Tamper Resistance Mechanisms for Secure Embedded Systems

advertisement

High-level Power Analysis

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

2

CMOS Power Consumption Basics

What are the various components of CMOS power

consumption?

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

3

Levels of Design Abstraction

Controller

x = input_x;

y = input_y;

while (x != y)

{

if (x < y) {

y = y - x;

} else {

x = x - y;

}

}

out = x;

(a)Behavioral

description

Scheduling

ST_1:

x = input_x;

y = input_y;

goto ST_2;

input_x out

FSM

Binding

ST_2:

c0 = x!=y;

c1 = x<y;

y1 = y –x;

goto ST_3

(b) Cycle-accurate

functional description

!=

<

-

reg_c0

reg_c1

reg_y1

reg_x

input_y

reg_y

(c) RTL description

Logic Synthesis

Layout

(d) Transistor-level layout

Copyright Agarwal & Srivaths, 2007

(d) Logic-level netlist

Low-Power Design and Test, Lecture 4

4

Why Address Power at Higher Levels of Design

Abstraction?

System-level

design

Power models

for system-level

components

System-level

power analysis

High-level synthesis,

RTL optimizations

Architecture-level

power analysis

Power models

for macroblocks,

control logic

Benefits: Estimation

Early feedback about power

budget

Faster / Fewer design iterations

Benefits: Optimization

ü

Large power savings possible at

higher levels

Power reduction

opportunities

Power analysis

iteration times

System level

Logic-level

power analysis

Transistor-level/

Layout synthesis

Transistor-level

power analysis

Algorithm level

Power models

for gates, cells,

nets

Register-transfer

level

2-5X

Logic level

Design flow

with high-level

power

analysis

Copyright Agarwal & Srivaths, 2007

Transistor level

20 - 50%

Increasing power savings

seconds - minutes

Logic synthesis

Layout level

Low-Power Design and Test, Lecture 4

minutes - hours

hours - days

Decreasing design iteration times

10-20X

5

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

6

Fast Synthesis based Power Estimation

Map design through “low-effort” to a netlist for power estimation

[Llopis98]

Use gate-level power data to perform power estimation

Approach followed by some commercial tools

Low-Effort

Synthesis

Gate-Level

Power Estimation

Power

Copyright Agarwal & Srivaths, 2007

RTL estimates

RTL

15-20% dev

Source: (Llopis-98)

Gate Level estimates

Low-Power Design and Test, Lecture 4

7

Analytical Methods

Correlate power consumption to simple measures of design

complexity

■ Logic Structures: Use gate count [Glaser91]

Pint GE( Etyp Vdd 2 .CL ). f . Aint

■

■

■

■

■

GE : Circuit size in NAND2 gate equivalent

Etyp: Typical power dissipation per MHz for a NAND2 gate

CL : Estimated load capacitance per gate

f, Vdd: Clock frequency, Voltage

Aint : Estimated activity factor per clock cycle (20-30%)

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

8

Analytical Methods

■ Memories [Liu94]

Pmem Pmemcell Prow

Pcol Psense

Dominant

component

2k

nk

memcell 2 ( c int l column 2 C tr )Vdd .Vswing . f mem _ clock

P

■ 2k : No. of memory cells, 2n-k : No. of rows

■ cint : Capacitance of unit wire length

■ lcolumn: Column interconnect length

■ Ctr : Drain

diffusion capacitance

on the bit/bit line

Copyright Agarwal

& Srivaths, 2007

Low-Power Design and Test, Lecture 4

9

Analytical Methods

Entropy based approach [Nemani96]

■ Entropy: Measure of uncertainty in a random variable

■ Entropy H of a random variable x is given by

1

1

H ( x) p log (1 p) log

p

1 p

■ p: Probability of x being 1

Recall that

Pavg Davg .GE.Cavg

■ Davg: Average node switching activity

■ GE: Gate equivalents, Cavg: Average gate capacitance

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

10

Analytical Methods

Hypothesis

■ Can Davg be estimated only from knowledge of inputs and

output behavior?

Answer: Yes!

Pavg H .GE.Cavg

Entropy H is given by

2/3

H

(H i 2H o )

nm

Hi and Ho are respectively the input and output entropies

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

11

Analytical methods

Entropy Based Power Estimation Methodology:

■ Run a structural RTL simulation to measure input/output

entropies

■ Using input/output entropies, estimate Pavg for the

combinational block

■ Use other techniques [Liu94] to estimate latch and clock

power

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

12

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

13

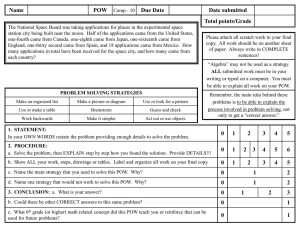

Characterization Based Approaches

■ Characterization based

power macro-models

[Raghunathan-book, Raviaspdac05]

● Characterize a lower

RTL COMPONENT

LIBRARY

level implementation of

an RTL block

● Construct a macromodel

or power models

Power = f(I/O signal

statistics)

● Applicable in behavioral

synthesis environments

Copyright Agarwal & Srivaths, 2007

Macromodel template

selection

- Complexity analysis

- Variable / parameter

selection

Pattern

generation

Training

sequences

Logic- /

transistor-level

power simulator

Power

Profiles

Data fitting /

coefficient

extraction

Power

macromodels

Low-Power Design and Test, Lecture 4

14

Power Models

Power = coeff_0 + transition_count(in1[t], in1[t-1]) * coeff_1 +

What does the

transition_count(in2[t], in2[t-1]) * coeff_2 +

power model

……………………. +

implement?

transition_count(inN[t], inN[t-1]) * coeff_N

Queues

D

Q

in2

D

D

●●●

Coeff_2 [31:0]

inN

Power

summation

Q

●●●

Component

Inputs/Outputs

Coeff_1 [31:0]

●●●

■Queues to store

present and past

values

■Transition count

function is a simple

computation

■Coefficients

aggregated based

on output of

transition count

function

in1

+

What does the power

model contain?

Coeff_0[31:0]

D

Q

Power[31:0]

Transition count

function

Q

Coeff_N [31:0]

POW_STROBE

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

15

Constructing Power Models: An Example

In1[0:15]

16

In2[0:15]

16

ADDER

16

Out[0:15]

(1) Macromodel template

Power = coeff_0+

transition_count(in1_0[t], in1_0[t-1]) * coeff_1 +

transition_count(in1_1[t], in1_1[t-1]) * coeff_2 +

……………………. +

transition_count(in1_15[t], in1_15[t-1]) * coeff_16 +

transition_count(in2_0[t], in2_0[t-1]) * coeff_17 +

transition_count(in2_1[t], in2_1[t-1]) * coeff_18 +

……………………. +

transition_count(in2_15[t], in2_15[t-1]) * coeff_32

(2) Training Sequence

10101011011011011010010010110010;

11101011101101101110011110001001;

11110100011111100000100100101010;

…………………

………………..

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

16

Constructing Power Models: An Example

(3) Gate-Level Power Data

0.079140

0.030423

0.126169

………………

………………

(4) Outputs from Regression – Inputs (1), (2), and (3)

coeff_0 = 0.04110908

coeff_1 = 0.001006622

coeff_2 = 0.001146324

………………

………………

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

17

Constructing Power Models: An Example

(5) Putting it all together

entity add_power IS

port (in1 : IN std_logic_vector;

in2 : IN std_logic_vector;

POW_STROBE: in std_logic;

power : out real);

end addd_power;

architecture VHDLgen OF add_power IS

type queue1 is ARRAY (1 downto 0) of

std_logic_vector(0 to (in1'high - in1'low) );

type queue2 is ARRAY (1 downto 0) of

std_logic_vector(0 to (in2'high - in2'low) );

Store current and previous I/O

values

-- QUEUE MANAGEMENT

queue_in1(1) :=

queue_in2(1) :=

queue_in1(0) :=

queue_in2(0) :=

queue_in1(0);

queue_in2(0);

in1;

in2;

Compute bit-level I/O switching

activity and weigh them by their

power coefficients

-- MACROMODEL COMPUTATION

case bw IS

begin

process(POW_STROBE)

variable queue_in1: queue1;

variable queue_in2: queue2;

variable bw : integer;

variable flag : integer;

begin

Infer bitwidth

-- BIT-WIDTH INFERENCE

of RTL component

flag := 0;

bw := (queue_in1(1)'high - queue_in1(1)'low) + 1;

for i in 0 to bw loop

if (flag = 0) then

if (bw <= 2**i) then

bw := 2**i; flag := 1;

end if;

end if;

end loop;

if POW_STROBE = '1' AND (POW_STROBE'event) then

Copyright Agarwal & Srivaths, 2007

when 2 => power <=

tc(queue_in1(0),queue_in1(1),0) * 7.88452e-05

+ tc(queue_in1(0),queue_in1(1),1) * 7.800038e-05

+ tc(queue_in2(0),queue_in2(1),0) * 0.0002803612

+ tc(queue_in2(0),queue_in2(1),1) * 5.245284e-05;

when 4 => power <=

tc(queue_in1(0),queue_in1(1),0)

+ tc(queue_in1(0),queue_in1(1),1)

+ tc(queue_in1(0),queue_in1(1),2)

+ tc(queue_in1(0),queue_in1(1),3)

+ tc(queue_in2(0),queue_in2(1),0)

*

*

*

*

*

0.0002173669

0.0002525756

0.00023067

0.0001498218

0.0001684765

. . . . . . . .

. . . . . . . .

end case;

end if;

end process;

end VHDLgen;

Low-Power Design and Test, Lecture 4

18

Improvements to Macromodels

RTL components can exhibit significantly different power behavior for different parts

of the input space [Potlapally00]

See Example Circuit:

■ C5 implements part of the GCD algorithm

■ C5 also implements operand gating for the subtractor

If (x>y)

z=x-y

else

z=y

C5 Behavior

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

19

Improvements to Macromodels

Conventional Approach

98% of the points in the upper

cluster satisfy the condition

(x>y): Power Mode 1

Proposed Approach

All the points in the lower

cluster satisfy the condition

(x<=y): Power Mode 2

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

20

Improvements to Macromodels

Power mode identification function (PIF) deduces the power mode based on

the input vectors

Appropriate macromodel gets invoked based on the identified power mode

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

21

Characterization Based Power Estimation

Synthesizable

spec. for each

component

Synthesis

conditions

RTL

library

CHARACTERIZATION FLOW

- Speed (fast/medium/slow)

- Output cap. load

- Input slew rate

Synthesis

P&R

Post-layout

netlists

RTL design

(HDL)

Structural power profile

Characterization based

macromodeling

Simulate-able power libraries

Tightly coupled with RTL

design planning

RT-level design planning

/ mapping

Testbench /

stimuli

Power model

library

generator

Structural

(macro)

netlist

RTL

Powerlib.vhd

Power model inference

and estimation code

generation

simulation

Power

Characterization

Powerlib.c

Power

macro-model

database

Power Profiles

Powerlib.v

Power

Output

Simulateable Power

Model Libraries

Copyright Agarwal & Srivaths, 2007

Enhanced

RTL

Cycle-by-cycle power report

Support rel. and abs. accuracy

Input

Low-Power Design and Test, Lecture 4

22

Enhanced RTL: Graphical View

●●●

first last value data

FSM

1

Power

Model

Power

Model

Controller

+

+/<

=

<=

reg_c0

reg_c1

reg_c1

-1

Functional

Units

>> 1

reg_mid

reg_first

reg_last

reg_out

Registers

Power

Model

Bus 1

Bus 2

Bus 3

addr

out

Power

Aggregator

Power

Strobe

Generator

Total

Power

Power

Model

Power

Model

Power

Model

Power

Model

●●●

Example: Power Model Enhanced RTL

Main components include

■

■

■

Power models for every component: Monitor component I/O values and compute power

Power strobe generator: Trigger power models (statistical sampling employed

for improved efficiency since RTL simulation can also be slow for large designs)

Power aggregator: Compute total power consumption

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

23

Enhanced RTL: An illustration

ENTITY gcd is

port ( RESET :

CLOCK :

yi : IN

xi : IN

. .

IN std_logic;

IN std_logic;

std_logic_vector(0 to 7);

std_logic_vector(0 to 7);

. .);

end gcd;

ARCHITECTURE VHDLgen of gcd is

signal M_39 : std_logic;

signal M_38 : std_logic;

signal VHDLgen_fu3000 : real := 0.0;

-- POWER MODEL TRIGGERING

POW_STROBE_GEN : process( CLOCK )

begin

POW_STROBE <= CLOCK after POW_STROBE_DELAY;

end process POW_STROBE_GEN;

-- POWER AGGREGATION FOR EACH COMPONENT CLASS

component cmp_lt POW_TOTAL:process

begin

port (i1 : IN std_logic_vector(0

to 7) ;

wait until (POW_STROBE='1' AND POW_STROBE'event)

OR(POW_STROBE_REG='1' AND to

POW_STROBE_REG'event);

i2 : IN std_logic_vector(0

7) ;

. . . .

. . . .

o1 : BUFFER std_logic);

component cmp_lt

FU_power <= VHDLgen_fu3000 + VHDLgen_fu3001 + . . . .;

port (i1 : IN std_logic_vector(0 to 7) ;

end

component;

REG_power <= VHDLgen_reg3008 + VHDLgen_reg3009 + . . .

i2 : IN std_logic_vector(0 to 7) ;

o1 : BUFFER std_logic);

end component;

.;

end process;

component cmp_lt_power

-- POWER AGGREGATION FOR COMPLETE

port (in1 : in std_logic_vector;

ENERGY_GEN : process

-- POWER MODEL

component cmp_lt_power

port (in1 : in std_logic_vector;

in2 : in std_logic_vector;

out1 : in std_logic;

POW_STROBE : in std_logic;

power : out real);

end component;

. . . .

begin

. . . .

DESIGN

begin

wait until CLOCK'event OR POW_STROBE'event OR

POW_STROBE_REG'event;

if( ( POW_STROBE = '1') and POW_STROBE'event ) then

main_cycle_energy := (GATE_power + FU_power +

MUX_power )*characterization_period;

main_energy := main_energy + ( GATE_power + FU_power

+ MUX_power)*characterization_period;

end if;

if( CLOCK = '1' and CLOCK'event ) then

num_clocks := num_clocks + 1;

main_power := main_energy / (real(num_clocks) *

clock_period);

end if;

end process energy_gen;

end VHDLgen;

in2 : in std_logic_vector;

out1 : in std_logic;

POW_STROBE : in std_logic;

power : out real);

end component;

cmp_lt port map(cmp_lt1i1, cmp_lt1i2,

cmp_lt1ot);

cmp_lt_power port map ( cmp_lt1i1(0 to 7),

cmp_lt1i2(0 to 7), POW_STROBE, VHDLgen_fu3000);

. . . .

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

24

Enhanced RTL: An illustration

ENTITY gcd is

port ( RESET :

CLOCK :

yi : IN

xi : IN

POW_STROBE_GEN

: process( CLOCK ) -- POWER MODEL TRIGGERING

IN std_logic;

POW_STROBE_GEN : process( CLOCK )

IN std_logic;

begin

begin

std_logic_vector(0 to 7);

POW_STROBE <= CLOCK after POW_STROBE_DELAY;

std_logic_vector(0

7);

POW_STROBE

<= CLOCKto after

POW_STROBE_DELAY;

end process POW_STROBE_GEN;

. . . .);

end

process

POW_STROBE_GEN;

gcd;

end

ARCHITECTURE VHDLgen of gcd is

signal M_39 : std_logic;

signal M_38 : std_logic;

signal VHDLgen_fu3000 : real := 0.0;

POW_TOTAL:process

begin

. . . .

wait

until (POW_STROBE='1' AND

component

cmp_lt

port

(i1 : IN std_logic_vector(0 to 7) ;

POW_STROBE'event)

i2 : IN std_logic_vector(0 to 7) ;

OR(POW_STROBE_REG='1'

AND

o1 : BUFFER std_logic);

end component;

POW_STROBE_REG'event);

. . . .

-- POWER MODEL

component cmp_lt_power

port (in1 : in std_logic_vector;

in2 : in std_logic_vector;

out1 : in std_logic;

POW_STROBE : in std_logic;

power : out real);

end component;

-- POWER AGGREGATION FOR EACH COMPONENT CLASS

POW_TOTAL:process

begin

wait until (POW_STROBE='1' AND POW_STROBE'event)

OR(POW_STROBE_REG='1' AND POW_STROBE_REG'event);

. . . .

FU_power <= VHDLgen_fu3000 + VHDLgen_fu3001 + . .

REG_power <= VHDLgen_reg3008 + VHDLgen_reg3009 + .

.;

end process;

. .;

. .

-- POWER AGGREGATION FOR COMPLETE DESIGN

ENERGY_GEN : process

begin

wait until CLOCK'event OR POW_STROBE'event OR

POW_STROBE_REG'event;

if( ( POW_STROBE = '1') and POW_STROBE'event ) then

main_cycle_energy := (GATE_power + FU_power +

MUX_power )*characterization_period;

main_energy := main_energy + ( GATE_power + FU_power

+ MUX_power)*characterization_period;

end if;

if( CLOCK = '1' and CLOCK'event ) then

num_clocks := num_clocks + 1;

main_power := main_energy / (real(num_clocks) *

clock_period);

end if;

end process energy_gen;

end VHDLgen;

FU_power <= VHDLgen_fu3000 + VHDLgen_fu3001 +

. . . .;

REG_power <= VHDLgen_reg3008 +

VHDLgen_reg3009 + . . . .;

. . . .

end process;

begin

. . . .

cmp_lt port map(cmp_lt1i1, cmp_lt1i2,

cmp_lt1ot);

cmp_lt_power port map ( cmp_lt1i1(0 to 7),

cmp_lt1i2(0 to 7), POW_STROBE, VHDLgen_fu3000);

. . . .

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

25

Enhanced RTL: An illustration

ENTITY gcd is

-- POWER MODEL TRIGGERING

port

( RESET : IN :std_logic;

ENERGY_GEN

process

POW_STROBE_GEN : process( CLOCK )

CLOCK : IN std_logic;

begin

begin

yi : IN std_logic_vector(0 to 7);

POW_STROBE

wait

CLOCK'event

OR <= CLOCK after POW_STROBE_DELAY;

xi : until

IN std_logic_vector(0

to OR

7); POW_STROBE'event

end process POW_STROBE_GEN;

. . . .);

POW_STROBE_REG'event;

end gcd;

-- POWER AGGREGATION FOR EACH COMPONENT CLASS

ARCHITECTURE

of gcd is = '1')

if( (VHDLgen

POW_STROBE

and POW_STROBE'event

)

POW_TOTAL:process

signal M_39 : std_logic;

begin

thenM_38 : std_logic;

signal

wait until (POW_STROBE='1' AND POW_STROBE'event)

signal VHDLgen_fu3000 : real := 0.0;

OR(POW_STROBE_REG='1'

AND POW_STROBE_REG'event);

main_cycle_energy := (GATE_power + FU_power

+

. . . .

. . . .

MUX_power

component

cmp_lt )*characterization_period;

FU_power <= VHDLgen_fu3000 + VHDLgen_fu3001 + . .

port (i1 main_energy

: IN std_logic_vector(0

to 7) ;

:= main_energy

+ ( GATE_power

+ VHDLgen_reg3008 + VHDLgen_reg3009 + .

REG_power <=

i2 : IN std_logic_vector(0 to 7) ;

FU_power

+ MUX_power)*characterization_period;

o1 : BUFFER

std_logic);

.;

end component;

end process;

. .;

. .

end if;

-- POWER

MODEL

if(

CLOCK = '1' and CLOCK'event ) then-- POWER AGGREGATION FOR COMPLETE DESIGN

component cmp_lt_power

ENERGY_GEN : process

num_clocks

:= num_clocks + 1;

port (in1

: in std_logic_vector;

begin

in2

: in std_logic_vector;

wait until CLOCK'event

OR POW_STROBE'event OR

main_power

:= main_energy / (real(num_clocks)

*

out1 : in std_logic;

POW_STROBE_REG'event;

clock_period);

POW_STROBE : in std_logic;

if( ( POW_STROBE = '1') and POW_STROBE'event ) then

end : if;

power

out real);

main_cycle_energy := (GATE_power + FU_power +

end end

component;

MUX_power

)*characterization_period;

process energy_gen;

main_energy

:= main_energy + ( GATE_power + FU_power

. . . .

+

MUX_power)*characterization_period;

begin

end VHDLgen;

end if;

. . . .

if( CLOCK = '1' and CLOCK'event ) then

cmp_lt port map(cmp_lt1i1, cmp_lt1i2,

num_clocks := num_clocks + 1;

cmp_lt1ot);

main_power := main_energy / (real(num_clocks) *

cmp_lt_power port map ( cmp_lt1i1(0 to 7),

clock_period);

cmp_lt1i2(0 to 7), POW_STROBE, VHDLgen_fu3000);

end if;

. . . .

end process energy_gen;

end VHDLgen;

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

26

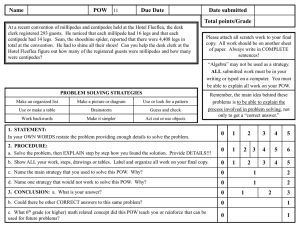

The CPU time overheads of RTL power estimation

Need improvements

in efficiency for large

designs [Ravi03]

5

4

Functional

Simulation

RTL Power

Estimation

3

2

CKT6

CKT5

CKT4

CKT3

0

CKT2

1

CKT1

LOG (Time in Seconds)

6

1.25 million trans.

Simulation time data obtained using ModelSim 5.3 (ModelTech)

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

27

Observations

Power estimation time depends on the HDL constructs used in the

power estimation code

HDL-aware Optimizations

Computation can be traded off for storage to improve

efficiency

Computation versus

Storage Trade-offs

Power estimation effort should be directed where

needed

– Significant contributors

– Tough to estimate portions

Copyright Agarwal & Srivaths, 2007

Partitioned

Statistical Sampling

Low-Power Design and Test, Lecture 4

28

Solution 1: HDL-aware optimizations

• Convert operations with complex datatypes into

operations with simpler datatypes

• Inline HDL functions to eliminate function maintenance

overheads

• Minimize power model activations

• Reduce workload of a power model process

EXAMPLE: BIT-WIDTH INFERENCE CODE IN POWER MODEL

flag := 0;

bw := (queue_in1(1)'high

- queue_in1(1)'low)+1;

for i in 0 to bw loop

if (flag = 0) then

if (bw <= 2**i) then

bw := 2**i;flag := 1;

end if;

end if;

end loop;

Copyright Agarwal & Srivaths, 2007

if (flag = 0) then

bw := (queue_in1(1)'high –

queue_in1(1)'low) + 1;

for i in 0 to bw loop

if (flag = 0) then

if (bw <= 2**i) then

bw := 2**i; flag := 1;

end if;

end if;

end loop;

end if;

Low-Power Design and Test, Lecture 4

29

store

compute

store

compute

store

compute

store

compute

store

store

store

compute

store

store

compute

• Compute average power

consumption once in k

cycles

• Store observed signal

bits of RTL component

for k cycles

• Compute transition

counts and power

consumption only in

the kth cycle

store

Solution 2: Computation vs Storage Trade-offs

Simulation Time

4600

4400

4200

4000

3800

Variations in simulation

time with queue length

3600

3400

3200

100

104

101

102

103

Queue Length

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

30

Partitioned Sampling

Motivation: Smart “allocation of effort” during power estimation

Components with low mean

power, low variance (low

impact on accuracy)

Components with high

mean power, high variance

(deserve high estimation

effort)

Mean and Variance Scatter Plot (MVSP)

for an example design

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

31

Partitioned Sampling Algorithm

Power model

enhanced

design in HDL

HDL compilation

Apply clustering algorithm

on MVSP to group

components with

similar mean and variance

4

1

Fix sampling probabilities

for clustered

RTL components

Simulate for a user-specified

fraction of the

overall simulation time

5

2

Transform HDL to

incorporate sampled partitions 6

Power profiles of

all the

RTL components

Determine Mean Variance

Scatter Plot (MVSP) for

the RTL design

Copyright Agarwal & Srivaths, 2007

3

HDL compilation

7

Full Simulation

8

RTL power estimate

Low-Power Design and Test, Lecture 4

32

Fixing the Sampling Probabilities

Objective: Determine the sampling probabilities for n clusters C1, C2 … Cn

n

Obs. #1: The error due to sampling given by P Pi must be minimized

i 1

Obs. #2: The error in sampling a cluster Ci that accounts for a greater

fraction (fi) of the total power must be kept small. That is,

n

Minimize Pweighted

fi * Pi

i 1

Pi

comp

compCi

Power estimation

error due

to sampling for a

component

comp

scomp

comp

C

i

const *

Ni

Standard deviation

of the power profile

of a component

comp

Copyright Agarwal & Srivaths, 2007

Equation 1

Number of

samples for

the cluster Ci

Low-Power Design and Test, Lecture 4

33

Fixing the Sampling Probabilities

Formulation: Minimize Equation 1 subject to the following constraints

Computational

budget

Number of component-samples

n

| C1 | .N1 | C2 | .N2 | Cn | .Nn n f * Ntot * |Ci|

i 1

Ni 1, i 1.. n

Formulation now a “Linearly constrained Optimization” problem

-- Many solvers available (Excel, Ampl)

Solution: Pri

Copyright Agarwal & Srivaths, 2007

Ni

Ntot

Low-Power Design and Test, Lecture 4

34

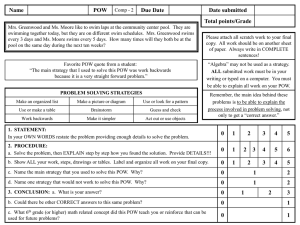

RTL Power Estimation: Results

Designs as large as 1.25 million transistors have been successfully evaluated

using our RTL Power Estimator (RTL-PEST)*

0.8

3.8%

Power (mW)

0.7

13.9% 2.9%

0.6

• RTL power estimates roughly 5 to

10% off gate-level power estimates

• RTL power estimation 10-50X

faster than gate-level power

estimation

0.5

4.1%

0.4

12.2%

0.3

14.8% 1.2%

0.2

0.1

0

CKT1

CKT2

CKT3

CKT4

CKT5

CKT6

CKT7

Gate

0.3694

0.7308

0.503

0.5237

0.1518

0.1708

0.2332

RTL

0.3541

0.7038

0.433

0.5398

0.1783

0.1687

0.2622

* For further information, please see [Ravi03]

8

RTL-PEST

1000

6

Speedup over Comm

5

100

4

3

10

2

1

1

0

D1

Copyright Agarwal & Srivaths, 2007

7

Comm

Speedup

• Power Estimation speed

better than the best available

commercially

Execution Time (sec)

10000

D2

D3

D4

Low-Power Design and Test, Lecture 4

D5

D6

D7

35

RTL Power Estimation: Results

Percentage error versus

CPU time trade-off for

partitioned sampling and testbench

reduction techniques

Copyright Agarwal & Srivaths, 2007

Local power estimation errors for

partitioned sampling and conventional

sampling techniques

Low-Power Design and Test, Lecture 4

36

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

37

Power Emulation Technology Overview

New paradigm for power estimation ! [Coburn05]

fi

r

s

t

l

a

s

t

v

al

u

e

da

ta

Basic Observations

1.

Power estimation uses power models for different components

2.

Power models are themselves simple functions

3.

Emulation is commonly used to speed up circuit simulation

●●●

FSM

1

Power

Model

+/-

+

Power

Model

<

=

<=

reg_c0

reg_c1

reg_c1

-1

>> 1

reg_mid

reg_first reg_last reg_out

Power

Model

fi

r

s

t

l

a

s

t

Power

Aggregator

+

Power

Strobe

Generator

v

al

da

ta

FSM

adu

dre

ou

t

1

Power

Model

<

=

reg_c0

reg_c1

Power

Model

<=

Power

+/Model

Power

Model

●●●

-1

>> 1

reg_mid

reg_c1

reg_first reg_last reg_out

Total

Power

ad

dr

out

Testbench

Outputs

2 to 3 orders of magnitude

Power speedup possible !

Host PC

FPGA platform

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

38

Power Emulation: Challenges

Size of design enhanced with power models is very large!

■ Size increases on an average of 18.2X for MPEG4 sub-designs

■ Enhanced version exceeds capacity of largest Xilinx Virtex-II FPGA

20.4X

135000

Normal Design

120000

Design for Power Estimation

Capacity of XC2V8000 FPGA

FPGA Area (LUTs)

105000

20.6X

90000

75000

17.7X

16.3X

60000

14.7X

45000

17.5X

Need to reduce the area

requirements of power models !

30000

15.0X

15000

ld

V

ea

d

_b

it

M

v

M

c

q

Is

p

t_

R

Id

c

D

ct

_c

oe

ff

da

0

MPEG4 Design Module

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

39

Power Emulation: Challenges

Why area increase?

■ Resource-hungry power models used for every RTL

component in the design

How to reduce area?

■ Optimize the number of power models used

■ Make the implementations of power models resourceefficient

■ Catch: Ensure minimum loss of estimation accuracy due to

area reduction techniques

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

40

Area Optimization Techniques

Clustering of power models

■

Single power model servicing multiple components

Changing component granularity

■

Constructing power models for complex components that

subsume several smaller components

Exploiting correlation

■

Using power correlation between components to reduce

the number of monitored components

Optimizing power model implementations

■

■

Multi-cycling additions in power model computations

Using FPGA block memories for efficient storage of power

model coefficients

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

41

Power Emulation: Results

Evaluation on various NEC designs, Comparison with RTL-PEST, Comm-RTL

CKT

Sort

Estimation Time (sec)

RTL-

Comm-

PEST

RTL

11.6

80.2

Emulation

Acc

Estimated Power (mW)

FPGA Area (LUTs)

RTL-

RTL-

Emulatio

PEST

n

1605

5665

Emulation

Error

PEST

1.2

9.7 X,

0.33

0.31

0.14

0.14

8.22

7.76

3.53%

AO

3.53X

66.8X

HVPeakF

120.3

136.8

1.7

70.8X,

80.5X

172.9

DCT

173.3

3.7

46.7 X,

RTL-PEST

46.8X

MPEG4

3300

2587

MPEG4

6.3

524X,

3300sec

411X

3192

9016

2.82X

Nearly

500X

speedup possible !

0%

5.6%

6121

4.9%

24907

Comm-RTL

4.74

4.51

2587sec

19242

Power 3.14X

Emulation

72351

6.3sec

2.9X

Upto 500X speedup compared to RTL power estimation

3% Loss of accuracy on an average

•For further information, please see [Coburn05]

Area overheads lowered to ≈3X

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

42

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

43

Cycle-Accurate Functional Descriptions (CAFDs)

x = input_x;

y = input_y;

while (x != y)

{

if (x < y) {

y = y - x;

} else {

x = x - y;

}

}

out = x;

Scheduling

(a) Behavioral description

out

input_y

FSM

!=

<

cmp

Registers

ST_3:

if (c0) {

if (c1) {

y = y1;

Increasingly

} else {used in

ST_2:

x = x - y;

System-level

simulation

c0 = x!=y;

}

c1 = x<y;

goto ST_2;

y1 = y –x;

}

goto ST_3

out = x;

goto ST_1;

(b) Cycle-accurate functional

Binding

description

input_x

Controller

Functional

units

ST_1:

x = input_x;

y = input_y;

goto ST_2;

reg_c0

-

sub

lt_cmp

reg_c1

reg_y1

reg_x

reg_y

Bus2

Bus1

Copyright Agarwal & Srivaths, 2007

(c) RTL implementation

Low-Power Design and Test, Lecture 4

44

Cycle-Accurate Functional Descriptions (CAFDs)

x = input_x;

y = input_y;

while (x != y)

{

if (x < y) {

y = y - x;

} else {

x = x - y;

}

}

out = x;

Scheduling

(a) Behavioral description

out

input_y

FSM

!=

<

cmp

Registers

ST_3:

if (c0) {

if (c1) {

y = y1;

Challenge:

} else {

No

structural

ST_2:

x = x - y;

c0 = x!=y;

}

Information

c1 = x<y;

goto available

ST_2;

y1 = y –x;

}

goto ST_3

out = x;

goto ST_1;

(b) Cycle-accurate functional

Binding

description

input_x

Controller

Functional

units

ST_1:

x = input_x;

y = input_y;

goto ST_2;

reg_c0

-

sub

lt_cmp

reg_c1

reg_y1

reg_x

reg_y

Bus2

Bus1

Copyright Agarwal & Srivaths, 2007

(c) RTL implementation

Low-Power Design and Test, Lecture 4

45

Overview of Power Estimation using CycleAccurate Functional Descriptions (CAFDs)

(Scheduled

Behavior)

Objectives

■ Extract minimum

RTL structural info.

■ Back-annotate RTL

structural info.

More information in

(Zhong04)

Simulation

test bench

CAFD

Preprocessing

Resource,

timing

constraints

Synthesis

RTL

RTL information extraction

Virtual component instantiation

Idle cycle analysis

(C++/SystemC)

structure-aware

CAFD

Power

model

library

Cycle-accurate

functional simulation

Power

Power

report

Copyright Agarwal & Srivaths, 2007

Output

Input

Low-Power Design and Test, Lecture 4

Power vs. time

46

Structure-aware CAFD

Virtual component

• Stores I/O values

for current &

previous cycles

• Invokes the power

macro-model in

each cycle

Structure-AWARE CAFD

SIMULATION

TEST BENCH

Original

cycle-accurate

functional

description

I/O mapping

• Traces appropriate

CAFD variables to

capture component

I/Os in each cycle

• Generates idle

cycle input values

POWER MODEL

LIBRARY

add_power

reg_power

Copyright Agarwal & Srivaths, 2007

Power

aggregation

& reporting

code

Low-Power Design and Test, Lecture 4

47

Example Snippet of an Structure-aware CAFD

ST_1:

x = input_x;

y = input_y;

goto ST_2;

ST_2:

c0 = x!=y;

c1 = x<y;

y1 = y –x;

goto ST_3

ST_3:

if (c0) {

if (c1) {

y = y1;

} else {

x = x - y;

}

goto ST_2;

}

out = x;

goto ST_1;

VC<bus,8> bus1,bus2;

VC<reg,8> reg_y1;

VC<lt,1> lt_cmp;

…

ST_1:

…

ST_2:

bus1.RecordInput(x)

bus2.RecordInput(y);

c0 = x!=y;

reg_c0.RecordInput(c0);

eq_cmp.RecordIO(x,y,c0);

c1 = x<y;

reg_c1.RecordInput(c1);

lt_cmp.RecordIO(x,y,c1);

Instantiate

virtual

components

Update

virtual

component

I/O values

y1 = y -x;

reg_y1.RecordInput(y1);

sub.RecordIO(y,x,y1);

CalculatePower();

goto ST_3

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

48

C-based HW Power Estimation: Results

Compared accuracy, efficiency vs. gate-level and RTL-PEST

■

50-100X speedup (or more) for various designs, less than 20% error w.r.t POWERD

Average

Cyclelevel

Absolute

Error

Speedup vs.

Slowdown vs.

RTL

Estimation

Functional

Simulation

Circuit

Power

Error

DES

2.1%

2.2%

83 X

1.1 X

HDTV-1

1.7%

4.0%

356 X

3.2 X

JPEG

2.7%

6.6%

1,143 X

3.3 X

MPEG4-IDCT

3.1%

5.1%

412 X

3.2 X

MPEG4-ISPQ

1.5%

2.4%

438 X

2.1 X

SORT

1.7%

5.4%

266 X

1.7 X

VITERBI

1.4%

6.5%

305 X

3.0 X

5.1%

223 X

2.1 X

•For further

information, please see2.4%

(Zhong04)

WAVELET

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

49

Outline

Background

■ CMOS Power Consumption Basics

■ Why Address Power Consumption Issues in High-Level Design

High-Level Power Analysis

■ RTL Power Estimation

● Fast Synthesis

● Analytical Approaches

● Characterization

■ Accelerating RTL Power Estimation

● Power Emulation (Hardware Accelerated Power Estimation)

■ Beyond RTL Power Estimation

● Power Estimation at the Cycle-accurate Behavior Level

■ Architectural Power Estimation

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

50

Architectural Power Estimation

Requirements

■ Need to evaluate trade-offs in processor configuration

■ Need to evaluate trade-offs in software running on system

■ Must be very fast compared to HDL based power estimators.

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

51

Architectural Power Estimation (Wattch)

Overall structure of an architectural power

estimator Wattch [Brooks00]

Parameterized models for different CPU units

■ Can vary size or design style as needed

■ Use the fundamental equation for

dynamic power consumption

● P=CV2. A.f

On each cycle, determine which units are

accessed and accumulate energy

consumption

Capacitance modeled for various critical

components

Activity factors

■ Runtime measurements using a cycleaccurate performance simulator called

SimpleScalar (has been ported to many

simulators)

■ Assume an activity factor of 0.5 for which

the simulator cannot report statistics

Copyright Agarwal & Srivaths, 2007

Binary

HW Config

Cycle-Level

Performance

Simulator

Cycle-by-Cycle

Hardware Access

Counts

Parameterizable

Power

Models

Performance

Estimate

Low-Power Design and Test, Lecture 4

Power

Estimate

52

Architectural Power Estimation

(source: Brooks_hpca2001)

Good relative accuracy even

when absolute accuracy may be

off

Copyright Agarwal & Srivaths, 2007

10-15% accuracy variations

with low-level industry data

Low-Power Design and Test, Lecture 4

53

Conclusions

High-level power analysis techniques are finally coming of age

Efficiency

Accuracy

What we could not cover today?: Using high-level power

analysis for optimization

■ Power reports provide information about a design’s

“hotspots”

■ Presence of power analysis in a high-level design flow

makes optimization and design space exploration easy

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

54

References

Books/Tutorials

■ [Raghunathan-book] A. Raghunathan, N. K. Jha, and S. Dey, "High-level power analysis and optimization",

Kluwer Academic Publishers, 1997

■ [Ravi-aspdac05] “Power Analysis in C-based Design” (part of tutorial entitled “C-based Design: Industrial

Experience”), Asia-South Pacific Design Automation Conference (ASP-DAC), January 2005

Conference Papers

■ [Llopis98] R. Llopis, K. Goossens, “The petrol approach to high-level power estimation”, ISLPED 1998: 130132

■ [Glaser91] K. D. Glaser, K. Kirsch, and K. Neusinger, ``Estimating essential design characteristics to support

project planning for ASIC design management,'' in Proc. Int. Conf. Computer-Aided Design, pp. 148--151, Nov.

1991.

■ [Liu94] D. Liu and C. Svensson, ``Power consumption estimation in CMOS VLSI chips,'' IEEE J. Solid-State

Circuits, vol. 29, pp. 663--670, June 1994

■ [Nemani96] M. Nemani and F. N. Najm, ``High-level power estimation and the area complexity of Boolean

functions,'' in Proc. Int. Symp. Low Power Electronics & Design, pp. 329--334, Aug. 1996.

■ [Potlapally01] N. R. Potlapally, A. Raghunathan, G. Lakshminarayana, M. S. Hsiao, and S. T. Chakradhar,

"Accurate power macro-modeling techniques for complex RTL circuits", IEEE International Conference on

VLSI Design, January 2001

■ [Ravi03] S. Ravi, A. Raghunathan, and S. T. Chakradhar, "Efficient RTL Power Estimation for Large Designs,"

IEEE International Conference on VLSI Design, January 2003

■ [Zhong04]L. Zhong, S. Ravi, A. Raghunathan, and N. K. Jha, "Power estimation for cycle-accurate functional

descriptions of hardware," IEEE/ACM International Conference on Computer-Aided Design, November 2004

■ [Coburn05] J. Coburn, S. Ravi, and A. Raghunathan, "Power emulation: A new paradigm for power

estimation," ACM/IEEE Design Automation Conference, June 2005

■ [Brooks00] David Brooks, Vivek Tiwari, and Margaret Martonosi, “Wattch: A Framework for Architectural-Level

Power Analysis and Optimizations,” 27th International Symposium on Computer Architecture (ISCA), June

2000

Copyright Agarwal & Srivaths, 2007

Low-Power Design and Test, Lecture 4

55