Tabela 5. Chemical composition of milled corn and extruded

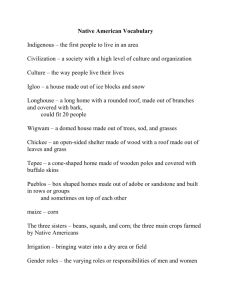

advertisement

Dragan Živančev, Slavko Filipović, Šandor Kormanjoš, Jelena Filipović, Marijana Sakač Institute for food technology, Bulevar cara Lazara 1, 21000 Novi Sad, Serbia ACKNOWLEDGEMENTS This work was supported by Ministry of Science and Technological Development, Republic of Serbia, the Project No. 20068 (Foods for Consumers with Special Demands and Needs), ABSTRACT Food production worldwide is one of the major challenges of the modern life. Therefore, novel technology processes are applying to increase the nutritional value of raw materials, food and feed. One sophisticated technological process for improving nutritional value and quality of raw materials is extrusion. Heat treating of cereals is used for improving their nutritional, hygiene, physico-chemical and other properties, i.e. it increases the nutrient value of some nutrients, improve sensory properties (i.e. increasing, "sweetness" of extruded product), provides the microbiological safety of the products and inactivate possibly present thermo-labile nutrients. This paper presents the technicotechnological parameter of the process, physico-chemical composition and microbiological safety of raw materials before and after extrusion. Table 1. Particle size distribution of whole-milled corn and light buckwheat flour Sieve mash Ø (mm) 2.00 1.25 1.00 0.63 0.25 0.125 0.63 Bottom Sieve overtails (%) Whole-milled corn Light buckwheat flour/ 19.1 25.9 9.9 13.6 0.2 19.9 8.5 11.5 32.6 0.1 46.8 11.9 2.00 14.9 1.25 15.4 1.00 8.1 0.63 18.5 0.25 34.8 0.125 8.3 0.063 - Bottom - Quality characteristic Moisture Crude proteins Crude fat Starch Total sugars Reducing sugars 17.32 7.44 Light buckwheat flour (%) 11.70 11.38 Mixture (90% Extruded whole-milled mixture at corn: 10% light 115 °C buckwheat flour) 16.76 7.83 13.30 8.44 Extruded mixture at 150 °C 9.63 8.50 3.44 62.12 2.71 69.16 3.37 62.82 3.40 65.87 2.92 66.90 1.44 1.48 1.44 2.16 3.60 0.96 0.59 0.92 0.86 0.48 Table 3. Chemical composition of Chemical composition of extruded products and raw materials in dry matter Quality characteristic s Crude proteins Crude fat Starch Total sugars Reducing sugars WholeLight milled buckwheat corn (%) flour (%) Mixture (90% whole-milled corn: 10% light buckwheat flour) Extruded mixture at 115 °C Extruded mixture at 150 °C Sieve opening (Ø, mm) 4.00 2.00 1.25 1.00 0.63 0.25 0.125 0.63 Bottom Quality characteristic Corn (%) Extruded corn at 90 °C Extruded corn at 95 °C Crude proteins 9.25c 9.07b 8.97a Crude ash 1.83b 1.56a 1.58a Crude fiber 3.45c 2.47a 2.80b Crude fat 4.80c 2.08a 2.66a NSI 15.91c 6.66a 6.21a Starch 70.90c 67.06b 64.98a Total sugar 1.00a 3.99b 4.12b Reducing sugar 0.40a 0.42a 0.45a Table 7. Physical and chemical characteristics of enriched corn meal and extruded enriched corn meal (T = 95 ° C) Quality characteristics 9.00a 12.89c 9.41ab 9.73b 9.41ab 4.16a 75.13a 1.74a 3.07b 78.32d 1.68a 4.04a 75.47ab 1.73a 3.92ac 75.97b 2.49b 3.23bc 74.03c 3.98c 1.16a 0.67bc 1.11a 0.99ac 0.53b Sieve overtails (%) Extruded corn Corn meal meal 0.00 0.30 0.50 3.00 5.00 9.00 11.85 7.85 23.85 34.30 25.75 36.45 27.55 8.20 5.00 0.90 0.50 0.00 Tabela 5. Chemical composition of milled corn and extruded corn at 90 and 95 °C in dry matter 22 Table 2. Chemical composition of extruded products and raw materials Wholemilled corn (%) Table 8. Particle size distribution of enriched corn meal and extruded enriched corn meal Table 4. Particle size distribution of milled corn Sieve opening Sieve overtails (Ø, mm) (%) Water content (%) Crude protein content (%) Celullose content (%) Starch content (%) Ash content (%) Fat content (%) Phosphorous (%) Calcium (%) β-carotene content (mg/kg) Test weight (g/l) Corn meal 14.5 11 3.5 55 4.0 7.5 0.50 0.20 1.10 526.1 Extruded corn meal at 95 ° C 8.50 11.0 3.50 50.68 2.50 7.50 0.50 0.20 1.11 359.0 CONCLUSIONS Stable products were obtained by extrusion of whole-milled corn and light buckwheat flour mixture (ratio 9:1) at 115 ºC and 150 ºC. Application of higher extrusion temperature caused greater changes in physico-chemical properties of extrudates. Statistically significant changes in starch content, total and reducing sugar content, crude fat content and test wieght were detected for extrudate at 150 °C in comparison with extrudate obtained at lower temperature (115 °C) and with nonterated mixture. Corn extrusion at 90 and 95 ° C leads to physico-chemical changes in treated material, primarily to changes in the structure of proteins, which is demonstrated through significantly different levels of NSI, and accompanied by statistically significant differences of crude protein content. Dry extrusion of corn resulted in statistically significant changes of crude fat content in extruded product in comparison to untreated corn. The starch content of extruded corn was statistically significantly lower, with the consequent increase in the content of total sugar and reducing sugar. Extruded enriched corn meal feed have higher nutritional value in comparison to the meal which is not extrude, also it is microbiological safe.