... when your manager tells you to walk, you walk; when he tells you to sit down, you sit down ...”

FREDERICK TAYLOR

How many ideas have your XY’s generated?

Management by Results:

The negative side

When standards are unattainable “games” are played and figures “juggled”

Fear tends to be the motivator

Fosters “play it safe” or “blame it on them” behavior

The organizational “box” becomes the customer

Production that exceeds standards is stored so it can be used another day

Fight “fires”, but never understand the process that caused the fire

Exhorting the masses

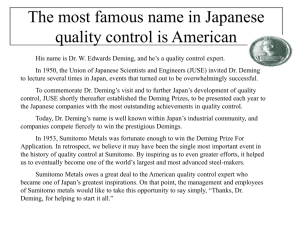

Common Principles

DEMING - CROSBY - JURAN

Internal and external customers define quality

Management creates a quality culture

Quality is prevention-based rather than inspection-based

Systems and statistical thinking

Team approach

Continuous improvement of processes

Education and training is vital

An empowered workforce

A paradigm shift

“Systems Thinking and Puzzles”

A Process is ...

“A series of sequentially oriented, repeatable operations having both a beginning and an end which generates either a product or service.”

– It can be any set of conditions, causes, or inputs that work together to produce a given result or output.

–

Management is the ultimate owner of the process

Deming Nugget

“I burn the toast, Jim scrapes it, and by

God, we get it out.”

Dr. W. Edwards Deming

The Current Process

R

E

A

M

U

P

S

T

PROCESS

PRODUCT

REWORK

PASS

INSPECTION

FAIL

CUSTOMER

SCRAP

S

T

R

E

D

O

W

N

A

M

- INCREASED COST - LACK OF PRIDE - BURNOUT - DELAY

94% of defects are caused by a common cause (the system)

6% of defects are caused by special causes (people or events)

From “Out Of The Crisis” by W.E. Deming

“We need to Change our Thinking”

OLD THINKING

Work on Results

Short-Term

Authoritarian

Status Quo

Fear

Conformity to

Specifications

Individuals Caused

Defects

NEW THINKING

Work on Processes

Long-Term

Participative

Continuous

Improvement

Open Atmosphere

Customer Defined

Process Caused Defects

Open Book Management

If you want employees to act like owners you need to treat them like owners.

When Use of Measurement

Drives Improvement ...

MEASUREMENT

QUALITY

IMPROVEMENT

AND

PRODUCTIVITY

When Desire for Improvement

Drives Measurement ...

QUALITY

IMPROVEMENT

AND

RODUCTIVITY

MEASUREMENT

Identify customers

Internal

External

Ultimate

Tools to Determine Customer

Requirements

COPIS

Focus groups

Personal interviews

Surveys

Do surveys tell all?

Who wrote your survey?

The most important numbers are unknown

Key Quality Characteristics

(KQC)

Work with your customer to get an operational definition for the KQC.

If the customer wants your service or product on time as their KQC; what is on time ?

Get your customer to help define on time .

Operational Definition

In the bleachers/Steve Moore

Customer Expectations

Levels of customer expectations about quality

– ONE - Assumed

– TWO - Satisfied

– THREE - Delighted

–

FOUR - ????

Process flow charts are used to ...

Understand a system or process

Verify or clarify work processes

Identify customers/supplier relationships

Identify value-added work

Identify potential problems or opportunities for improvement

Eliminate redundant steps

Value / Cost Added

Value Added Cost Added Only

Type

Eval

Originator

NOT OK

OK

Check

NOT OK

OK

Check

NOT OK

Check

Send to

HR

NOT OK

Check

File in

Personal record

OK

“The Questioning Technique”

Analyze the process in its entirety, then ask the following questions about each task or step:

WHAT :

– Why is it done at all? / Why is it necessary? / Why not eliminate it?

WHERE :

– Why is it done there? / Why not change the place? / Why not change the sequence? / Why not combine?

WHO :

– Why does the person do it? / Why not change the person? / Why not change the sequence? / Why not combine?

HOW :

–

Why is it done this way? / Why not do it a different way? / Why not improve it? / Why not make it easier?

Process Flow Chart Diagram

YES

Does the damn thing work?

Don't mess with it

NO

Does anyone know?

YES

Hide it!

You dummy

YES

NO

YES Did you mess with it?

NO

Will you catch hell?

You poor victim !!!

NO

NO

Can you blame anybody else !!!

YES

No problem !!!

The hell with it

“Paperwork Shuffle” Flowchart

A Quote

“It is a capital mistake to theorize before one has data.”

Arthur Conan Doyle

A Message To Leaders

“If I had to reduce my message to management to just a few words, I’d say it all had to do with understanding and reducing variation.”

W. Edward Deming

Basic Concepts

Variation is inherent in all processes

Individual fluctuations are random in nature

Stable processes fluctuate within predictable boundaries

Unstable processes do not fluctuate randomly

There are two kinds

Example

The Traditional Approach to

Data...

MONTH 1

Incidents: 8

Last Month: 10

Change: -20% (good)

Comments: Good Job! Way to Go!

Congratulations! Awards and Promotions to follow...

The Traditional Approach to

Data...

MONTH 2

Incidents: 11

Last Month: 8

Change: +38% (bad)

Comments: Get it together! Get tough! No more

Mr. Nice Guy! Increase training! Threats and

Warnings follow...

The Traditional Approach to

Data...

MONTH 3

Incidents: 12

Last Month: 11

Change: +9% (bad)

Comments: See attached trend analysis...

The “Big Gear” Syndrome

What happened?

What are you doing about this?

I don’t know.

I’ll go find out.

I’ll get back to you with a plan.

I’m looking!

I’m looking!

What’s going on?

Why did this happen?

What are we going to do?

We’re looking!

We’re looking!

Trend Analysis

12

8

Month 1 Month 2 Month 3

Comments: You have lost control of your people, didn’t you see it coming? Emergency Training! Reprimand! One more increase and you’re fired!

What a Traditional Manager might do...

Good job!

100

That’s better!

80

60

What are you doing about this?

Watch out!

You’re fired!

0

19 21 23 25 27 29 34 36 39 41 43

Time in Weeks

The present process may not be capable...

In here!

the Voice of the Process the Voice of the Boss

An Improvement is ...

A reduction in the degree of variation

An adjustment (shift up or down) in the middle value

The Paperwork Shuffle

BEFORE

30

20

10

0

60

50

40

OCCURRENCES

The Paperwork Shuffle

AFTER

4

3

2

1

7

6

5

OCCURRENCES

Some Good Reads...

The Fifth Discipline (Senge)

The Fifth Discipline Field Book (Senge)

The Power of Open Book Management (Shuster)

Any book on the Malcolm Baldridge criteria