HYSYS REPORT PROPYLEN OXIDE CO

advertisement

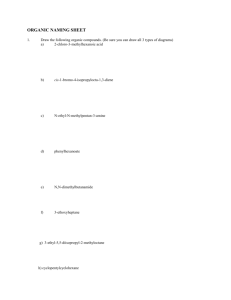

HYSYS REPORT PROPYLEN OXIDE CO-PRODUCTION WITH t-BUTYL ALCOHOL BY THE TEXACO HYDROPEROXIDATION PROCESS Done by: Adel Abdullah Sultan Mohammad Khaled Suad Khaled Al-matoog Outlines: • Introduction • Assumptions • Process Description • Over All Mass & Mole Balance • Comparison of Actual and Hysys Simulation • Final Results INTRODUCTION • There are tow types of process : • Isobutene Oxidation : it has two reactions • (CH3) 3 CH+02→ (CH3)3COO • (CH3)3 CH+0.5 02→ (CH3)3 COH. • Propylene Epoxidation: • CH3 CH = CH2 + (CH3)3 COOH → CH3CH-CH2 + (CH3)3 COH Programming Production PO into HYSYS Adding components: Assumptions : 1) Fluid package used is Wilson. Assumptions : • 2. The Reactors types are conversion reactor . • 3. The pressure drop inside all Distillation • • Columns not exceed 5 Psia. 4. We change the type of condenser in distillation column (C-302) from partial reflux to total reflux so it could be solved . 5. There are many pumps , compressor , heaters ,valves and cooler when we need to control pressure and temperature . Equipment used in Hysys simulation: • • • • • • • • Total Total Total Total Total Total Total Total number of mixers :5 number of reactors:2 number of heat exchangers:7 number of distillation columns:5 number of Tees :4 number of compressors:2 number of pumps: 5 number of valves: 2 Process Description Isobutene Oxidation : (CH3) 3 CH+02→ (CH3)3COO (CH3)3 CH+0.5 02→ (CH3)3 COH The column operated with the subsistence of the specifications: 1-we gave a component recovery for isobutane 0.995and for TBHP 0.967. 2- A reflux radio at the condenser with value of 1. 3-The numbers of trays was used 39 The specifications entered for the distillation column(C-102) are: -The reflux ratio half a specified of 5. -The number of trays used was 34. - The distillation operators at 100 Psia at the top and 105 psia at the bottom. Propylene Epoxidation: CH3 CH = CH2 + (CH3)3 COOH → CH3CH-CH2 + (CH3)3 COH The specification entered for the distillation column (C-301) are: -The reflux ratio had specified value of 2. -The number of trays used was 35. -The distribution operates at 60 psia at the top and 65 psia at the bottom. The specifications entered for the distillation column(C-304) are: -The number of trays used was 17. The distillation operators at 15 Psia at the top and 20 psia at the bottom.-The reflux ratio had specified value of 17- The specifications entered for the distillation column(C-302) are: -The reflux ratio half a specified of 5. -The number of trays used was 24.- The distillation operators at 120 psia at the top and 125 psia at the bottom. Over All Mass & Mole Balance • Mass balance: 240,522 (lb/hr) 239,235 (lb/hr) Over All Mass & Mole Balance • Mole balance: 2,219 (kgmole/hr) 2,007 (kgmole/hr) Comparison of Actual and Hysys Simulation Stream data Final Results: • The resulting propylene oxide from this plant has purity of 97.9% with flow rate of 49,122 lb/hr and 94,646 of TBA as co product.