Sensors

advertisement

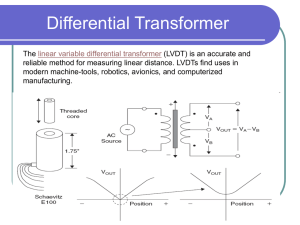

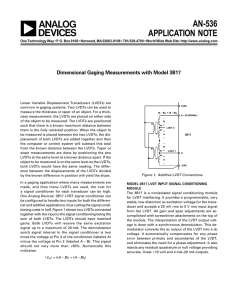

Sensors Optical Encoders and Linear Variable Differential Transformers Chris Davidson Ari Kapusta Overview • Optical Encoders – What is an optical encoder – Types of optical encoders – Components – How do they work? • LVDT (Linear Variable Differential Transformer) – What is a LVDT – Types of LVDT – How do they work? – Applications Optical Encoders • An electro-mechanical device that senses angular (or linear) position or motion Types of Encoders • Rotary: Converts rotational position/velocity to an analog or digital signal • Linear: Converts linear position/velocity to an analog or digital signal • Absolute: Gives absolute position and knowledge of the previous position is not needed • Incremental: Measures displacement relative to a reference point Fundamental Components • Light Source(s): Light provided by LED and focused through a lens • Photosensor(s): Photodiode or Phototransistor used to detached light • Opaque Disk (Code Disk): One or more tracks with slits to allow light to pass through them • Masking Disk: Stationary track(s) that are identical to the Code Disk. Fundamental Components Absolute Encoders Advantages Disadvantages • A missed reading does • More expensive/complex not affect the next reading • Only needs power when on when taking a reading Binary Encoding Note: Simplified Encoder (3 Bit) Angle Binary Decimal 0-45 000 0 45-90 001 1 90-135 010 2 135-180 011 3 180-225 100 4 225-270 101 5 270-315 110 6 315-360 111 7 Gray Encoding Notice only 1 bit has to be changed for all transitions. Angle Binary Decimal 0-45 000 0 45-90 001 1 90-135 011 2 135-180 010 3 180-225 110 4 225-270 111 5 270-315 101 6 315-360 100 7 Gray Code to Binary Code 1.) Copy MSB 2.) Perform XOR (Exclusive OR) between bi and gi+1 3.) Repeat Example: Gray Code to Binary Code Convert the gray code value of 0101 to binary code. Solution: 0110 Incremental Encoders Advantages • Cost Disadvantages • Must be “zeroed” at a reference location for each startup Incremental Disk Incremental Disk Quadrature • • • • Quadrature describes two signals 90° out of phase Used to determine direction of measurement Only two possible directions: A leads B or B leads A Provides up to 4 times the resolution Encoder Resolution • Absolute Optical Encoder 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = 𝑛 2 𝑛 = Number of Encoder Bits Encoder Resolution • Incremental Optical Encoder 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = 𝑛 𝑛 = Number of Windows on Code Disk per Channel If we read the rising edge of Channel A and Channel B, 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = 2𝑛 If we read the falling edge of Channel A and Channel B, 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = 2𝑛 If we read the rising edge and the falling edge of Channel A and Channel B, 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = 4𝑛 Example: Resolution What is the best resolution you can get on an incremental encoder with 500 windows per channel? By counting both rising and falling edges of both channels, 360° 360° 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 = = = .18° 4𝑛 4 ∗ 500 Error and Reliability • Quantization Error – Dependent on sensor resolution • Assembly Error – Dependent on eccentricity of rotation (Is track center of rotation the same as the center of rotation of disk) • Manufacturing Tolerances – Code printing accuracy, sensor position, and irregularities in signal generation • Mechanical Limitations – Disk deformation, physical loads on shaft, rotation speed (bearings) • Coupling Error – Gear backlash, belt slippage, etc… • Ambient Effects – Vibration, temperature, light noise, humidity, dust, etc… Applications • Old Computer Mice • Speed Feedback from Motor/Gearbox • Angular Position of Robotic Arm LVDT (Linear Variable Differential Transformer) Presenter: Ari Kapusta • • • • What is a LVDT How do they work? Types of LVDT Applications What is a LVDT • Linear Variable Differential Transformer • Electrical transformer used to measure linear displacement Construction of LVDT • One Primary coil • Two symmetric secondary coils • Ferromagnetic core Primary coil •The primary coil is energized with a A.C. •The two secondary coils are identical, symmetrically distributed. Ferromagnetic core Secondary coils How LVDT works • A current is driven through the primary, causing a voltage to be induced in each secondary proportional to its mutual inductance with the primary. How LVDT works • The coils are connected in reverse series • The output voltage is the difference (differential) between the two secondary voltages Null Position • When the core is in its central position, it is placed equal distance between the two secondary coils. • Equal but opposite voltages are induced in these two coils, so the differential voltage output is zero. Moving Core Left • If the core is moved closer to S1 than to S2 • More flux is coupled to S1 than S2 . • The induced voltage E1 is increased while E2 is decreased. • The differential voltage is (E1 E2). Moving Core Right • If the core is moved closer to S2 than to S1 • More flux is coupled to S2 than to S1 . • The induced E2 is increased as E1 is decreased. • The differential voltage is (E2 E1). Output • The magnitude of the output voltage is proportional to the distance moved by the core, which is why the device is described as "linear". • Note that the output is not linear as the core travels near the boundaries of its range. LVDT Types - Distinction by : - Power supply : - DC - AC - Type of armature : - Unguided - Captive (guided) - Spring-extended Power supply : DC LVDT • • • • Easy to install Signal conditioning easier Can operate from dry cell batteries High unit cost Power supply : AC LVDT • • • • Small size Very accurate –Excellent resolution (0.1 μm) Can operate with a wide temperature range Lower unit cost Armature : Free Core (Unguided) • Core is completely separable from the transducer body • Well-suited for short-range applications • high speed applications (high-frequency vibration) Captive Core (Guided) • Core is restrained and guided by a low-friction assembly • Both static and dynamic applications • Long range applications • Preferred when misalignment may occur Spring-Extended Core • Core is restrained and guided by a low-friction assembly • Internal spring to continuously push the core to its fullest possible extension • Best suited for static or slow-moving applications • Medium range applications LVDT Applications • LVDT measures absolute position. • Can be sealed against environment. • LVDT is useful for any application where you want linear position. – Machine tool position – Robot arm position – Forklift/hydraulic actuator position • Often used for position feedback LVDT Applications • • • • Crankshaft Balancing Testing Soil Strength Automated Part Inspection Automotive Damper Velocity Questions? Presenter of Optical Encoder: Chris Davidson Presenter of LVDT: Ari Kapusta References • • • • • • • • • • • http://www.macrosensors.com/lvdt_tutorial.html http://zone.ni.com/devzone/cda/tut/p/id/3638#toc3 http://en.wikipedia.org/wiki/Linear_variable_differential_transformer http://prototalk.net/forums/showthread.php?t=78\ http://www.transtekinc.com/support/applications/LVDT-applications.html http://www.sensorsmag.com/sensors/position-presence-proximity/modern-lvdtsnew-applications-air-ground-and-sea-7508 http://www.macrosensors.com/lvdt_tutorial.html http://zone.ni.com/devzone/cda/tut/p/id/3638#toc3 http://en.wikipedia.org/wiki/Linear_variable_differential_transformer Sensors Lecture: Fall ME6405 2009 http://electricly.com/absolute-optical-encoders-rotary-encoders