Operations Management Material Requirements Planning (MRP

advertisement

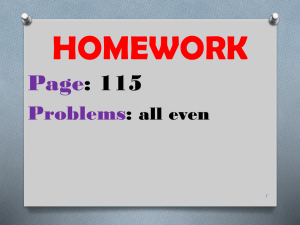

Operations Management Material Requirements Planning (MRP) Chapter 14 Review of the Production Planning Process SAP R/3 Approach to Production Planning Production Process for the T-W101 Ore Wagon: 1) Two wheels are attached to an axle to make an axle assembly. 2) Two axle assemblies are attached to a wagon bed to make the ore wagon. Bill of Material T-W101(AB&C) Ore Wagon Three General Approaches to Production • Make-to-stock: Items produced in anticipation of orders, often from a sales forecast (DiGiorno frozen pizza, Miller Lite beer) • Make-to-order: Items produced to meet specific customer orders (Boeing 737s for Southwest Airlines) • Assemble to order: Final product assembled from make-to-stock items (Dell desk top computer) • IDES Manufacturing uses a “Make-to-stock” approach. Production of ore wagons will be driven by a sales forecast. Sales and Operations Planning The “Rough-Cut” Plan screen for the SAP R/3 system. Sales and Operations Planning 1) Sales Forecast 2) Production Plan 3) Stock Level 4) Working Days 5) Capacity 6) Utilization 7) T-W101 (units) 50% 8) T-W102 (units) 30% 9) T-W103 (units) 20% Jan 240 240 0 22 440 55% 120 72 48 Feb 280 280 0 20 400 70% 140 84 56 Mar 320 320 0 22 440 73% 160 96 64 Apr 400 400 0 21 420 91% 200 120 80 May 360 360 0 23 460 78% 180 108 72 SAP R/3 Approach to Production Planning MPS/MRP Independent versus Dependent Demand • Independent demand - demand for item is independent of demand for any other item • The TW101A is an example of an independent demand item. It is scheduled for production as a result of a sales forecast. • Dependent demand - demand for item is dependent upon the demand for some other item • The TWB101A is an example of a dependent demand item. It is scheduled to be purchased because of the demand for its parent, the TW101A ore wagon. Structure of the MRP System BOM (Bill-of-Material) Master Production Schedule Lead Times (Item Master File) MRP by period report MRP by date report MRP Programs Planned orders report Inventory Data Purchase requirements Purchasing data Exception reports Lead Times and Lot Sizing • The BOM is used to determine how many of each component is required to produce a “parent”. For example, one wagon bed and two axle assemblies are required to produce on ore wagon (parent). Two wheels and one axle are required to produce one axle assembly (parent). • To determine the timing and quantity for the purchase orders for the components requires information about lead-times and lotsizing. This is found in the Material Master File (Item Master): Material Master File for T-W101A (Ore Wagon) Component Description Vendor Lot Size Lead Time T-W101A Ore Wagon Internal Fabrication LFL 5 Days T-WB101A Wagon Bed Minnesota Mfg 200 10 Days T-AA101 Axle Assembly Internal Fabrication 100 5 Days T-AX101 Axle Sooner Milling 100 5 Days T-WH101 Wheel Minnesota Mfg 400 5 Days Master Production Schedule The production plan starts with the Sales Forecast for the month of April. This is broken down into a Detailed Production Schedule for each week. Earlier, we determined that the total demand in April for model T101A is 200. IDES Marketing Department wants these to be available for shipment at the end of each week as shown below. Model T-W101A Week 14 50 Week 15 25 Week 16 75 Week 17 50 Once this has been agreed to, it becomes the Master Production Schedule (MPS). Information from the Material Master File • T-W101A IDES Mfg has determined that the cost effective way to fabricate the ore wagon is to make exactly the number that are required. If 50 are needed, then make 50; If 38 are needed, then make 38. This is called “lot-for-lot” sizing (“Lot Size” = LFL). It takes 5 days to make ore wagons (“Lead-Time” = 5 days). • T-WB101A IDES Mfg has determined that the cost effective way to purchase the wagon bed is to order in quantities of 200 (“Lot Size = 200). It takes 10 days to receive an order after it has been placed (“Lead Time = 10 days). The “MRP Record” for T-W101A • Week 14: • Week 15: Independent Requirements 50 Scheduled Receipts 0 Projected on Hand (BI) 0 Net Requirements 50 Planned Order Receipts 50 (LFL) Planned Order Release ? To fabricate wagons in Week 14, a Planned Order Release must be made at the beginning of Week 14 (Lead Time = 5 days) Independent Requirements Scheduled Receipts Projected on Hand (BI) Net Requirements Planned Order Receipts Planned Order Release 25 0 0 25 25 (LFL) ? The “MRP Record” for T-WB101A (Wagon Bed) • Week 14: • Week 15: Dependent Requirements 50 Scheduled Receipts 0 Projected on Hand (BI) 0 Net Requirements 50 Planned Order Receipts 200 (Lot Size) Planned Order Release ? To receive 200 wagon beds at the beginning of Week 14, a “Planned Order Release” must be made at the beginning of Week 12 (Lead Time = 10 days) Dependent Requirements 25 Scheduled Receipts 0 Projected on Hand (BI) 150 Net Requirements 0 Planned Order Receipts 0 Planned Order Release ? There are zero (0) net requirements in Week 15. No wagon beds must be received in Week 15. No Planned Order Release is necessary. Homework Assignment • Based on the Master Production Schedule for April 2003, complete the Material Requirements Planning for all materials. • Have this assignment ready to turn in at the beginning of class on Thursday March 13th.