Fa12-3110-Formulas

advertisement

Fall 2012 – MGT 3110

Exam 3 Formulas

Chapter 12 Inventory Management

ROP Models

Discrete Probability model

Total cost = Annual Holding cost + Annual stock-out cost

Annual Holding cost = Safety stock x H

Annual stock-out cost = Expected stock out per cycle x N x Cs

Where, Expected stock-out = (Stock-out x Probability)

N = No. of orders per year = D/Q

Cs = Cost of stock-out per unit

Reorder point model with Normal distribution:

Reorder point (ROP) = Average demand during lead time + Safety stock

i.e. ROP = d x L + Z dLT

where, d = Demand rate per period

L = Lead time

Z = Normal table value for the given service level

dLT= Standard deviation of demand during lead time (as give in table below)

Lead time is constant

Lead time is variable

Demand is constant

𝜎dLT = 0

𝜎dLT = d𝜎𝐿

Demand is variable

𝜎dLT = d√𝐿

𝜎dLT = √𝐿𝜎𝑑2 + 𝑑 𝜎𝐿2

2

Single-Period model

𝐶

Service level = 𝐶 +𝑠𝐶 , where Cs = Cost of shortage, Co = cost of overage

𝑠

𝑜

Cs = Lost profit = Selling price per unit – Cost per unit

Co = Cost/unit – salvage value/unit

Order quantity = + Z, where = mean demand, = standard deviation of demand

Stock-out risk= 1 - service level

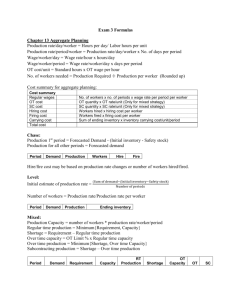

Chapter 13 Aggregate Planning

Production rate/day/worker = Hours per day/ Standard hours

Production rate/period/worker = Production rate/day/worker x No. of days per period

Wage/worker/day = Wage rate/hour x hours/day

Wage/worker/period = Wage rate/worker/day x days per period

OT cost/unit = Standard hours x OT wage per hour

No. of workers needed = Production Required ÷ Production per worker

Cost summary for aggregate planning:

Cost summary

Regular wages

OT cost

SC cost

Hiring cost

Firing cost

Carrying cost

Total cost

No. of workers x no. of periods x wage rate per period per worker

OT quantity x OT rate/unit (Only for mixed strategy)

SC quantity x SC rate/unit (Only for mixed strategy)

Workers or units hired x hiring cost

Workers or units fired x firing cost

Sum of ending inventory x inventory carrying cost/unit/period

Chase:

Production 1st period = Forecasted Demand - (Initial inventory - Safety stock)

Production for all other periods = Forecasted demand

Month

Demand

Production

Days

(if different)

Production

rate

Workers

Hire

Fire

Level:

(Sum of demand−(Initial inventory−Safety stock)

Initial estimate of production rate =

Number of periods or days

Number of workers = Production rate/Production rate per worker – round up

Month

Demand

Days

(if different)

Production

Ending

inventory

Mixed:

Production Capacity= workers * production/worker/period

RT production = Minimum{Requirement, Capacity}

Shortage = Requirement – RT production

OT Capacity = OT Limit % x RT Capacity

OT production = Minimum{Shortage, OT Capacity}

SC production = Shortage - OT production

Month

Demand/

Requirement

Capacity

Days

(if different)

Production

Shortage

OT

Capacity

OT

SC

Chapter 14 Material Requirements Planning

Gross requirement:

= Number of units required per unit of Parent (from BOM) x MPS quantity if parent

is at Level zero of BOM

or

= Number of units required per unit of Parent (from BOM) x Planned Order Release

(PORL, the last row) if parent is at an intermediate Level of

BOM

Projected on-hand for week t+1

= Project on-hand for week t + Scheduled Receipt for week t – Gross Requirement for week t

After the first net requirement, = Planned order receipt for week t – Net requirement for week t

(Projected on-hand is never negative)

Net requirement

= If Projected on-hand for week t+1 is negative, then

Net requirement = (Projected on-hand + Scheduled Receipt) - Gross

requirement

Lot sizing: Lot-for-lot:

Total cost = No. of setups x Setup cost + Total ending inventory x Holding cost/week

EOQ:

Q

2dS

H / week

d = Average demand per week

S = Setup cost

H = Holding cost per week

Total cost/week = (d/Q)S + (Q/2)*Holding cost per week

Total cost for n weeks = Total cost/week x n

Part-period balancing:

EPP = S/H, where EPP = Economic part periods, S = Setup cost, H = holding cost

Periods

combined

(Lot size)

Quantities

combined

Periods brought

forward for the

last quantity

Total cost = Total setup cost + Total carrying cost

i.e. = No. of lots x S + Sum of Part-periods in the lots x H

New Partperiods

(Lot PP)

Total combined partperiods