Contract Manufacturing - New England Supply Chain Conference

advertisement

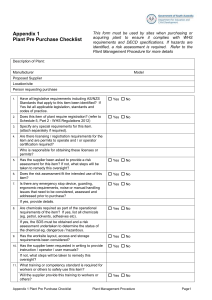

KPIs: Improving Supply Chain Performance Management Northeast Supply Chain Conference and Exposition Framingham, MA September 19 – 21, 2004 Tim Dolan, C.P.M. Manager, New Product Support Global Procurement Organization The Gillette Company Agenda • • • • • • The Gillette Company Overview Key Performance Indicators – What Are They? The Case for Measuring Indirect KPIs Developing Indirect KPIs Sample KPI Scorecard Guidelines and Benefits Gillette History • Founded in 1901 by King C. Gillette • Boston, Massachusetts World-Class Brands, Products, People • $9 Billion in Sales (2003) • Multinational Corporation • Gillette - Recognized Brand Worldwide • 32 Manufacturing Centers – 15 Countries – 200+ Markets • Approximately 29,000 employees worldwide • 4 primary Business Units – Grooming • Blades & Razors • Personal Care – Batteries – Oral Care – Appliances • Innovative: 47% of Sales from Products less than 5 years old Gillette Products What are Key Performance Indicators (KPIs)? Price Delivery Quality Total product cost Performance to schedule Product reliability and consistency KPIs are measurements of a supplier or service provider’s performance in key activity areas KPIs have historically been used to measure direct material suppliers’ performance Price • Cost reductions • Cost competitiveness Delivery • Quantity • On-time delivery • Paperwork • Shipment condition Quality • Rejected and nonconforming • Process capability, data/samples History of Indirect KPIs Jim Kilts’ “Circle of Doom” • Centralize procurement Supply Chain • Implement Strategic Sourcing (SSI) Trade Practices Financial Practices Source: “Jim Kilts Is An Old-School Curmudgeon”, Fortune, December 30, 2002 KPIs sustain strategic sourcing savings What is Indirect Spend? • • • • • • Computer/Telecom Energy/Utilities Printing/Marketing/Advertising Employee Benefits Office Products MRO • • • • • • Travel Facilities Professional Services Fleet Logistics Capital Equipment Indirect spend is the sum of expenditures for goods or services that are not components of the end product or service delivered to a customer The average indirect spend for Fortune 500-size companies is 50% of total spend Direct $700 $600 $500 $400 $300 $200 $100 $0 ($ Millions) Group Total Indirect General Consumer Chemical/Petroleum Aerospace, Utilities/ Defense, DoD Engineering Manufacturing & Products Mining and DoE Construction Contracting Source: CAPS Critical Issues Report, September 2003 Spend for services accounts for more than half of a company’s indirect spend Purchase Spend as a Percentage of Total Purchase Spend Median spend = $434M Total Indirect Goods 21% Services 33% 5% 5% 6% 8% 8% Construction/Eng Inventory 20% Manufacturing 48% Other: Accounting Facilities Legal Logistics Real Estate Temp Labor Travel Direct Material 51% Source: Defining and Determining the “Services Spend” in Today’s Services Economy, CAPS, July 2003 Marketing IT Pro Services Participants in a recent CAPS survey expect indirect spend for services to increase Indirect Spend - Services ($ Millions) $434 2002 = Projected 5-yr CAGR = 5% $456 2003 $478 2004 $502 2005 Source: Services Purchases: Not Your Typical Grind, Inside Supply Management, September 2003 Note: Chart represents respondents’ median spend $529 2006 Developing KPIs for Indirect Suppliers Evaluation criteria for indirect suppliers can be grouped into three categories Contract Compliance Customer Satisfaction Cost Competitiveness and Continuous Improvement Definitions of Supplier Criteria • How well does the supplier deliver on the terms, conditions and prices agreed to in the contract? • How well does a supplier satisfy our customers from a product or service quality perspective? • How cost competitive is the supplier from an industry perspective and from a historical perspective? • How well does the supplier continue to enhance the product/service, process or cost? Ultimate objective is to be able to quantifiably measure and compare individual supplier’s performance Specific KPIs can be tailored to meet the needs of various suppliers Contract Compliance Customer Satisfaction Cost Competitiveness and Continuous Improvement Attributes • • • • • • Actual cost vs. budget SLA responsiveness On time deliveries Return rate Order and billing accuracy Average lead-time • • Customer Surveys Technical Support • • • Supplier vs Industry Supplier vs Other Benchmark Ecommerce capability • • Supplier Partnership Initiative Cost Reduction Target Objective and subjective attributes are necessary for measuring indirect suppliers Indirect KPIs can use a 1 to 5 scale to score KPIs and a weighting system which allows some flexibility, but keeps weights significant and relatively consistent Indirect Supplier Evaluation Criteria Contract Compliance Customer Satisfaction 30-50% 20-30% Cost Competitiveness and Continuous Improvement 30-50% = 100% Standard Scores 5 4 3 2 1 = = = = = Superior – far exceeds expectations Exceeds expectations Meet expectations Does not meet expectations Needs improvement; significantly does not meet expectations Allowing flexibility with category weighting ensures that the KPI scorecard is tailored to meet the unique needs of the measured supplier Contract Compliance Contract Compliance Attributes • • • • • • Actual costs versus budget Service level results On time delivery Return rate Order and billing accuracy Average lead-time Contract compliance attributes mirror the supplier’s contractual commitments Customer Satisfaction While KPIs measured with objective data are the most reliable, it can be argued that they do not capture the entire picture in regards to supplier performance Traditional KPI constraints: • Difficult to evaluate the interactions of supplier personnel with customers • Quality can only be measured in regards to damage or breakdown, and is difficult to measure for services • Strong traditional supplier KPI data does not necessarily indicate whether or not the customer is satisfied Customer Satisfaction Surveys provide mechanism to help evaluate supplier performance Customer Satisfaction Surveys capture the customer‘s opinions in regards to supplier performance. Supplier Interaction: Infrequent ___ Moderate____High ____ Questions: – – – – – – – I feel the supplier provides high quality goods and services. I feel the supplier provides high value for the cost. I would recommend this supplier to others. When I have questions, this supplier responds in a timely manner. If there is an issue, this supplier resolves the issue in a timely manner. If there is an issue, this supplier resolves the issue to my satisfaction. In my opinion, this supplier deserves recognition as a top supplier. Scale: – – – – – 1: Strongly Disagree 2: Disagree 3: Neutral 4: Agree 5: Strongly Agree Customer satisfaction surveys can be a primary determinant of customer satisfaction A comprehensive supplier measurement system can mitigate customer satisfaction survey limitations Issues Mitigating Techniques • Customer satisfaction tends to be overwhelmed by bad experience, even if the bad experience was not the supplier‘s fault • Most recent experience is recalled; not overall supplier performance • Surveys tend to be subjective • A single negative response can skew results • Response rate tends to be low • Evaluate responses in relation to other KPI data. Conduct enough surveys to mitigate this effect • Adjust weighting for Customer Satisfaction Survey where commodity has a great deal of objective data • Utilize statistically significant sample size and possibly discard highest and lowest scores • Target key customers with vested interest and explain significance of KPI Cost Competitiveness and Continuous Improvement Benchmarking establishes cost competitiveness • Supplier vs industry • Supplier vs other benchmark – – – – Standard or target prices “Should” cost prices “Price paid” indices Consumer Price Index (“CPI”) • Ecommerce capability Comparing supplier pricing against benchmarks assists in avoiding “price creep” Cost Competitiveness and Continuous Improvement Guidelines • In addition to KPIs that measure cost versus competition and industry standards, continuous improvement, supplier process improvements and/or cost saving targets can be established • Define baseline spend that generates the savings target Cost Saving Guidelines 5 4 3 2 1 = = = = = Superior – far exceeds expectations Exceeds expectations Meet expectations Does not meet expectations Significantly does not meet expectations 6% or more 4 – 6% 2 – 4% 0 – 2% 0% Collecting the Data Evaluate the costs/benefits of each data collection method available Unbiased company collected data electronically Cost to collect data Recommended approach Data collected / tracked by supplier Data collection is the most difficult and time-consuming activity in the KPI process. However, it is integral to a successful KPI program. A wide range of sources can provide measurement data Data Warehouse ERP Systems Third-party data Supplierprovided reports Industry benchmarks Customer Satisfaction Surveys Attaching the data and documentation to the scorecard validates scoring and makes it possible for the supplier to take corrective action The KPI Scorecard Sample Scorecard - Temp Labor KPIs Global Procurement Balanced Scorecard Target Performance Actual Performance Weight Weighted Score Contracts Compliance Customer Satisfaction Cost Competitiveness/ Continuous Improvement 4.0 4.0 4.0 4.3 30% 30% 1.20 1.29 4.0 3.5 40% 1.40 OmniMark Cutoff Vendor Score OmniMark Eligible 4.00 3.89 No TEMPORARY LABOR : ABC Staffing SUPPLIER: ABC Staffing Contract Compliance Metric Act Score Weight Weighted Confirmation of Order Delivery w/i 2 hours Superior 100% 5 0.1 Excellent 95-100% 97% 4 0.1 Good 92-95% 3 0.1 Needs Improv 90-92% 2 0.1 Not Acceptable <90% 1 0.1 Customer Satisfaction Satisfaction Customer Metric Act Score Weight Cost Competitiveness Metric Act Score Weight Weighted Weighted 0 0.4 0 0 0 Candidates Received Survey (beginning of process) Superior 100% 100% 5 0.3 Excellent >=90% 4 0.3 Good >=80% 3 0.3 Needs Improv >=70% 2 0.3 Not Acceptable <70% 1 0.3 1.5 0 0 0 0 Base Pay Rates vs. Benchmark "Recruited" Superior Fav >=5% 5 Excellent Fav <5% 4 Good Parity X 3 Needs Improv Unfav <=5% 2 Not Acceptable Unfav >5% 1 Qualified Resumes Received w/i 24 hours Superior 100% 5 0.4 Excellent 97-100% 98% 4 0.4 Good 95-97% 3 0.4 Needs Improv 92-95% 2 0.4 Not Acceptable <92% 1 0.4 0 1.6 0 0 0 Temporary Attendance Rate Superior 100% Excellent >=90% 90% Good >=80% Needs Improv >=70% Not Acceptable <70% 5 4 3 2 1 0.2 0.2 0.2 0.2 0.2 0 0.8 0 0 0 Markup Rates vs. Benchmark (SSI Target = 30%) Superior Fav >3 BP 5 0.2 Excellent Fav 1-3 BP 4 0.2 Good Parity < 1BP Fav 0.5 3 0.2 Needs Improv Unfav <3 BP 2 0.2 Not Acceptable Unfav >3 BP 1 0.2 0 0 0.6 0 0 Selected Candidates Available w/i 72 hours Superior 100% 5 0.3 Excellent 95-100% 97% 4 0.3 Good 90-95% 3 0.3 Needs Improv 85-90% 2 0.3 Not Acceptable <85% 1 0.3 0 1.2 0 0 0 Temporary Turnover Rate Superior 0% Excellent <=2.5% 2.0% Good <=5.0% Needs Improv <=10% Not Acceptable >10% 5 4 3 2 1 0.1 0.1 0.1 0.1 0.1 0 0.4 0 0 0 Consolidated Billing / Accuracy Superior 100% Excellent 96-100% 97% Good 93-96% Needs Improv 90-93% Not Acceptable <90% Pass-Through Costs Superior Fav >=5% Excellent Fav <5% Good Parity Needs Improv Unfav <=5% Not Acceptable Unfav >5% 0 0 0.15 0 0 0 0.8 0 0 0 Candidates Selected Survey (end of process) Superior 100% 5 Excellent >=90% 90% 4 Good >=80% 3 Needs Improv >=70% 2 Not Acceptable <70% 1 0.4 0.4 0.4 0.4 0.4 0 1.6 0 0 0 Benchmark vs. previously paid on "recruited" talent 5 4 3 2 1 0.2 0.2 0.2 0.2 0.2 Weighted Cat Avg Comments Top 3 metrics covered by new T&A log Progress reviewed with supplier semi-monthly (initially) Each resume / position category is a "transaction" 4.0 Weighted Cat Avg Comments Survey should be all temp "managers" Survey should not be anonymous "Received" survey for quality vs. minimum guidelines "Selected" survey for work quality & quantity/efficiency, and hire-ability 4.3 X 5 4 3 2 1 0.25 0.25 0.25 0.25 0.25 0.05 0.05 0.05 0.05 0.05 Comments Cost of drug / background + other pass-throughs vs. competitors 0 0 0.75 0 0 Continuous Improvement Continuous Improvement Metric Act Score Weight Weighted Systems Upgrades / Process Improvements Implemented Superior Fav >=10% 11% 5 0.25 1.25 Excellent Fav >5% 4 0.25 0 Good Fav < 5% 3 0.25 0 Needs Improv None 2 0.25 0 Not Acceptable Unfav 1 0.25 0 Base Pay Rate Savings Methodologies Implemented Superior Fav >10% 5 0.2 0 Excellent Fav >5% 4 0.2 0 Good Fav < 5% X 3 0.2 0.6 Needs Improv None 2 0.2 0 Not Acceptable Unfav 1 0.2 0 Pass-Through Cost Methodologies Implemented Superior Fav >10% 5 0.05 Excellent Fav >5% 4 0.05 Good Fav < 5% 3 0.05 Needs Improv None 0% 2 0.05 Not Acceptable Unfav 1 0.05 Weighted Cat Avg Comments 0 0 0 0.1 0 3.5 Value assessment of upgrades to process / systems employed Base Pay Savings measured by market rate before / after agency input Pass-Through Savings vs. currently paying An overall score is calculated and used to measure indirect suppliers’ performance Indirect Supplier Evaluation Criteria Contract Compliance Cost Competitiveness and Continuous Improvement Customer Satisfaction Weight X Score = Indirect Supplier KPI Score • • Weight = 30% Score = 4 • • Weight = 30% Score = 4.3 • • Weight = 40% Score = 3.5 Indirect Supplier KPI Score EXAMPLE 3.89 Guidelines for developing KPIs KPI Guidelines • Determine criteria for identifying which suppliers will be measured by KPIs Business Benefits • What gets measured, gets done. Be clear on what you’re measuring and why. • Generates supplier improvements that benefit you • Develop jointly with suppliers to achieve buy-in • Justifies supplier’s inclusion in your supply base • Align KPIs with your goals and objectives • Identifies need to re-source supplier • Develop KPIs that are objective and measurable • Strengthens and improves supplier relationships • Limit KPIs to a manageable number • Develops suppliers • Communicate results to suppliers and management on a timely basis • Rewards for performance • Complete the process and follow-up on results and corrective actions KPIs drive continuous improvement and cost savings Questions