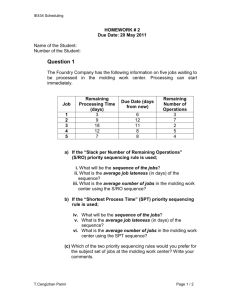

History and Current Status of the Plastics Industry

advertisement

Thermosets_ Epoxy, Polyesters, Vinyl esters, Polyurethanes, and Phenolics Professor Joe Greene CSU, CHICO 1 Thermosets Reference: Appendix E. Industrial Plastics, Modern Plastics Encyclopedia (p142) • • • • • • • • • • • History Chemistry and Chemical Structure Applications Mechanical Properties Physical Properties Processing Characteristics Advantages/Disadvantages Reinforced thermosets- composites Other thermosets Review Questions 2 Thermoset Definition • Thermoset materials are polymers that under go a chemical reaction to build molecular weight and viscosity. • Thermosets are set or crosslinked with heat and can not be reheated for forming repeated forming. 3 Thermosets History • Thermosets are polymers that undergo a chemical reaction during the polymerization. • Thermosetting reaction is not reversible under heat. • Epoxy – Standard epoxy is based on bisphenol A and epichlorohydrin. – Others based on phenols and formaldehyde or aromatic amines and aminophenols – Curing can occur at room temperature with the use of 2 component systems. Curing at elevated temperature with use of one-component. – Properties include good adhesion to many substrates, low shrinkage, high electrical resistivity, good corrosion resistance, and thermal. – Processing is achieved without generation of volatiles. 4 Thermoset Chemistry Epoxy Chemistry 5 Epoxy Chemistry • Epoxy: O C C H H epoxide group H H H + H2N (C) N (C) NH2 H H + amines (DETA) epoxy • Other epoxy resins – – – – diglycidyl ether of bisphenol A (DGEBRA) tetraglycidyl methylene dianiline (TGMDA epoxy phenol cresol novolac cycloaliphatic epoxies (CA) • Curing agents (hardeners, catalysts, cross-linking agents) – aliphatic or aromatic amines (DETA, TETA, hexamethylene tetramine,etc.) – acid anhydrides (phthalic anhydride, pyromellitic dianhydride, etc.) • Active hydrogen react with epoxide groups. • As much as 15% hardener is needed 6 Epoxy Chemistry 7 Polyester Chemistry • Unsaturated Polyesters – Thermoset reaction between a difunctional acid (or anhydride) and a difunctional alcohol (glycol) – At least some of the acid (or anhydride) features double bonds between adjacent carbon atoms for unsaturation. – Characteristic ester linkages are formed, hence the name Polyester O O C6H4(COOH)2 + (CH2)2(OH)2 terephthalic acid + ethylene glycol -[(CH2)2 -O- C - C-O]- Polyethylene terephthalate (PET) – Acids include: maleic, fumaric, isophthalic, terphthalic, adipic, etc. – Anhydrides include: maleic, phthalic – Glycols include ethylene glycol, diethylene glycol, propylene glycol 8 Polyester Chemistry • Heat or radiation can trigger the cross linking reaction • Catalyst (or initiator) is used. Methyl ethyl ketone (MEK) peroxide, benzoyl peroxide, and cumene hydroperoxide • Accelerators (or promoters) speed up the reaction. • Inhibitors extend shelf life (hydroquinone, tertiary butyl catechol) • Condensation Reaction results in CO2 and H2O • Monomer required to polymerize, e.g., Styrene, to react with the unsaturations in the polyester molecules to form 3-D network. – Styrene at 30% to 50% in commercial polyester systems – vinyl toluene for vinyl ester – methyl methacrylate for methyl methacrylate ester 9 Polyester Chemistry 10 Sheet Molding Compound (SMC) • SMC is the paste that is compression molded – 33% polyester resin and stryrene, which polymerizes and crosslinks – 33% glass fibers (1” fibers) – 33% Calcium Carbonate 11 Polyester Molding Operations • Molding of SMC with compression molder • Molding of BMC with compression molder 12 Materials that are Compression Molded • SMC- Sheet molding compound- Polyester, glass fiber, CaCO3 • BMC- Resin, fiber, and filler – BMC stands for Bulk Molding Compound, – compression molded under high temperature and pressure. – BMC has a solid, uniform constitution. By changing the blend design, the characteristics can be altered to meet a wide range of applications. – We have succeeded in developing BMC as the world's first cultured marble that has the functional specialization for home use. 13 Polyester Use with RTM • RTM: Resin Transfer Molding – The process of injecting a liquid resin trough a glass mat while in a heated mold. – Materials • Polyester • Vinyl ester • Epoxies 14 SCRIMP Process • Used for polyester, vinyl ester, and epoxies 15 Polyurethane Chemistry • Reaction between isocyanate and alcohol (polyol). • Crosslinking occurs between isocyanate groups (-NCO) and the polyol’s hydroxyl end-groups (-OH) • Thermoplastic PU (TPU) have some crosslinking, but purely by physical means. These bonds can be broken reversibly by raising the material’s temperature, as in molding or extrusion. • Ratio between the two give a range of properties between a flexible foam (some crosslinking) to a rigid urethane (high degree of crosslinking). • In PUR foams density can range from 1 lb/ft3 to 70 lb/ft3. • Foams are produced by chemical blowing agents. • Catalyst are used to initiate reaction. • RIM process is used to produce fenders and bumper covers 16 Polyurethane Chemistry 17 Polyurethane Processing • Polyurethane can be processed by – Casting, painting, foaming – Reaction Injection Molding (RIM) 18 • Epoxy Applications for Thermosets – Protective coatings: maintenance coatings for industrial and marine, tank linings, industrial floorings, beer and beverage can coatings, food cans, appliance primers, hospital and laboratory furniture. – Bonding and adhesives: Automotive and aircraft industries adhesive to metals and composites. – Molding, casting and tooling: Molding compounds in electrical and electronic industries, casting resins, potting resins. Prototype and master model tools. – Laminating and composites: Binders in fiber reinforced laminates and composites. Laminates are used in printed wiring boards. Composite applications include filament winding (high performance pipes in oil fields, pressure vessels, tank and rocket motor housings), pultrusion, casting, and molding (graphite composites for aerospace applications) – Building and construction: Flooring (seamless, self-leveling, or epoxy terrazzo floors), repair of bridges and roads with glass and carbon fiber wraps, concrete crack repair, coat reinforcing bars, binders for 19 patios, swimming pool decks, and soil around oil-well drills. • Applications for Thermosets Polyester – – – – – Boat hulls, shower stalls, electrical components, appliances Recreation vehicles, automotive body panels, floor pans; SMC Soft tooling, patterns Cultured marble, buttons, corrosion resistant tanks and parts, Corrugated and flat paneling, simulated wood furniture, bowling balls, polymer concrete, and coatings • Polyurethane – Rigid foams: (MDI) Laminated board stock, Moldings, Bun, Foam in place insulation, sprayed foam, packaging – – – – – – Semi-flexible foam: (MDI and TDI) Moldings, Integral-skin moldings Flexible foam:(TDI) Moldings, integral skin molding, carpet underlay Packaging: (TDI) Furniture cushioning Microcellular foam: (MDI) RIM parts, shoe soles Non-foam cast elastomers Coatings, binders, thermoplastic elastomers, sealants, paints 20 Other Thermosets • Phenolic – Applications • Pistons, Thrust pulleys 21 Mechanical Properties of Thermosets Density, g/cc Tensile Strength, psi Tensile Modulus, psi Tensile Elongation, % Impact Strength ftlb/in CLTE 10-6 mm/mm/C HDT 264 psi Epoxy 1.11-1.40 Polyester 1.04 - 1.46 PET (Thermoplastic) 1.29-1.40 Polyurethane 1.03 - 1.15 4,000 – 13,000 350K 3%-6% 0.20 - 1.0 600 – 13,000 300K - 640K 2% - 6%% 0.2 - 0.4 7,000 – 10,500 400K - 600K 30% - 300% 0.25 - 0.70 175 - 10,000 10K - 100K 3% - 6% 25 to no break 45-65 55 - 100 65 100 - 200 115F-550F 140F -400F 70F -100F 70F - 150F 22 Advantages of Thermosets • Epoxy – Excellent chemical and corrosion resistance – Excellent thermal properties and low creep – High stiffness and modulus properties • Polyester – Rigid, resilient to chemical and environmental exposures, corrosion resistant, and flame retardant – Easily processed in low cost equipment • Polyurethane – High strength to weight ratios, resistance to flame spread, excellent thermal insulation, low cost, easily processed 23 Disadvantages of Thermosets • Epoxy – Moisture absorption, toxicity, not recyclable – Cost • Polyester – Moisture absorption, toxicity, not recyclable – Styrene emmisions • Polyurethane – Moisture absorption, toxicity, not recyclable 24 Additives and Reinforcements to Polyesters • Additives– UV stabilizers, colorants, heat stabilizers, blowing agents – Catalyst, inhibitors, promotors • Fillers – Talc – Calcium carbonate • Reinforcements – – – – Glass fiber- short fiber (1/8” or long fiber 1/4”) Mineral fiber (wolastonite) Mica carbon fibers 25 Properties of Reinforced Thermosets Epoxy Epoxy With 50w% glass Density, g/cc Tensile Strength, psi Tensile Modulus, psi Tensile Elongation, % Impact Strength ftlb/in CLTE 10-6 mm/mm/C HDT 264 psi Epoxy With 60w% graphite 1.11-1.40 1.84 1.9 4,000 – 13,000 350K 3%-6% 0.20 - 1.0 27,000 3,000K .5% 10 20,000 6,000K .4% 10 45-65 2 1 115F-550F 500F 500F 26 Processing of Composites • Open Mold processes – Hand lay-up and Spray-up – Filament winding 27 Processing of Composites • Open Mold processes – Vacuum bag, pressure bag, SCRIMP – autoclave: Apply Vacuum Pressure and Heat in an oven which can be 5 feet to 300 feet long 28 Thermoset Reacting Polymers • Process Window – Temperature and pressure must be set to produce chemical reaction without excess flash (too low a viscosity), short shot (too high a viscosity), degradation (too much heat) 29 Processing of Composites • Closed Mold Processes – Compression molding [moderate pressure] – Injection Molding [high pressure] – Resin Transfer Molding (RTM), Structural Reaction Injection Molding (SRIM) [low pressure] – Pultrusion [low pressure] Injection Molding Annual Part 30K – 200K Production Volume Part Size Small < 2 lbs Compression Molding 30K – 200K Structural RIM 5K – 200 K Medium 2 lbs – 20 lbs Fixed Assets Tooling Cost Cycle Time $500K-$2M Medium Medium to large 5 lbs 2 lbs – 20 – 50 lbs lbs $300K-$1M $10K - $150K Materials $300K -$2M $50K -$500K $150K-$500K $50K$300K 1 sec – 30 sec – 30 sec – 30 sec 90 sec 120 sec Thermoplastic Thermoplastic Thermoset Thermoset Resin Transfer Molding 0.5K –5 K $20K - $300K 5 min – 30 min Thermoset 30 Injection Molding Glass Reinforced Composites • Plastic pellets with glass fibers are melted in screw, injected into a cold mold, and then ejected. Glass filled resin pellets 31 Composites Have a Fiber Preform • Fiber type – Roving form that can be sprayed into a 3-D preform – Roving form that is woven into a glass sheet and then formed to shape (preform) 32 Compression Molding • Compression molding was specifically developed for replacement of metal components with composite parts. The molding process can be carried out with either thermosets or thermoplastics. However, most applications today use thermoset polymers. In fact,compression molding is the most common method of processing thermosets. 33 Resin Transfer Molding • In the RTM process, dry (i.e.,unimpregnated ) reinforcement is pre-shaped and oriented into skeleton of the actual part known as the preform which is inserted into a matched die mold. • The heated mold is closed and the liquid resin is injected • The part is cured in mold. • The mold is opened and part is removed from mold. 34 Structural RIM • Fiber preform is placed into mold. • Polyol and Isocyanate liquids are injected into a closed mold and reacted to form a urethane. 35 Homework Questions 1. Define PBT and PET chemical structure. 2. Why was Carothers not successful in developing polyesters? 3. Density of PET is _____ which is higher/lower than PBT and nylon?. 4. What is the tensile strength of PET with 0%, 30% glass fibers? What is the tensile modulus? 5. Plot tensile strength and tensile modulus of PET, PBT, Nylon 6, PP, LDPE and HPDE to look like the following 50 Tensile Modulus, 10 Kpsi xHDPE xLDPE 2 5 Tensile Strength, Kpsi 36 Homework Questions 6. Four typical Physical Properties of Polyester are Optical = _______, Resistance to moisture= ______ , UV resistance= _____, acid resistance=_______ 7. The Advantages of Polyester are ________, ________, _______, and __________. 8. The Disadvantages of Polyester are ________, ________, _______, and __________. 9. Glass fiber affects Polyester by (strength) ________, (modulus)________, (elongation)_______, (density) __________, and (cost) ____________. 10. What affect does the copolymer have on the crystallinity of polyesters and why?_________________________________ _________________________________________________. 37