Mark P

advertisement

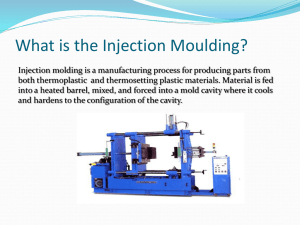

Mark P. Jaynes Po Box 63 Leominster, Ma. 01453-0063 Email: basscab@hotmail.com Cell: 978-786-1447 Summary of Qualifications: 23 Years experience working in a Manufacturing / Assembly / Injection Molding and indexing equipment. Experienced with the disassembly of up to 2200 ton injection molding machines(HPM), i.e. removal of hydraulic clamp rams, barrels & screws. Strong problem solving / troubleshooting skills for Injection Molding processing, automation systems, hydraulics, pneumatics and mechanical applications. Demonstrate a zero loss mindset in order to achieve business goals and objectives while leveraging the mindset of “Doing the right Thing”. Approachability, teamwork, integrity, building diverse relationships are characteristics I am able to demonstrate on a daily basis. Value my ability to building capability in others and recognize their achievements / learnings. Equally as important, is to ensure that those learning’s are retained and verified. Focus on equipment loss areas and implement countermeasures to drive out these losses. Also, identify potential failures or a “what if” that may occur on a piece of equipment. Proficient in troubleshooting injection molding machinery and processing issues. Demonstrate disciplined behavior regarding safety & quality. Certified instructor for Fluid Power Systems training. Employment History: “Proctor&Gamble (Gillette)” 1997 – Present Create SOP’s / Job Aids via MS Word for tasks required during equipment planned maintenance and daily equipment inspection and cleaning activities Team Leader for Injection Molding Line of Female shaving system. Functions include setting daily direction and building capability within the team. Perform maintenance and inspection tasks for equipment in order to mitigate the occurrence of unplanned downtime. Lead 10 member Autonomous Maintenance team for restoring and/or sustaining desired equipment conditions, identifying losses and establishing countermeasures to eliminate the recurrence of that particular loss identified. Provide 1:1 Autonomous Maintenance coaching. Perform regular visual and mechanical inspection tasks of finished components to ensure dimensional specifications are achieved. Required to identify critical equipment / safety inspection points to develop daily, weekly, monthly, etc. maintenance checklists to maintain equipment. Seek out equipment defects, schedule maintenance via SAP in order for the defect to be eliminated in a planned fashion. Assigned ownership for maintaining 6S standards for work cell. Drive loss elimination management system in order to reduce costs for the business. Identify critical process settings to be monitored via daily centerline checklists to ensure stable process is sustained. Functional leader of Quality, Safety, PM and Centerlining DMS’s “Tucker Housewares" 1991 - 1997 Responsible for hydraulic troubleshooting and repair of injection molding machinery(HPM),up to 2200 TON, for the manufacture of household products i.e.-food containers, clothes hangers, trash barrels,etc. Provide support for various ancillary and / or facilities equipment. Collaborate with maintenance group with the design and implementation of material handling(resin deliver) upgrades and additions. Additional responsibilities include…STICK / MIG welding, pipefitting, hydraulic pump/ motor rebuild, press troubleshooting via hydraulic schematics. Experience with blow molding process / maintenance. Education: High School Diploma awarded (1988) Plastics processing technology certificate awarded via Umass Lowell (2005) Computer applications training/experience: Microsoft Excel, Word, PowerPoint and Access. SAP ActivPlant (MDA) DAR(Datamyte Analysis and Reporting) Design and build Quality Alert database via MS Access Other Training: Attended five day class for HPM injection molding machines at Ohio facility Attended training courses via Umass Lowell for pneumatics, control systems, hydraulics, SPC, engineering drawings, elastomers, injection molding, etc. Attended the following Proctor & Gamble on-site courses…Making effective decisions, SPC, Train the Trainer, Lean Manufacturing Principles, Communicating with others and influencing others. Attend “Team Facilitation Skills” and “Coaching for Everybody” training. 7 Habits of Highly Effective People Interests: Member of Leominster Art Center Enjoy playing lead / rhythm guitar & working on learning the piano Learning a new language(Spanish) Designing Home Décor Maintaining a healthy lifestyle via exercise, diet and positive thinking