water conservation

advertisement

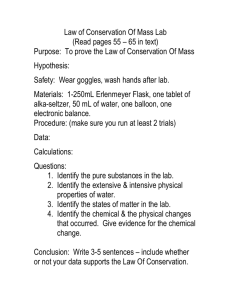

WATER CONSERVATION CUSTOMIZED ENVIRONMENTAL TRAINING WELCOME Water Conservation 1/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC INSTRUCTOR Insert Instructor Name Here Water Conservation 2/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC OBJECTIVES Discuss the Need for Water Conservation. Discuss the Need for Monitoring, Submetering, and Leak Detection. Explain How Water Pressure Relates to Water Conservation. Discuss Water Recycling and Water Reuse. Discuss Cooling Water Conservation. Discuss Industrial Water Conservation Measures. Discuss Bathroom Water Conservation Measures. Discuss Xeriscape Landscaping. Discuss Water Conservation Education and Employee Participation. Water Conservation 3/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC GOALS Understand the Need for Water Conservation. Understand the Need for Monitoring, Submetering, and Leak Detection. Be Familiar With How Water Pressure Relates to Water Conservation. Understand the Principles of Water Recycling and Water Reuse. Be Familiar With Cooling Water Conservation. Be Familiar With Industrial Water Conservation Measures. Understand Bathroom Water Conservation Measures. Understand the Basic Principles of Xeriscape Landscaping. Understand the Importance of Water Conservation Education and Employee Participation. Water Conservation 4/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC BACKGROUND Drought costs ranchers and farmers an estimated $6-8 billion a year, more than damages caused by floods or hurricanes. The Dust Bowl Drought from 1931-1938 affected 50 million acres of land and left thousands of farmers homeless. In 1999 drought caused 1,695 counties in 44 states to be declared agricultural disaster areas. Water Conservation 5/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LEARNERS Supervisors Facility Engineers Maintenance Personnel Department Managers Building Occupants Process Specialists Environmental and Safety Committees Water Conservation 6/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC OVERVIEW The goal of this course is to provide supervisors with the tools needed to help conserve water. It recommends practical, actions that can be carried out by facility management, maintenance personnel and building occupants. The course will help you to integrate good water conservation management activities into your existing organization and identify which of your staff have the necessary skills to carry out those activities. Water Conservation 7/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WHAT THIS COURSE DOES NOT DO The course is not intended to provide information to install, repair, or modify plumbing equipment, nor is it intended to teach personnel to become landscape architects. These specialties required training beyond the intended scope of this course. Where this expertise is needed, outside assistance should be solicited. Water Conservation 8/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC SAFE DRINKING WATER ACT The Safe Drinking Water Act, Section 1455, as amended in 1996, requires the United States Environmental Protection Agency (EPA) to publish guidelines for use by water utilities in preparing a water conservation plan. States are to administer water conservation programs and to enact state regulations to conform to these guidelines. Water Conservation 9/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WHAT IS A DROUGHT? The National Weather Service defines a drought as “a period of abnormally dry weather that persists long enough to produce a serious hydrologic imbalance (for example crop damage, water supply shortage, etc.) The severity of the drought depends upon the degree of moisture deficiency, the duration and the size of the affected area.” Water Conservation 10/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WHY CONSERVE WATER? 1. It is a resource that is a benefit to everyone. 2. To save money. Lower consumption means lower water bills. 3. To keep rates low. Maximizing current water supplies helps defer the need to develop new, more expensive sources of water. 4. To prepare for a drought. Many areas of the country have experienced drought conditions in the past few years. Water conservation helps prepare for these worst of times. 5. To comply with regulations. Many states and local regulators have established efficient water use regulations. Water Conservation 11/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC TWO TYPES OF PRACTICES 1. Engineering practices: practices based on modifications in plumbing, fixtures, or water supply operating procedures. 2. Behavioral practices: practices based on changing water use habits. Water Conservation 12/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC MONITORING Provides baseline information on quantities of overall company water use, the seasonal and hourly patterns of water use, and the quantities and quality of water use in individual processes. Baseline information on water use can be used to set company goals and to develop specific water use efficiency measures. Monitoring also raises employee awareness. Records of meter readings can be used to identify changes in water use rates and possible problems in a system. Water Conservation 13/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC SUBMETERING The practice of placing water meters throughout a facility is called submetering. Submetering helps account for water usage and can help in the process of leak detection. Areas to consider submetering are landscaped areas, cafeterias, laundries, and major industrial equipment that use water. Submetering makes water users more aware of how much water they use and its cost. By placing meters and monitoring those meters throughout a facility, experts estimate that a facility can help reduce water usage by 20 to 40 percent. Water Conservation 14/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METER ACCURACY Water meters can be damaged and deteriorate with age, thus producing inaccurate readings. All meters, especially older meters, should be tested for accuracy on a regular basis. Meters that are used to measure large volumes of water may be too large for a customer's level of use and will tend to under-register water use. A Meter testing, calibration, repair, and replacement program needs to be established. Water Conservation 15/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LEAK DETECTION Repairing leaks saves money on water bills. The early detection of leaks also reduces the chances that leaks will cause major property damage. A leak detection strategy needs to employ regular on-site testing methods for detecting leaks along water distribution mains, valves, services, and meters. Leak detection programs are especially important in facilities that have large, old, deteriorating systems. Water Conservation 16/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LEAK DETECTION Automated sensors/telemetry. Remote sensors and monitoring software can alert personnel to leaks, fluctuations in pressure, problems with equipment integrity, and other concerns. Visual inspection program. This may include pipe inspection, cleaning, lining, and other maintenance efforts to improve the distribution system and prevent leaks and ruptures from occurring. Water Conservation 17/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WATER AUDITS Audits of large-volume users. Begin by identifying the categories of water use for the large-volume user. These may include process, sanitary, domestic, heating, cooling, outdoor, and other water uses. Second, a water audit should identify areas in which overall water use efficiency can be improved through alternative technologies or practices. Large-landscape audits. Effective audit programs can save 10 to 20 percent for both general industrial water usage and for large landscape water audits. Water Conservation 18/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC REDUCING WATER PRESSURE Reducing excessive pressures in the water distribution system can save a significant quantity of water. Reducing water pressure can decrease leakage, the amount of flow through open faucets, and stresses on pipes and joints that may result in leaks. Lower water pressure may also decrease system deterioration, reducing the need for repairs and extending the life of existing facilities. Lower pressures can help reduce wear on end-use fixtures and appliances. Water Conservation 19/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC REDUCING WATER PRESSURE Pressure-reducing valves. Can be installed on street mains, as well as individual buildings. Companies might also insert flow restrictors on services at the meter. Seek technical assistance from your water provider on pressurereducing valves. Water Conservation 20/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WATER RECYCLING Water recycling is the reuse of water for the same application for which it was originally used. Factors that should be considered in a water recycling program include: - Identification of water reuse opportunities - Evaluation of the minimum water quality needed for a particular use - Evaluation of water quality degradation resulting from the use - Determination of the treatment steps. Water Conservation 21/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WATER REUSE Water reuse is the use of wastewater or reclaimed water (sometimes called “graywater”) from one application for another application. Some potential applications include other industrial uses in cooling water at power plants and oil refineries or industrial process water for such facilities as paper mills and carpet dyers, toilet flushing, dust control, construction activities, concrete mixing, and artificial lakes. Reused water can also be used in landscape irrigation, agricultural irrigation, aesthetic uses such as fountains, and fire protection. Water Conservation 22/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC WATER REUSE Factors that should be considered in an industrial water reuse program include: Identification of water reuse opportunities Determination of the minimum water quality needed for the given use Identification of wastewater sources that satisfy the water quality requirements Determination of how the water can be transported to the new use Water Conservation 23/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC COOLING WATER RECIRCULATION The use of water for cooling in industrial applications represents one of the largest water uses in the United States. The most water-intensive cooling method used in industrial applications is once-through cooling, in which water contacts and lowers the temperature of a heat source and then is discharged. Recycling water with a recirculating cooling system can greatly reduce water use by using the same water to perform several cooling operations. Three cooling water conservation approaches that can be used to reduce water use are evaporative cooling, ozonation, and air heat exchange. Water Conservation 24/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC EVAPORATION COOLERS The principal use of water by evaporative coolers is to increase the humidity of incoming air being drawn into a building and decrease its temperature. The building’s air cools as it absorbs the moisture. Evaporative coolers require an annual maintenance check-up for the most efficient cooling. Water Conservation 25/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC OZONATION The use of ozone to treat cooling tower water (ozonation): Can result in a 99% reduction in the appearance of bacteria. And personnel no longer have to handle chlorine, bromine, phosphates, and other chemicals. It helps keep the metal surfaces of pipes and equipment clean, making equipment more energy efficient. Controls corrosion by producing a protective coating on metal surfaces, extending equipment life. Acts as a strong disinfectant. Can use lower amounts of high-quality water and it reduces cooling tower blowdown water consumption by 50 to 90%. Water Conservation 26/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC AIR HEAT EXCHANGE Air heat exchange works on the same principle as a car's radiator. In an air heat exchanger, a fan blows air past finned tubes carrying the recirculating cooling water. Air heat exchangers involve no water loss, but they can be relatively expensive when compared with cooling towers. Air heat exchangers can be more reliable and more productive than water cooling. Water Conservation 27/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC ONCE-THROUGH COOLING Many facilities have one or more pieces of equipment cooled by a single-pass flow of water. After passing through and cooling the equipment, the water is usually discarded to a sanitary sewer system. Equipment that might use a once-through cooling system include degreasers, rectifiers, hydraulic equipment, x-ray machines, condensers, and viscosity baths. Also air conditioners, air compressors, hydraulic presses, welders and vacuum pumps. Water Conservation 28/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC ONCE-THROUGH COOLING Alternatives for more efficient ways of cooling include: Air heat exchange Closed-loop recycled water. Use the pass-through water for landscape irrigation or other graywater uses. Water Conservation 29/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Platers and finishers, printed circuit board operators, fabricators, integrated circuit metal fabricators and other facilities use numerous process rinses and reaction baths. Water is essential in the manufacturing process for these facilities. There are several water conserving methods that manufacturers should consider including: Flow Monitoring and Control, First Stage Static Tanks, Counterflow Rinsing, Spray Rinsing, Membrane Technologies, Ion Exchange and Electrolyte Recovery. Water Conservation 30/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Flow Monitoring and Control Flow meters and manually-operated valves are relatively simple to operate and low in cost to install. Require operator attentiveness and knowledge of allowable rinse tank concentrations. Automatic control of rinsewater flows is possible using conductivity control or measurements of total dissolved solids (TDS) concentrations in rinses to control electrically operated valves. Water Conservation 31/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING First Stage Static Tank For multi-tank rinsing, the first tank may be a “static” rinse tank rather than a continuous overflow tank. Water conservation is achieved by a high percentage of the drag-out is discharged into this first rinse tank. The first rinse tank can be allowed to become more concentrated than the rinses that follow it. Less water is used to periodically dump and refill the tank than for continuous overflow dilution. Water Conservation 32/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Counterflow Rinsing. Water Conservation 33/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Spray Rinsing Spray rinse systems may offer significant rinse water savings. As much as 60% reduction has been claimed by such systems when compared to immersion tanks. Spray rinsing should be combined with an automatic spray system that will reduce the chance of operator error. Water Conservation 34/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Membrane Technologies There are at least four different types of membrane technologies that include Microfiltration, Ultrafiltration, Reverse Osmosis and Electrodialysis. Generally, membrane technology is easy to maintain and operate. Pressure is applied to the feed side of the membrane which causes water and some selected solids to pass through. Water Conservation 35/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Ion Exchange Ion exchange is another common method and it involves the use of deionized water for removing contaminants from products and equipment. Deionized water contains no ions (such as salts), which tend to corrode or deposit onto metals. The reuse of once-used deionized water for a different application should also be considered. Water Conservation 36/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC METAL FINISHING Electrolytic Recovery This process removes metal ions from solution, oxidizes cyanide, and reduces chromium in wastewaters. Metal ions are reduced at a cathode while oxygen evolves at an anode. This method conserves water by keeping a low metals concentration in the drag-out recovery tank, minimizing drag-out to the the rinse tank(s). This method is effective with copper, tin, silver, and other metals. Water Conservation 37/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CAFETERIAS AND RESTAURANTS Use water in garbage disposer only during operation. If thawing foods in cold running water, change to thawing under refrigeration, in a microwave, or in the cooking process. “Double Dip” to clean large volumes of produce. Replace "once through" water cooled ice machines and refrigeration condensers with air cooled machines. Limit dishwashing to full loads. Turn off the continuous flow used to clean the drain trays of the coffee/milk/soda beverage island. Water Conservation 38/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LAUNDRIES Reprogram machines to eliminate a rinse or suds cycle, if possible, and not restricted by health regulations. Reduce water levels, where possible, to minimize water required per load of washing. Wash full loads only. Evaluate wash formula and machine cycles for water use efficiency. When purchasing new machines, buy water-saving models. Water Conservation 39/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC HOSPITALS AND CLINICS Turn off water required for film processing or cooling in the X-ray department when not in use. Recycle water where feasible, consistent with state and county requirements. Use full loads in sanitizer, sterilizer, dishwasher, and washing machines. Overhaul faulty steam traps on sterilizers. Replace equipment with water-saving models. Reduce the load on air conditioning units by shutting off air conditioning when and where it is not needed. Recover condensate and use it as make-up water. Water Conservation 40/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CLOSED-LOOP VEHICLE WASHERS Closed Loop Vehicle Washers The closed loop vehicle washers are facilities that completely recycle the wash water used in cleaning cars, trucks, etc. Wash water will go through three different treatment units before being recycled for reuse. The alpha treatment unit is an oil/water separator. The beta treatment unit removes fine dirt particles and any remaining hydrocarbons. The omega treatment adds ozone to the water before reuse. Water Conservation 41/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC BATHROOM WATER To calculate the savings from a retrofit program, planners are required to make a number of assumptions about water use and savings. Some of the assumptions used in retrofitting are: Toilets (4-6 flushes per person per day) Showerheads (5-15 shower-use minutes per person per day) Bathroom Faucets (1/2 to 3 faucet-use minutes per person per day) Water Conservation 42/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LOW-FLUSH TOILETS More than 4.8 billion gallons of water is flushed down toilets each day in the United States. The average American uses about 9,000 gallons of water to flush 230 gallons of waste down the toilet per year. Conventional toilets use 3.5 to 5 gallons or more of water per flush, but low-flush toilets use only 1.6 gallons of water or less. Effective January 1, 1994, the Energy Policy Act of 1992 (Public Law 102-486) requires that all new toilets produced for home use must operate on 1.6 gallons per flush or less. Water Conservation 43/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC TOILET DISPLACEMENT DEVICES By placing a one gallon milk jug in the tank of an older toilet, you can save one gallon of water per flush. Do not use bricks or stones because they can break up and cause damage to the plumbing. A toilet dam, which holds back a reservoir of water when the toilet is flushed, can also be used instead of a plastic container to save water. Toilet dams result in a savings of 1 to 2 gallons of water per flush. Water Conservation 44/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC LOW-FLOW SHOWERHEADS Showers account for about 20 percent of total indoor nonindustrial water use. By replacing standard 4.5gallon-per-minute showerheads with 2.5-gallon-per-minute heads, which cost less than $5 each, one study found that shower water use was reduced over 34% with low flow showerheads. Water Conservation 45/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC FAUCETS Faucet aerators can be easily installed and can reduce the water use at a faucet by as much as 60 percent while still maintaining a strong flow. Other options to consider are metered faucets (which stay open for a pre-set period of time and then close), self-closing faucets (which close as soon as you let go of the knob) and automatic sensor controlled faucets. Water Conservation 46/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC RAIN WATER HARVESTING Rain Water Harvesting is capturing and storing rainfall to irrigate plants or to supply people and animals. A well-designed system will also decrease your landscape maintenance needs. All you need for a water harvesting system is rain, and a place to put it. A "catchment" is any large surface that can capture and/or carry water to where it can be used immediately or stored. Water Conservation 47/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC RAIN WATER HARVESTING A water surplus available at the right time of year makes storage well worth the time and effort. A surplus becomes impractical when it must be stored for more than several months. Water stored for long periods of time will stagnate and become a health hazard. You can store water in a variety of ways: 55-gallon steel drums, oak barrels or underground storage tanks. Regular maintenance is critical to any dependable water harvesting system. Water Conservation 48/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Businesses can save water in landscaping by using the principles of Xeriscape™, an efficiency-oriented approach to landscaping that encompasses seven essential principles: Planning and design Limited turf areas Efficient irrigation Soil improvement Mulching Use of lower water demand plants Appropriate maintenance Water Conservation 49/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Planning and design Sketch your landscape with locations of existing structures, trees, shrubs and grass areas. Then consider the landscape budget, appearance, function, maintenance and water requirements. "Right Plant, Right Place": Select plants appropriately based upon their adaptability to climate, micro-climate, geological, and topographical conditions of the site. Protect and preserve native species. Use only ornamental fountains that incorporate water recirculation should be installed and operated. Water Conservation 50/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Limited turf areas When considering a landscape's water requirement, it is important to note that turf grasses require more frequent watering and maintenance than most other landscape plants. When at all possible, minimize turf and other high water use, ornamental plants sparingly and only where necessary (such as sports fields, recreation areas and site entries). Avoid placing turf in long narrow areas and small oddshaped areas. Water Conservation 51/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Efficient Irrigation Hydrozones: Separate the landscape area plants with similar water needs in a similar microclimate. Provide water budget statement estimation. Design irrigation systems to avoid runoff. Incorporate electronic controllers with precise individual timing. Utilize irrigation-only meters (deduct meters). Use drip or other low volume irrigation whenever possible. Water Conservation 52/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Soil improvement •To increase plant health and conserve water, analyze your soil. If needed, add organic matter to the soil of shrub and flower bed areas. This increases the soil's ability to absorb and store water in a form available to the plant. As a rule-of-thumb, till in 4 to 6 inches of organic material such as shredded pine bark, peat and rice hulls. For trees, however, incorporating organic matter is not necessary; for large turf grass areas, it is not economically feasible. Water Conservation 53/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Mulching Mulch is a layer of nonliving material covering the soil surface around plants. Mulches can be organic or inorganic materials. Use a mulch at least once a year. A good mulch conserves water by significantly reducing moisture evaporation from the soil. Mulch also reduces weed populations, prevents soil compaction and keeps soil temperatures moderate. Water Conservation 54/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Use of lower water demand plants Utilize native plants that are drought resistant first in your landscaping. Utilize non-native plants only if they are drought resistant. Consult your local nursery for the best selection of trees, shrubs and plants. Water Conservation 55/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC XERISCAPE LANDSCAPE Appropriate maintenance Plant establishment: Provide plant establishment period of 2-3 years. During this time, all plants should be sufficiently watered and not be subject to a water budget. Provide for the reduction and eventual elimination of supplemental irrigation for low water / drought tolerant plants after establishment period. Appropriate maintenance preserves the beauty of the Xeriscape landscape plus saves water. Pruning, weeding, proper fertilization, pest control and irrigation system adjustments all conserve water. Water Conservation 56/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC DEVELOPING A WATER CONSERVATION PLAN Company policy statement Goals Action Plan Assigned responsibilities for planned implementation Procedures for implementation, evaluation, and revision Water Conservation 57/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC EDUCATION Educating the workforce A successful water conservation program starts with educating the workforce. Supervisors should understand water bills, water usage rates and the company’s water system. Maintenance personnel should be familiar with water usage within the company. Shop personnel should be instructed on water conservation measures. Water conservation education should be a continual process. Water Conservation 58/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC EMPLOYEE PARTICIPATION Employee Participation and Public Awareness. Start off your awareness program with a letter to all employees from the head of the company showing full support of the plan. Use bulletins, newsletters, and paycheck stuffers to communicate policies, programs, ideas etc. Hold staff meetings to communicate your company’s water conservation plan and progress in water savings. Promote a suggestion and incentive system and recognize people who have water saving ideas. Distribute water conservation booklets. Promote slogan and poster contests. Water Conservation 59/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CHECKLIST OF WATER CONSERVATION IDEAS For interior plumbing: 1. Do dye-tablet test to check all tank toilets for leaks. 2. Retrofit showerheads with water-conserving hardware. 3. Retrofit faucets to flow at 2 gallons/minute or less. 4. Consider metered, self-closing and automatic sensor faucets. 5. Retrofit tank-type toilets with dams or water-filled plastic containers as displacement devices. 6. Consider replacing toilets with “ultra-low” volume models. 7. Retrofit urinals with flush valves that reduce the volume of water used per flush. Water Conservation 60/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CHECKLIST OF WATER CONSERVATION IDEAS For cooling towers: 1. Prepare an inventory of each cooling tower, its cooling capability, and the equipment or process it serves. 2. Meter and record the amount of makeup water added to each tower, and the amount of blow-down water discharged from each tower. 3. Inventory the chemicals used for the treatment of recirculating cooling tower water. 4. Tell your chemical vendor(s) that water conservation is a priority at your facility. Ask your vendor(s) to tell you about alternate programs that could reduce the amount of water that is bled-off from cooling towers. Water Conservation 61/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CHECKLIST OF WATER CONSERVATION IDEAS For evaporative coolers: 1. Be sure coolers have pumps to recirculate the water through them. 2. Check to make sure there is not an excessive amount of water in the coolers. For a typical small cooler, anything more than a few gallons per hour may be excessive. 3. Pipe the bleed-off from your coolers to help water a landscaped area. Water Conservation 62/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC CHECKLIST OF WATER CONSERVATION IDEAS For once-through cooling: 1. Eliminate all uses of “once-through” cooling unless you reuse the water elsewhere for a beneficial purpose. 2. Many water-cooled equipment can be replaced with aircooled models. 3. Connect a recirculating cooling water loop instead of a once-through cooling system. Water Conservation 63/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC TIPS FOR USING CONTRACTORS Remember, You Control Your Facility or Area! Review Procedures With Them Before Starting the Job! Ensure They Are Properly Trained! Determine Their Environmental Compliance Record! Determine Who Is in Charge of Their People! Determine How They Will Affect Your Facility’s Environmental Compliance! Water Conservation 64/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC ELEMENTS OF A SUCCESSFUL UST PROGRAM 1. DETAILED WRITTEN WATER CONSERVATION PLAN. 2. DETAILED WRITTEN WATER CONSERVATION BEST MANAGEMENT PRACTICES. 3. EXTENSIVE EMPLOYEE TRAINING PROGRAMS 4. PERIODIC REINFORCEMENT OF TRAINING 5. SUFFICIENT DISCIPLINE REGARDING IMPLEMENTATION 6. PERIODIC FOLLOW-UP Water Conservation 65/66 © Copyright Training 4 Today 2001 Published by EnviroWin Software LLC THE IMPORTANCE OF A CLEAN ENVIRONMENT “I would ask all of us to remember that protecting our environment is about protecting where we live and how we live. Let us join together to protect our health, our economy, and our communities -- so all of us and our children and our grandchildren can enjoy a healthy and a prosperous life.” Water Conservation 66/66 © Copyright Training 4 Today 2001 Carol Browner Former EPA Administrator Published by EnviroWin Software LLC