Control Systems EE 4314

advertisement

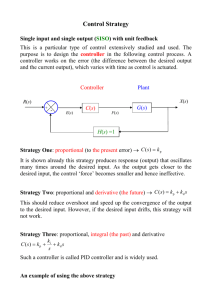

Control Systems EE 4314 Lecture 13 March 19, 2015 Spring 2015 Indika Wijayasinghe Steady-State Error • In the unity feedback system, error equation 𝐸 =𝑅−𝑌 =𝑅− 𝐺𝐷 1 𝑅= 𝑅 = 𝑆𝑅 1 + 𝐺𝐷 1 + 𝐺𝐷 where 𝑆: sensitivity • Let input 𝑟 𝑡 = 𝑡𝑘 𝑘! , which is 𝑅 𝑆 = 1 𝑠 𝑘+1 – For 𝑘 = 0, step input or position input – For 𝑘 = 1, ramp input or velocity input – For 𝑘 = 2, acceleration input • Using Final Value Theorem lim 𝑒(𝑡) = 𝑒𝑠𝑠 = lim 𝑠 𝐸(𝑠) 𝑡→∞ 𝑠→0 1 𝑅(𝑠) 𝑠→0 1+𝐺𝐷 1 1 = lim 𝑠 𝑠→0 1+𝐺𝐷 𝑠 𝑘+1 = lim 𝑠 Steady-State Errors Steady-state errors as a function of system type Type Input Step (position) Ramp (velocity) Type 0 1 1 + 𝐾𝑝 Type 1 0 1 𝐾𝑣 Type 2 0 0 1 𝐾𝑎 • Position error constant 𝐾𝑝 = lim 𝐺 𝐷(𝑠) • Velocity error constant 𝐾𝑣 = lim 𝑠𝐺 𝐷(𝑠) 𝑠→0 𝑠→0 • Acceleration error constant 𝐾𝑎 = lim 𝑠 2 𝐺 𝐷(𝑠) 𝑠→0 Parabola (acceleration) State-State Error • Example: Consider an electric motor control problem including a unity feedback system. System parameters are 1 𝐺 𝑠 = , 𝐷 𝑠 = 𝑘𝑝 𝑠(𝜏𝑠 + 1) Determine the system type and relevant steady-state error constant for input 𝑅 and disturbance 𝑊. 𝑊 𝑅+ − Controller 𝑈 + 𝐷(𝑠) + Plant G(𝑠) 𝑌 State-State Error PID Control • PID Controller 𝑢(t)=𝑘𝑝 e+𝑘𝐼 e dt + 𝑘𝐷 e 𝑘𝐼 𝐷 𝑠 = 𝑘𝑝 + + 𝑘𝐷 𝑠 𝑠 Where 𝑘𝑝 : proportional gain, 𝑘𝐼 : integral gain, and 𝑘𝐷 : derivative gain 𝑊 𝐷(𝑠) 𝑅+ 𝐸 − 𝑘𝐼 𝑘𝑝 + + 𝑘𝐷 𝑠 𝑠 𝑈 + + Plant G(𝑠) 𝑌 Proportional (P) Control • Proportional Controller 𝐷 𝑠 = 𝑘𝑝 Let second order plant 𝐺 𝑠 = • Transfer function 𝑇 = 𝐷𝐺 1+𝐷𝐺 𝐷(𝑠) 𝐴 𝑠 2 +𝑎1 𝑠+𝑎2 = 𝐴𝑘𝑝 𝑠2 +𝑎1 𝑠+𝑎2 𝐴𝑘𝑝 1+ 2 𝑠 +𝑎1 𝑠+𝑎2 𝑘𝑝 = 𝐴𝑘𝑝 𝑠 2 +𝑎1 𝑠+𝑎2 +𝐴𝑘𝑝 • Characteristic equation: 𝑠 2 + 𝑎1 𝑠 + 𝑎2 + 𝐴𝑘𝑝 = 0 (2nd order system: 𝑠 2 + 2𝜔𝑛 𝑠 + 𝜔𝑛 2 ) • Designer can determines the natural frequency (𝜔𝑛 ), but not damping of the system. Large 𝑘𝑝 reduces steady-state error. Proportional plus Integral (PI) Control 𝑘𝐼 𝑠 𝐴 𝜏𝑠+1 • Proportional Controller 𝐷 𝑠 = 𝑘𝑝 + • Example 1: first order plant 𝐺 𝑠 = 𝐷𝐺 – T.F. 𝑇 = 1+𝐷𝐺 = 𝑘 𝐴(𝑘𝑝 + 𝐼 ) 𝑠 𝜏𝑠+1 𝑘 𝐴(𝑘𝑝 + 𝑠𝐼 ) 1+ 𝜏𝑠+1 = 𝜏𝑠2 + 𝐷(𝑠) 𝑘𝑝 + 𝐴𝑘𝑝 𝑠+𝑘𝐼 𝑘𝐼 𝑠 𝐴𝑘𝑝 +1 𝑠+𝐴𝑘𝐼 – Characteristic equation: 𝜏𝑠 2 + 𝐴𝑘𝑝 + 1 𝑠 + 𝐴𝑘𝐼 = 0 – Controller parameters can set two coefficients. It can fully determine the natural frequency and damping of system. • Example 2: – T.F. 𝑇 = 2nd 𝐷𝐺 1+𝐷𝐺 order plant 𝐺 𝑠 = = 𝑘 𝐴(𝑘𝑝 + 𝐼 ) 𝑠 𝑠2 +𝑎1 𝑠+𝑎2 𝑘 𝐴(𝑘𝑝 + 𝐼 ) 𝑠 1+ 2 𝑠 +𝑎1 𝑠+𝑎2 = 𝐴 𝑠 2 +𝑎1 𝑠+𝑎2 𝑘 𝐴(𝑘𝑝 + 𝐼 ) 𝑠 𝑘 𝑠 2 +𝑎1 𝑠+𝑎2 +𝐴(𝑘𝑝 + 𝐼 ) 𝑠 – Characteristic equation: 𝑠 3 + 𝑎1 𝑠 2 + (𝑎2 +𝐴𝑘𝑝 )𝑠 + 𝐴𝑘𝐼 = 0 – Controller parameters can set two coefficients, not three. Proportional plus Derivative (PD) Control • Proportional Controller 𝐷 𝑠 = 𝑘𝑝 + 𝑘𝐷 𝑠 Let second order plant 𝐺 𝑠 = • Transfer function 𝑇 = 𝐴(𝑘𝑝 +𝑘𝐷 𝑠) 𝐷𝐺 1+𝐷𝐺 𝐷(𝑠) 𝐴 𝑠 2 +𝑎1 𝑠+𝑎2 = 𝐴(𝑘𝑝 +𝑘𝐷 𝑠) 𝑠2 +𝑎1 𝑠+𝑎2 𝐴(𝑘𝑝 +𝑘𝐷 𝑠) 1+ 2 𝑠 +𝑎1 𝑠+𝑎2 𝑘𝑝 + 𝑘𝐷 𝑠 = 𝑠 2 +(𝑎1 +𝑘𝐷 )𝑠+𝑎2 +𝐴𝑘𝑝 • Characteristic equation: 𝑠 2 + 𝑎1 + 𝑘𝐷 𝑠 + 𝑎2 + 𝐴𝑘𝑝 = 0 • Controller parameters can set two coefficients. It can fully determine the natural frequency and damping of system. Summary of PID Controller • Proportional control (𝑘𝑝 ): it tends to stabilize the system. Higher proportional gain reduces an steady-state error and increases the natural frequency of system (fast response) • Integral control (𝑘𝐼 ): it tends to eliminate or reduce steady-state error. The control system may become unstable. Integral term increases the order of the system dynamics. (e.g.: 2nd order system becomes 3rd order system) • Derivative control (𝑘𝐷 ): although it does not affect the steady-state error directly, it adds damping to the system, which results in an improvement in the steady-state accuracy. It tends to increase the stability of the system. Reduces an overshoot. Derivative control is never used alone because it operates on the rate of error, not an error. Ziegler-Nichols Tuning of PID Controller • Controller tuning: the process of selecting the controller parameters (𝐾𝑝 , 𝑇𝑖 , 𝑇𝐷 ) to meet given performance specifications. • Ziegler and Nichols suggested rules for tuning PID controller gains (𝐾𝑝 , 𝑇𝑖 , 𝑇𝐷 ) based on step responses (First method) and or based on the value of 𝐾𝑝 that results in marginal stability (Second method) when mathematical models of plants are not known. Ziegler-Nichols Tuning Rules: First Method • First method: obtain the response of the plant to a unit-step input. • S-shaped curve may be characterized by two constants: delay time L and rise time T. • Choose PID controller gains (𝐾𝑝 , 𝑇𝑖 , 𝑇𝐷 ) from time delay L and rising time T. Ziegler-Nichols Tuning Rules: Second Method • Second method: Using the proportional control (𝐾𝑝 ) only, increases 𝐾𝑝 from 0 to a critical value 𝐾𝑐𝑟 until system becomes marginally stable. (sustained oscillation). The critical gain 𝐾𝑐𝑟 and its corresponding period 𝑃𝑐𝑟 are experimentally obtained. Sustained oscillation when 𝐾𝑝 is 𝐾𝑐𝑟 Ziegler-Nichols Tuning Rules: Second Method • Example: Tune PID controller gains (𝐾𝑝 , 𝑇𝑖 , 𝑇𝐷 ) using the second method 1 𝐺 𝑠 = 𝑠(𝑠 + 1)(𝑠 + 5) Ziegler-Nichols Tuning Rules: Second Method • Using only proportional gain 𝐾𝑝 , increases gain to obtain sustained oscillation – 𝐾𝑝 = 30 (𝐾𝑐𝑟 ) – Its corresponding period 𝑃𝑐𝑟 : 2.8 Step Response Step Response 2 2 1.8 1.8 1.6 1.4 1.4 1.2 1.2 Amplitude Amplitude 1.6 1 1 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0 0.2 0 2 4 6 8 10 Time (seconds) 12 14 16 18 20 0 0 2 4 6 8 10 Time (seconds) 𝐾𝑝 = 20 12 14 𝐾𝑝 = 30 (𝐾𝑐𝑟 ) 16 18 20 Ziegler-Nichols Tuning Rules: Second Method – From 𝐾𝑐𝑟 and 𝑃𝑐𝑟 , control gains: 𝐾𝑝 : 18, 𝑇𝐼 : 1.4, 𝑇𝐷 : 0.35 – Response by use of Ziegler-Nichols Tuning Rules • Overshoot 62% • Rising time: 0.8 sec • Setting time: 15 sec Step Response 1.8 1.6 1.4 Amplitude 1.2 1 0.8 0.6 0.4 0.2 0 0 5 10 Time (seconds) 15 Ziegler-Nichols Tuning Rules: Second Method • Increase 𝑇𝐼 (integral) and 𝑇𝐷 (derivative) to 3 and 0.77 from 1.4 and 0.35 – 20% overshoot – Fast rising time (0.8sec) – Less oscillation Step Response 1.4 1.2 Amplitude 1 0.8 0.6 0.4 0.2 0 0 1 2 3 4 5 Time (seconds) 6 7 8 9 Ziegler-Nichols Tuning Rules: Second Method • Increase 𝐾𝑝 (proportional) to 39 from 18 • 𝐾𝑝 : 39, 𝑇𝐼 : 3, 𝑇𝐷 : 0.77 – 25% overshoot – Fast rising time (0.4sec) – Fast setting time Step Response 1.4 1.2 Amplitude 1 0.8 0.6 0.4 0.2 0 0 1 2 3 4 Time (seconds) 5 6 7 8