Air Force Program Review Template

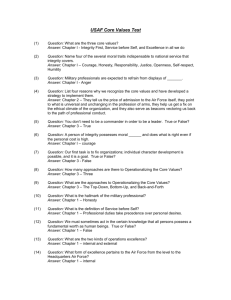

advertisement

Headquarters U.S. Air Force

Integrity - Service - Excellence

Program Title

Air Force Review Board (AFRB) Date

This template is for guidance

and is not mandatory

See Notes Page

Rank, Name

Office Symbol

Date

Updated: August 2015

FOR OFFICIAL USE ONLY – PRE-DECISIONAL

1

Briefing Outline – Key Items

Bottom Line Up Front (BLUF)

Program Description/Overview

This template is for guidance

CONOPS

and is not mandatory

Requirements

APB-KPPs

MS C Affordability

Portfolio Perspective

Affordability Template

Should Cost

Product Support Quad Chart

Test and Evaluation

Acquisition Strategy—Framing Assumptions

Proposed Schedule and Schedule Assessment

Business Strategy (Include Competitive Strategy)

Product ion Rate

Funding

Program Risk and Risk Mitigation

Industrial Base & Manufacturing Readiness

Document Status

Exit Criteria

Recommendations for ADM

Way ahead

Back-up

International Cooperation, Program Office Resources, Technical and Systems Engineering Assessment,

Test and Eval, FMS, Other (eg., open actions from prior ADMs, Congressional concerns/funding cuts)

Integrity - Service - Excellence

2

BLUF

Purpose

Decisions you are requesting (examples)

Present Way Ahead for Program

Discuss oversight and management plan for Program

Approval Milestone C (or FRP or FDD) (if AF is MDA)

Approval to proceed to OIPT and DAB (if OSD is MDA)

Approve Applicable delegations/waivers

List Outstanding Issues

Issue 1--Integrated Test events

4 flight tests remaining

Issue 2—Production funding

Need FYxx Budget to begin LRIP – GAO report pending

Integrity - Service - Excellence

3

Program Description/Overview

Description

250-lb Class, Precision Guided, Air-to-Ground Munition

Kill Mobile and Fixed Targets Through Weather from Standoff

Uses Tri-Mode Seeker & Dual-Band Data Link (Link 16 + UHF)

Services: USAF, DoN

Threshold Platforms: AF--F-15E; USMC--F-35B; USN--F-35C

ACAT Level: ID

MDA: USD (AT&L)

PEO: AFPEO (Weapons), Maj Gen Blaster

PM: 918 ARSG/CC, Col Boomer

Schedule

Second Increment Miniature Munitions

SDB I-Fixed Targets; SDB II-Adds Movers

Required Funding

Air Force TY$M

CFY FY+1 FY+2

FY+3

FY+4

FY+5

Total

AF RDT&E

86.4 79.2

165.6

FYxx PB RDTE 126.5 153.5 162.4

731.0

AF Proc

46.9

84.4 125.7 125.7 125.7 508.4

FYxx PB Proc

46.9

84.4 125.7 120.0 120.0 497.0

DoN TY$M

DoN RDT&E

16.5 32.2

48.1

46.5

46.5

189.8

FYxx PB RDTE 43.7 44.2

74.9

37.6

37.6

238.0

DoN Proc

10.3

10.3

FYxx PB Proc

16.3

16.3

AF/DoN Committed to Service Cost Position

Acquisition Strategy

Evolutionary Acquisition

Sole Source Production contract for LRIP

Raytheon Missile Systems, Tucson

The Boeing Company, St Louis

LRIP-Fixed-Price Incentive Firm Target (FPI(F))

Production

Lots 1-3 -- FPI(F)

Lots 4-5 – Fixed-Price NTE w/ Economic Price

Adjust

Approved 21 Sept 09

4

CONCEPT OF OPERATIONS

5

See footnotes

Interrelationships, Dependencies and

Synchronization with Complementary

Systems

Aviation Platforms:

KC-135

KC-10

AWACS

H/MH-60

CV-22

MH-47

MH-6

CH-53

A/OA-10

Ground Teams:

GAWS

SF

SEAL

STS

HC/MC-130 Recap

Mission Planning

PFPS

JMPS

Be sure to include CYBER links and

infrastructure.

C-130J:

Indicate any issues/cybersecurity

risks

introduced by

Aircraft Procurement

program interconnection.

LAIRCM

& Block Upgrades

Solid denotes current system

Dash denotes future system

Arrow to Recap denotes supports Recap

Arrow from Recap denotes Recap supports

Indicates program are interdependent

6

No known issues affecting inter-related programs

Resolvable interface issues affecting programs

Unresolvable interface issues affecting programs

Integrity - Service - Excellence

Requirements

Operational Requirements

When Approved (AOA, ICD/CDD/CPD, CONOPS)

Key KPPs—fully identified and clearly stated?

Incremental Requirements?

How does the program baseline compare to validate requirements

Operational Capabilities/Impacts

Capabilities / missions (today & future)

Relationship to established roadmap(s) / architecture(s)

Family of Systems (FOS) / System of Systems (SOS) /

Complementary Systems

Example for E-10A: MP-RTIP, Global Hawk, MP-CDL,

Army CGS

AFSPC/AFMC/CC Attestation Statement (See notes)

Integrity - Service - Excellence

7

APB Key Performance Parameters

Characteristic

Objective

Threshold

Demonstrated

Current Est.

MFHBA (hrs)

35

24

26.7

50.6

MMH/FH (hrs)

3.6

4.3

2.8

3.2

Cruise Speed (kts)

165

135

138

138

Payload (Hot Day) (lbs)

3500

2500

3179

3179

6

4

4

4

Why they matter. . .

AH-1Z

Weapon Stations Universal Mounts

Precision Guided Munitions

16

12

16

16

-0.5 to 2.5

-0.5 to 2.5

-0.5 to 2.79

-0.5 to 2.5

200 x 1 (Aux Fuel)

110 x 1

135nm x 1

135nm x 1

Yes

Yes

Yes

Yes

All Top Level IERs

All Critical Top

Level IERs

All Critical Top

Level IERs

All Critical Top

Level IERs

MFHBA (hrs)

40.2

33.1

55.8

52.3

MMH/FH (hrs)

2.9

3.9

2.5

2.4

Cruise Speed (kts)

165

140

156

156

Payload (Hot Day) (lbs)

4500

2800

3079

3079

2 Univ. Mounts

2 Hard Mounts

2 Hard Mounts

2 Hard Mounts

-0.5 to 2.3

-0.5 to 2.3

-0.5 to 2.3

-0.5 to 2.3

200 x 1 (Aux Fuel)

110 x 1

129nm x 1

129nm x 1

Maneuverability / Agility (G's)

Mission Radius (nm)

Shipboard Compatibility

Interoperability

UH-1Y

Weapon Stations

Maneuverability / Agility (G's)

Mission Radius (nm)

Shipboard Compatibility

Interoperability

Yes

Yes

Yes

Yes

All Top Level IERs

All Critical Top

Level IERs

All Critical Top

Level IERs

All Critical Top

Level IERs

*AH-1Z Cruise Speed revised in CPD

COLOR DEFINITIONS:

Exceeds Objective Requirement

Exceeds Threshold Requirement

At risk of not meeting Threshold

BREACH: Does not meet Threshold

8

FOUO

Program X Requirements

Top Cost Drivers

Performance (KPPs & select KSAs)

1.

Engine (link to KPP)

2.

Seeker FPA, Warhead, Fuze,

Extended Range

KPP 2

MME

Guidance & Control (link to KPP)

KPP 3

25%

3.

Production Support

4.

Manufacturing

5.

Fuel tanks & Valves, Superframes,

Wings, Tail

KPP 1

26%

18%

KPP 4

Net Ready

7%

KSA 1

Reliability

6%

(link to KPP)

* Analysis

Mat. Availability*

N – No Capability

T – Threshold

O - Objective

Technology Readiness Assessment

N

T

MS B Date: N/A

MS C Date: Oct 10

Acquisition Program Baseline (APB)*

Baseline (O)

Critical Technologies

Engine

To Date

Est. @ FRP

8

8

9

FMU 156/B Fuze

9

9

Low Observable

7

7*

GPS

7

7*

PAUC

Cost

Baseline (O)

APUC

(O) Sep 10

- MS C

- Assets Avail.

FOUO

+15%

$1.21M

+10%

$1.265M

+15%

G

$1.1M

Schedule

+10%

G

$1.1M

* Due to testing constraints

TRLs meet LRIP entrance criteria

Cost

9

Engine Lube System

O

$1.21M

$1.265M

(T) Dec 11

G

(O) Apr 13

(T) Apr 14

G

* Based on proposed APB

9

MS C Affordability

Basic Questions:

Portfolio Related:

What adjustments are necessary to the existing

portfolio to fit this program in?

Program Related:

What do you (PM/PEO) think are the cost drivers in

your design and why?

Are the largest drivers related to technical,

schedule or other factors?

Schedule impact on Affordability Cap

Integrity - Service - Excellence

10

All Core Functions Affordable

within Flat Budget

Since the Sand Charts are classified, please provide sand charts on the SIPR net to the PEM to be provided separately

to the SAE with a copy to SAF/AXQC

Integrity - Service - Excellence

11

All Programs within

Core Function Affordable

Since the Sand Charts are classified, please provide sand charts on the SIPR net to the PEM to be provided separately

to the SAE with a copy to SAF/AXQC

Integrity - Service - Excellence

12

Affordable Acquisition Program

Since the Sand Charts are classified, please provide sand charts on the SIPR net to the PEM to be provided separately

to the SAE with a copy to SAF/AXQC

Integrity - Service - Excellence

13

MS C AFFORDABILITY

REQUIREMENT: NOTIONAL SYSTEM

Cost Drivers & Trade

Excursions

Proposed Affordability

Requirements

Description

APUC

O&S

Affordability

Requirement

$22.6M

$32.9B

Discussion Points:

• #1

• #2

• #3

Current Estimate

$24.4M

$35.6B

Description

APUC

PAUC

RDT&E

Proc.

O&S

Schedule

Impact

Original Cost

Estimate

$26.7

M

$32.3

M

$1.32

B

$15.1

B

$39.1

B

N/A

- Range

Readjustment

$0.3M

$0.4M

+$2M

-$75M

$100M

None

- Reliability

Growth

+$2.2

M

+$2.3

M

+$15

M

+$50

M

-$1.5B

+6

Months

- Engine Redesign

$0.7M

$1.1M

+$4M

$125M

$75.0

M

+3

Months

- Prognostics &

Health

Management

+$0.2

M

$0.3M

$0.0M

$0.0M

-$2.0B

None

- F/A-XY Avionics

Reuse

$1.9M

$2.4M

-$16M

-$50M

+$200

M

-6

Months

- Reduced

Ordnance Load

$1.8M

$2.0M

+$2M

-$15M

$0.0M

None

Current Cost

Estimate

$24.4

M

$29.0

M

$1.31

B

$14.9

B

$35.6

B

N/A

14

Should Cost Summary

$M

Total Acq Will Cost (ICE)

FY12

Budget Authority

81.6

[Current Year] PB

FY13

62.4

100.0

100.0

[Should Cost Initiative Title]

Phase 1 Test Activities

Phase 2 (Contract Award)

Flight Body-2

Streamline Training

Net Should Cost Savings

Total Should Cost Estimate

FY14

33.0

100.0

FY15

FY16

FY17

FY18

FY19

To

Complete

Total

1,090.7

198.4

213.5

207.9

153.7

97.3

42.9

100.0

100.0

100.0

100.0

100.0

500.0

800.0

(1.4)

(11.0)

(24.6)

(22.5)

(24.5)

(1.4)

(11.0)

(70.3)

(24.5)

(26.0)

(23.2)

(26.0)

0.0

100.0

(12.4)

87.6

0.0

100.0

0.0

100.0

(24.6)

75.4

(47.0)

53.0

(49.2)

50.8

0.0

100.0

(133.2)

666.8

379.2

Realized

Planned

Realized

• FY13:

• FY13:

$ 1.400M; EMD Phase 1 Aircraft Integration

Ensure all Should Cost Initiatives are PEO-Approved in

$11.000M; EMD Phase 1 Test Activities

Planned

• FY16-FY18:

• FY 17:

• FY18:

$70.292M; EMD Phase 2 (Contract Award) Source Selection Savings

$24.500M; Flight Body-2

$26.000M; EMD Phase 2 Test Activities

CCaRS and values are consistent. Use Back-up slides

to elaborate on each initiative.

Integrity - Service - Excellence

See Notes Page

SAMPLE PROGRAM: “ABC”

Date:

Product Support Strategy

Sustainment Approach

Current (initial CLS covering total system)

Future (sub-system based PBL contracts)

Shortfall in O&M funding in FYDP

Reliability and availability estimates are below goals

LCSP requires update before DAB

Resolution

POM request for O&M restoration submitted

Reliability improvement plan with clear RAM goals up for

final signature

LCSP in draft

Original

Goal

Current

Goal

Current

Estimate/

Actual

Materiel

Availability

76%

80%

77%

71%

Materiel

Reliability

37 hrs

50 hrs

50.5 hrs

48 hrs

Ownership

Cost

245.6B

385.5B

395.1B

395.1B

Mean Down

Time

12 hrs

20 hrs

18 hrs

15 hrs

* Test or fielding event data derived from _______

Notes:

Sustainment Schedule

Today

MS B

Antecedent

Actual

Metric

Issues

Metrics Data

MS C IOC FRP

BCA

FOC

BCA

O&S Data

Sustainment

BCA

BCA

PBL Recompete

LCSP

LRIP Contract Award

Avionics PBL

CLS Start

PBL Recompete

Antecedent

Cost

ABC Original

Baseline

ABC Current

Cost

1.0 Unit-Level Manpower

3.952

5.144

5.750

2.0 Unit Operations

6.052

6.851

6.852

3.0 Maintenance

0.739

0.605

0.688

4.0 Sustaining Support

2.298

2.401

2.401

5.0 Continuing System Improvements

0.129

0.025

0.035

6.0 Indirect Support

1.846

1.925

1.956

15.046

16.951

17.682

Cost Element

Total

Depot Standup

Blended Partnership

Startup

ATTACHMENT

Cost based on average annual cost per squadron

Total O&S Costs

Antecedent

ABC

Base Year $M

102,995.2

184,011.9

Then Year $M

245,665.3

395,147.2

16

Sample Program Schedule

FISCAL YEAR

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

NEED TO ADD TOP LEVEL CRITICAL PATH

F-15E

Integration

F-15E APG-70 GMTT

Dev & Test

AOA

JROC

DT

Normal attack

OA

EOA

1998-2000

MS-C

SDB-II

Development

Timeline*

*Will be updated after

contract award

F-35B & C

Integration

BRU-61/A

1st AUR Avail

RISK REDUCTION

EMD

2 COMPETITIVE CONTRACTS

SRR

PDR CTV GTV

SVR MS-C

2017

59 mos

DT

CAM/SAL

F-15E

Full

Capability

IT OT

CAM/SAL

OTRR

PCA IPR

2018

83 mos

F-15E

F-15E

RAA

RAA

Normal Attack

OTRR

IT OT

F-15E Suite 7E OFP

Note: Due to delay of MS B, shaded blue

region will move right accordingly

2016

To Complete

FY19-FY23

12,966

SVR FRP

PRODUCTION

CA/Lot LRIP 1

LRIP 2

LRIP 3

LRIP 4

FRP 1

FRP 2

Quantity

1050

144

250

390

550

CDR Post-CDR

83 mos

Report

F-35 Block 3.X OFP

F-35B/C

F-35B & F-35C

Initial Fielding

F-35B

OTRR

DT

IT

OT

Dual Power BRU-61/A

F-35C

DT

IT

OT

Delta Qual BRU-61/A for F-35 environment

- Required Assets Available (RAA): SDB II RAA is the capability to arm twelve (12) F-15Es with two (2) fully loaded BRU-61/A carriage systems each

for 1.5 sorties (144 assets total)

- DoN Assets for Initial Fielding: Initial quantity of SDB II weapons required is 90 weapons and 22 carriage systems based upon one ten (10) plane

squadron with two (2) fully loaded carriage systems each plus ten spare weapons.

Integrity - Service - Excellence

Sample Program X Schedule

FY13

FY14

FY15

FY16

FY17

FY18

FY19

FY20

FY21

IOC

MDD

FY22

FY23

FY24

FY25

FDDR

AFRB

Milestones

FOC

RIT

Requirements

Review/Management Board

ICD

Requirements

Annual

X-Plan

System/Architecture Studies

Design & Integration

Highlight critical path.

Test & Evaluation

Acquisition

OUE

OT&E

Contracting

CA

Operations & Support

Strategic & focused on Milestones and critical events between milestones.

18

I n t Must

e g r i communicate

t y - S e r v i c schedule

e - E x c echanges

llence

Test and Evaluation

Describe the Strategy for T&E and how it supports the acquisition,

requirements, and cyber security strategies

Describe any disconnects between these 4 strategies

Any OSD issues with TEMP or IOT&E plan approval?

Time constraints

Funding constraints

Test article and test facility/range constraints

Qualified T&E personnel shortfalls

Has the system been certified ready for dedicated operational

testing?

Are all Critical Operational Issues (COI), Critical Technical Parameters

(CTP), and Measures of Effectiveness (MOE) linked and covered?

What problems and deficiencies remain unresolved from DT&E?

Address negative Test results

Address DT&E issues remaining

Integrity - Service - Excellence

19

“PRE-DECISIONAL – NOT FOR RELEASE”

SAMPLE APT Framing Assumption #1

Purpose-built will

be competitive with

existing designs

Framing Assumption

Implications

Expectations

Basic aircraft and training system

designs will be complete through

vendor-conducted CDRs

Enter at

MS B

Limited

EMD of

“deltas” to

meet spec

PDR and

competitive

prototype

waivers

applicable*

Best-value

source selection

must consider

risk

Contractor

flight data to

validate

performance

Single step to

full capability

Single

award for

EMD, Prod

and ICS

RAA in 2023

FOC in 2031

*Air Force will still conduct comprehensive PDR and Critical Design Review (CDR) events post-contract

award in support of Better Buying Power (BBP) 3.0 “Strengthen organic engineering capabilities” and

SAF/AQ’s OTB Initiative.

Integrity - Service - Excellence

20

“PRE-DECISIONAL – NOT FOR RELEASE”

Sample APT Framing Assumption #2

APT

requirements

only

Framing Assumption

Implications

Expectations

Mature

technologies and

systems available

Single step,

limited EMD,

waivers etc.

AETC sole

customer

Separate

PPBE

process for

other T-38

owners

Integrity - Service - Excellence

Separate Planning

Programming

Budgeting and

Execution (PPBE)

process for APT

derivative use

capabilities

IOC 2023

21

Alt Sample Framing

Assumptions

Assumption*

Implications**

Expectations***

Design is

Mature

Production

Schedule to IOC will be

concurrency possible achieved

Threat levels

Capability changes

will not change

unlikely

much in the next

5 years

Costs to

Commercial

demand will

reduce unit cost

No additional funding

needed nor cost growth

Production cost Est

is realistic

Metric****

Schedule

growth below

historical

median

See Notes pages for information

Integrity - Service - Excellence

22

Business Strategy

•

Competition Strategy

–

How will competition be established and maintained through all

phases of the acquisition (to include spares and depot repair) ?

– How does the competition strategy facilitate the acquisition strategy?

– What is the competition strategy for the upcoming acquisition phase?

– How do the results of the last acquisition phase impact the strategy

for the upcoming phase?

•

For Each Contract

–

–

–

–

–

–

–

What is the purpose, type and value of the contract?

How is the contract aligned with the acquisition/competition strategies?

What is the incentive structure and how will the incentives foster

contractor behavior resulting in favorable cost, schedule and performance

outcomes?

What criteria will be used to select the winning bidder? How do those

criteria emphasize what is most important to the government?

Will warranties be employed? How will they benefit the government?

Does the contract anticipate the acquisition of technical data?

Are you able to buy in economic ordering quantities?

Integrity - Service - Excellence

23

Acquisition to O&S Cost Ratio

Total Req'd Acq (BYXX$M):

4,456

Total Req'd O&S (BYXX$M):

10,358

Program Funding & Quantities

($ in Millions / Then Year)

RDT&E

Prior $ (PB 16)

Current $ (POM 17)

Delta $ (Current - Prior)

Required1 $

Delta $ (Current - Required)

Prior

FY16

FY17

FY18

FY19

(BY yyyy)

PAUC:

APUC:

FY20

FY21

Curr Est

D Current

55.7M

+4.6%

50.4M

-3.2%

D Original

+10.2%

+60.2%

FY17-21 To Comp Prog Total

Prim ary Line Item s: APPN 0400D - BA 7 - PE 1160403BB; APPN 1319N - BA 5 - PE 0604262N; APPN 3600F - BA 5 - PE 0401318F

108.0

108.0

108.0

-

PROCUREMENT

Prior $ (PB 16)

Current $ (POM 17)

Delta $ (Current - Prior)

Required1 $

Delta $ (Current - Required)

FY15

30%

70%

32.4

30.0

(2.4)

32.4

(2.4)

44.2

43.1

(1.1)

44.2

(1.1)

45.1

45.6

0.5

45.6

-

37.9

38.3

0.4

46.0

(7.7)

12.4

12.5

0.1

15.0

(2.5)

5.3

5.4

0.1

6.5

(1.1)

3.2

3.2

4.0

(0.8)

103.9

105.0

1.1

117.1

(12.1)

-

288.5

286.1

(2.4)

301.7

(15.6)

Prim ary Line Item s: APPN 0300D - BA 2 - BLI 1000CV2200; APPN 1506N - BA 1 - BLI 0164; APPN 3010F - BA 4 - BLI V022A0

-

99.9

99.5

(0.4)

99.9

(0.4)

MILCON

150.4

148.2

(2.2)

150.4

(2.2)

200.2

203.1

2.9

203.1

-

304.8

309.2

4.4

312.3

(3.1)

618.6

522.9

(95.7)

528.1

(5.2)

627.6

530.5

(97.1)

535.8

(5.3)

360.1

538.1

178.0

543.5

(5.4)

2,111.3

2,103.8

(7.6)

2,122.8

(19.0)

2,257.3

1,954.5

(302.8)

1,974.1

(19.5)

4,618.9

4,306.0

(313.0)

4,347.1

(41.2)

Prim ary Line Item s: APPN 0500D - BA 1 - PE 1140494BB; APPN 1205N - BA 1 - PE 0204696N

Prior $ (PB 16)

Current $ (POM 17)

Delta $ (Current - Prior)

Required1 $

Delta $ (Current - Required)

-

-

-

6.1

6.1

6.1

-

2

SYSTEM O&M

Prior $ (PB 16)

Current $ (POM 17)

Delta $ (Current - Prior)

Required1 $

Delta $ (Current - Required)

1.3

1.4

0.1

1.4

-

1.6

1.7

0.1

1.7

-

-

2.1

2.0

(0.1)

2.0

-

2.3

2.1

(0.2)

2.1

-

3.0

3.0

3.0

-

9.0

8.8

(0.2)

8.8

-

15.3

12.6

(2.7)

12.6

-

25.6

22.8

(2.8)

22.8

-

Prim ary Line Item s: APPN 0100D - BA 1 - PE 1120172BB; APPN 1106N - BA 1 - PE 0206312M

8.3

8.3

8.3

-

10.4

11.4

1.0

11.4

-

26.5

29.2

2.7

29.2

-

37.8

41.6

3.8

41.6

-

55.0

60.5

5.5

60.5

-

91.4

98.6

7.2

98.6

-

221.1

241.2

20.1

241.2

-

5,904.8

(5,904.8)

235.5

255.6

20.1

6,160.4

(5,904.8)

257.3

261.8

4.5

261.8

-

369.2

376.6

7.4

387.4

(10.8)

670.9

579.0

(91.9)

586.7

(7.7)

690.2

598.5

(91.7)

604.9

(6.4)

457.7

642.9

185.2

649.1

(6.2)

2,445.3

2,458.8

13.5

2,489.9

(31.1)

2,272.6

1,967.1

(305.5)

7,891.4

(5,924.3)

5,168.5

4,870.5

(298.0)

10,832.0

(5,961.5)

TOTAL

Prior $ (PB 16)

Current $ (POM 17)

Delta $ (Current - Prior)

Required1 $

Delta $ (Current - Required)

108.0

108.0

108.0

-

138.4

135.6

(2.8)

138.4

(2.8)

204.2

201.0

(3.2)

204.3

(3.3)

QUANTITIES 3

Prior Qty (PB 16)

0

2

3

4

6

12

12

0

34

41

80

Current Qty (POM 17)

0

2

3

4

6

10

10

10

40

35

80

Delta Qty (Current - Prior)

0

0

0

0

0

(2)

(2)

10

6

(6)

0

Required1 Qty

0

2

3

4

6

9

9

9

37

38

80

Delta Qty (Current - Required)

0

0

0

0

0

1

1

1

3

(3)

0

Note 1. Requirement Source: [e.g., OSD CAPE ICE, Nov 2014]

Note 2. O&M requirement assumes [e.g., a service life to 2035; includes ctr field mx, petro/oil/lube, spare/repair parts, depot mx, sustaining engineering & software mx.]

This line does not include $8.3M (FY17-21) of Acquisition-related O&M for program office expenses, nor does it include O&M-funded disposal costs.

Note 3. Quantities in FY15-16 are funded with RDT&E.

Version POM 17.0

Program Risks

Insufficient funding to execute aircraft quantity

requirements

Sep 20xx

Consequence

Likelihood

Driver: Two Forward Price Rate Agreement (FPRA) increases, Apr

FPRA and Nov Forward Price Rate Recommendation (driven by a

reduction in the base vs. predictions, erosion in the commercial

business, efficiencies in production, a recent strike, and pension

liabilities) and potential additional rate impacts due to Pension Protection

Act compliance and projected business base loss in FY14 due to

decreasing procurement of V-22s are creating additional budget

pressure to execute yearly budgeted a/c quantities and pressurizing

APB and Nunn-McCurdy acquisition thresholds.

Mitigation Plan:

Finalize technical evaluation and negotiation of the lot 7 contract

{Leadership intervention as required}

Assess potential future rate increases and impacts on budget across

program fiscal years (ongoing)

Pension Protection Act assessment (AIR 4.2 Lead)

• Business base (DCMA lead)

• Continue to Pursue cost reduction/control initiatives (ongoing; see

affordability risk)

Update program manager’s cost estimate

Engage Service for funding resolution

•Support PEO(A)/DCMA rate control initiative with Bell (ongoing)

Date: Oct 10 (AH-1Z FRP decision)

Ability to Achieve Affordability Targets to Meet Inventory Objectives

Driver: Higher than anticipated costs due to Bell enterprise growth (overhead rates); raw materials; cabin; supplier

performance; increased labor hours. Two rate increases, Apr Forward Price Rate Agreement and Nov Forward

Price Rate Brochure (driven by a reduction in the base vs. predictions, erosion in the commercial business,

efficiencies in production, a recent strike, and pension liabilities) have recently created additional budget pressure.

Mitigation Plan:

Establish Affordability plan

Implement GFE CRIs (Engines, OTO)

Obtain Advanced Procurement in FY10

Execute Long Term Agreements/Long Term Contracts

Finalize SOF inspection requirements

Implement cost growth control and cost reduction initiatives

Assess impacts of PBxx Budget and rate increases with Lot 5 Production Proposal

Include spares in production contract

• Complete Business Case Analysis for MYP

• If supported by BCA, ensure MYP budget approval/lay-in and implement MYP to begin in FY14

Date: On-going

Failure to Meet Total Ownership Cost Reduction

Goals

Driver: Delayed I and D level standup, dynamic component DL&T

disposition, extended interim support period, components not making

reliability targets

Mitigation Plan:

Conduct BCA for long term logistics sustainment/PBL strategy

• Stand up Organic Intermediate and Depot Level repair

• NAVAIR approval of H-1 DL&T’s

• Execute 5 year Interim Support Plan contract awards

• CILR drives component redesign efforts/BCAs

Date: Ongoing

Bell Supply Chain Management to Support Increase

to Full Rate Production

Driver: Poor performance of key suppliers, long lead times (bearings,

forgings, castings), LLT purchase orders, staffing, parts shortages,

and limited capacity in critical suppliers

Mitigation Plan:

Obtain Advanced Procurement in FY10

Hire Govt Supply Chain Manager (V-22)

Identify dual source for critical suppliers

Rationalize supply base

Place Bell reps on-site at critical suppliers

Hire staffing to meet demand

Utilize Bell gated process for outsourcing

Award FY10 Long Lead

Support Prime key supplier visits with government representation

Production Readiness Review (support FRP decision)

Date: COMPLETE Jul 10 (Risk will be closed/deleted next quarter)

Integrity - Service - Excellence

25

Industrial Base Assessment

Industry capabilities validated during EMD phase

Group A and B kits produced for 7 a/c installs

Production Readiness Reviews complete

Supplier proposals / price quotes submitted for entire bill of

materiel

FPI option negotiated for LRIP & FRP

Diminishing Manufacturing Sources (DMS) / Material Shortages

(MS) issues identified and mitigated

Proactive screening program to identify new issues as they

emerge

In place Life of Type (LOT) purchases provide mitigation

38 items identified and on-contract

Integrity - Service - Excellence

Manufacturing Readiness

MRA Summary

Assessed manufacturing readiness to manage risk while

increasing ability to transition technology to weapon systems

Status of Production Readiness Review (PRR)

MRL 8 - Pilot line demonstrated ready for LRIP

MRA Objectives:

MRL 8 by Milestone C

Identify items to watch during LRIP

Bottom line:

Program X contractor & suppliers have adequately

demonstrated manufacturing maturity to proceed into LRIP

All sub-systems have achieved MRL of 8 or higher

See Footnotes

Integrity - Service - Excellence

27

MS C Document Status

Documentation

S/R*

Status

2366b Certification (if program

initiation)

S

In OSD Coord

Acquisition Decision

Memorandum (ADM)

R

In draft form

Acquisition Program Baseline

(APB)

S/R

In-Work

Acquisition Strategy

(update)

S/R

Complete

Affordability Analysis

(update)

R

In Coord

Analysis of Alternatives

(AoA) (update)

S

Final

Bandwidth Requirements

Review (update)

S

Final

Capability Production

Document (CPD)

R

Final

Clinger-Cohen Act

Compliance

S

In-Work

Concept of Operations/

Operational Mode

Summary/ Mission Profile

R

Complete

Comments

Program Office will finalize after AFCAA

In SAF 3-ltr Coord

.

To be completed prior to MS C DAB

* S=Statutory, R=Regulatory

Complete

On-Track

Minor Issues

Major Issues

28

MS C Document Status

Documentation

S/R*

Status

Comments

Core Logistics

Determination/Core

Logistics and

Sustaining Workload

Estimate

S

In-work

AFMC should complete by end of June

Component Cost

Estimate

R

In-Work

SCP in work to finalize 30 May. Affordability analysis to finalize after SCP

numbers available

Component Cost Position

R

In-work

Cost Analysis

Requirements

Description (update)

R

Final

Exit Criteria

R

Final

Frequency Allocation

Application (DD Form

1494)

S

Final

Full Funding

Certification

R

On-track

Awaiting ICE

Independent Cost

Estimate

S

In-Work

To be completed NLT 30 June (AFCAA coordinating with CAPE)

Independent Logistics

Assessment

S

Finished

* S=Statutory, R=Regulatory

Complete

On-Track

Minor Issues

Major Issues

29

MS C Document Status

Documentation

S/R*

Status

Comments

Information Support Plan

• Net-Centric Data

Strategy

R

Complete

Life Cycle Mission Data

(update)

R

In-Work

Update to be complete by 30 June

Life Cycle Support Plan

(update)

R

On-track

Awaiting AQD coordination

Manpower Estimate

Report (update)

S

Complete

Preservation & Storage of

Unique Tooling Plan

S

Complete

Problem Statement (DBS)

(Update)

R

Complete

Program Environ.Safety

and Occ Health Eval

(update)

S

Complete

Program Protection Plan

(update)

• Cybersecurity Strategy

R

Complete

S

* S=Statutory, R=Regulatory

Complete

On-Track

Minor Issues

Major Issues

30

MS C Document Status

Documentation

S/R*

Status

Should Cost Target

R

Complete

Spectrum Supportability

Risk Assessment

R

Complete

Systems Engineering Plan

(Update)

• Item Unique ID

implementation Plan

• Corrosion Prevention

Control Plan (Update)

• Manufacturing Risk

and Readiness

R

In-Work

System Threat

Assessment Report

(Update)

R

Final

Technology Readiness

Assessment (as applicable)

S

Finished

Test & Evaluation Master

Plan (update)

R

In-work

Waveform Assessment

Application (Update)

R

Final

Complete

On-Track

Minor Issues

Major Issues

Comments

In work to finalize 30 May.

In final coordination at DOT&E

PEO signed 14 May

* S=Statutory, R=Regulatory

31

Proposed LRIP Exit Criteria

(sample)

Element

Criteria

Technical

Demonstrate system

performance,

effectiveness, software

maturity and

interoperability

Manufacturing

Validate production

facilities are ready

Supportability

Demonstrate suitability

and long-term

sustainment strategy

Cost

Demonstrate

production affordability

100% verification/validation of CPD-defined Key Performance Parameters

Receipt of DOT&E beyond LRIP Report

Classification of all DRs—no unfixed/unverified CAT 1 DRs

Airworthiness approval

Completion of Functional Configuration Audit and Physical Configuration

Audits

Completion of kit proofs

Completion of manufacturing risk assessments

MRL of 9 or manufacturing maturity plan in place

Demonstrate a Full Rate Manufacturing capability

100% compliance w/CPD supportability/maintainability threshold

requirements

100% organizational technical orders published

Delivery of support equipment/spares

Delivery of 1 Weapons System Trainer, 1 Avionics Part Task Trainer

Demonstrate a Full Rate Manufacturing capability

Demonstrate Reliability

Updated production-cost estimate, based on LRIP actuals

Budget must fully support fully funded estimate

Integrity - Service - Excellence

ADM Proposed language

Proposed Acquisition Decision Memorandum

language:

I approve MS C and authorize entrance into

Low Rate Initial Production phase

Approval of MS C Acquisition Strategy

LRIP quantity up to 250 missiles

Delegation of MDA to AF (ACAT IC or IAC)

I approve the proposed Exit Criteria

XXX

YYY

ZZZ

Integrity - Service - Excellence

33

Way Ahead

Awaiting OSD approval of APB

OIPT scheduled for XX Date

DAB scheduled for XXX Date

Integrity - Service - Excellence

34

BACKUP

See Footnotes for additional information

Integrity - Service - Excellence

35

International Cooperation

Choose appropriate

funding chart below

*-from Spruill chart

Cooperative Activities: (list cooperative partners, describe

cooperative participation in the program, both current and planned, to

include list of actual international agreements-- e.g., bilateral or

multilateral discussions, loans of equipment, information exchanges,

cooperative RDT&E, co-production DEA/IEAs in technology area, etc)

Foreign sales: (list current or potential FMS or Direct Commercial

Sales buyers)

Interoperability Requirements: (list all international

objective and threshold requirements in program documents (JCIDS and

5000 series); describe plan to achieve those requirements, to include

which increment of a program they will be achieved)

Foreign technology assessment: (from TDS and AoA;

guidance in Deskbook Acquisition Guidebook, Section 2.3.6., identify how

10USC2350a statutory requirement has been met; assessment whether

or not a project similar capability is in development or production in a

partner nation that could be procured or modified to meet DoD needs)

Key Technologies: (description of the technologies and CPI in

the program)

Anti-Tamper Analysis: (based on ATEA Guidance and Defense

Exportability assessment)

Differential Capability Analysis:

(Assess potential need

for development of differential capabilities for a range of anticipated

coalition partners in view of the interoperability requirements,

cooperative activities, and potential foreign sales efforts envisioned)

Proposed Approach: (Describe how

design and development

of validated AT and Differential Capability requirements will be

addressed in the program’s master schedule )

(Identify issues specific to international -- e.g.,

impact (cost, schedule, performance) of

proposed cuts on partner(s)/buyer(s),

updated APUC, status of negotiations and

impact to US and partners under the relevant

agreement(s) (MOU, MOA, LOA)

26

Program Office Resources

Address Critical manpower positions / expertise (program

office manning) & facilities

Provide Organizational Structure (Org Chart)

Resources

Identify current DAWIA certification levels for all key

government personnel (SPMs, PMs, etc.)

Program Office Staffing and Support Contractor

Resources Available to PM

Identify any shortage of personnel

Integrated Product Teams (IPTs)

Integrity - Service - Excellence

37

SYSTEMS ENGINEERING ASSESSMENT:Snapshot

Assessment

H-1 Upgrade Example

of Program

FY2010

SE Issues

PRR

FY2011

MS III

• Significant past engagement through numerous

reviews

• Program and contractor supported SE engagement

• No further issues going forward

• SE will remain engaged in the main rotor cuff/yoke

redesign

• Support MS III and transition to ACAT 1C

Discussion of

SE issues

being worked

1. Systems Engineering

SEP ready for approval; IUID held up

2. Design Maturity

Mature; redesign of MR cuff/yoke

3. Reliability

Excellent RAM numbers

4. Software

No issues

5. Integration

No issues

6. Manufacturing

Mature processes; 7 LRIP lots

7. KPPs/KSAs

6 of 7 demonstrated, one on track

8. Others

Summary of Risks,

Mitigation Steps and

Risks, Issues, Opportunities Issues/Opportunities

*See notes section for rating criteria

Mitigation Activities (Closure Dates)

R1. Failure to meet TOC reduction goals

may cause budget exceedance

Continue current plan; expedite cuff/yoke redesign (Dec 2015)

R2. Main rotor cuff/yoke redesign not

complete in time for test

Certification milestone plan developed and monitored by PM. (Jun

2011)

Consequence

Likelihood

Technical Risks

Comments

Program Health

R1

Benefit

Technical Issues

Continue focus on contractor’s SCM and make parts (ongoing)

2. Structural Repair Manual late to need

Expedite approval of DL&T‘s (ongoing with NAVAIR)

Opportunities

O1. Capture lessons learned; best

practices; store in command library

Likelihood

1. Production parts; spares

R2

O1

Low investment; great benefit for program and NAVAIR

Note: Any item not rated green should be addressed in the issues section. If more space is required, to accommodate the technical risks, address the

“technical issues” in the “SE Issues” or “Program Health” sections. Delete “Opportunities” if not applicable.

38

SAMPLE

APB Summary

Cost Baseline (TY$M)

Objective

RDT&E

$282.5M

N/A

$9.4M

N/A

$0M

N/A

Total Acq Cost

$291.9M

N/A

O&S

$174.9M

N/A

Total Life Cycle Cost

$466.8M

N/A

Schedule Baseline

Objective

Threshold

MS B

Feb 2008

Aug 2008

MS C

Nov 2011

May 2012

FDD

Nov 2012

May 2013

FD

TBD*

TBD*

Procurement

Acq O&M

* FD date to be set at FDD

Threshold