Productivity Management 23 jan 2015

advertisement

Productivity Management

Semester VI

K.J. Somaiya Institute of Management Studies and

Research (SIMSR)

By

Dr J S Lamba

1

Why “Productivity”?

2

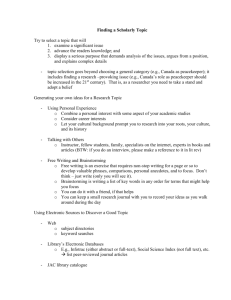

Course overview

Productivity

techniques

• Concept of

productivity

• Application in

manufacturing

and service

industries

• Application in

different

functional areas

3

Measurement

of

productivity

Approach to

Productivity

improvement

• Partial, multi• Classic ILO

factor and total

approach

factor models

• Modern TQC

• Sumath’s total

approach

productivity

• Sumanth’s five

model

pronged approach

• Sink’s multi-factor – product,

model

technology,

people, material

• Productivity by

and task based

objectives

techniques

• Americal

productivity

centre models

• Value analysis and

Value engineering

Quality

Circles

• Relationship with

total quality

management

• Seven QC tools

• Organizing for

quality circles

• Structure &

method of

implementation

of quality circles

Creativity

based

techniques

• Brainstorming

• Whole brain

thinking

• Nominal group

techniques

Live examples all through and caselets for application of knowledge

Your expectations

CASE TUDIES

NEUMERICALS

TOOLS OF PRODUCTIVITY

REAL LIFE EXMPLES

HOW TO INCREASE PRODUCTIVITY

4

Productivity is a vast subject

Started in 1800s with global industrial revolution

Measure of operational, organizational, industrial and

national competitiveness

Spread across Economics, Finance & Accounting,

Management, Psychology, Human Resource Management,

and Industrial Engineering

5

Productivity Concept, Measurement

and Improvement

What is Productivity?

ILO defines Productivity as the ratio between “Output of

Work” and “Input of Resources.

Productivity= Output Input

Process

Input

Output

Waste

6

This definition applies to an enterprise, an industry or an

economy as a whole.

Productivity is simply the ratio between the amount

produced and amount of resources used in the course of

production.

These resources can be: (Unit of resources is in brackets.)

1. Land (Hectares)

2. Material (Metric Tons)

3. Plant and Machinery (Machine Hours)

4. People (Man Hour)

5. Capital (Rupees)

7

Units of productivity

Quantity per person

Revenue productivity: Revenue (in $) per person

Value added (in $) per full-time employee

Value added (in $) per machinery value (in $)

Value added (in $) per sq.ft (or hectare)

8

Better productivity means…

Lower operating cost

Improved competitiveness

9

Is Productivity different from

Performance?

Productivity takes into account output in relation to input.

Performance takes into account output alone.

Productivity = Output÷ Input

In performance, we consider only the output and not the input.

A performance index becomes comparison of actual output

with some standard or expected output.

Performance Index = Actual work done÷ Ideal or standard

expected work.

10

→Case: It takes 3 Mtrs. of cloth to make a coat. In a day Prashant is

expected to make 50 coats. He makes 40 coats from 111 Mtrs. Of

cloth.

What is Prashant’s Performance ?

- 40 coats

Performance Index ?

- {40 ÷ 50} x100= 80%

What is Prashant’s cloth productivity index?

11

- Normally Prashant should have consumed 120 Mtrs. of cloth.

However he managed to make 40 coats in 111 Mtrs. Of cloth.

- Cloth Productivity Index = {120÷ 111} x 100= 108%

What is productivity of cloth?

- Cloth productivity= 40/ 111 = 0.36 Coats/Mtr.

12

Case: Shalini was busy going through the production and machine

hour consumption report of the past three months.

MONTH

INPUT

(Machine Hours)

OUTPUT

(No. of Units)

September

90,000

99,000

October

1,00,000

1,00,000

November

1,50,000

1,35,000

The reports clearly showed that there had been an increase in production

with a simultaneous increase in machine hour consumption.

Shalini was not sure whether it really indicated a rise in productivity or merely

increase in production. How should she get an answer to this?

13

Solution:

- Productivity per Machine Hour= Production Units÷ Machine

Hours

- Productivity for September= 99,000÷ 90,000= 1.1

- Productivity for October= 1,00,000÷ 1,00,000= 1.0

- Productivity for November = 1,35,000÷ 1,50,000= 0.9

14

MONTH

INPUT

(Machine Hours)

OUTPUT

(No. of Units)

PRODUCTIVITY

September

90,000

99,000

1.1

October

1,00,000

1,00,000

1.0

November

1,50,000

1,35,000

0.9

We can see from the table that while production is rising from September

to November; productivity is falling.

15

Typically when markets are booming it is worth increasing

production so as to capture market-share even if productivity does

not increase.

Conversely, during the lean periods when selling becomes difficult,

increasing production will only result in increasing unsold

inventory stocks.

It is, therefore, important to focus on increase in productivity as it

helps in maintaining profitability.

Today’s organizations are looking at Productivity improvements by

cost reduction thereby protecting their profit margins.

16

Application of Productivity

Finance

…

…

…

…

…

…

List of functions

Manufacturing

Service

Industries

17

Partial Productivity

Definition

Ratio of output to one class of input.

At a given time it considers only one input and ignores all

other inputs.

Its significance lies in its focus on utilization of one resource.

For instance, labour productivity is measured using

utilization of labour hours; whereas capital productivity is

measured in Rupees.

18

→Case:

- As a part of new assignment, Parag of Pop-Corn Products was asked to

identify areas for productivity improvements. He collected data on all

inputs and outputs of previous year’s operations being transferred into

equivalent of money units. The table below gives details with all figures in

lakh rupees.

OUTPUT

1000

INPUT

Human

300

Material

200

Capital

300

Energy

100

Other Expenses

50

Parag plans to calculate values of partial productivity to aid in his study. Please

help him in his endevour.

19

→Solution:

- Partial productivity of various inputs is as follows:

Human productivity= 1000/300= 3.3

Material Productivity= 1000/200=5.0

Capital Productivity= 1000/300 =3.3

Energy Productivity= 1000/ 100= 10.0

Productivity of other expenses= 1000/50=20.0

20

Advantages

Disadvantages

Easy to understand

Misleading if used alone.

Easy to obtain data

Cannot explain overall cost

increase

Diagnostic tool to pinpoint

areas of improvement

Profit control is not precise

21

Total Factor Productivity

In an effort to improve productivity of labour, company may

install more machinery.

Then productivity of labour will go up bringing down the

capital productivity.

Partial productivity that typically uses only one resource at a

time fails to grasp this paradox.

Historically labour and capital were considered to be the

most significant in contribution in the process of production.

22

Therefore, in The Total Factor Productivity model developed by

John W. Kendrick in 1951, he has taken only labour and capital as

only two input factors.

→ For instance, Products worth Rs 100 lakhs were manufactured

and sold in a month. It consumed Rs 20 lakhs worth labour hours

and Rs 55 lakhs worth capital.

- The Factor Productivity = 100÷ (20+55)= 1.33

23

Advantage

Disadvantage

Data is easy to obtain

Does not consider impact of

material and energy inputs, though

material typically forms 60% of the

product cost.

Appealing from the viewpoint of

the corporate and the National

economist.

24

Multi-factor Model of Productivity

Developed by Scott D. Sink Multi-factor Productivity

Measurement Model considered Labour, Material and

Energy as major inputs.

Capital was deliberately left out as it is most difficult to

estimate how much capital is being consumed per unit/ time.

The concept of depreciation used by accountants make it

further difficult to estimate actual capital being consumed.

25

Total Productivity Model

Total Productivity Model developed by David J. Sumanth in

1979 considered 5 items as inputs.

These are Human, Material, Capital, Energy and other

expenses.

This model can be applied in any manufacturing or service

organization.

Total Productivity= Total Tangible Output÷ Total

Tangible Input.

26

Total tangible output= Value of finished units produced +

partial units produced + Dividends from securities +

Interests from bonds +Other incomes.

Total tangible inputs= Value of human inputs+ capital

inputs+ materials purchased+ energy inputs + other

expenses (taxes, transport, office expenses etc.)

Advantages

Disadvantages

All quantifiable inputs are considered.

Data is difficult to compute.

Sensitivity analysis can be done.

Does not consider intangible factors of input

and output.

Provides both firm level and operational unit

level productivity.

27

American Productivity Centre (APC)

Model

American Productivity Centre has been advocating a

28

productivity measure that relates profitability with

productivity and price recovery factor.

Profitability= Sales Costs

{Output Quantities x Prices} {Input Quantities x Unit

Costs}

Productivity x Price Recovery Factor.

The APC model is different from other models in its

treatment, by inclusion of Price Recovery Factor.

What is price recovery factor?

It is a factor that captures the effect of inflation.

The changes in this factor over time indicate whether changes

in input costs are absorbed, passed on, or overcompensated

for, in the price of the firm’s output.

Thus inclusion of this factor will show whether gains or

losses of a firm are due to changes in productivity or it

merely indicates the fluctuations in the prices of material

consumed and sold.

29

Sumanth’s Five Pronged Model

All efforts towards productivity improvement have always been

30

focused on the resources i.e. men, material, money, time,

machinery, etc and the processes through they undergo to give

output.

In 1982, Sumanth and Omachanu proposed Five Pronged

Approach, classifying different techniques based on the five basic

types:

Technology

Employee

Product

Process, and

Material

In the areas of product and process improvement: value analysis

aids in eliminating non-value adding function i.e. those function

resulting in low performance at high costs from the product and

processes.

On the technology front, extremely precise and accurate highspeed machines and systems like CAD,CAM,CIM,FMS etc have

drastically reduced the processing time.

On the human front, incentive plans, job enrichment, fringe

benefits etc are used to encourage value-adding inputs from

people.

31

Inventory control, MRP, material handling systems etc. reduce

the time, space, effort and money involved in making material

available for its time and place utility.

Techniques like work-study, ergonomics, etc eliminate motions

that are non-productive or make them easy to perform are

included in the human factor.

Today, Lean Production System approach is a holistic one, which

covers all areas of productivity improvement.

32

In order to sustain, a few other techniques like JIT, TPM, TQC,

KAIZEN, Quality Circles etc can be applied simultaneously.

Summary

A. Technology Based

- CAD, CAM, Integrated CAM, Robotics, Laser Beam Technology,

Energy Technology, Group Technology, Computer Graphics,

Simulation, Maintenance Management, Rebuilding Old

Machinery, Energy Conservation.

33

B. Employee Based

- Financial Incentives, Group Incentives, Fringe Benefits,

Promotions, Job Enrichment, Job Enlargement, Job Rotation,

Worker Participation, MBO, Skill Enhancement, Learning Curve,

Working Condition Improvement, Communication, Zero Defects,

Punishment, Recognition, Quality Circles, Training, Education,

Role Perception, Supervision Quality.

34

C. Product Based

- Value Engineering, Product Diversification, Product

Simplification, R&D, Product Standardization, Reliability

Improvement, Advertising & Promotion.

D.Task Based

- Method Engineering, Work Measurement, Job Design, Job

Evaluation, Job Safety Design, Ergonomics, Production

Scheduling, Computer Aided Data Processing.

E. Material Based

- Inventory Control, Material Requirement Planning, Materials

Management, Quality Control, Material Handling and

Recycling.

35

ILO Approach to Productivity

Improvement

The classic ILO approach is Task Based.

It breaks manufacturing time into basic work content, added

work content, and ineffective time.

The main focus is on reducing inefficient time in the total

work content.

The Basic Work Content

The amount of work “contained” in a given product or

process measured in man-hours or machine hours.

36

- The basic work content is the irreducible minimum time

theoretically required to produce one unit of output.

B.AddedWork Content

Work content added by defects in the design or specification of the

product. It may be due to lack of standardization and/or

incorrect quality standards.

- This additional work content is the time taken over and above the

time of the basic work content due to features inherent in the product

which could be eliminated.

37

(2) Work content added by inefficient methods of production or

operation.

- This is the time taken over and above the basic work content plus

(1), due to inefficiencies inherent in the process or method of

manufacture or operation.

- This includes wrong machine used, processes operated in bad

conditions, wrong tools used, bad layout, operator’s bad working

methods etc.

38

C. Ineffective time

- All interruptions which cause the worker or machine or both to

cease producing or carrying out the operations on which they are

supposed to be engaged.

- Irrespective of the cause, these must be regarded as ineffective time

because no work towards completing the operation in hand is

being done during the period of the interruption.

39

(1) Ineffective time due to shortcomings on the part of the

management.

- Time during which man or machine or both are idle because

management failed to plan, direct, coordinate or control efficiently.

(2) Ineffective time within the control of the worker.

- Time during which man or machine or both are idle for the reasons

within the control of the worker himself.

40

Focus on reducing added work content

& inefficient time in the total work

content

Following are the methods by which added work content &

41

inefficient time can be reduced.

→By reducing

Poor design and frequent design changes

Waste of materials

Incorrect quality standards

Poor layout and poor utilization of space

Inadequate material handling

Frequent stoppage in production

Ineffective method of work

Poor planning of work

Frequent breakdowns

Absenteeism & late coming

Poor workmanship

Accidents and occupational hazards.

42

Quality Circles

Quality Circles were the logical consequence of the various

waste elimination programmes that were run in many

Japanese corporations in early fifties.

It provided a platform for the workers to get together and

use techniques for their quest for continuous selfdevelopment and organizational improvement.

In 1980, the first Quality Circle was launched in Hyderabad

plant of Bharat Heavy Electricals Limited.

43

Definition and Meaning

Quality Circle is a small group of employees in the same

work area or doing a similar type of work who voluntarily

meet regularly for about an hour every week to identify,

analyze and resolve work related problems, leading to

improvement in their total performance ad enrichment of

their work life.

This definition is quite comprehensive and most commonly

accepted.

Every part of the definition is significant.

44

→Why small group of employees?

- Experience indicates that the optimum number of a Q.C. is about

eight to ten.

- If a circle is formed with less than five members, one can imagine

the strength of the group when absenteeism is high.

- Interaction and participation becomes more pronounced when

group members are more than say, six.

45

→Why in the same work area or doing similar type of work?

- This ensures Q.C. to be a homogeneous and cohesive group

- The discussion that takes place remains interesting to everyone only

if members are from the same background.

- It also helps the members to understand the intricacies of the

problem.

- Also the application of QC tools that are recommended require the

expertise in the field.

46

→Why is participation voluntary?

- ‘Voluntary’ in the Japanese context has a different

interpretation as compared to

what is normally

understood in the Indian context.

- To the Japanese , the very word ‘voluntary’ implies 100%

participation.

- Hence, when a company in Japan decides to implement

Quality Circle, every body has to enroll as a member.

- Japanese have refrained from using from using the word

‘compulsory’ as it indicates not just 100% participation

but achievement of targets as well.

47

Quality circle requires some amount of creativity

that is not

under control, therefore, the word voluntary is used to indicate

that achieving targets is not mandatory, but participation is

compulsory.

In India the term ‘voluntary’ has been used to circumvent the

possible opposition from the trade unions.

→Why to meet regularly for an hour every week?

Meeting regularly is absolutely essential for the success of Q.C.

48

If the meetings are kept at longer intervals then cancellation of

one or two meetings will further lengthen the interval leading to

complete stoppage of work.

→ Why to analyze and resolve work related problems?

As employees know more about their own work area than any

body else, they are in a better position to solve problems

occurring there.

49

Structure of Quality Circle

Steering Committee/

Departmental Committee

Top Management

Coordinating centre

TM

Steering Committee

Facilitator

Leader/Deputy Leader

Member

Non Member

50

Role of Each Element

1. Non-Members

Initially, all the employees in a particular work area may not

volunteer in joining QC activity.

Some others may not be interested in activity but prefer not

to get directly into it.

QC members must understand that solutions they find

cannot be implemented without the cooperation of these

non-members.

Members must encourage non-members to participate in

activities so that they change their attitudes and form circle

on their own.

51

2. Members

- Members must be restricted to grass root level persons.

- If membership is kept open only to officers and executive, the very

purpose of QC gets defeated.

- Members actively participate in selecting problems of their

concern, analyzing it, finding solution to it and finally making

presentation to the management.

52

3. Leader/Dy. Leader

- In Japan, first line supervisors are nominated as leaders.

- However, in India, it is advisable to make members choose their

own leader.

- Earlier there used to be only one person as leader.

- But considering heavy absenteeism that prevails in our country,

there can be one deputy leader who will take charge in absence of

leader.

53

The leader or the deputy leader’s endeavour is

- To maintain cohesiveness of the team.

- To plan agenda for meetings.

- To ensure participation from every member by assigning them

work.

- To encourage consensus decision making process.

4. Facilitator

- Facilitator is the senior officer of the department where QC is

working and is nominated by management.

54

The facilitator

- Can facilitate more than one QC.

- Is responsible for success of QC’s operating in his area.

- Ensures necessary facilities are available to the team for

operation.

- Joins Steering Committee meetings and gives results of activities

of QC.

55

5.

-

56

Steering Committee

The committee comprises of heads of major functions as members

and chief executive as the chairman.

The committee makes top management’s support visible.

Steering committee

Meets regularly once in two months.

Takes overview of QC activity in entire organization.

Gives policy guidelines fr the propagation of movement

6. Coordinating Agency

- The job of coordinating agency is similar to facilitator but on a large

scale.

- It coordinates QC activities throughout the organization.

- Steering committee decides the composition of coordinating agency.

Coordinating agency

- Organizes a training programme for members when QC is formed.

- Evolves norms to assess performance of different QCs.

57

- Prepares budget for QC activity.

- Arranges guest speaker or library facility for members.

7. Top Management

- Top Management does not fall within the formal structure of

QC.

- Its main job is to

Convey its commitment to all employees

Extend necessary support by attending conventions and

sanctioning funds.

Form quality council and establish a conducive atmosphere.

58

Quality Control Tools

Quality circles use certain basic tools to identify, analyze,

and resolve their problems, called QC tools.

A. Stratification

Stratification refers to segregation of problem area into

smaller units so that each can be taken more effectively.

What appears to be a single problem may actually consist

of a set of problems, each with a different root cause.

59

For instance, the problem of ‘Low output during the day’

may have different set of causes during the first and second

shift.

There is no way of knowing the correct way of stratifying

the problem but when faced with a problem, one needs to

use his skills and expertise to be able to do good

stratification.

The underlying principle is that when you find a problem,

break into sub problems and find out the root cause of each.

This procedure becomes faster and simpler.

60

Examples of Stratification

Operation Wise

Skill, Experience, Years in job, Gender, individual, Union,

Educational qualification.

Machinery

Type of machine, Machine number, order new, structure, functions, moulds,

jigs etc.

Material Wise

Maker, lot, date of arrival, date of use, Type, constituents, storage period,

storage place, production place.

Method Wise

Operation method, place of operation, Temperature, Humidity, Pressure,

No. of revolutions, speed, sampling etc.

Time Wise

Day, day and night, shift (in case of shifts), days of the week, month, normal

day and the day after holiday, immediately after commencement, right

before end, hour, around machine adjustment.

Product Wise

Lot, vendor, New & old products, standards, special products. Etc.

Inspection,

calibration

Inspector, Testing machine, Gauge, person in charge of calibration, place of

calibration.

61

B. Check Sheet or Tally Table

A data-recording tool where the frequencies of each type

are marked against it.

The frequencies against each will indicate its relative

importance and subsequently help in drawing pareto

diagramme.

62

Sr. No.

Cause

Tally Marks

Frequency

Remarks

1.

Broken Pin

//// //

7

-

2

Broken Link

///

3

-

3

Loose contact

//// //// //

12

-

4

No Power

//

2

Known Before

C. Pareto Analysis

This technique was developed by Italian economist Pareto

which showed that 20% population of a country controls

80% wealth and vice versa.

This is applicable in most cases and is called 80-20

principle.

Along these lines, Pareto diagramme can be drawn by

finding out which 20% causes create 80% problems.

63

Pareto’s Analysis- A Case Study- Cause of decline in production

in Rubber component manufacturing company.

64

Code

Item

Causes

Time (Min)

Time

(Min)/Case

A

Rubber Recovering

16

145

9.1

B

Repair Delays

3

255

85.0

C

Repairs

5

344

68.8

D

Adjustments

12

206

17.2

E

Preparations

48

232

4.8

F

Component Search

5

137

27.4

G

Component

Replacement

9

110

12.2

H

Raw Material Delay

2

780

390

I

Miscellaneous

17

303

17.8

117

2512

21.5

Total

It can be seen problem H consumes most of the time.

If we take care of this problem then there will be a dramatic

increase in productivity as compared to taking other

problems in the beginning.

Thus the important problems need to be tackled on top

priority.

65

D. Histogram

Histogram is also called frequency distribution chart and

represents the condition of variance through the chart .

It is a visual presentation of the spread on distribution of

data to monitor a process and determine its consistency in

meeting customers’ requirements.

The population in the data is classified on the basis of their

similarity into different groups or classes.

66

Each class or group is classified on the basis of their

similarity into different groups or classes.

Each class or group is represented by a rectangle or a bar.

The class interval or causes of the problem or defects are

placed on x-axis and frequencies or the number of defects

is placed on the y-axis.

The height of each bar is proportional to the number of

frequency of its class interval and each bar should be of

same width.

67

68

Uses of Histogram

The shape of the diagramme reveals the mean value

variance.

By frequency distribution chart the standard deviation and

mean deviation can be calculated.

By comparing with rated value, the process efficiency and

rate of defective goods could be calculated.

By visualizing variances, abnormalities come to light.

69

E. Ishikawa or Fish Bone Diagramme (Cause and Effect

Diagramme)

Investigative tool developed by Dr. Ishikawa of Japan.

This diagramme is arrangement of all possible causes, which

give rise to the effect or problem in hand.

Prior to plotting this diagramme, it is necessary to list down

all possible causes by brain storming, so that no important

cause is missed.

They are segmented broadly into four ‘M’s viz Men,

Machine, Method, and Material.

70

Machines

Men

Sub cause

Sub cause

Final Effect

Sub cause

Sub cause

Method

Materials

71

F. Control Charts

Control charts

are used to investigate whether the

manufacturing process is in stable condition or not and is

used to maintain the manufacturing process in stable

condition.

Central line (CL), upper control line (UCL), and lower

control limit (LCL) are the main three lines which

constitute a control chart.

UCL

CL

LCL

72

→X (bar) Charts

Central Line =Grand Mean

UCL= Grand Mean + A2 x Mean Range

LCL= Grand Mean - A2 x Mean Range

→R (bar) Charts

Central Line= Mean Range

UCL= D4 x Mean Range

LCL= D3 x Mean Range

73

A case of a Vending Machine

Shalini is a vending machine operator at a coffee shop. The

machine at her shop gives 50 ml of coffee at a time. Lately

Shalini has noticed that machine never fills the glass exact

ml but it either under fills or over fills. She complained to

the manufacturer who sent Sachin, the service engineer to

her shop. After inspecting the machine, Sachin said “I think

we must test this machine fr precision and accuracy.”

“How do we do that?” asked Shalini

74

“Let us take five samples of four readings each of this

machine and then we can plot control chart and know

answers to our questions.”

Following is the chart that shows the readings recorded by

Sachin and Shalini.

Sample No.

X1

X2

X3

X4

Mean

Range

1

49

50

50

49

49.5

1

2

49

49

49

50

49.25

1

3

48

48

50

49

48.75

2

4

48

48

48

49

48.25

1

5

50

49

51

48

49.25

3

Grand Mean

75Mean Range

49.05

1.6

Looking at both the graphs, Sachin told Shalini, “ Your

machine is perfectly all right. And whatever variations

you are getting is the inherent variation of the

machine.”

→ Thus control charts help workers monitor the quality

of their work, doing away with inspection.

G. Scatter Diagrammes

It is a graphical technique for studying relationships

between two variables (which occur in pairs) to figure

out if there is a connection between the variables and

how strong this relationship is.

The density and the direction of the cloud indicates

how the two variables influence each other.

76

A positive relationship between two variables means that

increasing values of one variable are associated with

increasing values of the other.

A negative relationship means that increasing values of one

variable are associated with decreasing values of the other.

→A scatter diagramme is used after a cause and effect

analysis to determine what will happen to the one variable

if the other is changed.

69

Benchmarking

Benchmarking is the systematic and continuous process of

determining what the best performances and underlying skills of

leading organizations are in their strive for excellence.

And based on above, stimulate the organization’s own strive for

excellent performances at all organizational levels.

It is a strategy to stimulate changes and optimize performances.

78

The Benchmark Process

1. What is to be

benchmarked

8. Implementation &

Monitoring

3. Gather data

4. Analyze the data

7. Develop action

plans

6. Formulate the

functional goals

79

2. Identify the

benchmark

partners

5. Determine the

performance gap

When do you use Benchmarking?

Benchmarking is mostly used to compare processes and

performances against those of recognized leaders.

Based on this, the performance gap between the organization

and the best competitor is evaluated.

Organizational processes usually used for benchmarking are:

(a) Marketing,

(b) Sales,

(c) Purchasing,

(d) Technology development,

(e) Product development, and

(f) Logistics

80

Types of Benchmarking

1.

-

81

Internal Benchmarking

Internal benchmarking involves comparison of internal activities

and processes within own company.

Usually of interest to large organizations where it is determined

as to how far other departments and divisions execute similar

activities within their own organizations more efficiently and

effectively.

2. Competitive Benchmarking

- A comparison is made with direct competitors.

- Operations processes of these competitors are measured and

compared against its own situation.

- Based on what is done by the competitor and what is lacking

within the own organization, the own processes can be

adjusted to improve efficiency and produce a better and

cheaper product.

- For example, a software producer who wants to improve his

competitive position can try to figure out what Microsoft has

done to become the market leader.

82

3. Process Benchmarking

- Involves search for the best in class of a certain process,

regardless if it is a competitor or not and in which industrial

branch it is applicable.

- For example, the logistical activities of a chemical company

can be compared with an electronics company with an

excellent logistical process.

4. Strategic Benchmarking

- Used to obtain sweeping breakthroughs in the areas of

productivity in order to strengthen its competitive position.

- This type of benchmarking helps determining the relative

competitive position of all business activities and suggests the

best course to follow.

83

This can be done in several ways such as

- Comparing your own strategy and financial performance against

those of competitors.

- Determining from the strengths and weaknesses of the competitors

in which areas your organization can outdo these competitors, and

- Which improvements are best contributed to its own core

competencies.

84

Steps to execute Benchmarking Process

1.

-

-

85

Determine what should be benchmarked.

It is determined which functions, tasks, processes, or activities

within the own organization will be subjected to benchmarking.

Based on the critical success factors, one or more of processes

will be selected for benchmarking.

Appoint a team that will map these processes in detail.

- The team will identify process stages and determine the process

flow, the procedure for each process stage, relevance performance

indicators, inputs and outputs of the process and customer

requirement.

2. Identify the benchmark partners.

- Important criterion for the selection of benchmark partners

should be outstanding regarding the competitiveness of activities,

availability of reliable information about the partners.

86

- Identifying benchmark partners requires consultation of sources

such as databases, professional magazines, newspapers, bank

reports, annual report of competitors, seminars, consultancy

bureaus, universities etc.

- Also, interviews with customers, suppliers, employees and

bankers.

3. Gather Data about the performances of partners.

- Through interviews, surveys, consultation and technical magazines.

87

- Process and working methods of partners are examined

thoroughly.

- Performance indicators are measured and qualitative and

quantitative data is gathered.

4. Analyze the data.

5. Determine the gap between the performance level of organization

and that of its benchmark partner.

- Differences in working methods and causes of the differences in

performance is documented.

- The main question to be asked is “why is the efficiency and

effectiveness of the own process lagging behind that of the best in

class?”

88

6. Based on the results of the benchmark study, new functional goals

are established to close the performance gap.

7.The goals are now transformed into concrete action plans.

8. Implement specific actions and monitor the progress.

- Verify whether actions are executed as planned, whether the

process is changing, and if the benchmark goals are being met.

- If required, possible adjustments are made.

89

9. Start again

- Benchmarking is a process of continuous improvement.

- There are always better and improved methods.

- Competition is not standing idle.

- In due course of time, new best practices are developed.

90

Example from Rank Xerox, Netherlands

“In the past, the order processing department of Rank Xerox

had 20 employees, wherein the throughput time of an invoice

was 5 to 8 days. After a benchmark study, the activities within

the department were divided into four segments based on the

invoice amount. Finally, the number of persons in the

department was reduced and an invoice was sent within 24

hours in respect of 95% orders.”

The reason for the benchmark study was that customers were

displeased about long delivery time.

A shorter delivery time also resulted in an accelerated

invoicing, a smaller department, a higher customer satisfaction

and improved liquidity.

91

Creativity Based Techniques

Innovators have known since long that the process of

generating ideas is not logical or analytical process; it is a

creative process.

Some of the commonly used creativity techniques are:

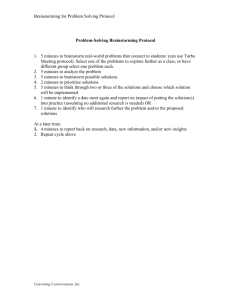

(1) Brainstorming

Brainstorming is defined as a means of getting large

number of ideas from a group of people in a short time

by following certain rules.

92

The definition focuses on three aspects:

(a) Large number of ideas

-

93

Brainstorming is a tool to generate a large number of

ideas.

There is no guarantee that the ideas will be practicable.

There is no guarantee that the ideas will be best.

The hypothesis underlying the efficacy of brainstorming is

that the quantity leads to quality.

- Often good ideas are under the bad ones in the brain

94

and unless the bad ideas are permitted to exit, the good

ones do not surface.

(b) A group of people

- Brainstorming is a group process.

- The optimum size of a group is about twelve; but it can

vary between six to twenty.

- Ideally the group should be heterogeneous, with as

much diversity in gender, age, qualifications and

experience, as possible.

- Such heterogeneity permits observation of problem

from different view points, which is the crux of the

brainstorming process.

(c) In a short time

- This refers to the rate of flow of ideas.

- This rate can be as high as one hundred ideas in a period

of ten minutes.

- Once again, the emphasis is on quantity.

→ The success of Brainstorming

- Following four basic guidelines can ensure the success

of a brainstorming process.

(a) Suspend judgment

- Just listen and list the ideas.

- Do not try to judge or evaluate any idea till you finish

the session

95

(b) Encourage free-wheeling of ideas

- Permit wild ideas; encourage dreaming, and thinking

around the problem.

(c)Quantity

- Go for quantity i.e. number of ideas.

- Do not examine quality or feasibility of idea at this

stage.

(d) Cross fertilization of ideas

- Encourage members of the brainstorming group to hitch

hike on each other’s ideas.

- Show no interest in identification of ownership of each

idea.

96

The Stages of Brainstorming

The process of brainstorming consists of six stages

(1) Stating the problem

All the participants of brainstorming sessions must know

some details of the problem.

Therefore, in the first stage, we need to state the problem

and try to provide some information about it.

(2) Re-stating the problem

-

97

- Ask the participants to look at the problem in a different

ways and identify as many facets of it as they can.

- Participants restate the same problem depending on the

way they look at it.

- If the problem is looked at from many angles, it becomes

easy to generate a large number of solutions.

(3) Select a basic re-statement

- After listing down all the re-statements, select one or two of

these as a lead to brainstorming session.

98

- This selection is done by the leader alone.

- This stage must be closed with a clear definition of the

objective of the brainstorming session i.e. expected

outcome.

- If this is not done, the session could easily turn into a

‘gossip’ session.

(4) Warm up

- In this stage participants do free-wheeling for the purpose

of actual generation of ideas.

- Some participants observe silence for a few minutes.

99

- Silent meditation can be a great tool for use in this stage.

(5) Idea generation

- Generally participants sit in circle.

- The leader displays the selected statement and invites ideas.

- People are encouraged to speak out the moment they get an

idea.

- The leader notes down each and every idea, without

evaluation or judgment.

- The process goes on till the ideation dries up.

100

(6) Wildest idea

- In this final stage, the group takes up the wildest of the

ideas and attempts to turn into something useful for further

brainstorming.

- After this, the session is ended.

→Dos and Don'ts of Brainstorming

101

Do’s

Don'ts

Suspend judgment

Spend too long on initial discussion

Allow wild and silly ideas

Allow observers

Have a warm up session

Tape record the proceedings

Encourage noise and laughter

Accept interruptions

Take more than one statement of the problem

Drag a session that has dried up.

(2) Nominal Group Technique

- In the Nominal Group Technique, a group of qualified

individuals come together to present their ideas and then

vote for the most favoured one.

- This idea is taken up as the decision of the group.

- The group is referred to as ‘nominal’ since the group

members do not directly interact with each other.

- Every member works on the solution independently.

102

Steps of Nominal Group Technique

1. A small group gathers around a table, receives

2.

3.

4.

5.

6.

103

instructions, and identifies the problem.

Participants silently write down ideas about problem

solving.

Each participant presents ideas one at a time; leader

writes them on the chart.

Group discusses, clarifies and finally evaluates each

idea.

Participants privately rank ideas in order of their

preference.

The highest ranking idea is taken as group decision.

Advantages & Disadvantages

It allows formation of an informed opinion.

Ranking of ideas by the group members is facilitated by

supplying information held by each member to all other

members.

Fairly rapid process, permitting objective exchange of

ideas.

Requires a trained facilitator to run the session.

→ As it is important to remove the element of personal

bias and prejudices, it is advisable to record the ideas

without mentioning the name of the person giving it.

104

Lateral Thinking

→“You are on the terrace of a ten storied building.” Prashant

was posing a riddle before his friends, “and suddenly you

hear a fire alarm. Hw will you reach the ground floor?”

→ “Very simple” exclaimed Shalini, “ I will rush down the

staircase. Don’t tell me there is no staircase.”

→ “I’ll use the elevator”, Sachin joined in, “a ten storied

building is bound to have an elevator. It will be faster.”

105

→ “I have a faster way” said Prashant, “I can jump down

from the terrace”

→ “Talk sense” Sachin said, “You will not reach in one

piece.”

Sachin and Shalini’s reactions are quite expected because

Prashant’s solution sounds illogical.

But it is certainly not impossible.

Our resistance to change makes us reluctant to accept

something new or different.

106

When we have a couple of standard, tried and tested

solutions in hand, we stop looking further.

We fall into the syndrome of ‘the good being the enemy of

the better.’

Having something good, we cease our search for the better.

To be more innovative, we must learn to think in radically

different ways, away from conventional patterns of

thinking.

107

Definition and Meaning

Lateral Thinking is defined as a thinking process in which

we make deliberate attempts to generate new ideas by

introducing a discontinuity in our thought process.

Lateral thinking implies considering a problem from fresh

perspective, a point o view which is different from the

norm, the obvious.

The change in perspective can be relaxing as well as

productive.

108

Some examples are:

(a) Visualizing the extreme opposite of the situation or

-

-

109

reversing the objective.

Suppose you want to bring down your high inventory

levels, try thinking “what can be done to increase

inventory?”

This might bring to light some inherent weaknesses in the

system.

Even if you don’t strike the solution, you will at least

know what Not to do.

(b) Looking at the surroundings of the problem rather than the

problem itself.

- Suppose you have a machine that breaks down frequently.

- Is it a machine designed for air-conditioned room but kept

at room temperature.

(c) Challenging the assumption

- Believe that your information is wrong.

- Try something that goes against the assumption.

- It may turn out that that some of the old ways can be

improved or replaced.

110

The Principles of Lateral Thinking

(a) Background

-

-

111

The need for Lateral Thinking arises from the fact that

dominance of an idea or concept suppresses other useful

and efficient ideas stopping the progress.

Dominance blocks the way to explore continuously more

and more useful and efficient ideas stopping the progress.

(b) Escape

- This principle suggests recognition of the dominant idea

and deliberate search for alternate ways of doing things.

- The search has to be for alternate ways and not for the

best way.

(c) Provocation

- This assumes that it may be necessary to be wrong at

some stage in order to reach the final right solution.

- Therefore, we use one idea to provoke or generate

another set of ideas, rather than checking its individual

correctness.

112

Difference Between Conventional Thinking

and Lateral Thinking

Conventional (Vertical) Thinking

Lateral Thinking

Conventionally we think to chose and prove

something.

Here we think to generate and explore ideas.

It is in search of answers.

It is in search of questions.

Uses information in its meaning.

Uses information for its effect.

Seeks continuity i.e. expects one thing to follow

another.

Seeks discontinuity.

Concentrates only on relevant facts eliminating

irrelevant facts.

Doesn’t consider anything as irrelevant.

It is a close ended procedure aimed at result.

It is an open ended process giving maximum

results, but makes no promise.

113

Whole Brain Thinking

→ “Reaching Somaiya Campus……..Visiting SIMSR, the

canteen…. …The first day of the class…..new faces, new

ways of learning……..”

→“Hey, where are you,” said Shalini, snapping her finger in

front of Vaibhavi’s face.

→ Suddenly, coming back to reality, Vaibhavi shook her face

and said smilingly, ‘just moved from my right brain to the

left.’

→What did she mean?

→ She was referring to the split-brain theory.

114

The Split-Brain Theory

The theory proposed by neurosurgeon Rober Sperry says

that our abilities, skills and personality traits are strongly

influenced by our habit of using one side of the brain more

than the other.

The two hemispheres of our brain have distinct thinking

processes.

Visualization, emotions, intuition, and motor skills are

housed in the right brain.

115

Logic and communication are functions of the left brain.

Our genes and the way we have been brought up or trained

often determines which hemisphere of our brain we prefer to

use and in turn that determines the way we function.

We could be right dominated or left and accordingly our

interests or abilities would emerge.

Artists or sportspersons are right dominated while those

excelling at maths or language would be left dominated.

116

Whatever our dominance or preference be, we do make

automatic shifts as per the occasion.

When Vaibhavi was daydreaming, her right brain was at

work.

And then she experienced a shift as she used her left brain

to analyze what she had been doing.

Typically, we use our right brain while listening to music or

while painting and the left brain while speaking or solving

a puzzle.

117

Examples of your Hemispherical

Dominance

→ How would you go about solving a problem?

Would you follow an organized approach like defining

the problem and breaking into parts, conducting

research and recording possible solutions, eliminating

the non-viable solutions and then selecting the best of

the rest?

If yes, then you are probably a left dominant.

A right dominant person would try to see the picture as

a whole, get a feel of what will work and place his trust

in hunches or gut feeling.

118

→ How would you guide a person to a particular place if

asked to give directions.

A left dominant person would be precise and say something

like “take the second left and then the first right.”

Right dominant go for visuals cues, say “Turn left when you

come across this tall green building with a dome-shaped

structure at the top.”

119

Why Whole Brain Thinking?

Ever tried giving a speech?

The best of the words and impeccable grammar wouldn’t

be sufficient to deliver an effective rhetoric.

In terms of public speaking, we would say that speech

needs to come from the heart to make an impact.

If we use the terms of split brain theory, we would say that

in order to speak well, we must use both sides of the brain.

120

Left brain skill to form thoughts into words and the right

brain ability to give the speech an emotional touch, thus

making it more absorbing.

Learning to use both sides of brain would help unleash a

little more of the enormous amount of brain power we have.

We would be able to take better control of situations if we

consciously selected the task-appropriate hemisphere to

meet each demand.

If we think in terms of management functions: planning,

organizing, communicating etc these are all left brain skills.

121

Increasingly, managers are recognizing that problems

cannot be solved by logic, discipline, and detailed analysis.

To arrive at better solutions, free-spirited innovation and

comprehension of overall picture is equally important.

Hence, we must learn to draw from both the left side of the

brain, home of logic and efficiency and the right side of

brain, home of creativity, intuition and inspiration.

122

Delphi Technique in Creativity

A method of pooling a large number of expert judgments

through a series of increasingly refined questionnaires i.e.

gathering the judgments of experts for use in decision

making.

Used for complex, unstructured problems, to develop the

strong pros and cons for alternative solutions.

Based on generation of suggestions and arguments and

clustering on most favoured and least favoured alternatives.

123

→ The stages are:

(1) Generation of individual opinions on the nature of

problem and possible solutions.

(2) Tabulate results and show them to the group, preserving

anonymity.

(3) The most and least favoured opinions must be restated,

preserving anonymity.

(4) The group members read the list of opinions and,

individually, re-state their opinions.

(5) Results are re-tabulated and shown to the group.

124

Track suggested solutions.

Vote on alternatives, their desirability.

Vote on arguments, their importance and validity.

→ Delphi is based on anonymity of the grop members.

→Oriented towards avoiding any direct confrontation.

→ Decisions with Delphi express opinions rather than facts

which require group members to be experts.

→ Delphi does not require physical presence.

125

Total Quality management

Total Quality management is defined as an integrated approach in

delighting customer –both internal and external- by meeting their

expectations on continuous basis, through everyone involved with

the organization, working on continuous improvement along with

proper problem solving methodology.

The term ‘customer’ refers to all those to whom we supply a

product or a service or information.

126

Thus, apart from the ultimate users, the retailers and stockists

become the external customers to the company while the

transporters become the suppliers to the company.

Departments within the company become internal customers to

each other.

Thus, the Production department is a customer to the purchase

department and supplier to the sales and dispatch department.

127

Definition of Quality

1.

-

-

128

Quality is fitness for use.

Definition put forth by Juran represents the customers’ point of

view.

Customers are usually multiple, and they may put the product

or service to such multiple uses, which the manufacturers may

not have intended.

In any case, customer’s viewpoint is most important as it is he

who uses the product.

2. Quality is establishing standards and specifications.

- If the customer’s voice in terms of ‘fitness for use’ is to be

incorporated into the product or service, it can be done only

by laying down standards or specifications for the product or

service.

- Various agencies such as BIS (Bureau of Indian Standards),

United States Pharmacopeia (USP), Japanese Industrial

Standards (JIS), International Standards Organization (ISO)

establish a list of standards, specifications and tolerances to

facilitate manufacture of products of good quality.

129

3. Quality is conformance to standards

- Standards are meaningless unless they are conformed to.

- Statistical Process Control (SPC), Poka Yoke (Mistake Proofing),

and many Q.C. tools, focus on conformance to standards.

Very peculiarly if 99.9% conformance to standards is maintained

in the product, the customer satisfaction does not rise

proportionately .

130

When the conformance to standards reaches 100%, the customer

satisfaction jumps to 100%.

Customer delight, is all about gaining customer satisfaction in

excess of 100%.

Attempting customer delight before customer satisfaction is

impossible.

► A significant view of Total Quality Management.

Meeting the agreed requirements of the customer, at the

lower cost, first time and every time.

131

The standards and specifications provided by the customer

constitute the agreed requirements of the customer.

First time every time means without rework or rejection.

TQM is not one time activity but has to be pursued by all the

employees of the organization continuously.

132

Deming’s 14 points of Management

1.

133

Create constancy of purpose for the improvement of product and

service.

Establishing constancy of purpose means

Innovation

Put resources into research and education

Continuously improve in product and service

Invest in the maintenance of equipment, furniture and fixtures.

2. Adopt the new philosophy

- Don’t ask your customers to pay for your defects and delays.

3. Cease dependency on Mass Inspection

- Quality comes not from inspection but from improvement of

the process.

- If products are of high quality then there should not be any

need for inspection.

- Inspection of finished product would mean just a rework.

- If the problem can be eliminated at first stage then it is possible

that the final product will be defect free.

134

4. End the practice of awarding business on price tag alone.

- Price has no meaning without a measure of the quality being

purchased.

5. Improve constantly and forever the system of production and

service.

- Improvement is not a one-time process.

- To ensure whether a firm is improving or not ask the following

questions

Is the firm doing better than a year ago?

Is marketing more effective?

135

Whether customer satisfaction has increased?

Whether pride and performance of empolyees has improved?

6. Institute Training and Retraining

- Employees should be trained different set of skills for different jobs.

7. Institute Leadership

- Leadership is the job of management.

- Leadership has to help people do their jobs better and also to take

responsibility for their success and failure.

136

8. Drive out fear

- People are afraid of

Losing their raises and promotions.

New assignments

Superior’s threats

Admitting mistakes, etc

- Therefore, workers should feel secure so that they will come up

with innovative ideas, suggestions and improvements over existing

systems.

137

9. Breakdown barriers between staff areas

- It is management job to help the staff areas work together to

promote teamwork because people work in systems which

management has created.

10. Eliminate the slogans, exhortations and targets for the workforce

- Due to slogans, employees feel offended instead of being inspired.

- A goal without a method for reaching it is useless.

138

11. Eliminate numerical quotas

- It turns out to be numbers rather than quality.

12. Remove barriers to Pride ofWorkmanship

Management should listen and watch workers voicing their

frustrations at being unable to perform their jobs the way they

should like to.

13. Institute a vigorous programme of Education and Retraining

It is not enough to have good people in the organization.

They must be continually acquiring the new knowledge and new

skills.

139

- Education and retraining – an investment in people- are required

for long term planning.

14.Take action to accomplish the transformation

- Every employee of the company, including the manager should

acquire a precise idea of how to improve quality continuously.

- The initiative must come from the management.

140

PDCA Cycle

Plan

4. Study the results.

What did we learn?

Do

Act

3. Observe the effects of

the change or test

Check

141

1. What could be the most

important accomplishments

of this team? What changes

might be desirable? What

data is available? Are the

observations needed?

2. Search for data on hand

that can answer the question

propounded in step 1. Or carry

out

the changes or tests

decided upon.

Step 1.

- Study the process, decide what changes might improve it.

- Organize appropriate teams.

- The team to comprise of people from engineering, purchase,

production etc.

- Find what data are necessary.

- Do the data already exists or is it necessary to carry out a change

and observe it?

142

Step 2.

- Carry out tests or make the change, preferably on a small scale.

Step 3.

- Observe the effects

Step 4.

- Understand the outcome of the test.

- Repeat the test if necessary, preferably in a different environment.

143

Traditional Management Vs TQM Approach

Parameters

Traditional Management

TQM Approach

Organization structure

Is hierarchical and has rigid

lines of authority and

responsibility.

Becomes flatter and more

flexible and less hierarchical.

Focus

On maintaining the Status Quo

and operating efficiency.

On continuous improvement in

the system.

Relations between workers and

supervisor

Dependence, fear and control.

Workers perceive supervisors

as coaches and facilitators.

Management Perspective

Labour and training as cost.

Labour as asset and training as

investment.

Primary basis for decision

Gut feel and instinct.

Shifts to facts and systems.

Purpose

To control

To monitor and improve.

144

Deming’s Chain Reaction in TQM

Improve Quality

Provide jobs

more jobs

145

and

Cost Decreases

Stay in business

Productivity

improve

Capture market with

better quality and lower

prices

Quality Trilogy in TQM-Juran

Juran defines quality as fitness fr use in terms of design,

conformance, availability, safety, and field use.

Juran introduced the managerial dimensions of planning, organzing,

and controlling and focused on the responsibility of management

to achieve quality and need for setting goals.

Juran was less concerned with detailed techniques of quality

control and much more centered on the idea of management

responsibility.

146

Juran emphasized that quality issue need to be addressed

through management action in the same way as strategic

issues, financial issues or other similar concerns.

He suggested the use of cyclical process of quality

management , linking quality planning, quality control and

quality improvement termed as ‘Quality Trilogy’

‘Juran Trilogy’ approach explains three managerial processes

used in managing quality, as shown below.

Quality Planning

Quality Control

Quality Improvement

Leading to not just quality control but success

147

►Quality Planning

Objective: To achieve a process capable of meeting quality

goals.

- Identify customer needs (internal and external)

- Identify customer needs

- Develop features that satisfy customer needs

- Establish quality goods

- Process capability.

►Quality control

Objective: To achieve conduct of operations according to

quality plans.

148

- Choose units of measurement

- Establish how to measure

- Establish standards of performance

- Measure actual performance

- Interpret difference (Standard v/s actual)

- Take actions on the difference

► Quality improvement

Objective: To achieve conduct of operations at levels of

quality distinctly superior to planned performance.

149

- Prove the need for improvement

- Build awareness of opportunities to improve

- Organize for diagnosis

- Provide remedies

- Prove remedies are effective

150

Value Analysis and Value Engineering

Value Analysis is a technique that allows to increase the value

of a product or a service systematically, eliminating all the

functions that do not add any value or benefit to the product.

A product or process exists to fulfill a need.

This need or set of needs is termed as a function, that the

product or process satisfies.

For instance, knife exists to fulfill the need of cutting and

hence to cut is the function of knife.

151

What is meant by term Value?

Value is a function of ‘Desired Performance’ and ‘Cost’.

Expressed as Desired Performance (P) ÷ Overall Costs (C)

Desired performance is expressed by the term worth which is

defined as the lowest cost to achieve the Use (work) function and

Aesthetic (sell) function.

152

How do define VA & VE

Very often the two terms Value Analysis and Value Engineering

are used synonymously.

However, difference between them will be clear from the way

they originated.

How VA originated?

During the Second World War, U.S. government reserved

certain materials from armament industry.

Therefore, General Electric Company found itself in fix as many

of their regularly used materials suddenly became unavailable

due to reservation.

153

A purchase executive of the company, Lawrence D. Miles made

many substitutions in place of original materials.

Surprisingly, the results showed that substituted materials did

not affect the quality but brought costs down.

Later Larry developed a step by step approach for this exercise

and named the technique as Value Analysis.

Thus it is a step by step approach to identify the functions of a

product, process, system or service; to establish a monetary

value for that function and then provide the desired function at

an overall minimum cost without affecting any of the existing

parameters like Quality, Maintainability, Productivity, Safety

and other Performance Characteristics.

154

In the year 1954, U.S. Navy Bureau of Ships adopted same

technique in their effort at ‘cost avoidance’ during the design

stage and saved million of dollars .

They named this technique as Value Engineering.

Value Engineering is where the value of all components used

in construction of a product from design to final delivery

stage are completely analyzed and pursued.

Thus, Value Engineering indicates application at design stage

whereas Value Analysis is the application on the product that

is into manufacturing.

155

Difference between Value Analysis and

Value Engineering

156

Value Analysis

Value Engineering

Indicates application on the product that is

into manufacturing.

Indicates application on the product at its

design stage

Workers, subcontractors and engineers

come together to make a team with

experience and knowledge

Done by a specific product design team

(Engineers)

May change the present stage of the

product or operation

Changes are executed at the initial stages

only.

Worked out mostly with the help of

knowledge and experience

Requires specific technical knowledge

What is the meaning of overall costs?

For a manufacturer/ producer

Overall cost is summation of all elements of the costs required to

produce or service such as labour, material, overhead etc.

For a consumer

Overall cost is the monetary sum (price) for which the product or

service is purchased in the market.

157

The Value of the a function V= P/C can be increased by four

methods.

(1) Decrease the cost while ensuring the same level of

performance.

Reduce the thickness of wooden drums in case of packing of

telephone cables.

Earlier CDs and DVDs were sold at above Rs 100/- Moser

Baer introduced the same at almost half the price.

(2) Enhance the performance at the same cost

Providing a supplement of Mumbai Mirror along with the

copy of The Times of India at no extra cost.

158

(3) Decrease the cost and increase the performance

Intel’s Pentium chip is cheaper and has much more processing

power than all its earlier chips.

(4) Increase both performance and cost ensuring that

performance increases more than the increase in cost.

American cola giant increased quantity of soft drink from 250

ml to 300 ml (20% more) but increased price just by 10%

In all the above cases ‘cost’ is viewed at from customer’s

point of view.

159

Value Analysis Tests

►Each product or component is subjected to the following tests:

Does its use contribute value?

Is its cost proportional to its usefulness?

Does it need all its features?

Is there anything better for the intended use?

Can a usable part be made by lower cost method?

Can a standard product be found which will be usable?

Is it made on proper tooling, considering quantities used?

Do materials, reasonable labour, overhead, and profit total its cost?

Will another dependable supplier provide it for less?

Is anyone buying it for less?

160

Functions-Use and Aesthetics

Use function

Prashant wants to go for a trek to a place 15 kms from Karjat. He wants

to purchase shoes that will protect his feet from stones and thorns etc.

Therefore he opts for ‘Hunter shoes’.

To protect feet is called as the Use Function of the shoes.

B. Aesthetic function

Parag is preparing for prize distribution ceremony of his college. Dressed

in blazer he will be putting on black leather shoes with good appearance.

To give good appearance is called as the Aesthetic Function of shoes.

Use and Aesthetic functions are always present in all the products.

Depending on the user and the need, one function assumes

predominance over other.

A.

161

Primary Function & Secondary Function

AR Dairies is a Mumbai based milk and dairy products company. They

used to supply milk (cow and buffalo) in 500 ml glass bottles. Lately they

have introduced Masala Milk in 200 ml bottles, which became an instant

success. While Masala Milk is supplied throughout the day, other type of

milk is supplied only in the morning. While going through the audit

reports, Shalini found that there is a transit loss of 2% due to breakage of

bottles. To overcome that Shalini introduced polythene bags in place of

500 ml bottles. However Masala Milk continued to be sold in glass

bottles.

Why did Shalini not introduce polythene bags for Masala Milk?

162

The Primary Function of bottle is ‘to hold the liquid’ and

Secondary Function is ‘to facilitate drinking’.

In this case, shape of the bottle facilitates drinking; however

when primary function is achieved by some other means i.e.

polyethylene bag then secondary function ceases to exist.

As a consumer drinks Masala Milk on the spot, secondary

function of facilitation of drinking is very important whereas

cow milk or buffalo milk is never drunk without heating it.

Therefore Shalini could sacrifice secondary function in case

of cow & buffalo milk but not in case of Masala Milk.

163

Higher Order & Lower Order Function

The basic function of a Torch is ‘To Give Light’

Let us analyze order of functions.

Give Light (why) Facilitates Viewing (How) Light the Bulb (How)

164

Supply Current (How) Insert Battery

When we ask question ‘Why’ to the basic function; then the answer we

get is called as ‘Higher Order function’.

And when we put question ‘How’ to the Higher Order Function we get

‘Lower Order Function’.

Thus ‘Facilitate Viewing’ is higher order function and ‘Light the Bulb’ is a

lower order function.

As we continue asking questions ‘How’ we will get functions still lower in

order.

Therefore ‘Insert Battery’ is lower than ‘Supply Current’ which in turn is

lower than ‘Light the Bulb’.

Incidentally if we take any part or function and put the question

‘Why’ , then we will get functions higher in order.

Insert Battery (Why)Supply Current (Why)Light the Bulb

(Why)FacilitateViewing.

165

Summary of Functions

Type of Function

Meaning

Use Function

Perform some action, expresses in active

tone.

Aesthetic Function

Pleases customer, expressed in passive or

non-measurable tone.

Primary Function

Basic purpose for which a product exists

Secondary Function

Arises out of specific design chosen to

fulfill the Primary Function.

Higher Order Needs

Reasons of satisfying the Basic Function

Lower Order Needs

Means of achieving the Basic Function.

166

A product can have more than one primary function

For example, LPG cylinder apart from holding the LPG must

also withstand high pressure and must prevent leakage of gas.

Therefore any cylinder design must address all these factors.

Many times some of the secondary functions are unnecessary

or even undesirable.

For example, Lamp used for producing image in OHP also

produces heat that calls for fan. The fan is quite unnecessary

but with present level of technology we have not been able to

produce light without heat.

Therefore, a customer has to pay for fan even though it does

not add any direct value to him.

167

Function Analysis System Technique

Helps in a thorough understanding of the scope and

intricacies of the problem under study.

Provides a determinate logic for testing the functions.

Assists in identifying the basic, required secondary and

unwanted functions, and establishes their inter-linking in a

logical sequence.

Highlights the missing links or functions which might have

been overlooked.

Demonstrates that the problem has been thoroughly analyzed

by the team and helps in persuading the decision makers to

accept the VE team recommendations

168

FAST Diagram for Pen

169

Part

Function

Head

Position Refill

Locate Refill

Cylinder

Provide Grip

Protect Refill

Improve Aesthetic

Show ink-level

Tail

Support Refill

Rings (Front & Back)

Help Location

Cap

Protect Tip

Facilitate Carrying

Refill

Contain Ink

Control Flow

Ink in Refill

Make Marks

Remark

Serration on cylinder

Carry Name & Logo

Transparency

Projection on the Cap

The alternatives can be

(1) Eliminate head and make it part of Cylinder

(2) Eliminate Tail and make it part of Cylinder

(3) Eliminate Rings

Financials & Operational Report

(1) Design change suggested

(2) Reason for change

(3) Additional expenditure required for new die, advertising expenses