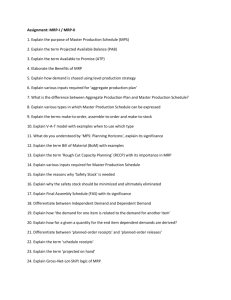

MRP & ERP

advertisement

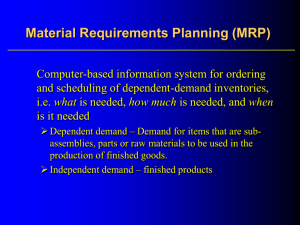

MRP Material Requirements Planning MRP • …is a planning and scheduling technique used for batch production of assembled items. • … is a computer-based information system that translates master schedule requirements for end items into time-phased requirements for subassemblies, components, and raw materials. • It… – enables low levels of in-process inventories – helps to track material requirements – helps to evaluate capacity requirements – is a means of allocating production time Independent and dependent demand • A demand is independent if it is needed for its own. The demand of end-products are usually independent. • Dependent demand is a demand for items that are subassemblies or component parts to be used in production of finished goods. • Once the independent demand is known, the dependent demand can be determined. Stable demand Demand Demand Comparison of independent and dependent demand Time Amount on hand Amount on hand Time “Lumpy” demand Safety stock Time Time Independent Demand Dependent Demand A C(2) B(4) D(2) E(1) D(3) F(2) Independent demand is uncertain. Dependent demand is certain. MRP • Based on the master schedule, it is • working backward from the due date using lead times and other information, • to determine when and how much to order from materials, components, subassemblies etc. • So that ordering, fabrication, and assembly can be scheduled for timely completition of end items while inventory leveles are kept low. Overview of MRP MRP Inputs MRP Processing MRP Outputs Changes Order releases Master schedule Planned-order schedules Primary reports Bill of materials Inventory records MRP computer programs Exception reports Planning reports Secondary reports Performancecontrol reports Inventory transaction Inputs of MRP • Master production schedule: states which end products are to be produced, when and in what quantities. Inputs of the master schedule are customer orders and forcasts. Separates the planning horizonts into time buckets. It should cover the cumulative lead time. • Bill-of-Materials (BOM): a listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce one unit of a product. It is hierarchical and shows the quantities, too (assembly diagram, product structure tree, low level coding). • Inventory records: Includes information on the status of each item by time period (Gross requirements, scheduled receipts, amount on hand, lead times, lot sizes, etc.) Processing MRP (assembly time chart) Procurement of raw material D Fabrication of part E Subassembly A Procurement of raw material F Procurement of part C Final assembly and inspection Procurement of part H Fabrication of part G Procurement of raw material I 1 2 3 Subassembly B 4 5 6 7 8 9 10 11 MPR Processing 2 • Gross requirements – Total expected demand • Scheduled receipts – Open orders scheduled to arrive • Planned on hand – Expected inventory on hand at the beginning of each time period MPR Processing 3 • Net requirements – Actual amount needed in each time period • Planned-order receipts – Quantity expected to received at the beginning of the period – Offset by lead time • Planned-order releases – Planned amount to order in each time period Updating the System • Regenerative system – Updates MRP records periodically • Net-change system – Updates MPR records continuously MRP Outputs • Planned orders - schedule indicating the amount and timing of future orders. • Order releases - authorization for the execution of planned orders. • Changes - revisions of due dates or order quantities, or cancellations of orders. MRP Secondary Reports • Performance-control reports: evaluate system operation • Planning reports: help to forecast future inventory requirements, e. g. purchase commitments • Exception reports: call attention to major discrepancies Other Considerations • Safety Stock • Lot sizing – – – Lot-for-lot ordering Economic order quantity Fixed-period ordering MRP is services • Services also need material components like packages, tools, physical environment or materials used in the services. MRP II • Expanded MRP with emphasis placed on integration – Financial planning – Marketing – Engineering – Purchasing – Manufacturing MRP II Market Demand Finance Manufacturing Master production schedule Marketing Production plan MRP Rough-cut capacity planning Capacity planning Adjust production plan Yes Problems? No Requirements schedules No Problems? Adjust master schedule Figure 13.14 Yes Enterprise resource planning (ERP) – Next step in an evolution that began with MPR and evolved into MRPII – Integration of financial, manufacturing, and human resources on a single computer system. Thanks for the attention!