Value Chain Transformation

advertisement

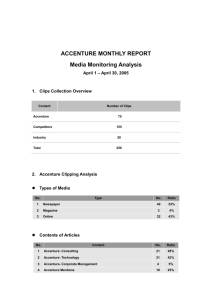

Anti Theft Source Protection Roadmap ECR Workgroup Jos Joos, Practice Leader Consumer Industrial & Technology Markets Jan Somers ECR Belgium Summary Start WG Aim/ Deliverable WG Who is involved? Different phases to work on … Next Steps Questions © 2005 BearingPoint, Inc. 2 Start WG & Deliverable The trigger was FEDIS (Federation of Distributors) Within the ECR Belgium WG was then decided to start a sub WG in anti-theft Kick-off meeting on the 28th of April 2006 of the ANTI-THEFT SOURCE PROTECTION PROJECT Aim/deliverable of the WG : an Anti-Theft Roadmap/Protocol (recommendation at least on national level, if possible on European level) © 2005 BearingPoint, Inc. 3 Who is involved? Retailers : security and lost prevention managers/risk management CARREFOUR Belgium – Colruyt – Cora - Delhaize Group – Makro - HUBO Belgium (DO-IT-YOURSELF) - FEDIS Manufacturers : security/logistics managers DHL – Henkel - L’Oreal - P&G/Gillette Solution Providers : solution managers/ technical advisors Checkpoint Benelux – TYCO ADT Sensormatic – BearingPoint (management & technology consulting) © 2005 BearingPoint, Inc. 4 Different phases to work on ... PHASE 1 : Clarify business needs & requirements of all nodes in the Supply Chain Define scope incl. product categories (f.e CD, alcohol, textile, razors, ...) Size the business opportunity (gathered data, quantified losses, ...) Current Situation (measures taken and efficiency, pain points, ...) Brainstorming about TO-BE situation (what has to change?, info needs, ...) PHASE 2 : Evaluate technical solutions Define services/functionalities around required information per node in the SC Overview/evaluation of potential technologies Benchmark existing SW solutions Evaluation of implications for implementation (technical issues, process changes, integration of captured information, public issues, cost & benefits sharing, ...) © 2005 BearingPoint, Inc. 5 Different phases to work on ... PHASE 3 : Pilot Proof of concept Test on a selected number of products with the selected technologies, evaluate SW Evaluate the results before and after PHASE 4 : Deployment Validate rules for deployment Agree on scope for deployment Apply learnings from pilots Propose Roadmap PHASE 5 : Extension towards traceability beyond theft Evaluate applicability to track and tracing in general © 2005 BearingPoint, Inc. 6 PHASE 1 : Clarify business needs & requirements of all nodes in the Supply Chain I. Definition Anti-theft according to ECR Europe Shrinkage Report definitions in Charter DIY/Protocol FEDIS II. Gathering data anti-theft, quantify losses, ... III. Define product categories IV. Current situation (current protocols, ...) © 2005 BearingPoint, Inc. 7 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation Taking the definition for Shrinkage as a starting point… Process Failures Internal Theft Out-of-date products Staff theft Incorrect pricing Collusion staff/customers Product identification errors Employees eating stock Scanning errors Deliberate manipulation of prices ... ... External Theft Inter-company fraud Delivering/returning fewer goods than agreed Incidents of shoplifting Vendor and contractor fraud Fraudulent return of goods ... Till snatches Burglary ... Source: ECR Europe Shrinkage Report © 2005 BearingPoint, Inc. 8 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation Costs for Stock Loss are tremendous The costs are tremendous € 465 million per week in FMCG Europe or € 2.8 million per hour in FMCG Europe Taking into account the razor-thin margins in the sector, it is clear that the pressure to reduce stock loss is high DANTE Consulting © 2005 BearingPoint, Inc. 9 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation Shrinkage – Best Estimates on Causes of Loss Primary Causes External theft Process failures Inter-company fraud Internal theft ECR Europe 2004 38% 27% 7% 28% Checkpoint Theft Barometer 48% 16% 7% 29% University of Florida 2003 32% 15% 5% 48% ECR Australia 2002 35% 29% 11% 25% Note: Surveys all asked loss prevention professionals to estimate the Contribution of each root cause to the total loss within their organisation © 2005 BearingPoint, Inc. 10 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation Retailer’s Missed Profit Opportunity Average Retailer Margin 5% 4% 1.8% 3% Average Retailer Shrink Margin 4.8% 2% Average Retailer Net Profit 3% 1% 0% Current Potential Source: Cranfield University © 2005 BearingPoint, Inc. 11 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation Unizo Top List of Theft Sensitive Product Categories Perfumery 62.7% Drinks 47.8% Clothing 36.4% Digital cameras 34.0% GSM 33.0% Dry Grocery 31.3% Cigarettes, ... 17.9% Cosmetics 16.7% DANTE Consulting © 2005 BearingPoint, Inc. 12 PHASE 1 : definition ant-theft/ gathering data antitheft / product categories/ current situation The same exercise has been done in the Belgian WG anti-theft. Hot product categories to be focused on have been agreed upon and figures collected. Grocery (wine & spirits, chatka/salmon/truffles, confectionary, tobacco, drinks, meat, …) Health & Beauty Care (razor blades, cosmetics, sun protection, body care/face care/make –up, haircare/ colouring, perfumes & aftershave, …) Home Entertainment (CD/DVD/Film/books, digital cameras, GSM accessories, PC accessories, PC software, batteries, play station, MP3, toys, ink cartridges & supplies, pet accessories, photo paper, auto accessories, sport articles, kitchen accessories, …) Clothing (woman's underwear, sunglasses, jewellery, wallet/leader, woman's clothing, sportswear, …) © 2005 BearingPoint, Inc. 13 PHASE 1 : definition ant-theft/ gathering data antitheft / current situation What consensus and/or proposals have already been made? DIY sector in Belgium and France opted for the E.M. technology as a standard for anti-theft source protection BDA has published a charter for the sector © 2005 BearingPoint, Inc. 14 PHASE 1 : definition ant-theft/ gathering data antitheft / current situation FEDIS has drafted a proposal… pure Belgian proposal still to be completed and approved. PROTOCOLE PROTECTION A LA SOURCE CONTENU I. GENERAL II. OBJECTIF III. DEFINITIONS IV. CHOIX DE LA TECHNOLOGIE V. POLITIQUE PROTECTION A LA SOURCE VI. EXIGENCES VII. ECHANGE DE DONNEES © 2005 BearingPoint, Inc. 15 PHASE 1 : definition ant-theft/ gathering data antitheft / current situation Vol à l’étalage : impact financier annuel le plus important. Proposition d’usage d’un système EAS. De préférence des éléments de protection invisibles Objectif : communiquer à tous les acteurs la position des parties signataires concernant la politique de la protection à la source + choix des technologies arrêter les règles lors de l’utilisation de cette solution (responsabilité partagée entre distributeurs et fournisseurs) Définitions : Application d’un élément de protection de manière intégrée et invisible sur ou dans l’article ou sur ou dans l’emballage par le producteur ou l’emballeur avant que l’article ne parvienne dans le centre de distribution des points de vente Technologie RF : élément de protection RF qui réagit à un signal à radiofréquence, émis et reçu par une antenne, à moins qu’il ne soit désactivé Autres technologies: • • EM (électromagnétique) AM (acoustique magnétique) © 2005 BearingPoint, Inc. 16 PHASE 1 : definition ant-theft/ gathering data antitheft / current situation Choix de la technologie : La technologie de protection à fréquence radio de 8.2 Mhz choisie en raison de • • • bon rapport coût-efficacité application simple dans différentes chaînes de production la radiofréquence s’impose comme la technologie majoritaire dans les magasins en Belgique Exigences Eléments de protection utilisées doivent pourvoir être désactivés et ne pourront être réactivés Fournisseur devra fournir une fiche de renseignements (localisation) Éléments de protection à signal RF de 8.2 Mhr +/-5% Fournisseurs/producteurs ont le choix du fournisseur des éléments de protection Magasins équipés d’antennes de détection doivent être simultanément équipés de systèmes de désactivation … DANTE Consulting © 2005 BearingPoint, Inc. 17 PHASE 2 : Evaluate technical solutions I. Comparing different anti-theft solutions Expectations of consumers (study CARREFOUR GROUP – GFK) II. Source Tagging : different technologies on the market : EM AM RF (RFID/EPC with EAS functionality in the future) IIV. Functionalities / SW analysis of each technology IV. Usage of EAS technologies in the market (national/European/international level) V. Evaluation of implications for implementation (technical issues, process changes, integration of captured information, public issues, cost & benefits sharing, ...) © 2005 BearingPoint, Inc. 18 PHASE 2 : Evaluation technical solutions I. comparing anti-theft solutions Example of Anti-Theft Measures and Solutions in Use Cash protection equipment, safes, caches (84%) Intruder alarm systems (84%) Live closed circuit televistion (77%) Mystery shoppers (74%) Electronic Article Surveillance equipment (EAS) (71%) Employee integrity checks (71%) Plain clothes store detectives (71%) Safer cases or protector boxes (71%) Automated store stock ordering system (68%) Random till checks (68%) Checking stock deliveries at the store (at SKU level) (65%) Regular counts on vulnerable lines (65%) Staff searches (65%) Analysis of EPOS data/ data mining (61%) Stock loss database (61%) Uniformed security goards (61%) External security measures shutters, bollards, fences (58%) Unique PIN numbers for till operators (58%) Dummy closed circuit television (55%) Process review team (55%) Specialist display equipment (fixed) (48%) EPOS/CCTV linkage software (45%) Dummy cards/Empty boxes on display (39%) GPS on delivery lorries (32%) Full time stock loss analysis (26%) © 2005 BearingPoint, Inc. 19 PHASE 2 : Evaluation technical solutions I. comparing anti-theft solutions European consumers expectations on anti-theft solutions (study CARREFOUR GROUP – GFK) © 2005 BearingPoint, Inc. 20 PHASE 2 : Evaluate technical solutions I. comparing anti-theft solutions The ideal anti-theft solution ‘Musts’ for European Consumers Accessibility & Non Damaging System are equally important for Clothes & Sport Shoes © 2005 BearingPoint, Inc. 21 PHASE 2 : Evaluate technical solutions I. comparing anti-theft solutions Anti-theft solutions do prevent purchase in some cases Base : All countries When being asked about protection systems if they ever prevent them from buying a product, Europeans gave us positive answers regarding: • 72% for Cosmetics in Closed-Window Shelf • 61% for Spirits in Closed-Window Shelf • 48% for Mobile Phones, in Closed-Window Shelf • 41% for Cosmetics with Plastic Safer • 15% for Clothes with Hard Tag • 12% for Spirits with Locker As a matter of fact, Germans, French and English are particularly intolerant to closed window shelves. * Could this protection system prevent you from buying the product…? (On 5 pts scale Top 2 Boxes Scores (total of respondents answering ‘all the time’ and ‘most of the time’’) © 2005 BearingPoint, Inc. 22 PHASE 2 : Evaluate technical solutions I. comparing anti-theft solutions Conclusions • Consumers do have expectations on Protection Systems, these expectations being, in some cases, fundamental and acting as purchase facilitators or barriers. • The most important dimensions an Anti-Theft Solution must deliver against are: • ACCESSIBILITY: Key dimension for all category of goods • NOT DAMAGING: Particularly determining on Textile and Shoes • NOT TIME WASTING: Especially true for Clothes, Cosmetics & Spirits purchases • From a consumer point of view, the protection system is integrated in the mix, as an extension of the packaging. Just like any other part of the pack, it impacts consumers perception of the product. => For all these reasons, Invisible Protection Systems, such as Source Tagging, should definitely be prioritized, being only perceived positively by consumers. © 2005 BearingPoint, Inc. 23 PHASE 2 : Evaluate technical solutions II. Source tagging : different technologies on the market The EAS technologies on the market today are the following RF works at 8,2 MHz Radiofrequency signal Frequency variation is between 7,2 – 9,0 MHz Other frequencies exist but disappear 8,2 MHz is the worldwide standard for source tagging in RF EM works with a low frequency electromagnetic field signal Frequency variation between 5 – 12,5 KHz Different types of EM technology co - exist which are not fully compatible AM works with an electromagnetic field signal at 58 KHz . Based on principle of causing vibration of two metal plates inside the target (called magneto strictive effect and which is picked up ‘ acoustically’ ) Frequency variation is very small © 2005 BearingPoint, Inc. 24 PHASE 2 : Evaluate technical solutions II. Functionalities/ SW analysis of each technology Performance of main EAS technologies per key criteria Technologies Labels Aisle Width Detection Integrity Deactivation Total AM 3 5 4 3 15 EM (Harmonic) EM (Barkhausen) EM (Intermodulation) 2 3 5 2 2 3 2 3 4 1 1 2 7 9 14 RF (Swept) RF (P/L) 4 4 3 4 3 4 4 5 14 17 => Source tagging: fast & reliable deactivation is key © 2005 BearingPoint, Inc. 25 PHASE 2 : Evaluate technical solutions IV. Usage of EAS technologies in the market Major market shifts in EAS technology since 2005. Who has recently chosen for NDRF and why? Carrefour: all hypermarkets go NDRF (globally) Source tagging program Metro Group global (C&C, Real , Media Markt): decision taken to go NDRF Source tagging & migration path to RFID AHOLD: (Albert Heyn, HyperNova, AHOLD USA etc) NDRF Deactivation reliability & source tagging Tesco in Asia goes NDRF Deactivation reliability & source tagging Auchan, CORA: go bitechnology RF – EM due to: Alignment with source tagging in RF + small items tagging at store level in EM Delhaize Group has also chosen RF © 2005 BearingPoint, Inc. 26 PHASE 2 : Evaluate technical solutions IV. Usage of EAS technologies in the market Survey in Belgium by Fedis in Sept 2006 In total, 34 respondants (cross sector) 6 companies with source tagging in use already • Sport, Brico, Electro, Food (C4, DLL, Metro) 23 companies with source tagging in the future • 4 companies foresee source tagging on all products (Brico, Electro, Textile, Computer) • 8 companies do not foresee explicitly source tagging in the future © 2005 BearingPoint, Inc. 27 PHASE 2 : Evaluate technical solutions IV. Usage of EAS technologies in the market Survey in Belgium by Fedis in Sept 2006 Technology long term RFID : electro, computer, food Current technology choice = 23 RF : shoes, textile, food (C4, DLL, Metro, Match) > 10 EM : brico, sport, books, textile, computer > 8 AM : electro, garden, textile, perfume > 5 Future technology choice = 23 RF : shoes, textile, perfume, electro, food (C4, DLL, Metro, Match) > 14 EM : brico, sport, books, textile, computer > 6 (2 to RF) AM : electro, garden, textile > 3 (2 to RF) © 2005 BearingPoint, Inc. 28 PHASE 2 : Evaluate technical solutions V. Evaluation of implications for implementation EAS does not solve everything: Like all good technology it depends on: Reliability of the equipment Consistency in your processes and the 20 / 80 rule (ECR: sell more, lose less) A balanced combination between • automated processes ( like source tagging ) • human interaction (understanding how it works, alertness, deterrence) and enforcement (compliance and vigilance when alarming) Labour cost management • Low operation costs • Maximizing people’s efficiency EAS is not a stand alone solution, implementation procedures need to be taken into account to make it a real success. But using EAS in a right way can make a big € difference ! © 2005 BearingPoint, Inc. 29 PHASE 2 : Evaluate technical solutions VI. Cost Benefits Analysis/Benefits Sharing • Costs • 15 to 45 € per 1.000 tags • 30.000 € for an applicator (20.000 labels/min) if no use yet for promotions • Blisters or adaptations of packaging but depending on technology, information needs, marketing • Benefits WIN-WIN-WIN • Retailer: no manual handling, less theft • Supplier: less out of stocks, better (open) merchandising and visibility • Consumer: less out of stocks, better merchandising and visibility, better availability (less waiting) • General: open merchandising = 30% sales increase (pilots USA) • Cost sharing on the basis of 50/50 between retailer and supplier since both win or invoicing of additional cost (cfr Scandinavian model) © 2005 BearingPoint, Inc. 30 Next Steps PHASE 3: Pilot and measure • Share information (Fedis, ECR database?) at a detailed level and focus on a very limited number of hot items per Product Category that really cause the problem •Alcohol: •Johnny Walker 75cl red label, J&B 75cl, Gordon Gin 75cl, Smirnoff 75cl white, Bacardi 75cl white, Laurent Perrier 75cl brut •L’Oreal: • top 5 products •Gillette: • top 5 products •Duracell and Energizer: • AA batteries •DIM •Cartridges HP •DVDs: • top 10 sellers for the moment and their loss percentages • Set up a pilot between 1 retailer - 1 supplier for an item that is in closed merchandising • Set up a pilot between 1 retailer - 1 supplier for an item that is not source tagged but in open merchandising • Measure results and describe procedures, Best Practices © 2005 BearingPoint, Inc. 31 Next Steps PHASE 4: Deployment • Design the Roadmap: • technology, • list products, • timeframe, • cost/benefits, • procedures, • international standards © 2005 BearingPoint, Inc. 32 Questions & Answers © 2005 BearingPoint, Inc. 33