PROCESS CONTROL & AUTOMATION

advertisement

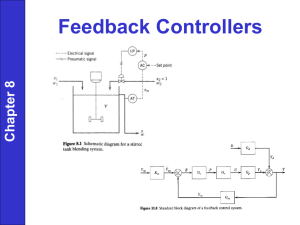

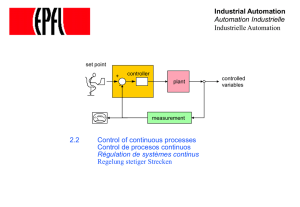

PROCESS CONTROL & AUTOMATION BY SOBUKOLA, O.P. (PhD)/KAJIHAUSA, O.E. (MRS) Department of Food Science & Technology, University of Agriculture, PMB 2240, Abeokuta, Nigeria. sobukolaop@unaab.edu.ng Grading • Continuous Assessment Test – CAT - 20% • Examination - 70% • Attendance - 10% • Total - 100% Course Outline • Lecture 1- Introduction • Lecture 2- Control Systems • Lecture 3- Measuring and Detecting Elements • Lecture 4- Control Actions • Lecture 5- Frequency response Analyses • Lecture 6- Computer-based Systems LECTURE ONE INTRODUCTION Automatic control has played a vital role in the advance of engineering and science. In addition to its extreme importance in space-vehicle systems, robotic systems and the like, automatic control has become an important and integral part of modern manufacturing and industrial processes. - A process – is the transformation of a set of inputs, which may be material, actions, methods and operations into desired outputs in the form of a product. - Control - means measurement of the performance of a process and the feedback required and corrective actions where necessary. - Automation – Automation means reductions in the use of direct labour during food processing. Advantages of Automation include: • Consistency and accuracy in the positioning of moving parts of an equipment. • A more consistent product. • The more economic use of existing plant by saving of fuel/and or electrical energy. • The release of skilled personnel for other productive work . • Reduction of physical effort with consequent reduction of fatigue and boredom • Improved working conditions. Limitations of automation: – Initial cost is high – power fluctuations, – Lack of skilled personnel etc. Basic steps in process control are: • Measurement of the process variable; • Evaluation and comparison with desired level; and • Control of the required level of the parameter involved LECTURE TWO Definition of some terms in process control • Controller – A device that measures a variable condition (Temperature, pressure, humidity, moisture content) like thermostats, humidistat or pressure controllers. • Control system – consist of controller, controlled device and source of energy or input. • Controlled device – it reacts to the signal received from a controller and varied the flow of the controlled agents. Valve, damper, electric relay or a motor driving a pump, fan etc. • Control agents – the medium being manipulated by the action of controlled device e.g. air or gas. • Controlled variables – are system parameters which are under control e.g. Temperature, pressure, humidity etc. • Manipulated variable – is the quantity or condition that is varied by the controller so as to affect the value of the controlled variable. • Plant – This may be a piece of equipment or a set of machine parts functioning together, the purpose of which is to perform a particular operation. • Disturbances – A disturbance is a signal that tends to adversely affect the value of the output of a system. CONTROL SYSTEMS Self controlled systems Pneumatic system Hydraulic system Electrical system Electronic System LECTURE THREE MEASURING AND DETECTING ELEMENTS (SENSORS) They are the main interfere between the control system and process. In food processing, they are required for incoming material selection; material waste control; process quality control; packaging inspection; equipment maintenance/failure prediction, environmental control. Variable Detecting element Strain or Load Resistance strain gauge Displacement/ Potentiometer, differential Position Transformer, capacitance Transducer Speed Weights moved by centrifugal force, Tachometer generator Rate of flow Orifice plate or venturi tube Temperature Thermometer, Thermocouple, Thermopile Pressure Bourdon tube, diaphragm, and bellows Liquid level Electrodes at various depths, Dip-tube (pneumatic), capacity probe pH Glass and calomel electrodes Block diagram • A control system consist of a number of components that perform certain factors which are represented by block diagram in control engineering. • It is a pictorial representation of functions performed by each component and of the flow of signals. • It depicts the interrelationships that exist among the various components. Open loop control system – Those systems in which the output has no effect on the control action. In other words, in an open loop control system the output is neither measured nor fed back for comparison with the input. Feedback/Closed loop system- The term closedloop control always implies the use of feedback control action in order to reduce system error. LECTURE FOUR CONTROL ACTIONS The relationship between the deviation and the signal sent from the controller to the correcting unit determines the control action. Most control actions derive their names on the basis of mathematical or functional relationship between the output and the error. An automatic controller compares the actual value of the plant output with the reference input (desired value), determines the deviation, and produces a control signal that will reduce the deviation to zero or to a small value. The manner in which the automatic controller produces the control signal is called the control action. Industrial controllers are usually classified according to their control actions: • Two step Action or on-off controllers • Proportional Action • Integral Control Action • Proportional plus integral control Action • Proportional plus derivative control Action • Proportional plus Integral plus derivative control actions Frequency response of controller A controller may be regarded as an amplifier. For sinusoidal input signals, a controller with proportional action only gives an output proportional to the input, but in phase opposition to it, whatever the frequency may be. LECTURE FIVE FREQUENCY RESPONSE ANALYSIS Frequency response – Is the relationship between output signal and input signal when the sinusoidal input is a component or system is varied over a wide range of frequencies. When the plant and the controller are connected together to form a closed loop, we have a system similar to a voltage amplifier with feedback mechanism. • The input to the controller is a signal representing the output condition of the process and the output of the controller is fed into the process. • The process may be broken down into a series of individual stages, called transfer stages and time lags due to the finite time taken for signals to travel from one point to another. • As the frequency of the input signal is increased the angle of lag increases, the largest possible lag for a signal stage being 90o. • The attenuation also increases as frequency is increased. Attenuation – is the production of an output signal smaller than the corresponding input. Frequency response of controller A controller may be regarded as an amplifier. For sinusoidal input signals, a controller with proportional action only gives an output proportional to the input, but in phase opposition to it, whatever the frequency may be. Transient response and stability It is time variation of the output signal when a specified step input signal or disturbance is applied. The transient response of a speed control system is illustrated by the shape of the speed/time graph immediately following the sudden application of load or a sudden change in the desired speed setting. LECTURE SIX Computer-based systems • The increasingly widespread use of microprocessor-based process controllers over the last twenty years is due to their flexibility in operation, their ability to record (or ‘log’) data for subsequent calculations and the substantial reduction in their cost. • Computers can not only be programmed to read data from sensors and send signals to process control devices, but they can also store and analyse data and be connected to printers, communications devices, other computers and controllers throughout a plant. • They can also be easily reprogrammed by operators to accommodate new products or process changes. • Examples of the different types of computer controlled systems are described below. Programmable logic controllers (PLCs) • A significant development in process control during the 1980s was the introduction of PLCs. • They are based on microcomputers, and have the same functions as relays, but with vastly greater flexibility. • Historically, they were first used to replace relays in simple repetitive applications, but the greater power was quickly used to develop other functions, including recipe storage, data transfer and communications with higher level computers. Types of control systems The different combinations in which PLCs and larger computers can be linked together in an integrated control system can be described in three categories: 1. dedicated systems 2. centralised systems 3. distributed systems. Neural networks • Where complex relationships exist between a measured variable and the process or product, it has not yet been possible to automate the process. • Recent developments of ‘expert systems’ or ‘neural networks’ may have the potential to solve such problems. • These are able to automatically deduce complex relationships and also to quickly ‘learn’ from experience.