Objective 3

advertisement

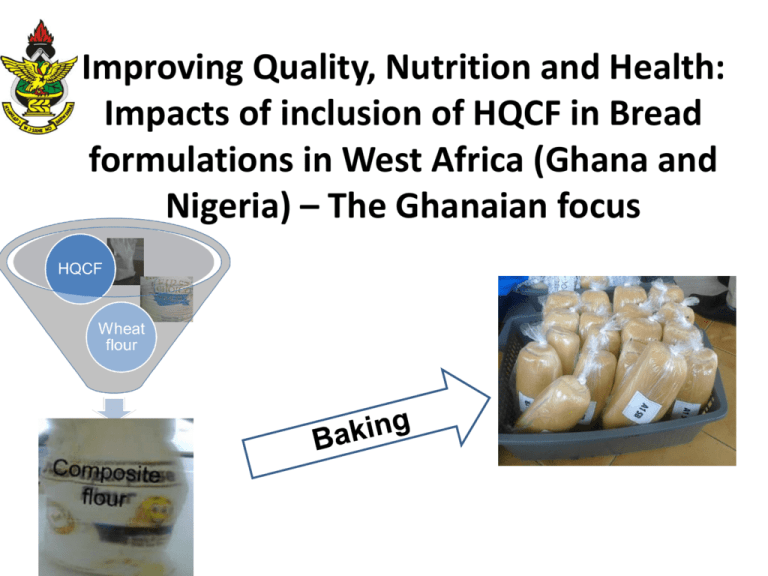

Improving Quality, Nutrition and Health: Impacts of inclusion of HQCF in Bread formulations in West Africa (Ghana and Nigeria) – The Ghanaian focus Recipe standardization of Ghanaian bread types using cassava-wheat composite flour with commercial bread bakers Presentation Outline Background Problem statement Specific Objectives Methodology Findings On-going Studies Conclusion 3 Background • The use of High Quality Cassava Flour (HQCF) in the bread industry has great potential to - Promote the indigenous crop - Improve livelihoods - Boost national economies especially through job creation along the value chain • Studies on cassava-wheat composite bread has been done in Ghana with acceptable substitution up to 20% (Eriksson, 2013; Komlega et al., 2012; Apea-Bah et al., 2011) 5 PROBLEM STATEMENT However, there is dearth of information on a culturally acceptable recipe of cassava-wheat composite bread by stakeholders 6 SPECIFIC OBJECTIVES 1. Determine the physicochemical characteristics of HQCF, wheat and composite flours 2. Develop a standard recipe for 2 types of bread in Ghana using cassava-wheat composite flour 3. Determine characteristics of the two bread types 7 Materials and Methods Materials • HQCF (bankye esam variety) – JOSMA processing limited • Other ingredients for baking – Retail markets, Kumasi 9 Materials… 5kg each of, • 100% wheat flour • 10 and 20% cassava-wheat composite flours 10 Methods • Proximate analysis (AOAC, 2004) – % moisture, ash, protein and fiber • Bulk density • Water activity (Hygrometer) • Colour determination (Minolta chromameter) • Pasting properties (RVA) 11 Concept “Learning to learn” Create/ Generate Knowledge with the bakers Transfer Ownership 12 Methods… Recipe development • Survey – 29 bakers interviewed from 5 towns in 2 Regions, Ghana • Sugar Bread (N=13) • Tea Bread (N=16); N= Number of recipes 13 Methods… • Averages of each basic ingredient was then determined and used as the test recipe 14 Methods… Using two bakers, Each presented with 5 kg of three blind coded flour samples (0%, 10%, 20% HQCF) plus other weighed ingredients Baker divides the given ingredients into two equal parts (one-half for Tea bread & the other for sugar bread) Baker bakes bread using the traditional method Swiss oven 15 Methods… 16 Methods… • Determination of bread characteristics (AACC, 2000) • • • • Loaf weight Loaf volume (modified rapeseed displacement method) Specific volume Density 17 Methods… • Sensory Evaluation – Bench top studies using bread bakers and distributors 18 Methods… Statistical analysis • Data obtained was analysed and presented as mean ± stdev Using SPSS software (version 20.0) • Two-way ANOVA was used to determine the effect of the bread type and level of substitution on the physical characteristics of bread • One-way ANOVA and Tukey’s test were used to obtain any significant differences in all determinations at 95% confidence level • Pearson’s correlation was also used to assess the relationship between level of substitution and physical characteristics of bread 19 Findings Findings (Objective 1) Table 1: Some physicochemical properties of the flours Flour Sample % Moisture % Ash % Protein % Fiber 100% WF 10.22±0.51b 0.88±0.00a 12.34±0.00a 0.1±0.00a 10% HQCF+90% WF 10.00±0.33b 0.65±0.01b 10.58±0.63b 0.20±0.00ab 20% HQCF+80% WF 8.89±0.51ab 0.99±0.04c 8.59±0.31c 0.35±0.07bc 1.69±0.01d 1.32±0.00d 0.43±0.04c 100% HQCF 8.22±0.84a Values are represented as mean ± stdev Values in the same column with different superscripts are significantly different at p<0.05 21 Findings (Objective 1) • Increased fiber content with increasing substitution • Depending on the starting moisture of the HQCF and wheat, it had implication on the overall moisture content of the composite 22 Findings (Objective 1) Table 2: Bulk density, water activity and pH of flours Bulk density (g/mL) Water activity 100% WF 0.72±0.01a 6.14±0.01a 10% HQCF+90% WF 0.73±0.01ab Higher bulkc 0.70±0.01 densities preferredabin 0.68±0.00 baking flours 20% HQCF+80% WF 0.75±0.01b 0.69±0.00bc 5.87±0.01c 100% HQCF 0.71±0.01a 0.68±0.00a 8.40±0.01d Flour Sample pH (10mins; 25.0±2.0C) 6.45±0.01b Values are represented as mean ± stdev Values in the same column with different superscripts are significantly different at p<0.05 23 Findings (Objective 1) Table 3: Pasting properties of flours Flour Sample 100% WF 10% HQCF 20% HQCF 100% HQCF Pasting temp. (°C) 75.65±0.21b 75.38±0.46ab 88.30±0.00c 74.45±1.41a Peak time (min) 7.00±0.00a 7.00±0.00a 7.00±0.00a 4.20±0.00b Peak viscosity(RVU) 2255.50±2.12a 2512.50±20.51b 1961.00±65.05c 4086.00±4.24d Breakdown (RVU) 523.00±15.56a 488.50±28.99a 514.00±53.74a 2404.00±4.24b Setback (RVU) 734.50±2.12b 768.00±46.67bc 559.00±56.57a 906.50±4.95c Values are represented as mean ± stdev Values in the same row with different superscripts are significantly different at p<0.05 24 Findings (Objective 1) • No significant differences observed in the setback and breakdown viscosities of the composite flours and 100% wheat flour Staling of bread from the composite flours, expected not to be significantly different from that of bread from 100% wheat flour 25 Findings (Objective 1) Table 4: Colour of flours a b Chroma (Color intensity) SAMPLE L 100%WF 97.67±0.15a 4.00±0.05a 1.90±0.05a 1.90±0.05a 10%HQCF 98.73±0.02b 0.35±0.03b 1.27±0.03b 1.32±0.02b 20%HQCF 96.97±0.19c -0.07±0.06c 3.08±0.18c 3.08±0.18c 100%HQCF 101.08±0.02d 1.02±0.01d -1.30±0.05d 1.65±0.04a Values are represented as mean ± stdev Values in the same column with different superscripts are significantly different at p<0.05 26 Findings (Objective 2) Reduced salt, yeast and margarine content in the test recipe Table 5: Test recipe of the two bread types and that from FRI (per 2.5 kg flour) Ingredient #FRI Tea Bread Sugar bread 140 290 207.5 18.42 11.87 22.5 Margarine (g) 190 190 415 Yeast (g) 0.67 5.53 15 Nutmeg (g) 1.13 1.08 5 Water (L) 1.670 1.500 1.090 Sugar (g) Salt (g) # source: Recipe (Eriksson, et al., 2014) 27 Findings (Objective 2) tea bread Sugar bread Cross sectional view of sliced tea bread 28 Findings (Objective 3) Physical properties of bread samples Bread type Tea bread Sugar bread FRI bread Loaf weight Loaf (g) volume(cm3) Density (g/cm3) Specific volume (cm3/g) 0% HQCF 485.00±13.24a 2016.00±28.87a 0.24±0.01a 4.16±0.10a 10% HQCF 533.00±5.99b 1860.00±14.14b 0.29±0.01b 3.49±0.06b 20% HQCF 500.00±4.02ab 1475.00±35.35c 0.34±0.01c 2.94±0.05c 0% HQCF 561.00±23.79ab 2425.00±35.35a 0.23±0.01a 4.32±0.25a 10% HQCF 590.00±0.34b 2280.00±113ab 0.26±0.01a 3.86±0.19a 20% HQCF 518.00±5.89a 1900.00±141.42b 0.27±0.02a 3.66±0.23a Flour formulation 0% HQCF - - 0.29 3.46 10% HQCF - - 0.29 – 0.33 3.07 – 3.43 20% HQCF - - 0.31 – 0.36 2.74 – 3.25 Values are represented as mean ± stdev Values with different letters in the same column per type of bread are significantly different at 95% confidence level 29 Findings (Objective 3) Implication of physical characteristics of bread samples • Substituting WF with HQCF in tea bread significantly increased (p<0.05) its density - It will be more filling per unit bread - This may be preferred by the Ghanaian consumer who looks out for heavy bread loaf • Specific volume of tea bread samples significantly decreased (p<0.05) with increasing substitution of HQCF – The Ghanaian consumer also prefers bigger loaves, thus the need to create the balance between the specific volume and density 30 Findings (Objective 3) • However, this was not observed in the sugar bread – No significant differences (p<0.05) in the bread samples with respect to density and specific volume 31 Findings (Objective 3) Correlation between substitution level and specific volume, density Tea Bread • A strong positive significant correlation (r = +0.994, p<0.01) observed between level of substitution and density but negative (r = -0.991, p<0.01) for specific volume Sugar bread • A strong positive significant correlation (r = +0.847, p<0.05) observed between substitution level and density for sugar bread but negative (r = -0.846, p<0.05) for specific volume 32 Findings (Objective 3) Influence of bread type and ingredients on specific volume and density • A significant difference was observed between bread types with respect to specific volume and density - This may be due to the variation in quantity of ingredients used 33 Findings (Objective 3) Some comments from bakers and distributors 34 Findings (Objective 3) Comments: dough characteristics Baker1: “Slight differences observed in dough characteristics… Not sure whether this will have an impact on bread quality though” 35 Findings (Objective 3) Comments: Sugar bread “Prefer A: tastes like it has more margarine. Texture also good” 2 preferred 20% HQCF (A2) “Like A2 best the on 1 preferred whole” 10% HQCF (A1) 1 preferred 0% HQCF (A) “Like A1 best on the whole” “Like A2 best. Loaf volume too Ok. However, appearance not appetizing: colour looks pale” 36 Findings (Objective 3) Comments: Sugar bread “Size of sugar bread may have resulted from the high yeast” 37 Findings (Objective 3) Comments: Tea bread A1= 10% HQCF A2= 20% HQCF “Tastes cassava in bread but love it” “A1 slightly lighter, hard and fibrous. However taste not bad” “A2 quite heavy and may be well appreciated by the older generation who grew up with heavier loaves” 38 Findings (Objective 3) Benchtop studies on tea bread (11 panelists) Overall acceptability Aroma 3 2.5 2 Crumb Texture 0%HQCF 1.5 10%HQCF 1 Taste Crust Texture Crumb Colour 20%HQCF Crust Colour Scale: 1 – most preferred; 3 – least preferred 39 Findings (Objective 3) Benchtop studies on sugar bread (11 panelists) Overall acceptability Taste Crust Texture Aroma 3 2.5 2 1.5 1 Crumb Texture 0%HQCF Crumb Colour 10%HQCF 20%HQCF Crust Colour Scale: 1 - most preferred; 3 – least preferred 40 Findings (Objective 3) Implication of benchtop studies Tea bread • 10% substitution was more comparable to the 0% HQCF in all sensory attributes – Therefore consumers may prefer 10% substituted tea bread to the 20% Sugar bread • With the exception of crust texture and colour (for 20%), the trend was not same, as both 10% and 20% showed differences from the 0% HQCF 41 Observed challenges (pointers for further work) • Inconsistent baking parameters from different commercial sites • Variation in yeast quantities for the two bread types - Variation in yeast type from different commercial sites 42 Way forward • Use 6-10 bakers from 2 regions to test the recipe • Final recipe modification based on comments from bakers and consumers • Fine tune the baking process parameters in the lab 43 Further work • Glycemic index and load • Draft of manuscripts/report 44 Conclusion • No significant difference observed between the wheat flour and composites in terms of their breakdown and setback viscosities • Recipe has been developed – This had reduced salt and margarine compared with composite bread from FRI – Bread from the recipe has a potential for consumer acceptability 45 Conclusion… • Heavier tea bread produced as substitution levels increased, although loaf volume was reduced – Bread type had an influence on the density and specific volume • No significant difference observed in sugar bread but opposite was true for tea bread – Benchtop study indicated that 10% substituted tea bread was more comparable to 100% wheat flour tea bread 46 THANKs to YOU 47 References • Apea-Bah, F.B., Oduro, I., Ellis W.O. and Safo-Katanka, O. (2011). Factor analysis and age at harvest effect on the quality of flour from four cassava varieties. World Journal of Dairy Food Science, 6:43–54 • Eriksson, E. (2013). Flour from three local varieties of Cassava (Manihot Esculenta Crantz): Physico-chemical properties, bread making quality and sensory evaluation. Thesis submitted in partial fulfillment of a Master degree in Agronomy Program – Food Science at the Sweden University of Agricultural Sciences, Sweden • Eriksson, E., Koch, K., Tortoe, C. and Akonor, P. T. (2014). Evaluation of the Physical and Sensory Characteristics of Bread Produced from Three Varieties of Cassava and Wheat Composite Flours. Food and Public Health, 4 (5), 214–222. doi:10.5923/j.fph.20140405.02 • Komlaga, G. A, Glover-Amengor, M., Dziedzoave, N.T., Hagan, L.L. (2012). Consumer acceptability of wheat/cassava composite bread. World Rural Observations, 4 (2):78 - 81 48 Sample Questionnaire used The Ghanaian Team, KNUST 49 The Ghanaian Team, KNUST 50