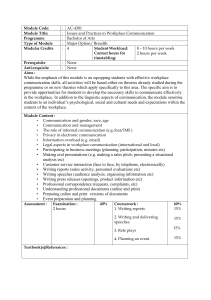

Course in Workplace Spotting for Service Assets * 22195VIC

advertisement