Class09b

advertisement

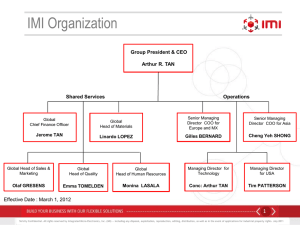

Design of a Multi-Stage Compressor Motivation: Market research has shown the need for a low-cost turbojet with a take-off thrust of 12,000N. Preliminary studies will show that a single-spool all-axial flow machine is OK, using a low pressure ratio and modest turbine inlet temperatures to keep cost down. Problem: Design a suitable compressor operating at sea-level static conditions with • compressor pressure ratio = 4.15 • air mass flow = 20 kg/s • turbine inlet temperature = 1100K Assume: Pamb = 1.01 bar, Tamb = 288 K Inlet rhub / rtip = 0.5 Mean radius is constant Polytropic efficiency = 0.90 Constant axial velocity design No swirl at exit of compressor Utip = 350 m/s Compressor has no inlet guide vanes kJ kg 0 K kJ c p 1.005 0 kg K 1.4 R 0.287 1 Steps in the Meanline Design Process Steps 1) Choice of rotational speed and annulus dimensions 2) Determine number of stages, using assumed efficiency 3) Calculate air angles for each stage at the mean radius meanline analysis 4) Determine variation of the air angles from root to tip - radial equilibrium 5) Investigate compressibility effects 6) Select compressor blading, using experimentally obtained cascade data or CFD 7) Check on efficiency previously assumed 8) Estimate off-design performance 2 Compressor Meanline Design Process Given Assume PR p0 , T0 m p T0in turbine Cx constant 1 0 U T 350 mps Steps 1) Choose Cx1 and rH/rT to satisfy m and keep Mtip low and define rT 2) Select N from rT and UT 3) Compute T0 across compressor and all exit flow conditions [keep rm same through engine] 4) Estimate T0 for first stage from inlet condtions [Euler and de Haller] 5) Select number of stages T0comp / T0stage 6) ….. 7) ….. 3 Step 1- Choice of Rotational Speed & Annulus Dimensions • Construct table of inlet / exit properties and parametric study of c1x vs. tip Mach number [next chart] • Chose c1x from spread sheet to avoid high tip Mach numbers and stresses • Calculate 1 from inlet static pressure and temperature • With mass flow = 20 kg/s and rhub/rtip = 0.5 r 2 m ACx rtip2 1 hub Cx rtip rtip2 m r 2 Cx 1 hub rtip • and compute rotational speed and tip Mach number N 2 rtip U tip M tip Wtip RT 2 where Wtip U tip C x2 4 Calculate Tip Radius and Rotational Speed Drive choice by compressor inlet conditions Cx T1 (degK) P1 (bar) P1 (kg/m2) rho1(kg/m3) rtip (m) rhub/rtip N rev/sec N (rpm) W1tip M1tip 100 283.0226 0.950214 9692.1879 1.17103756 0.254398876 0.4 218.9643 13137.86 364.0055 1.079401 0.261089548 0.45 213.3531 12801.19 0.269230464 0.5 206.9018 12414.11 0.279178986 0.55 199.5289 11971.73 0.291450527 0.6 191.1277 11467.66 150 276.8009 0.879091 8966.7278 1.10773699 0.213568228 0.4 260.8266 15649.6 380.7887 1.141789 0.219185056 0.45 254.1427 15248.56 0.226019368 0.5 246.458 14787.48 Pick this 0.234371166 0.55 237.6755 14260.53 0.244673143 0.6 227.6681 13660.09 200 268.0905 0.786018 8017.3822 1.0226367 0.192497422 0.4 289.3767 17362.6 403.1129 1.228207 0.19756009 0.45 281.9612 16917.67 0.203720123 0.5 273.4353 16406.12 0.211247926 0.55 263.6915 15821.49 0.220533502 0.6 252.5887 15155.32 250 256.8913 0.676972 6905.1159 0.91916112 0.181607916 0.4 306.7282 18403.69 430.1163 1.338742 0.186384191 0.45 298.868 17932.08 0.192195753 0.5 289.8309 17389.86 0.199297711 0.55 279.5028 16770.17 0.208058005 0.6 267.7344 16064.06 5 Compute Root (Hub) and Mean Radius • Choose N = 250 rev/sec or 15,000 RPM and rhub/rtip = 0.5 • With hub/tip radius ratio and tip radius: rhub rhub rtip 0.5 0 .2262 0.1131 m rtip and rmean 0.1697 m U1 2 r1 N 266.6 m / s 60 6 Compressor Meanline Design • Given: m, Utip, p01, T01, Pr, poly and c1x chosen to avoid high tip Mach numbers and stresses • Compressor inlet (1) T1 1 p1 p01 T01 2 1x C T1 T01 2c p 1 p1 RT1 1/ 2 m RT 2 RH c 1 1 1x R T RH 1 RH RT R RH RT m R 2 T Ctip 2 C12x U tip 1/ 2 M tip Select RH/RT and Utip (N) for turbine issues N U tip 2 RT Ctip RT1 1/ 2 7 Compressor Meanline Design • Compressor exit (2) T02 T01 Pr poly 1 p02 p01 Pr C x2 T2 T02 2c p T2 1 p2 p2 p02 2 RT2 T01 m A2 2C x A2 blade height at exit h RT RH 2 Rm 8 Compute Compressor Exit Conditions • Compute Compressor Exit Total Temperature P02 T02 T01 P01 ( 1) p • so that T02 = 288.0 (4.15)0.3175 = 452.5 0K, T0 compressor= 452.5 - 288.0 = 164.5 0K and other conditions: C2 1502 T2 T02 452.5 441.3 3 2c p 2 1.005 x10 T2 ( P2 P02 T02 1) 441.3 4.19 452.5 0 K 3.5 3.838 bar kg 3.838bar 10200 2 P2 m bar 2 3.03 kg / m3 kJ kg m RT2 0 0.287 102 441.3 K kg 0 K kJ 9 Compute Compressor Exit Conditions • Exit area, hub and tip radius: 20 m 0.044 m 2 A2 2Cx 3.031150 r rtip rhub 0.044 A2 0.0413 m 2 0.1697 2 rmean 0.0413 r 0.1903 m 0.1697 rtip rmean 2 2 0.0413 r 0.1491 m 0.1697 rhub rmean 2 2 10 Step 2 - Estimate the Number of Stages • From Euler’s Turbine Equation: T0stage U (CU 2 CU 1 ) UCx (tan 2 tan 1 ) cP cp and (tan 2 tan 1 ) (tan 1 tan 2 ) WU Cx tan( ) CU Cx tan( ) U1 2 r1 N 266.6 m / s 60 • With no inlet guide vane (Cu1=0, 1 = 0, and Wu1= -U), the relative flow angle is: tan( 1 ) U 266.6 1 60.640 Cx 150 • And the relative inlet velocity to the 1st rotor is: W1 Cx 150 305.9 m / s cos( 1 ) cos(60.64) 11 Maximum Diffusion Across Compressor Blade-Row • There are various max. diffusion criteria. Every engine company has it’s own rules. Lieblein’s rule is one example. Another such rule is the de Haller criterion that states: W2 0.72 1.0 W1 Note that de Haller’s criterion is simpler than Lieblein’s rule since it does not involve relative circumferential velocities or solidity. To first order, this is same as a 0<Dfactor<~0.4. Could use Lieblein’s rule but would have to iterate. • This criteria can also take the form of max. pressure ratio with correlations for relative total pressure loss across the blade row as a function of Mach number, incidence, thickness/chord, etc. Taking the maximum diffusion (de Haller), leads to: W2 0.72 W1 0.72 305.9 220 m / s cos( 2 ) T0stage U (CU 2 CU 1 ) cP C x 150 2 47.010 W2 220 266.6 150 (tan(60.64) tan(47.01)) 0 28 K 3 12 1.005 x10 Choose Number of Stages • Given poly and T0out/T0in T0 = T0out -T0in, so the number of stages is T0 compressor / T0stage = 164.5/28 = 5.9 • Typically (T0)stage 40K (subsonic) - 100K (transonic) • Therefore we choose to use six or seven stages. To be conservative (account for losses, ie. a<1), – Choose 7 stages • Recalculate the T0stage = 164.5/7 = 23.5 • So 1st stage temperature ratio is T0 ratio = 288 + 23.5/288 =1.0816 • The stage pressure ratio is then P0 ratio = (T0 ratio ) p / 1 = 1.2803 13 Compressor Meanline Design Develop estimate of the number of stages • Assuming Cx = constant Cx T0 stage – – – – – cp tan 1 tan 2 for axial inflow tan1 = Um/Cx V1 = Cx / cos 1 de Haller criterion (like Dfactor) V2/V1 0.72 cos 2 = Cx/V2 neglect work done factor (=1) (T0)stage = …. – (T0)stage Nstages T0out -T0in – Select Nstages and select nearly constant set of (T0)stage Develop Stage by Stage Design • Assume that continual blockage buildup due to boundary layers reduces work done, therefore stage 1 2 3 4 5 6 7 0.98 0.93 0.88 0.83 0.83 0.83 0.83 14 Compressor Meanline Design Develop Stage by Stage Design • C = absolute velocity, CU = absolute velocity in U direction CU 1 0 axial inf low tan 1 tan 2 Um cx U m CU cx W2 C2 c p T0 U m cx Um C1 Constant Cx W1 U 15 Step 3 - Calculate Velocity Triangles of 1st Stage at Mean Radius • So from Euler Turbine Equation: T0stage U (CU 2 CU 1 ) UCx (tan 2 tan 1 ) 23.5 cP cp • We can re-calculate the relative angles for the 1st stage: 1 0 tan 2 c p T0 stage UCx tan( 1 ) 1.005 x103 (23.5) 2 30.57 0 266.6 150 U 266.6 1 60.640 Cx 150 tan( 1 ) tan( 2 ) tan( 2 ) tan(1 ) 2 49.890 which leads to : W2 0.76 (acceptable according to de Haller criterion) W1 16 Velocity Components and Reaction of 1st Stage • The velocity components for the 1st stage (rotor) are therefore: C x 2 150 m / s C x 150 m / s CU 2 C x 2 tan 2 88.6 m / s CU 1 0.0 C1 150 m / s C 2 C x2 CU2 2 174.21 m / s U 1 266.6 m / s U 2 266.6 m / s WU 1 U 1 266.6 m / s WU 2 CU 2 U 2 178.0 m / s W1 C x2 WU21 305.9 m / s W2 C x2 WU22 232.77 m / s • The Reaction of the 1st stage is given by: Wu 2 Wu1 266.6 190.31 0.836 2U 2 (266.6) (which is high for typica l designs) R 17 Velocity Components for Stator of 1st Stage • Now consider the stator of the 1st stage. The h0 of the stator is zero so from Euler’s eqn.: • If design uses assumption of “repeating stage”, then inlet angle to stator is absolute air angle coming out of rotor and, exit absolute angle of stator is inlet absolute angle of rotor: CU 1 CU 3 0 Cx 3 Cx 2 U 0 for stator, so WU 3 0 1 stator 1 stator 2 rotor 2 stator 2 stator 1 rotor 18 Velocity Triangles of 1st Stage Using “Repeating Stage” Assumption 1=0 Cx1=150 W=C-U 1=60.64 W1=305.9 U=- WU1 =266.6 Notice that the velocity triangles are not “symmetric” between the rotor and stator due to the high reaction design of the rotor. The rotor is doing most of the static pressure (temperature) rise. STATOR 3=0 Cx3=150 3=60.64 C2=174.21 2=30.57 ROTOR CU2=88.6 Cx2=150 2=49.89 W3=305.9 U=266.6 U=266.6 WU2=178.0 W2=232.77 19 Stage Design Repeats for Stages 2-7 • Then the mean radius velocity triangles “essentially” stay the same for stages 2-7, provided: – mean radius stays constant – hub/tip radius ratio and annulus area at the exit of each stage varies to account for compressibility (density variation) – stage temperature rise stays constant – reaction stays constant • If, however, we deviate from the “repeating stage” assumption, we have more flexibility in controlling each stage reaction and temperature rise. 20 Non- “Repeating Stage” Design Strategy • Instead of taking a constant temperature rise T0stage 23.5 across each stage, we could reduce the stage temperature rise for the first and last stages of the compressor and increase it for the middle stages. This strategy is typically used to: – reduce the loading of the first stage to allow for a wide variation in angle of attack due to various aircraft flight conditions – reduce the turning required in the last stage to provide for zero swirl flow going into the combustor • With this in mind, lets change the work distribution in the compressor to: T0stage 20.0 1 T0stage 25.0 2, 3, 4, 5, 6 T0stage 20.0 7 21 1st Stage Design for “Non-Repeating Stages” • We can re-calculate the relative angles for the 1st stage: 1 0 tan 2 c p T0 stage UCx 1.005 x103 (20) 2 26.68 0 266.6 150 U 266.6 tan( 1 ) 1 60.640 (same as before) Cx 150 tan( 1 ) tan( 2 ) tan( 2 ) tan(1 ) 2 51.890 which leads to : W2 0.79 (still acceptable , i.e. 0.72) W1 (also note the reduced turning due to the reduced work requiremen t) 22 Velocity Components and Reaction of 1st Stage with Non-Repeating Stages • The new velocity components for the 1st stage (rotor) are therefore: C x 2 150 m / s C x 150 m / s CU 2 C x 2 tan 2 75.38 m / s CU 1 0.0 C 2 C x2 CU2 2 167.87 m / s C1 150 m / s U 2 266.6 m / s U 1 266.6 m / s WU 1 U 1 266.6 m / s WU 2 CU 2 U 2 191.22 m / s W1 C W W2 C x2 WU22 243.03 m / s 2 x 2 U1 305.9 m / s • The Reaction of the 1st stage is given by: R Wu 2 Wu1 2U 266.6 190.31 0.859 2 (266.6) with the assumption that C 3 C1 . (note that the reaction increased) 23 Design of 1st Stage Stator • The pressure ratio for this design with a temperature change, T0 = 20 is: T02 P02 P01 T01 P ( 1) 288 20 288 0.9 (1.4 ) .4 1.236 • So P03= P02 = 1.01 (1.236) = 1.248 bar and T03= 288+20=308 0K • Now we must choose a value of 3 leaving the stator. – When we designed with repeating stages, 3= 1. – But now we have the flexibility to change 3. 24 Design of the 1st Stage Stator & the 2nd Stage • Change 3 so that there is swirl going into the second stage and thereby reduce the reaction of our second stage design. • Design the second stage to have a reaction of 0.7, then from the equation for reaction: Rstage 2 Cx (tan 1 tan 2 ) 2U • And if we design the second stage to a temperature rise of 25 0, the Euler’s equation: T0 stage 2 UCx (tan 1 tan 2 ) cp • Which can be solved simultaneously for 1and 2 1 stage2 57.310 2 stage2 42.92 0 25 Design of 1st Stage Stator & 2nd Stage Rotor • Note that this is the same as specifying E, n, and R as in one of your homeworks and computing the angles. • And the absolute flow angles of the second stage can be found from U tan 1 tan 1 tan 2 tan 2 Cx • So 1 stage2 12.36 0 3 stage1 2 stage2 40.27 0 • Therefore, we have determined the velocity triangles of the 1st stage stator and the second stage rotor 26 Velocity Triangles of 1st Rotor Using “NonRepeating Stage” Assumption 1=0 Cx1=150 W=C-U 1=60.64 W1=305.9 Notice that the velocity triangles are not “symmetric” due to the high reaction design of the rotor. Also, there is swirl now leaving the stator. U=- WU1 =266.6 C3=153.56 STATOR 3=12.36 Cx3=150 3=57.31 C2=167.87 2=26.68 U=266.6 CU2=75.38 Cx2=150 ROTOR 2=51.89 W2=242.03 CU3=32.87 W3=277.73 U=266.6 WU2=191.2 2 WU3=233.7 7 27 Design of 2nd Stage Stator & 3rd Stage Rotor • Design of the 2nd stage stator and 3rd stage rotor can be done in the same manner as the 1st stage stator and 2nd stage rotor. • A choice of 50% reaction and a temperature rise of 25 degrees for the 3rd stage will lead to increased work by the stage but a more evenly balanced rotor/stator design. The velocity triangle of the stator will be a mirror of the rotor. • This stage design will then be repeated for stages 4 - 6. 28 Class 12 - The 7-Stage Compressor Design So Far Has Lead to 1st and 2nd Stages: STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 1 2 3 1 2 3 Cx Cu1 C1 W1 W u1 0 12.36 26.68 40.27 12.36 60.64 57.31 -51.89 -42.92 -57.31 150 150 0 32.87 150 153.56 305.9 277.73 -266.6 -233.77 M2 Mr2 Cu2 C2 W2 W u2 75.38 127.07 167.87 196.59 243.03 204.86 -191.22 -139.53 M3 Mr3 P01 P02 0.445072 0.804962 1.01 1.248 1.248 1.596 0.488438 0.707125 0.553668 0.576959 P03 1.248 1.596 T01 288 308 M1 Mr1 0.449778 0.917248 0.445072 0.804962 Cu3 C3 W3 W u3 T03/T01 153.56 277.73 -233.77 R 0.874 0.7 P03/P01 32.87 1.236 1.279 1.069 1.081 T02 T03 P1 P2 P3 T1 T2 308 333 T3 308 0.879088 1.060143 1.08932261 276.806 293.9799 296.2683 333 1.089323 1.295942 296.2683 313.7723 29 Design of 2nd Stage Stator • The pressure ratio for the 2nd stage design with a temperature change, T0 = 25 is: T02 P02 P01 T01 P ( 1) 308 25 308 0.9 (1.4 ) .4 1.279 • So P03= P02= 1.248 (1.279) = 1.596 bar and T03= 308+25=333 0K • Now we must choose a value of 3 leaving the 2nd stage stator that provides for the desired Reaction and Work in the 3rd stage using a similar technique as previously used. 30 Design of 2nd Stage Stator & 3rd Stage • We can change 3 so that there is swirl going into the third stage and thereby reduce the reaction of our second stage design. If we design the third stage to have a reaction of 0.5, then from the equation for reaction: Rstage 3 Cx (tan 1 tan 2 ) 2U • And if we design the third stage to a temperature rise of 25 0, the Euler’s equation: T0 stage 3 UCx (tan 1 tan 2 ) cp • Which can be solved simultaneously for 1and 2 1 stage3 50.26 0 2 stage3 29.88 0 31 Design of 2nd Stage Stator & 3rd Stage Rotor • And the absolute flow angles of the second stage can be found from U Cx • So tan 1 tan 1 tan 2 tan 2 1 stage3 29.88 0 3 stage2 1 stage3 50.26 0 2 stage3 50.26 0 2 stage3 29.88 0 • Note the symmetry in angles for 3rd stage due to the 50% reaction ! • Therefore, we have determined the velocity triangles of the 2nd stage stator and the third stage rotor. Check the de Haller number for the 3rd stage rotor: W2 cos 1 .74 which is OK W1 cos 2 32 Velocity Triangles of 2nd Stage C3=153.56 3=12.36 W=C-U Cx3=150 3=57.31 CU3=32.87 C3=172.99 U=266.6 3=29.88 W3=277.73 STATOR WU3=233.7 7 3=50.26 U=266.6 C2=196.59 2=40.27 ROTOR Cx3=150 CU3=86.18 W3=234.63 CU2=127.07 Cx2=150 2=42.92 W2=204.86 U=266.6 WU3=180.4 2 WU2=139.5 3 Notice that the velocity triangles are not “symmetric” for the second 33 stage due to 70%reaction design but will be for 3rd stage (50% reaction). Summary of Conditions for Stages 1 - 3 STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 1 2 3 1 2 3 Cx Cu1 C1 W1 W u1 0 12.36 29.88 26.68 40.27 50.26 12.36 29.88 29.88 -60.64 -57.31 -50.26 -51.89 -42.92 -29.88 -57.31 -50.26 -50.26 150 150 150 0 32.87 86.18 150 153.56 172.99 305.9 277.73 234.63 -266.6 -233.77 180.42 Cu2 C2 W2 W u2 M2 Mr2 Cu3 C3 W3 W u3 P03/P01 T03/T01 75.38 127.07 180.42 167.87 196.59 234.63 243.03 204.86 172.99 -191.22 -139.53 -86.18 32.87 86.18 86.18 153.56 172.99 172.99 277.73 234.63 234.63 -233.77 -180.42 -180.42 R 0.874 0.7 0.5 1.236 1.279 1.256 1.069 1.081 1.075 M3 Mr3 P01 P02 T02 T03 P1 P2 P3 T1 T2 0.445072 0.804962 0.483867 0.656279 0.465906 0.631918 1.01 1.248 1.596 1.248 1.596 2.005 0.488438 0.707125 0.553668 0.576959 0.643754 0.474632 P03 1.248 1.596 2.005 T01 288 308 333 308 333 358 M1 Mr1 0.449778 0.917248 0.445072 0.804962 0.483867 0.656279 T3 308 0.879088 1.060143 1.08932261 276.806 293.9799 296.2683 333 1.089323 1.295942 1.35979317 296.2683 313.7723 318.1117 358 1.359793 1.517323 1.72789178 318.1117 330.6113 343.1117 34 Design of Stages 4-6 • The velocity triangles of stages 4 through 6 will essentially be repeats of stage 3 since all have a 50% reaction and a temperature rise of 25 degrees. • Stagnation and static pressure as well as stagnation and static temperature of these stages will increase as you go back through the machine. • As a result, density will also change and will have to be compensated for by changing the spanwise radius difference (area) between the hub and tip (i.e. hub/tip radius ratio) 35 Velocity Triangles of Stages 3 - 6 C3=172.99 3=29.88 W=C-U Cx3=150 CU3=86.18 C3=172.99 3=50.26 3=29.88 U=266.6 Cx3=150 CU3=86.18 STATOR 3=50.26 W3=234.63 U=266.6 WU3=180.4 2 ROTOR W3=234.63 C2=234.63 2=50.26 Cx2=150 2=29.88 W2=172.99 CU2=180.42 WU3=180.4 2 U=266.6 WU2=86.18 Notice that the velocity triangles are “symmetric” due to the 36 50%reaction design. Summary of Conditions for Stages 1 - 6 STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 STAGE 1 2 3 4 5 6 7 1 2 3 1 2 3 Cx Cu1 C1 W1 W u1 M1 Mr1 0 12.36 29.88 29.88 29.88 29.88 26.68 40.27 50.26 50.26 50.26 50.26 12.36 29.88 29.88 29.88 29.88 29.88 -60.64 -57.31 -50.26 -50.26 -50.26 -50.26 -51.89 -42.92 -29.88 -29.88 -29.88 -29.88 -57.31 -50.26 -50.26 -50.26 -50.26 -50.26 150 150 150 150 150 150 0 32.87 86.18 86.18 86.18 86.18 150 153.56 172.99 172.99 172.99 172.99 305.9 277.73 234.63 234.63 234.63 234.63 -266.6 -233.77 180.42 180.42 180.42 180.42 0.449778 0.445072 0.483867 0.465906 0.449807 0.435269 0.917248 0.804962 0.656279 0.631918 0.610083 0.590365 Cu2 C2 W2 W u2 M2 Mr2 Cu3 C3 W3 W u3 P03/P01 T03/T01 75.38 127.07 180.42 180.42 180.42 180.42 167.87 196.59 234.63 234.63 234.63 234.63 243.03 204.86 172.99 172.99 172.99 172.99 -191.22 -139.53 -86.18 -86.18 -86.18 -86.18 0.488438 0.553668 0.643754 0.620713 0.599981 0.581197 0.707125 0.576959 0.474632 0.457644 0.442359 0.42851 32.87 86.18 86.18 86.18 86.18 86.18 153.56 172.99 172.99 172.99 172.99 172.99 277.73 234.63 234.63 234.63 234.63 234.63 -233.77 -180.42 -180.42 -180.42 -180.42 -180.42 R 0.874 0.7 0.5 0.5 0.5 0.5 1.236 1.279 1.256 1.237 1.22 1.206 1.069 1.081 1.075 1.07 1.065 1.061 M3 Mr3 P01 P02 P03 T01 T02 T03 P1 P2 P3 T1 T2 T3 0.445072 0.483867 0.465906 0.449807 0.435269 0.422056 0.804962 0.656279 0.631918 0.610083 0.590365 0.572443 1.01 1.24836 1.596652 2.005395 2.480674 3.026423 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 0.879088 1.089637 1.360349 1.728233 2.159102 2.657034 1.060449 1.296472 1.517622 1.913086 2.372762 2.903398 1.08963684 1.36034905 1.72823259 2.15910202 2.65703431 3.22898653 276.806 296.2683 318.1117 343.1117 368.1117 393.1117 293.9799 313.7723 330.6113 355.6113 380.6113 405.6113 296.2683 318.1117 343.1117 368.1117 393.1117 418.1117 288 308 333 358 383 408 308 333 358 383 408 433 308 333 358 383 408 433 37 Stage 7 Design • So going into stage 7, we have P01= 3.65 and T01 = 433. The requirements for our 7-stage compressor design we have – P0 exit = 4.15 * 1.01 = 4.19 bar – T0 exit = 288.0 (4.15)0.3175 = 452.5 0K • This makes the requirements for stage 7: T02 452.5 1.045 or T0 452.5 433 19.5 T01 433 P02 1.045 P01 0.9 1.4 0.4 1.149 38 Stage 7 Design • If we assume a Reaction = 0.5 for the 7th stage: R stage7 T0 stage7 Cx (tan 1 tan 2 ) 0.5 2U U Cx (tan 1 tan 2 ) 19.5 cp • Then, solving equations: 1stage 7 48.590 2 stage 7 32.770 39 Stage 7 Design • And from: U tan 1 tan 1 tan 2 tan 2 Cx or from symmetry of the velocity triangles for 50% reaction: 1 stage7 32.77 0 3 stage7 2 stage7 48.59 0 • Note that the absolute angles going into stage 7 have changed from those computed for stages 3 - 6 and that the exit absolute air angle leaving the compressor is 32.770. This means that a combustor pre-diffuser is required to take all of the swirl out of the flow prior to entering the combustor. 40 Summary of Compressor Design STAGE 1 2 3 4 5 6 7 1 2 3 1 2 3 Cx Cu1 C1 W1 W u1 M1 Mr1 0 12.36 29.88 29.88 29.88 29.88 32.77 26.68 40.27 50.26 50.26 50.26 50.26 48.59 12.36 29.88 29.88 29.88 29.88 29.88 32.77 -60.64 -57.31 -50.26 -50.26 -50.26 -50.26 -48.59 -51.89 -42.92 -29.88 -29.88 -29.88 -29.88 -32.77 -57.31 -50.26 -50.26 -50.26 -50.26 -50.26 -48.59 150 150 150 150 150 150 150 0 32.87 86.18 86.18 86.18 86.18 96.56 150 153.56 172.99 172.99 172.99 172.99 178.39 305.9 277.73 234.63 234.63 234.63 234.63 226.78 -266.6 -233.77 -180.42 -180.42 -180.42 -180.42 -170.08 0.449778 0.445072 0.483867 0.465906 0.449807 0.435269 0.435723 0.917248 0.804962 0.656279 0.631918 0.610083 0.590365 0.553917 STAGE 1 2 3 4 5 6 7 Cu2 C2 W2 W u2 M2 Mr2 Cu3 C3 W3 W u3 T03/T01 167.87 196.59 234.63 234.63 234.63 234.63 226.78 243.03 204.86 172.99 172.99 172.99 172.99 178.39 -191.22 -139.53 -86.18 -86.18 -86.18 -86.18 -96.56 0.488438 0.553668 0.643754 0.620713 0.599981 0.581197 0.547558 0.707125 0.576959 0.474632 0.457644 0.442359 0.42851 0.430721 32.87 86.18 86.18 86.18 86.18 86.18 96.56 153.56 172.99 172.99 172.99 172.99 172.99 178.39 277.73 234.63 234.63 234.63 234.63 234.63 226.78 -233.77 -180.42 -180.42 -180.42 -180.42 -180.42 -170.08 R 0.874 0.7 0.5 0.5 0.5 0.5 0.5 P03/P01 75.38 127.07 180.42 180.42 180.42 180.42 170.08 1.236 1.279 1.256 1.237 1.22 1.206 1.149 1.069 1.081 1.075 1.07 1.065 1.061 1.045 STAGE 1 2 3 4 5 6 7 M3 Mr3 P01 P02 P03 T01 T02 T03 0.445072 0.483867 0.465906 0.449807 0.435269 0.422056 0.425883 0.804962 0.656279 0.631918 0.610083 0.590365 0.572443 0.541407 1.01 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 4.193696 1.24836 1.596652 2.005395 2.480674 3.026423 3.649866 4.193696 288 308 333 358 383 408 433 308 333 358 383 408 433 452.5 308 333 358 383 408 433 452.5 P1 P2 P3 T1 T2 T3 0.879088 1.089637 1.360349 1.728233 2.159102 2.657034 3.20353 1.060449 1.296472 1.517622 1.913086 2.372762 2.903398 3.42041 1.08963684 1.36034905 1.72823259 2.15910202 2.65703431 3.22898653 3.70197943 276.806 296.2683 318.1117 343.1117 368.1117 393.1117 417.1677 293.9799 313.7723 330.6113 355.6113 380.6113 405.6113 426.9133 296.2683 318.1117 343.1117 368.1117 393.1117 418.1117 436.6677 41 Hub and Tip Radii for Each Blade Row • From the pressure and temperature, we can compute the density from the equation of state: STAGE 1 2 3 4 5 6 7 P1 P2 P3 T1 T2 T3 0.879088 1.089637 1.360349 1.728233 2.159102 2.657034 3.20353 1.060449 1.296472 1.517622 1.913086 2.372762 2.903398 3.42041 1.089637 1.360349 1.728233 2.159102 2.657034 3.228987 3.701979 276.806 296.2683 318.1117 343.1117 368.1117 393.1117 417.1677 293.9799 313.7723 330.6113 355.6113 380.6113 405.6113 426.9133 296.2683 318.1117 343.1117 368.1117 393.1117 418.1117 436.6677 1 1.10656 1.281488 1.490009 1.755031 2.043674 2.355046 2.675693 2 3 1.25687 1.439682 1.599425 1.874463 2.172154 2.494105 2.791621 1.281488 1.490009 1.755031 2.043674 2.355046 2.690866 2.953936 42 Hub and Tip Radii for Each Blade Row • From Continuity: rtip2 m r 2 Cx 1 hub rtip • and our design value of rmean = 0.1697, rmean 0.5(rtip rhub ) 0.1697 rhub 0.3394 rtip • we can calculate the hub and tip radii (i.e. area) at the entrance and exit of each blade row: rtip2 m .3394 r tip Cx 1 rtip 2 rtip m 0.1697 Cx (.6788) 43 Hub & Tip Radii for All Stages of Compressor • So we get: Station rotor stator rotor stator rotor stator rotor stator rotor stator rotor stator rotor stator 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 P P0abs T 0.879088 1.060449 1.089637 1.296472 1.360349 1.517622 1.728233 1.913086 2.159102 2.372762 2.657034 2.903398 3.20353 3.42041 3.701979 1.01 1.24836 1.24836 1.596652 1.596652 2.005395 2.005395 2.480674 2.480674 3.026423 3.026423 3.649866 3.649866 4.193696 4.193696 276.806 293.9799 296.2683 313.7723 318.1117 330.6113 343.1117 355.6113 368.1117 380.6113 393.1117 405.6113 417.1677 426.9133 436.6677 T0abs 288 308 308 333 333 358 358 383 383 408 408 433 433 452.5 452.5 rtip rhub 0.226203 0.219446 0.21849 0.213129 0.211662 0.208792 0.205326 0.203056 0.200294 0.198484 0.196249 0.194769 0.193067 0.192097 0.190866 0.113197 0.119954 0.12091 0.126271 0.127738 0.130608 0.134074 0.136344 0.139106 0.140916 0.143151 0.144631 0.146333 0.147303 0.148534 44 Conditions in Compressor Temperature vs. Blade Row # 500 450 400 T0 300 250 350 T 300 250 Blade Row # 15 13 11 9 Blade Row # Stagnation Pressure vs. Blade Row # Pressure vs. Blade Row # 4 Blade Row # 15 13 11 9 7 15 13 11 9 0 7 0 5 1 3 1 Blade Row # P 2 5 P0 2 3 3 3 Pressure 4 1 5 1 Stagnation Pressure 7 1 5 200 15 13 11 9 7 5 3 200 400 3 350 Tem perature 450 1 Stagnation Tem perature Stagnation Temperature vs. Blade Row # 45 Hub & Tip Radii Distribution - Flow Path Area Hub and Tip Radii vs. Blade Row # 0.25 0.15 rtip rhub 0.1 0.05 15 13 11 9 7 5 3 0 1 Radius 0.2 Blade Row # 46 Spanwise Variations • Blade wheel speeds vary with radius leading to a change in velocity triangles with span for each blade row. For instance, the first blade row has rhub = .1131, rmean = .1697, rtip = .2262 m and Uhub = 177.7 , Umean = 266.6, Utip = 355.3 m/s leading to relative flow angles: 1 hub 49.83 1 mean 60.64 1 tip 67.11 1 hub 1 mean 1 tip 0 • Next, we must choose the type of radial design strategy from: • – free vortex where CU r = constant (dh0/dr = 0) – constant reaction where U CU = constant – exponential where CU1 = a - (b/R) and CU2 = a + (b/R) The exit radial pressure gradient will be different for each of the designs47 Nonisentropic Designs • Include losses (nonisentropic effects) – see Mattingly – Common Meanline (CML) – bleeds, Dfactor, shocks, compressibility, ... 48 Real World Effects • 3-Dimensional effects – radial equilibrium – free vortex designs – secondary flows • Tip speed limitations maximum blade stresses (later) • Axial velocity compressibility, shocks, losses • High flow deflection Dfactor, de Haller, Carter’s rule • Blockage (Kbar) due to boundary layers work done factor 49 Axisymmetric Flow Analyses F Vdv V V dA t • Consider axisymmetric flows [ / 0 ] and steady flow [ / t 0 ] • In the radial direction, CU2 CS2 dCs cos s sin s rdrd Fr rs dt r 1 centripetal force due to circumferential flow 2 force due to streamline curvature 3 force for linear acceleration along streamline where Fr pdA r 50 Radial Equilibrium P+dp Mass = dm = r d dr dr CU P+1/2 dp P+1/2 dp P r If Cr=0 and Pressure Balances Centrifugal Forces, and streamline curvature effects neglected then: d 1 d dmCU2 p dp r dr d prd 2( p dp)dr 51 2 2 r Simple Radial Equilibrium • So from the radial momentum equation: dmCU2 1 p dp r dr d prd ( p dp)drd 2 r • reduces to: 1 dp CU2 dr r Radial equilibrium equation 1 dp CU2 dh ds T dr r dr dr • Tds/dr represents the spanwise variation in relative loss. If this is assumed to be zero, then (Simple Radial Equilibrium Equation with Cr=0): 1 dp C 2 dh dr U r dr 52 Simple Radial Equilibrium • Now: C x2 CU2 C2 h0 h h 2 2 • So that we get (vortex energy equation): dh0 CU2 dCx dCU Cx CU dr r dr dr • If dh0/dr = 0 (work is constant with r) and we assume that CX=constant as a function of span, then: CU2 dCU CU d (rCU ) CU 0 r dr r dr 53 Simple Radial Equilibrium • One important variations / solutions to this equation CU d (rCU ) 0 r dr – Free vortex flow CU dCU r dr • dCU dr or CU r constant CU r Later we will see more general form of this equaion will lead to another solution for forced vortex flow CU constant r 54 Consider Free Vortex Design for 1st Stage Rotor • CU r = constant so that: rmean CUtip CUmean rtip rmean CUhub CUmean r hub • So that at the exit of the first stage rotor we have: .1697 CU 2 tip 75.38 58.3 .2194 .1697 CU 2 hub 75.38 106.6 .12 1 58.3 0 tan 21.24 tip 150 106.6 0 2 hub tan 1 35.4 150 2 55 Free Vortex Design for 1st Stage Rotor • The axial velocity Cx is assumed to be constant as a function of radius (Note that it doesn’t have to be !) WU CU U 58.3 355.3 0 2 tip tan 63.2 150 106.6 177.7 0 2 hub tan 1 25.36 150 1 56 1st Stage Blade Spanwise Variations (Free Vortex Design) W=C-U 1=0 W1h=232.5 W1m=305. 9 W1t=385.7 Cx1=150 1h=49.83 Uh=- WU1h =177.7 1m=60.64 Um=- WU1m =266.6 Ut=- WU1t =355.3 1t=67.11 2h=35.4 C2h=184.02 C2m=167.87 C2t=160.93 2m=26.68 CU2h=106.6 2t=21.24 CU2m=75.38 CU2t=58.3 ROTOR Cx2=150 Uh=177.7 Um=266.6 W2m=166.0 2h=25.36 W2m=242.03 2m=51.89 W2m=332.73 2t=63.2 WU2h=71.1 Ut=355.3 WU2m=191.22 57 WU2t=297.0 Spanwise Variation in Reaction with Free Vortex Design • Remember that Reaction is given by: Cx Cx tan tan 1 tan 2 tan 1 2 1 2U 2U CU 1 CU 2 CU 1r CU 2 r R 1 1 2U 2U m r 2 / rm2 R where U U m R 1 r rm and CU r constant constant r2 • If R=50% at rm, radial variation may make root too small and tip too large for good efficiency • The free vortex design, Rh =0.7, Rm = 0.859, and Rt = 0.918 (high at the tip !!). This is why designers sometimes move away from free vortex design in favor of a different strategy, like constant spanwise 58 Reaction distribution or “forced vortex” design. Consideration When Diverting from Free Vortex Design • The free vortex design, Rh =0.7, Rm = 0.859, and Rt = 0.918 (high at the tip !!). This is why designers sometimes move away from free vortex design in favor of a different strategy, like constant spanwise Reaction distribution or “forced vortex” design. • When using a radial design strategy other than free vortex: – radial equilibrium is not satisfied, some error in velocities arise – total work of stage may not deliver design intent exactly – axial velocity may not be constant across span • mass flow may not reach design intent exactly • hub and tip radii would need to be re-computed 59 Non- Free Vortex Designs • Consider rotor inlet / exit swirl velocity distributions of the form CU 1 aR n b R and CU 2 aR n b R where a, b, n are constants and R r / rm 1) if n 1, reduces to free vortex design approach 2) if n 1, called first power or forced vortex design approach Equation of motion must be rederived with C x constant C x21 C x21 2 a 2 R 2 2ab ln R a 2 and m 2a ln R a R 1 Um Um 60 Airfoil Design • Once the velocity triangles for that blade-row are established from the meanline analysis, then the job remaining is to design the airfoil that will deliver the required exit velocity triangle given the inlet velocity triangle Correlations For Deviation and Loss are Derived from Cascade Data Deviation Loading Coefficient Gives Solidity 2Cos 2 2 C X 1 z Tan1 Tan 2 x CX 2 Solidity and Velocity Gives Dfactor D factor 1 Loss V2 Vu1 Vu 2 V1 2V1 Dfactor Gives /c, Loss, and Efficiency c 0.006 0.0002 e 2 c cos 2 7.5 D f C x 2 cos 1 C cos 2 x1 2 2 R 61 1 Cx S 1 2 2 E U cos 2 cos 2 1 Streamline Curvature Method • For Simple Radial Equilibrium (Cr=0), the solution is possible at any given axial plane with no information from up- or downstream! • Streamline Curvature Methods - Cr 0 (Axisymmetric Analysis with Models for Loss and Deviation) • 3D Velocity Diagram: 62 2D Throughflow Analyses Wu’s S1 & S2 surface method 63 Streamline Curvature Method • Inviscid Momentum Equation: P Substantial Derivative: • Using: DC 0 Dt DC C C C C Dt t x y z x r cos y r sin zz 64 Streamline Curvature Method • Radial, tangential & axial components of acceleration in cylindrical coordinates. 2 dC r CU ar dt r dCU CU C r a dt r dC z az dt • Using the chain rule in cylindrical coordinates: d dr dt t r dt C d Cr U dt t r r d dz dt z dt Cz z 65 Streamline Curvature Method • The radial component of the momentum equation becomes: C r CU C r C r CU 1 P C r Cr Cz r t r r z r 2 0 • The radial pressure gradient for steady, axisymmetric flow becomes: 1 P CU r r 2 Cr C r C r Cz r z • Modification to Simple Radial Equilibrium depends entirely on radial velocity! 66 Streamline Curvature Method • Axial (z) gradient - can't solve flow with information at only one axial location. Multiple stations are used in streamline curvature codes. • Derivative in meridional direction, along streamline in the r-z plane: r z Cm Cm Cm m mr mz Cm Cm sin Cm cos m r z Cm Cr Cz m r z C r 1 P Cu Cm r r m 2 67 Streamline Curvature Method • Further C r C m sin m m C m C r sin C m cos m m m Cm Cr 2 Cm Cm sin Cm cos m m m C m C m 2 cos C r Cm Cr m m rm • Meridional Momentum Equation: C m cos C m 1 P C u Cr r r rm m 2 2 68 Streamline Curvature Method • Above form shows effects of streamline curvature & meridional acceleration • Method used with cascade data for design & off design analysis • Method used to convert measured P & T into velocities, angles etc. • Extension of theory accounts for radial blade force terms at intra-blade stations • Same approach used for centrifugal designs, but in streamwise & normal coordinate system 69 Streamline Curvature Method • "Streamline" codes are only as good as the loss & blockage models in the code • Inherently weak prediction of endwall flows - secondary flow, seal & tip leakage effects • Streamline solutions quickly generate velocity diagrams for initial design • Reduce measured P & T into velocity diagrams 70 Potential Homeworks Problem 1: Re-design the first 3 stages of our 7-stage compressor: – holding the tip radius constant (half the class) – holding the hub radius constant (half the class) – keep the existing assumptions (constant Cx with r, constant work with r (free vortex), stage T (20,25,25), N, etc. – sketch the velocity triangles and airfoil shapes • Compare your results to Mattingly’s COMPR code • Compare your results with the constant mean radius and other design for this homework – how do airfoil shapes change? – which design is the best? Problem 2: Use Euler’s turbine equation to verify the hub and tip velocity triangles for the 1st stage rotor obtained in class from radial equilibrium – work is assumed to be constant with r (free vortex) – note that there is radius change at the hub and tip 71