Senior Design II Final Documentation

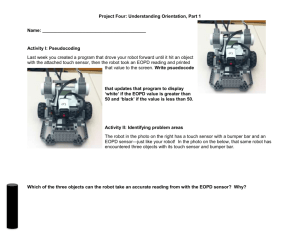

advertisement