AT-1927-14 - Allison Transmission

advertisement

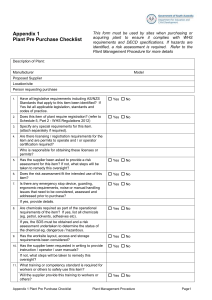

ALLISON TRANSMISSION, INC. APQP Kick-off Checklist The purpose of this meeting is to develop a common understanding concerning the total requirements of the part/material by ensuring proper communication and buy-in occurs between our companies. This form encompasses questions from the AIAG Advanced Product Quality Planning and Allison Transmission, Inc. (ATI) Supplier Quality Manual AT-1927. Its intent is to ensure advanced product quality planning activities occur at the appropriate time and establish customer requirements for part qualification, part availability, quality, packaging, scheduling, terms & conditions, unit cost information, and tooling information. This document should be completed and provided to the Commodity Manager & SQE prior to the meeting date. DATE: COMM. MGR.: PROJECT/PROGRAM: SUPPLIER NAME: MANUFACTURING LOCATION: DUNS #: ASQE PROD. ENGR.: SUPPLIER CONTACTS: - ACCT MGR: - QUALITY REP: PART NO: CHANGE LEVEL: PART DESCRIPTION: SECTION 1. CUSTOMER REQUIREMENTS 1. Does the supplier understand all the applications and intended end uses of the parts/materials for all customers? Yes No If Yes, Explain: 2. Does the supplier have the latest information about program timing (example: Drawing release, Prototype – series, Matching, LRIPs, SOP)? Yes No Explain: Review Program Milestones with supplier. Key Project Milestones Dates Key Project Milestones Dates 3. Does the supplier have and understand the latest TS16949 Manual & AIAG Manuals (FMEA, SPC, Measurement Systems Analysis, PPAP and the Advanced Product Quality Planning (APQP) and Control Plan Manual)? Yes No Explain: 4. Has the supplier provided all information listed in the Required Quality Information letter AT-1927-4 as outlined in the RFQ package? Yes No Explain: 5. Does the supplier have and understand all the requirements listed in the Supplier Quality Manual AT-1927? Yes No Explain: 18-Dec-2015 1 AT-1927-14 6. Does Supplier understand and agree to AT-1700 ATI Packaging & Identifications Requirements? Yes No Explain: 7. Has the AT-1703 Container Assumption Form been provided and returned to the Commodity Manager? Yes No Explain: 8. Are returnable containers required? Yes No Explain: 9. Are there any packaging issues to be resolved? Yes No Explain: 10. Does supplier have electronic communications capability and required systems testing complete for scheduling and shipping? Yes No Explain: SECTION 2. Product Design / Development 11. Does the supplier have and understand ALL of the latest drawings and specifications (TES, TIS, etc.) ? Yes No Explain plans to obtain: 12. Has an Advanced Development Validation (ADV) plan been provided, if specified in the requirements? Yes No Specify planned date: 13. If communication link for math data exchange is needed have appropriate contacts been taken? Yes No Explain: 14. If ATI is design responsible, has a Design-FMEA review been completed between supplier and the ATI Engineer? Yes No Specify planned date: 15. If Supplier is design responsible, has a Design-FMEA been completed? Are actions in place to reduce high RPNs? Has a review with the ATI engineer been completed? Yes No Specify planned dates: 16. If supplier is responsible for system, has a system FMEA been completed and been reviewed? Yes No Specify planned dates: 17. Have special characteristics (reference Supplier Quality Manual AT-1927) been identified and included in drawings and specifications? Is the supplier aware of the special characteristics? Is the supplier’s intended process able to meet the capability requirements of the special characteristics? Yes No Explain: 18. Are controls for special characteristics clearly identified? Yes No Explain: 19. Does the supplier understand the critical nature of dimensions that interface with the customer’s application of their mating parts? Yes No List all known interfaces: If no explain the process to control special characteristics 20. Are there any Pre-Prototype/Prototype requirements? Yes No List them in the space below: MRD Type & Date Quantity Supplier Promised Date Comments 21. Does the supplier understand the requirements of GP-11 procedure? Yes No Explain: 18-Dec-2015 2 AT-1927-14 22. Will the appropriate control plan be developed for use during each build phase? Yes No Explain: 23. Per the Supplier Quality Manual AT-1927, what amount of design and or test is required by supplier? SECTION 3. PROCESS DESIGN/DEVELOPMENT Key activities from the Supplier Quality Manual and Timing Chart (Ref. AT-1927 & AT-1927-2). 24. Does the supplier understand ALL items listed on the APQP Project Plan? Yes No Explain: 25. Has the supplier provided a APQP Timing Chart for these parts? Yes No Explain: 26. ATI APQP requires periodic reviews. Specify your planned reporting frequency: _ 27. Have the following preliminary documents been completed? Process Flow Chart If No: Yes No Specify completion date: Process FMEA Yes No Specify completion date Control Plan Yes No Specify completion date If Yes, upon completion of this checklist, review in detail these documents. 28. Has error proofing been considered during PFMEA creation and included in quoted price? Yes No If No, explain plans to achieve quality requirements 29. Is any new equipment, tooling, gages, special fixtures or test equipment needed to produce this part? Yes No Comment 30. Allison Transmission minimum required acceptance criteria for the PPAP initial study for special characteristics is established in the Supplier Quality Manual AT-1927. Are any print, material specifications or process control plan changes needed to meet these requirements? Yes No Explain: 31. Has the supplier confirmed their responsibility for management of all tiered suppliers & verified they will conduct AQPQ, PPAP and R@R of these sub-tiers? SECTION 4.0 PPAP (Production Part Approval Process) 32. Lead-time for tooling: _______________ starting when (provide specific date or event): _______________________ 33. After tool completion, first parts off tools, lead-time for PPAP submission: ____________________ 34. Is additional lead time required after PPAP approval to meet the contracted LCR/MCR? Yes No Explain: 35. Does the supplier understand the requirements for Full PPAP? Yes No Explain: 18-Dec-2015 3 AT-1927-14 36. Does the supplier know where to obtain the required forms for PPAP? Yes No Explain: 37. Define the number of samples to be submitted along with PPAP documentation. Total # of Samples: ________ Samples per Cavity: ________ Total # of Cavities: ________ 38. Is a production trial run required? Yes No Explain: 39. Will validation parts (if applicable) be produced from 100% production tools? Yes No Explain: 40. GP-12 Early Production Containment – In effect from PPAP approval through the period specified in GP-12. Does the supplier understand the GP-12 requirements in the Supplier Quality Manual AT-1927? Yes No Explain: Run @ Rate & Capacity Related 41. Fill in the following capacity information: A. What is the daily contracted capacity? B. Daily Max Capacity Rate (MCR) C. Number of tool sets required for LCR D. Number of machines/lines/cells required for LCR E. Capacity per tool set F. Net capacity per day G. Number of work hours per day H. Number of shifts per day I. Number of days per week J. Maximum sustainable tooling capacity 1) Hours per day 2) Days per week ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ 42. Will LCR be met in 5 days, in 20hr/day Yes No Explain: 43. Run @ Rate (Reference Supplier Quality Manual AT-1927) – Normally 8 Weeks Prior to SOP Does the supplier understand the requirements for Run @ Rate? Yes No Explain: 44. Does the supplier understand the procedures that apply when problems occur at a ATI plant? (Fast Response, Corrective Actions as described in Supplier Quality Manual, Controlled Shipping level 1 & 2, New Business Hold) Yes No Explain: SECTION 5.0 – SUPPLIER QUALITY PERFORMANCE 45. What is supplier’s PPM rating to ATI & overall? ________________________________________________ 46. Does supplier have any parts currently in controlled shipping environment? Yes No Explain: 47. Does supplier have any open quality notifications? Yes No Explain: SECTION 6.0 COMMERCIAL INFORMATION 48. Did supplier provide cost breakdown data sheet using form AT-1804? Yes No 18-Dec-2015 4 AT-1927-14 49. Are there any exceptions to the Supplier Quality Manual requirements? Yes No Explain: 50. Is tooling cost finalized? Yes No Explain: 51. Did supplier provide cost breakdown data sheet using form AT-1810? Yes No 52. Does ATI own tooling? Yes No 53. TIER II SUPPLIERS – Note the following information: Supplier Name Duns # Location SECTION 7 - OTHER ISSUES 54. Does the supplier understand they must complete a “Declaration of Conformance / Restricted and Reportable Substances for Parts” form (GMW 3059) prior to completion of PPAP? Yes No Explain: Date: ATI Attendees: Supplier Attendees: Advanced Supplier Quality Engineer (ASQE) Quality Manager Product Engineer Program Manager Commodity Manager Manufacturing Engineer Other Quality Engineer 18-Dec-2015 5 AT-1927-14