ppt

advertisement

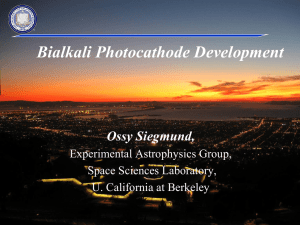

Bialkali Photocathode Development at SSL O.H.W. Siegmund, Experimental Astrophysics Group, Space Sciences Laboratory, U. California at Berkeley GALEX M31 LAPD Team Meeting 10/14/09 1 “Blue” Photocathode Overview Semi-transparent cathodes (thin film on entrance window) are commonly used in the visible/NIR (night vision, etc). Semit ransparent mo de Subst rat e Opaque cathodes are often used in the UV (astronomy) for large area detectors and are deposited onto microchannel plate surface. Photocathode Multi-alkali Wavelength 150-1000nm Cat hode e- eOp aque mo de QE high Environment Ultra high vacuum (UHV) Basic standard is Bialkali for our wavelength range, which is most often a combination of Na, K, and Sb LAPD Team Meeting 10/14/09 2 Photocathode Configuration Numerous processes affect the QE Bialkali is a few 100Å thick, and is compatible with deposition as semitransparent on the window, but is very difficult to achieve as an opaque cathode on the MCP surface. LAPD Team Meeting 10/14/09 3 Photocathodes, 100nm - 600nm Kapusta, IEEE 2007 Comparison of high efficiency Bialkali PMT Emission spectrum of Cherenkov in water compared with bialkali response. cathodes, processing not compatible with LAPD! LAPD Team Meeting 10/14/09 4 Photocathode Summary Comparison of Photonis cathodes Comparison of various cathodes LAPD Team Meeting 10/14/09 5 Multialkali Photocathode QE Most photocathodes in this arena are semitransparent, deposited on the inside of the window. However opaque photocathodes are generally higher efficiency and less dependent on thickness. Hamamatsu Bialkali photocathode Comparison of multialkali Photocathodes. LAPD Team Meeting 10/14/09 6 Bialkali Photocathode QE Relative Efficiency/Emission 1.2 AST (t) AST (d) STL 02 (d ) Chere nko v 1 0.8 0.6 0.4 0.2 0 350 400 450 500 550 600 650 Wavelength (nm) Examples of bialkali photocathode depositions with different wavelength optimizations (on fiber optics). LAPD Team Meeting 10/14/09 7 4” Tube and Cathode Process Tank System Small window cathode development, 1.3” samples - Process samples to optimize QE and bandpass - Use several substrate materials, verify Borofloat 33 - Apply AR coating/processes and test cathodes - Test metalization and sealing techniques Medium size window cathode study, 4” samples - Study source alkali design for large cathodes - Test metal/ITOconductor underlayer for cathodes - Develop techniques to make larger area uniform QE - Optimize cathode QE levels - Trial metalization and seals on 4in “frames” - Seal diode tubes to verify stability LAPD Team Meeting 10/14/09 8 4” Tube and Cathode Process Tank System Has been used to process alkali cathodes and tubes of small area (<4”). System of choice for test cathode processes. - Can take 6 samples/run - Small sample test runs - Substrate material tests - AR coating tests - Sealing tests to 4” - Cathodes up to 4” -Uniformity & QE LAPD Team Meeting 10/14/09 9 1.3” Cathode Substrates We have cut up one borofloat 33 window to make 30ea 1.3” test samples, also have 18ea fused silica as control samples. LAPD Team Meeting 10/14/09 10 Small Cathode Process Tank System Window can be moved from cathode processing station onto tube using external manipulator. Detector with MCPs and Indium seal ring. LAPD Team Meeting 10/14/09 Fused silica window, metalized, in holder. 11 Window Seal Development and Cathode Test “Diodes” • Can metalize window and produce an Indium seal on a frame to test leak tightness of the seal. • Can also make a cathode and produce an Indium sealed “diode” on a simple ceramic spacer with metal anode to test stability. LAPD Team Meeting 10/14/09 12 8” Tube and Cathode Process Tank System Large window cathode development, 8.66” square - Implement alkali source design for large cathode areas - Develop wet cleaning and plasma cleaning processes - Establish metalization scheme - Test metal/ITO conductor underlayer for 8” cathodes - Implement AR coatings/treatment on both surfaces - Develop techniques to make 8” area uniform QE - Optimize cathode QE levels - Trial seals on 8.66” “frames” - Then - Make LAPD 8” tubes LAPD Team Meeting 10/14/09 13 8” Tube and Cathode Process Tank System UHV 16” process Chamber:Initial use for cathode and seal development. Eventually use for complete tube process task. “Smokey Joe” tube process station - or - BBQ/meat smoker LAPD Team Meeting 10/14/09 14 Borofloat 33 8.66” windows - large area cathodes - uniformity tests - QE optimization Cathode Development Summary • Bialkali cathodes are still the standard for the wavelength • • • • regime Establish Semitransparent Bialkali processes and window treatments on small 1.2” substrates Test intermediate window size (4”) to confirm scaleability for larger sizes while the large station is being commissioned Confirm that bialkalis can be deposited on large windows and sealed into leak tight enclosures Make trial full up LAPD detector(s) LAPD Team Meeting 10/14/09 15