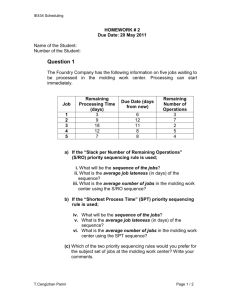

Forming techniques: Blow Molding

advertisement

EBB 220/3 POLYMER PROCESSING METHODS Introduction The beauty of polymeric compounds it can be shape to the desirable shape with the desirable characteristics. There are three things that involved in all basic processing methods: 1. Mixing of the compound ingredient to get the physical forms that can be shape. 2. Changes the compound shape to the desirable shape and size. 1. To ensure the products retained their shape and dimension after shaping process. Types of Mixing Process Based on 2 basic mixing functions; Blending Compounding • • Blending mixing is used when the fabrication process will be followed by compounding process (pigments must be mix into granules/powder followed by injection molding process), thermosetting powders and fillers are often blends which disperse upon fusion of the resin during molding Compounding mixing is used when accurate distribution & dispersion of ingredients is required (e.g. in rubber compounding, 4-5 additives have to act together for efficient cross-linking of the rubber) Blending Stirring together/blending of a number of solids, e.g.polypropylene powder, pigment, antioxidant, etc. The results is a mixture of powders; the individual powder remain and can be separated (in principle) Compounding Involves more intimate dispersion of the additives into the polymeric matrix It requires; A physical change in the component High shear force to bring about the change The polymer to be in the molted or rubbery state during mixing Some Processes and Machine (Blending) Vary from the simplest to sophisticated high speed machine The simplest- is to tumble together dry ingredients, e.g. using a twin-drum tumbler Twin-drum tumbler Some Processes and Machine (Blending) High speed mixer More sophisticated & rapid machine for blending Widely used for PVC dry blends, drying, incorporated pigments, antioxidant, etc. Run at several thousand rpm, and form a circulating powders which becomes heated by friction (150-200ºC) Mixing tank can be single wall or jacketted for temp. control Mixing tank High Speed Mixer Some Processes and Machine (Blending) Ball Mill Comprises of cylindrical vessel containing large number of steel or ceramic balls It rotates, the balls tumble inside together with the powder Agglomerates of powder are broken down by the grinding action of the tumbling balls Ball Mill Some Processes and Machine (Compounding) Involve high shear process & much more powerful machinery The simplest technique is two-roll mill Two roll mill Two roll mill consists of two adjacent, smooth, hardened-steel rolls set horizontally. They rotate in opposite directions (i.e towards each other) produce friction or grinding action between them. The ratio between the operating speed of the front and back roll is referred to as friction ratio. Mixing was achieved by the shearing action induced in the space between the roll which is adjustable. During the mixing operation, cutting and blending is carried out in order to obtain a thorough and uniform dispersion of the ingredients in the polymer mix Internal Mixer Consists of an enclosed chamber and two rotors with small clearance between them and the enclosing wall. The rotors rotate in opposite directions. The mixing chambers can be cooled by circulating water or heated by steam. Widely used for masticating rubbers and incorporating other ingredients. The mixed batch is dropped from bottom of internal mixer onto a sheeting mill and taken off for storage until further processing. Internal mixer fast, clean and works to mixed the large quantity of compounds. Forming techniques There are various methods to form the polymeric materials. Methods that can be used to polymeric materials depends on various factors : 1. Whether the materials is thermoset, themoplastic or elastomer 2. If themoplastics the temperature at which it softens 3. The atmospheric stability of the materials being formed 4. Geometry and size of the finished products. There are numerous similarity between some of the techniques and those utilized for fabricating metals and ceramic The production of polymeric materials normally done at elevated temperature and pressure. Thermoplastic : Normally been form at temperature above the Tg to form polymeric products As maintained during cooling process to maintained the shape. The advantages it can recyclable. Scrap from thermoplastics can be melt and reshape to new shape Thermoset : Involved two stages of production 1. 2. Preparation of linear polymer (prepolymer) liquid form with low molecular weight The liquid form then will change to the hard and rigid products with desirable shape Curing process will start during heating or with addition of catalyst with pressure. During curing chemical and structural changes occur crosslinking or structural network were formed. It can not be recycle, not melting and can be used at high temperature compared with thermoplastics. Plastic Molding Methods Forming techniques: Calendering The calender is a machine equipped with two, three or more heavy internally heated or cooled rolls usually placed above each other The rolls rotate in opposite directions and operate at even or uneven speeds as the applications requires The calender is used essentially for producing rubber sheets of various lengths and thickness. It is also widely used for frictioning or skin coating of fabrics including shower curtains, tablecloths, laminating film Calendering process Common roll configurations for four roll calenders Forming techniques: Extrusion & Calendering Alternate method for making sheets or flat film In this process, the extrudate is extruded directly into the nip area between two rolls. The roles have small gap between them, and plastics is forced through this gaps by the counterrotating of the rolls. Forming techniques:Extrusion Extrusion is the continuous semi-finished product with uniform cross section. The range of products extends from simple semi-finished products tubes, sheets and film to complicated profiles. In principle the extrusion process comprises the forcing of molten material through a shaped die by means of pressure. Forming techniques:Extrusion What is extrusion? The word extrusion comes from Greek roots-means ‘push out’ Continuous process Process which forcing a molten materials (plastic) through a shaped die by means of pressure- e.g. melting of plastic resin + adding mixing fillers In this process, screws are used to progress the polymer in the molten or rubbery state along the barrel of the machine Single screw extruder is widely used, however twin screw extruder are also used where superior mixing is needed Typical extrusion line showing major equipment Materials fed into hopper, falls through a hole in the top the extruder (feed throat) Onto the screw. The screw moves the molten plastic forward until the end of the Extruder barrel to which die has been attached. Die gives shape to molten plastics, Cooled in water tank. There are 3 zones; feed zone, compression zone and metering zone The channel depth decreases from feed end to die end Solid polymer is fed in at one end, inside the polymer melts and Homogenizes and molten extrudate emerges from the other Main features of a single Screw extruder Screw Extruder The screw extruder has one or two flights spiraling along its length. The diameter of the flight is constant along the length channel varies in depth to allow close fit in the barrel The root or core is varying diameter and so the spiraling channel varies in depth ( the channel depth decreases from feed end to the die end) A consequences of the decreasing channel depth increasing pressure along the extruder and drives the melt through the die. There are three zones whose functions as follows: 1. Feed zone Function to preheat the polymer and convey it to subsequent zones 2. Compression zone Function to expels air trapped between the original granules Heat transfer from the heated barrel walls is improved as the materials thickness decreases The density change during melting is accommodated 3. Metering zone The functions is to homogenize the melt and hence to supply to the die region materials which is of homogeneous quality at constant temperature and pressure Forming techniques: Compression Molding The principle of the compression molding can be outlined as follows: The mould is held between the heated platens of the hydraulic press A prepared quantity of molding compound is placed in the mold and the mould placed in the press The press closes with sufficient pressure to minimize flash at mould parts line The compounds softens and flows to shape, chemical cure then occurs as the internal mould temperature becomes high enough The press is opened and the molding removed. Molding press Before After The advantages of compression molding: The low scrap arising (2-5 %) The low orientation in the molding the product advantages: Fibrous fillers are well distribute are not disturbed or oriented during processing. The product has low residue stresses Mechanical and electrical properties are retained because there is little shearing flow Mould maintenance is low little erosion from low shear forces Capital and tooling costs are relatively low, plant and tooling are comparatively simple Forming techniques: Compression Molding The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms Transfer moulding Transfer molding is development of compression molding in which reservoir of the molding compound is located in the mold and upon closure is transferred via runner to the cavities. Transfer molding is used : To give many small parts easily To reduce the risk of damage or movement of thin or delicate mold parts It is claimed to be faster due to better heat transfer trough runners The disadvantages of transfer molding: The flow usually gives unwelcome orientation on the products It also increases wear and maintenance cost Tooling is rather complex and more expensive The runner are scrap not economical Before After Injection Molding The basic principle of injection molding is to inject molten polymer into a closed mold where it is solidifies to give the product. The molding is recovered by opening the mold to release it An injection molding machine has two main section to it The injection unit plasticizing part of the process The clamping unit or press which houses the mold essentially press closed by a hydraulic or mechanical systems Injection Molding The molding cycle: The mould is closed a short of melt is ready in the injection unit Injection occurs the valve opens and the screw acting as a plunger forces the melt through the nozzle into the mold The hold on stage when pressure is maintained during the early stages of cooling to counteract contraction The valves closes and screw rotation starts pressure develops against the closed off nozzle and the screw moves backwards to accumulate a fresh shot of melt in front Meanwhile the molding in the mould has continue to cool when ready the press and the mould open and the molding is removed. The mould closes again and the cycle repeats Principles of injection molding Blow molding and blown film extrusion Blow molding and blown film extrusion similar processes that utilize air to shape softened polymer tubes. 1. 2. Blow molding to produce hollow items such as milk and soda bottles. Blown film to produce relatively thin film and bag In both cases tube is formed in a shape that approximates the article to be made In the case of bottle like objects the tube called parison is either extruded or injection molded and is then clamped in a split mold with a blow pin inside. Air inflates the polymers until it conforms to the shape of the mold The polymer cools on contact with cold mold walls the mold is then open and the part is ejected In blown film extrusion no mold is required A continuous tube is extruded clamped between rollers at one end and blown with compressed air to form large hollow tube having a very thin wall. The tube continuously flattened and placed on a roll for bag production or it can split opened and used for film. Blow molding Stages in blowing a bottle Forming techniques: Blown Film extrusion The extruded materials flow through a tubular die The melt flow around a mandrel and exits the die as a tube A cooling ring is placed at the exit of the die to give the tube some dimensional stability Air is introduced through the back of the die and flow upwards inside the middle of the tube of materials Forming techniques: Blown Film extrusion The tube or bubble, continues to expand, cool and crystallize until the radial (tensile) strength of the plastics equals the pressure of the air inside. The bubble is then forced into a flat sheet by the collapsing guides, and moved into the nips rolls Then it travels down over some rollers and it was sealed Blown film extrusion Forming techniques: Blow Molding Plastic formation process-manufacture of bottles and hollow-shaped parts Competitive with other processes, injection molding Advantages; cycle is very short (low cost), lower mold cost than injection molding, high production rates in producing hollow parts with small or large opening Blow molding process; general steps Melting the resin- done in extruder Form the molten resin into a cylinder or tube (this tube is called parison) The parison is placed inside a mold, and inflated so that the plastic is pushed outward against the cavity wall The part is allowed to cool in the mold and is then ejected The part is trimmed Forming techniques: Blow Molding Image of Parison The parison can be formed by Extrusion process Injection molding process Blowing step in the blow molding process Stretch blow molding the plastic is first molded into a "preform" using the Injection Molded Process. These preforms are produced with the necks of the bottles, including threads (the "finish") on one end. These preforms are packaged, and fed later (after cooling) into an EBM blow molding machine. In the SBM process, the preforms are heated (typically using infrared heaters) above their glass transition temperature, then blown using high pressure air into bottles using metal blow molds. Usually the preform is stretched with a core rod as part of the process. The stretching of some polymers, such as PET (PolyEthylene Terepthalate) results in strain hardening of the resin, allowing the bottles to resist deforming under the pressures formed by carbonated beverages, which typically approach 60 psi. Thermoforming Term thermoforming reshaping of plastics under the influence of heat and pressure or vacuum. There are many techniques for performing this process the use of compressed air and/or vacuum has become preferred methods for reshaping thermoplastics. Thermoforming is a manufacturing process for Thermoplastic sheet or film Used on large scale for the manufacture of packaging For large parts such as swimming pool or motor vehicle parts. Thermoforming Products Thermoforming Process used to shape thermoplastic sheet into discrete parts Basic principles Heat a thermoplastic sheet until it softens Force the hot and pliable material against the contours of a mold by using either mechanical, air or vacuum pressure Held against mold and allow to cool, and plastics retains its shape Thermoforming process is differed from other plastic processing because the material is not melted, lower pressures are required to thermoform (the mold materials is less sturdy materials compared to other processings) Disadvantage; generates greater amount of scrap, cost of the sheet materials is raised (because of separate sheet-forming step), limited design parts (parts with sharp bends and corners are difficult to be produced), process results in internal stresses Summary of advantages & disadvantages of thermoforming process Forming Process: Fundamental Vacuum forming The material is clamped into a frame Material is heated, begin to sag, the center of materials moves downward and seal against the mold Vacuum is applied to the back of the mold (outside pressure of the air pushes the plastic against the mold) Hand methods a) - - Hand lay-up Mould is treated with a release agent-to prevent sticking Gel coat layers are placed on the mold- to give decorative and protective surface Put the reinforcement (woven rovings or chopped strand mat) The thermosetting resin is mixed with a curing agent, and applied with brush or roller on the reinforcement Curing at room temperature Concept of hand lay-up process Filament Winding/Pelilitan Filamen Process to produce a hollow (usually cylindrical) shape End products; pressure vessel, storage tanks, and aerospace parts such as helicopter blades. Wet winding (fiber + resin) & dry winding (prepreg) Schematic diagram of filament winding process Helical Circumferential Polar Methods; The fibers are passed through the resin bath Then continuously wound onto the mandrel After number of layers, curing is carried out in an oven or room temperature. Mandrel is removed Pultrusion Used to manufacture components with continuous lengths and constants crosssectional shape (rod, tubes, beam, etc) Continuous process, easily automated (production rates are high, hence it is vey cost effective), variety of shapes are possible Starting materials can be in the forms of Prepreg or fiber + resin Schematic Diagram of pultrusion process Methods; Continuous rovings of the reinforcement are impregnated with the resins (passing through a bath of resin) Then pulled through the heated die (compact & give shape to the composites) Curing takes place in the heated die & Oven Puller used to pull the whole system with certain speed (Pultrusion- pulling action) Example of the exams question Discuss the difference between compression molding and extrusion blow molding. What is the most suitable processing method to produce a film Discuss two polymeric methods that you know. processing