Lect 7 Transducer 2

advertisement

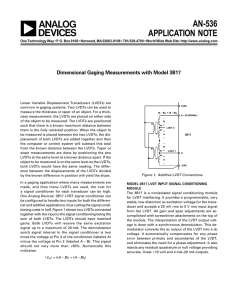

Differential Transformer The linear variable differential transformer (LVDT) is an accurate and reliable method for measuring linear distance. LVDTs find uses in modern machine-tools, robotics, avionics, and computerized manufacturing. LVDT The linear variable differential transformer (LVDT) is a type of electrical transformer used for measuring linear displacement. The transformer has three solenoidal coils placed end-toend around a tube. The centre coil is the primary, and the two outer coils are the secondary. A cylindrical ferromagnetic core, attached to the object whose position is to be measured, slides along the axis of the tube Linear Voltage Differential Transformer (LVDT) As shown in the last, the LVDT is a position-to-electrical sensor whose output is proportional to the position of a movable magnetic core. The core moves linearly inside a transformer consisting of a center primary coil and two outer secondary coils wound on a cylindrical form. The primary winding is excited with an ac voltage source (typically several kHz), inducing secondary voltages that vary with the position of the magnetic core within the assembly. The core is usually threaded in order to facilitate attachment to a non-ferromagnetic rod which, in turn, is attached to the object whose movement or displacement is being measured. LVDT The secondary windings are wound out of phase with each other. When the core is centered, the voltages in the two secondary windings oppose each other, and the net output voltage is zero. When the core is moved off center, the voltage in the secondary toward which the core is moved increases, while the opposite voltage decreases. The result is a differential voltage output that varies linearly with the core’s position. Linearity is excellent over the design range of movement, typically 0.5% or better. The LVDT offers good accuracy, linearity, sensitivity, infinite resolution, frictionless operation, and mechanical ruggedness LVDT A wide variety of measurement ranges are available in different LVDTs, typically from ±100 μm to ±25 cm. Typical excitation voltages range from 1 V to 24 V rms, with frequencies from 50 Hz to 20 kHz. Note that a true null does not occur when the core is centered because of mismatches between the two secondary windings and leakage inductance. Also, a simple measurement of the output voltage, VOUT, will not tell the side of the null position on which the core resides. LVDT A signal conditioning circuit that removes these difficulties is shown in Figure , where the absolute values of the two output voltages are subtracted. Using this technique, both positive and negative variations about the center position can be measured. IC related to LVDT use AD598 an IC The industry-standard AD598 LVDT signal conditioner, shown in simplified form in Figure 4, performs all required LVDT signal processing. The on-chip excitation frequency oscillator can be set from 20 Hz to 20 kHz with a single external capacitor. Two absolute value circuits followed by two filters are used to detect the amplitude of the A- and B channel inputs. Analog circuits are then used to generate the ratiometric function (A–B)/(A+B). Note that this function is independent of the amplitude of the primary winding excitation voltage, assuming the sum of the LVDT output voltage amplitudes remains constant over the operating range. This is the case for most LVDTs, but the user should always check with the manufacturer if it is not specified on the LVDT data sheet. Note also that this approach requires the use of a five-wire LVDT. AD698 IC with (LVDT) The AD698 LVDT signal conditioner (Figure 5) has similar specifications as the AD598, but processes the signals slightly differently using synchronous demodulation. The A and B signal processors each consist of an absolute value function and a filter. The A output is then divided by the B output to produce a final output that is ratiometric and independent of the excitation voltage amplitude. Note that the sum of the LVDT secondary voltages does not have to remain constant in the AD698 Strain Gauge L R= r A Under tension the strain narrows area therefore the effective resistance increases Under compression area of the strain thickens , therefore effective resistance decreases Strain Gauge Strain Gauge The strain gauge has been in use for many years and is the fundamental sensing element for many types of sensors, including pressure sensors, load cells, torque sensors, position sensors, etc. The majority of strain gauges are foil types, available in a wide choice of shapes and sizes to suit a variety of applications. They consist of a pattern of resistive foil which is mounted on a backing material. They operate on the principle that as the foil is subjected to stress, the resistance of the foil changes in a defined way. Strain Gauge The strain gauge is connected into a Wheatstone Bridge circuit with a combination of four active gauges (full bridge), two gauges (half bridge), or, less commonly, a single gauge (quarter bridge). In the half and quarter circuits, the bridge is completed with precision resistors. As the signal value is small, (typically a few millivolts) the signal conditioning electronics provides amplification to increase the signal level to 5 to 10 volts, a suitable level for application to external data collection systems such as recorders or PC Data Acquistion and Analysis Systems. Temperature compensation Under certain industrial conditions the temperature causes changes in resistance of the strain gauge and hence disguises any stress or compression measurement. Under such condition a dummy strain gauge is connected that remains unstressed but within same temperature environment therefore compensating any change caused by temperature. ½ Bridge arrangement However, when a downward force is applied to the free end of the specimen, it will bend downward, stretching gauge #1 and compressing gauge #2 at the same time. Such complimentary forces will cause larger differential of output voltage to be measured and hence provide bridge with better resolution. Full Bridge arrangement In applications where such complementary pairs of strain gauges can be bonded to the test specimen, it may be advantageous to make all four elements of the bridge "active" for even greater sensitivity. This is called a full-bridge circuit: Strain Gauge Most manufacturers of strain gauges offer extensive ranges of differing patterns to suit a wide variety of applications in research and industrial projects. They also supply all the necessary accessories including preparation materials, bonding adhesives, connections tags, cable, etc. Varieties of Strain Gauges