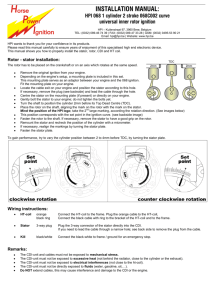

Class09b short 1

advertisement

Design of a Multi-Stage Compressor Motivation: Market research has shown the need for a low-cost turbojet with a take-off thrust of 12,000N. Preliminary studies will show that a single-spool all-axial flow machine is OK, using a low pressure ratio and modest turbine inlet temperatures to keep cost down. Problem: Design a suitable compressor operating at sea-level static conditions with • compressor pressure ratio = 4.15 • air mass flow = 20 kg/s • turbine inlet temperature = 1100K Assume: Pamb = 1.01 bar, Tamb = 288 K Inlet rhub / rtip = 0.5 Mean radius is constant Polytropic efficiency = 0.90 Constant axial velocity design No swirl at exit of compressor Utip = 350 m/s Compressor has no inlet guide vanes R 0.287 kJ kg 0 K c p 1.005 1.4 kJ kg 0 K 1 Steps in the Meanline Design Process Steps 1) Choice of rotational speed and annulus dimensions 2) Determine number of stages, using assumed efficiency 3) Calculate air angles for each stage at the mean radius meanline analysis 4) Determine variation of the air angles from root to tip - radial equilibrium 5) Investigate compressibility effects 6) Select compressor blading, using experimentally obtained cascade data or CFD 7) Check on efficiency previously assumed 8) Estimate off-design performance 2 Compressor Meanline Design Process Given Assume PR p0 , T0 m p T0in turbine Cx constant 1 0 U T 350 mps Steps 1) Choose Cx1 and rH/rT to satisfy m and keep Mtip low and define rT 2) Select N from rT and UT 3) Compute T0 across compressor and all exit flow conditions [keep rm same through engine] 4) Estimate T0 for first stage from inlet condtions [Euler and de Haller] 5) Select number of stages T0comp / T0stage 6) ….. 7) ….. 3 Step 1- Choice of Rotational Speed & Annulus Dimensions • Construct table of inlet / exit properties and parametric study of c1x vs. tip Mach number [next chart] • Chose c1x from spread sheet to avoid high tip Mach numbers and stresses • Calculate 1 from inlet static pressure and temperature • With mass flow = 20 kg/s and rhub/rtip = 0.5 and compute rotational speed and tip Mach number • Choose N = 250 rev/sec or 15,000 RPM and rhub/rtip = 0.5, calculated rhub, rtip, rmean 4 Calculate Tip Radius and Rotational Speed Drive choice by compressor inlet conditions Cx T1 (degK) P1 (bar) P1 (kg/m2) rho1(kg/m3) rtip (m) rhub/rtip N rev/sec N (rpm) W1tip M1tip 100 283.0226 0.950214 9692.1879 1.17103756 0.254398876 0.4 218.9643 13137.86 364.0055 1.079401 0.261089548 0.45 213.3531 12801.19 0.269230464 0.5 206.9018 12414.11 0.279178986 0.55 199.5289 11971.73 0.291450527 0.6 191.1277 11467.66 150 276.8009 0.879091 8966.7278 1.10773699 0.213568228 0.4 260.8266 15649.6 380.7887 1.141789 0.219185056 0.45 254.1427 15248.56 0.226019368 0.5 246.458 14787.48 Pick this 0.234371166 0.55 237.6755 14260.53 0.244673143 0.6 227.6681 13660.09 200 268.0905 0.786018 8017.3822 1.0226367 0.192497422 0.4 289.3767 17362.6 403.1129 1.228207 0.19756009 0.45 281.9612 16917.67 0.203720123 0.5 273.4353 16406.12 0.211247926 0.55 263.6915 15821.49 0.220533502 0.6 252.5887 15155.32 250 256.8913 0.676972 6905.1159 0.91916112 0.181607916 0.4 306.7282 18403.69 430.1163 1.338742 0.186384191 0.45 298.868 17932.08 0.192195753 0.5 289.8309 17389.86 0.199297711 0.55 279.5028 16770.17 0.208058005 0.6 267.7344 16064.06 5 Compressor Meanline Design • c1x chosen to avoid high tip Mach numbers and stresses • Calculate compressor inlet details (1) • Given: m, Utip, p01, T01, Pr, poly calculate compressor exit details including Aexit, h exit (2) • Calculate 1 from U, Cx • Calculate W2=0.72W1, 2 from Cx, W2 • From Euler, 1 and 2, calculate T0-12 6 Step 3-Choose Number of Stages • Given poly and T0out/T0in T0 = T0out -T0in, so the number of stages is T0 compressor / T0stage = 164.5/28 = 5.9 • To be conservative (account for losses, i.e. a<1), – Choose 7 stages • Recalculate the T0stage = 164.5/7 = 23.5 • Calculate 1st stage temperature ratio is T0 ratio and pressure ratio 7 Step 3 - Calculate Velocity Triangles of 1st Stage at Mean Radius [Rm] • Use Euler Turbine Equation to recalculate 2 and check de Haller • Calculate 1st stage rotor exit conditions [2] • Calculate Reaction [R1=0.84, high] • Consider the stator of the 1st stage, assume “repeating stage”, then inlet angle to stator [α1=0] is absolute air angle coming out of rotor [α3] and, exit absolute angle of stator is inlet absolute angle of rotor W2 C2 W1 U C1 Constant Cx Velocity Triangles of 1st Stage Using “Repeating Stage” Assumption 1=0 Cx1=150 W=C-U 1=60.64 W1=305.9 U=- WU1 =266.6 Notice that the velocity triangles are not “symmetric” between the rotor and stator due to the high reaction design of the rotor. The rotor is doing most of the static pressure (temperature) rise. STATOR 3=0 Cx3=150 3=60.64 C2=174.21 2=30.57 ROTOR CU2=88.6 Cx2=150 2=49.89 W3=305.9 U=266.6 U=266.6 WU2=178.0 W2=232.77 9 Stage Design Repeats for Stages 2-7 • Then the mean radius velocity triangles “essentially” stay the same for stages 2-7, provided: – mean radius stays constant – hub/tip radius ratio and annulus area at the exit of each stage varies to account for compressibility (density variation) – stage temperature rise stays constant – reaction stays constant • If, however, we deviate from the “repeating stage” assumption, we have more flexibility in controlling each stage reaction and temperature rise. 10 Non- “Repeating Stage” Design Strategy • Instead of taking a constant temperature rise T0stage 23.5 across each stage, we could reduce the stage temperature rise for the first and last stages of the compressor and increase it for the middle stages. This strategy is typically used to: – reduce the loading of the first stage to allow for a wide variation in angle of attack due to various aircraft flight conditions – reduce the turning required in the last stage to provide for zero swirl flow going into the combustor • With this in mind, lets change the work distribution in the compressor to: T0stage 20.0 1 T0stage 25.0 2, 3, 4, 5, 6 T0stage 20.0 7 11 Velocity Triangles of 1st Rotor Using “NonRepeating Stage” Assumption 1=0 Cx1=150 W=C-U 1=60.64 W1=305.9 Notice that the velocity triangles are not “symmetric” due to the high reaction design of the rotor. Also, there is swirl now leaving the stator. U=- WU1 =266.6 C3=153.56 STATOR 3=12.36 Cx3=150 3=57.31 C2=167.87 2=26.68 U=266.6 CU2=75.38 Cx2=150 ROTOR 2=51.89 W2=242.03 CU3=32.87 W3=277.73 U=266.6 WU2=191.2 2 WU3=233.7 7 12 Velocity Triangles of 1st Stage Using “Repeating Stage” Assumption 1=0 Cx1=150 W=C-U 1=60.64 W1=305.9 U=- WU1 =266.6 Notice that the velocity triangles are not “symmetric” between the rotor and stator due to the high reaction design of the rotor. The rotor is doing most of the static pressure (temperature) rise. STATOR 3=0 Cx3=150 3=60.64 C2=174.21 2=30.57 ROTOR CU2=88.6 Cx2=150 2=49.89 W3=305.9 U=266.6 U=266.6 WU2=178.0 W2=232.77 13 Design of 2nd Stage Stator & 3rd Stage Rotor • Design of the 2nd stage stator and 3rd stage rotor can be done in the same manner as the 1st stage stator and 2nd stage rotor. • A choice of 50% reaction and a temperature rise of 25 degrees for the 3rd stage will lead to increased work by the stage but a more evenly balanced rotor/stator design. The velocity triangle of the stator will be a mirror of the rotor. • This stage design will then be repeated for stages 4 - 6. 14 Design of 2nd Stage Stator • The pressure ratio for the 2nd stage design with a temperature change, T0 = 25 is: T02 P02 P01 T01 P ( 1) 308 25 308 0.9 (1.4 ) .4 1.279 • So P03= P02= 1.248 (1.279) = 1.596 bar and T03= 308+25=333 0K • Now we must choose a value of 3 leaving the 2nd stage stator that provides for the desired Reaction and Work in the 3rd stage using a similar technique as previously used. 15 Design of 2nd Stage Stator & 3rd Stage • We can change 3 so that there is swirl going into the third stage and thereby reduce the reaction of our second stage design. If we design the third stage to have a reaction of 0.5, then from the equation for reaction: Rstage 3 Cx (tan 1 tan 2 ) 2U • And if we design the third stage to a temperature rise of 25 0, the Euler’s equation: UCx T0 stage 3 (tan 1 tan 2 ) cp • Which can be solved simultaneously for 1and 2 1 stage3 50.26 0 2 stage3 29.88 0 16 Velocity Triangles of 2nd Stage C3=153.56 3=12.36 W=C-U Cx3=150 3=57.31 CU3=32.87 C3=172.99 U=266.6 3=29.88 W3=277.73 STATOR WU3=233.7 7 3=50.26 U=266.6 C2=196.59 2=40.27 ROTOR Cx3=150 CU3=86.18 W3=234.63 CU2=127.07 Cx2=150 2=42.92 W2=204.86 U=266.6 WU3=180.4 2 WU2=139.5 3 Notice that the velocity triangles are not “symmetric” for the second 17 stage due to 70%reaction design but will be for 3rd stage (50% reaction). Design of Stages 4-6 • The velocity triangles of stages 4 through 6 will essentially be repeats of stage 3 since all have a 50% reaction and a temperature rise of 25 degrees. • Stagnation and static pressure as well as stagnation and static temperature of these stages will increase as you go back through the machine. • As a result, density will also change and will have to be compensated for by changing the spanwise radius difference (area) between the hub and tip (i.e. hub/tip radius ratio) 18 Velocity Triangles of Stages 3 - 6 C3=172.99 3=29.88 W=C-U Cx3=150 CU3=86.18 C3=172.99 3=50.26 3=29.88 U=266.6 Cx3=150 CU3=86.18 STATOR 3=50.26 W3=234.63 U=266.6 WU3=180.4 2 ROTOR W3=234.63 C2=234.63 2=50.26 Cx2=150 2=29.88 W2=172.99 CU2=180.42 WU3=180.4 2 U=266.6 WU2=86.18 Notice that the velocity triangles are “symmetric” due to the 19 50%reaction design. Stage 7 Design • For stage 7, we have P01= 3.65 and T01 = 433. For this our 7-stage compressor design we have – P0 exit = 4.15 * 1.01 = 4.19 bar – T0 exit = 288.0 (4.15)0.3175 = 452.5 0K • If we assume a Reaction = 0.5 for the 7th stage: Cx R stage7 (tan 1 tan 2 ) 0.5 2U T0 stage7 • or: U Cx (tan 1 tan 2 ) 19.5 cp 1stage 7 48.590 2 stage 7 32.770 20 Stage 7 Design • And from: U tan 1 tan 1 tan 2 tan 2 Cx or from symmetry of the velocity triangles for 50% reaction: 1 stage7 32.77 0 3 stage7 2 stage7 48.59 0 • Note that the absolute angles going into stage 7 have changed from those computed for stages 3 - 6 and that the exit absolute air angle leaving the compressor is 32.770. This means that a combustor pre-diffuser is required to take all of the swirl out of the flow prior to entering the combustor. 21 Summary of Compressor Design STAGE 1 2 3 4 5 6 7 1 2 3 1 2 3 Cx Cu1 C1 W1 W u1 M1 Mr1 0 12.36 29.88 29.88 29.88 29.88 32.77 26.68 40.27 50.26 50.26 50.26 50.26 48.59 12.36 29.88 29.88 29.88 29.88 29.88 32.77 -60.64 -57.31 -50.26 -50.26 -50.26 -50.26 -48.59 -51.89 -42.92 -29.88 -29.88 -29.88 -29.88 -32.77 -57.31 -50.26 -50.26 -50.26 -50.26 -50.26 -48.59 150 150 150 150 150 150 150 0 32.87 86.18 86.18 86.18 86.18 96.56 150 153.56 172.99 172.99 172.99 172.99 178.39 305.9 277.73 234.63 234.63 234.63 234.63 226.78 -266.6 -233.77 -180.42 -180.42 -180.42 -180.42 -170.08 0.449778 0.445072 0.483867 0.465906 0.449807 0.435269 0.435723 0.917248 0.804962 0.656279 0.631918 0.610083 0.590365 0.553917 STAGE 1 2 3 4 5 6 7 Cu2 C2 W2 W u2 M2 Mr2 Cu3 C3 W3 W u3 T03/T01 167.87 196.59 234.63 234.63 234.63 234.63 226.78 243.03 204.86 172.99 172.99 172.99 172.99 178.39 -191.22 -139.53 -86.18 -86.18 -86.18 -86.18 -96.56 0.488438 0.553668 0.643754 0.620713 0.599981 0.581197 0.547558 0.707125 0.576959 0.474632 0.457644 0.442359 0.42851 0.430721 32.87 86.18 86.18 86.18 86.18 86.18 96.56 153.56 172.99 172.99 172.99 172.99 172.99 178.39 277.73 234.63 234.63 234.63 234.63 234.63 226.78 -233.77 -180.42 -180.42 -180.42 -180.42 -180.42 -170.08 R 0.874 0.7 0.5 0.5 0.5 0.5 0.5 P03/P01 75.38 127.07 180.42 180.42 180.42 180.42 170.08 1.236 1.279 1.256 1.237 1.22 1.206 1.149 1.069 1.081 1.075 1.07 1.065 1.061 1.045 STAGE 1 2 3 4 5 6 7 M3 Mr3 P01 P02 P03 T01 T02 T03 0.445072 0.483867 0.465906 0.449807 0.435269 0.422056 0.425883 0.804962 0.656279 0.631918 0.610083 0.590365 0.572443 0.541407 1.01 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 4.193696 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 4.193696 288 308 333 358 383 408 433 308 333 358 383 408 433 452.5 308 333 358 383 408 433 452.5 P1 P2 P3 T1 T2 T3 0.879088 1.089637 1.360349 1.728233 2.159102 2.657034 3.20353 1.060449 1.296472 1.517622 1.913086 2.372762 2.903398 3.42041 1.08963684 1.36034905 1.72823259 2.15910202 2.65703431 3.22898653 3.70197943 276.806 296.2683 318.1117 343.1117 368.1117 393.1117 417.1677 293.9799 313.7723 330.6113 355.6113 380.6113 405.6113 426.9133 296.2683 318.1117 343.1117 368.1117 393.1117 418.1117 436.6677 22 Conditions in Compressor Temperature vs. Blade Row # 500 450 400 T0 300 250 350 T 300 250 Blade Row # 15 13 11 9 Blade Row # Stagnation Pressure vs. Blade Row # Pressure vs. Blade Row # 4 Blade Row # 15 13 11 9 7 15 13 11 9 0 7 0 5 1 3 1 Blade Row # P 2 5 P0 2 3 3 3 Pressure 4 1 5 1 Stagnation Pressure 7 1 5 200 15 13 11 9 7 5 3 200 400 3 350 Tem perature 450 1 Stagnation Tem perature Stagnation Temperature vs. Blade Row # 23 Hub & Tip Radii Distribution - Flow Path Area Hub and Tip Radii vs. Blade Row # 0.25 0.15 rtip rhub 0.1 0.05 15 13 11 9 7 5 3 0 1 Radius 0.2 Blade Row # 24