ADVANCES IN FOOD REFRIGERATION Tuan Pham School of

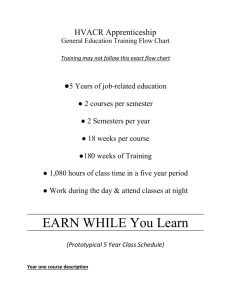

advertisement

ADVANCES IN FOOD REFRIGERATION Tuan Pham School of Chemical Engineering and Industrial Chemistry University of New South Wales tuan.pham@unsw.edu.au History of Food Refrigeration • • • • Harrison - ice making (1860), frozen meat export (1873) China 1000BC - ice harvesting Ancient Egypt - (evaporative cooling, ice making) Prehistory - use of caves and ice Food refrigeration is BIG • Annual investment in refrigerating equipment: US$170 • Annual refrigerated foodstuffs: US$1200 billion (3.5 times USA military budget) • 700-1000 million household refrigerators • 300 000 000 m3 of cold-storage facilities and causes big problems! • Ozone-depleting effects - Montreal protocol • Global-warming effects - Kyoto agreement Plan of talk Part I: Common industrial problems - Chillers and freezers - Cold stores - Refrigerated transport - Retail display Part II: Simulation of food refrigeration - Temperature and moisture changes - Quality and microbial growth Part III: Optimisation of food refrigeration PART ONE: COMMON PROBLEMS IN FOOD REFRIGERATION EQUIPMENT Typical refrigeration system Chillers and Freezers Chillers and freezers can be classified into • air-cooled • immersion • spray • cryogenic • surface contact chillers. Air Chillers/Freezers Immersion and Spray Chillers/Freezers • faster than air chilling, especially for small products • absorption of liquid or solutes by the product, leading to undesirable appearance or other quality losses • cross-contamination between products • leaching of food components such as fat • effluent disposal problem Surface contact chillers/freezers • Include plate chillers/freezers, mould freezers, belt chillers, scraped surface freezers • High heat transfer rate (similar to immersion freezers) - only metal bw refrigerant & product • No absorption of liquid • No liquid effluent. • Need products with flat surfaces, such as cartons Preferably thin or small products such as fish and peas. • Labor intensive or need sophisticated automation. How to have efficient cooling/freezing R 1 R tf (T f Ta ) h k Freezing time Surface resistance Internal resistance For faster cooling/freezing and higher throughput: • Reduce temperature Ta • Increase h (high air velocity, use spray/ immersion/ contact, less packaging) • Decrease product size R Biot Number hR/k (= external/internal resistance) should be not too far from 1 Cold store Cooling coil Air Infiltration through Doors Effectiveness of door protective devices • Vertical air curtain: 79% • Horizontal air curtain: 76% • Plastic strip curtain: 93% • Air + plastic strip: 91% Vapour barrier breach •Heat bridge •Delamination •Collapse Frost heave Problems with transport vehicles & containers are same as in cold rooms, but multiplied several-fold (because of high A/V ratio and fluctuating ambient conditions) Retail display Retail display Selection and Operation of Refrigeration Components • Reliability Food remains safe and wholesome according to specifications. • Flexibility Ability to handle different products or production rates • Capital and Operating costs Selection and Operation of Refrigeration Components Freezers and chillers: • Extract heat within a certain time from product and other sources • Cool product uniformly • Avoid surface drying, contamination, microbial growth and other quality problems • Avoid condensation Selection and Operation of Refrigeration Components • System must be well balanced to give optimal performance for given price. An undersized cooling coil or freezer will require oversized compressors, condensers etc. PART TWO: SIMULATION OF FOOD REFRIGERATION What happens in the product Heat & mass transfer Mass transfer in wrapped food Heat & mass transfer in Cartoned food Heat & mass transfer in irregular food Re-circulation causes • High temperature • Moist surface • Microbial growth Mathematical Simulation Objectives: to predict changes in • • • • • temperature at surface and centre moisture, especially surface moisture heat load quality changes microbial risks Simulation: Overview of models • Lumped capacitance (uniform temperature) model • Tank network model • Product discretization models: - finite differences - finite elements - finite volumes • Computational fluid dynamics (CFD) model Simulation: Tank models • Uniform temperature model dT mc p hA(TA T ) dt • Network of tank Accuracy of two-tank model for lamb freezing Simulation: (2-D) finite difference model Accuracy of F.D. model for beef chilling weight loss (70 tests) After 20 hours in Chiller FD Model Weight Loss (kg) 3 2 1 0 0 1 2 Experimental Weight Loss (kg) After 20 hours in Chiller 3 Simulation: (2-D) finite element model Accuracy of F.D. & F.E. model for beef chilling heat load (70 tests) 8 Davey and Pham (1997) FE Model During first 2 hours in Chiller Predicted Heat Removed (MJ) 7 6 5 4 3 2 1 0 0 1 2 3 4 5 6 Experimental Heat Removed (MJ) During first 2 hours in Chiller 7 8 Accuracy of predictions by various models (based on 70 beef chilling tests) 2-Tank Model Average % error in heat removed during first 2 hours Average % error in weight loss Running Time (Pentium 166 Mhz) FD Model FE Model -1.5 % -12.6 % -5.6 % N/A -1.2% 2.3 % < 1 sec < 1 min 5 hours CFD Models • Can simulate the flow field outside the product (air, water, cryogen...) as well as inside • Computationally expensive (fast computers, lots of memory, days of runtime) • Software expensive (especially for non-U) • Need lots of expertise to use properly • Need lots of time for data preparation • Accuracy NOT guaranteed even when all the above are satisfied! Why is CFD so difficult? • Solve several interacting partial differential equations simultaneously (density, v, T, c, turbulence parameters) • Must discretize the object and its surrounding into tens of thousands to millions of volume elements Why is CFD not quite accurate? • Calculation of turbulence only approximate • Turbulence affects boundary layer and hence heat and mass transfer rates CFD example: Beef chilling - model 100,000 nodes CFD example: Beef chilling - results Temperature, deg.C Heat load, W 1000 800 600 400 200 0 0 5 10 Time in chiller, h 15 20 45 40 35 30 25 20 15 10 5 0 0 5 10 Time in chiller, h 15 20 CFD model of display case: Predicted (color) vs measured (number) temperatures Other CFD Applications • • • • • Chillers and freezers Cold stores Transport containers Pasteurisation/cooling of liquid foods Design of cooling coils, air curtains Quality: Physical changes • Weight loss, dry appearance • Water absorption, bloated appearance • Drip • Crystal growth (ice cream) • Water penetration (bakery products) Quality: Biochemical changes • Tenderness (beef, lamb) • Fat rancidity flavour • PSE (pale soft exudative) (pork) • DFD (meat) • Flavour (fish) • Colour (meat) • Browning, spots, freezing injury (fruit) • Tissue breakdown (fruit) Quality: Fungal & microbial changes • Mildew, rot (fruit) • Spoilage organisms • Pathogenic organisms Modelling microbial growth Growth Rate = Optimum rate × Temperature Inhibition Factor × Water Activity Inhibition Factor × pH Inhibition Factor × Other Inhibition Factors Growth rate: dependence on Temperature Ratskowsky’s square root model: Zwietering model: m b(T Tmin ) m b(T Tmin )2 1 expc(T Tmax ) Growth rate: dependence on Humidity & pH Predictive microbiological modelling Predictive microbiological modelling Predictive microbiological modelling Microbial death • Death rate influenced by – High temperature – Low pH – Low water activity – Combination • Death during freezing – high solute concentration (low aw) – membrane shrinkage and damage – intracellular ice (?) Microbial death during freezing PART THREE: OPTIMIZATION OF FOOD REFRIGERATION The ultimate objective of simulation is to control and optimize Optimizer Results: Product quality Cost Reliability etc... Process inputs: Air temperature Washing, cleaning Product shape, wrap... etc. Process model Search (optimisation) methods Gradient (classical) methods - fast & methodical - ends up at nearest local optimum Stochastic methods (SA, GA...) - methods with madness - can be time consuming - 100,000 trials? - better at obtaining global optimum - better at dealing with errors - can perform multi-objective optimisation Optimising air temperature in beef chilling Objectives: • Chill centre to 7C in 24 hours • Tenderness score is minimized • E. Coli grows less than 8-fold at surface However • Fast chilling (low air T) causes toughness (high tenderness score) in loin • Slow chilling encourages microbial growth on leg surface Optimising air temperature in beef chilling A variable temperature regime is the answer: Controlling air temperature in lamb freezing Objective:To freeze all product in exactly 16 hours Problems: • Product weight varies (10-24 kg) • 16 hour lag time! Css weight Air T, v Controller FREEZER (16-h lag) Process Model Optimizer Frozen csses CONCLUSIONS • Attention to details needed in design and operation of refrigeration facilities. • Growing computer power allows more precise simulation of processes and prediction of product quality. • CFD is not yet the answer to the maiden’s prayers. • In near, computer control and optimisation of refrigeration processes will become more widespread.