Activity-Based-Costing

advertisement

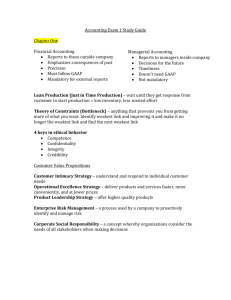

ActivityBased Costing Systems Dr. Nancy Mangold California State University, East Bay Traditional Cost Systems Allocate Overhead Costs to Production Cost Centers and Then to Products Overhead Cost Center 1 Overhead Cost Center 2 Overhead Cost Center 3 Allocations Production Cost Center 1 Machine Hours DM DL Production Cost Center 2 Products Production Cost Center 3 DL Hrs Traditional Cost Systems Factory overhead costs are allocated to production cost centers Using arbitrary bases, DL hours or headcount to assign overhead costs to production cost centers. Traditional Cost Systems Assign the costs in production cost centers to the products processed through each center. Use the cost drivers like DL hours, DL dollars, machine hours, units sold, or materials processed to allocation production cost center costs to products. ABC Systems Trace Resource Expenses to Activities and Use Activity Cost Drivers for Tracing Activity Costs to Objects Resource Expenses 1 Resource Expenses 2 Resource Expenses 3 Activity 2 Activity 3 Resource Cost Drivers Activity 1 Activity Cost Drivers DM Cost Objects: DL Products, Services, and Customers Activity-Based Costing Systems 1. 2. 3. 4. Develop the Activity Dictionary Determine how much the organization is spending on each of its activities Identify the organization’s products, services, and customers Select activity cost drivers that link activity costs to the organization’s products, services, and customers ABC Hierarchy of Activities Product Line Sustaining Channel Sustaining Brand Sustaining Customer Sustaining Product Sustaining Order Related Batch Unit Unit level activities Activities that have to be performed for every unit of product or service produced The quantity of unit-level activities performed is proportional to production and sales volume Drilling holes in metal parts, grinding metal, 100% inspection. Batch level Activities Activities that have to be performed for each batch or setup of work performed Setting up a machine for a new production run Purchasing materials Processing a customer order Product Sustaining Activities Activities performed to enable the production of individual products (or services) to occur Maintaining and updating product specifications Special testing and tooling for individual products and services Customer-Sustaining Activities enable the company to sell to an individual customer that that are independent of the volume and mix of the products sold and delivered to the customer Technical support provided for individual products and to service individual customers.