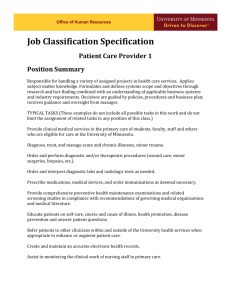

Water in the Clinical Laboratory

advertisement

Water in the Clinical Laboratory Role of water in Clinical Diagnostic Purification technologies basics Delivering water to the clinical analyzer Mikael Cleverstam WW Clinical Business Manager 1 Putting it all together Troubleshooting Your analyzer Diagnostic instruments Assay development Patient results CLSI New standards Water quality as part of the quality process Water purification Quality system Diagnostic Instruments Water Quality Medical Technologist Quality Control Patient Results 2 Normal seen Problems Frequent Calibrations High CV% Fluctuation in quality results over the day/week/month Interfered assays Calcium ALP CK Amylase LD Phosphorus Iron Magnesium Triglycerides Urea Troponin I Interfered by rocks, leaves, geology Interfered by biofilm, detergent, rocks Interfered by water treatment Interfered by citrus fruit, detergents, leaves Interfered by effluent, leaves, H2O2 Interfered by citrus fruit, leaves Interfered by rocks, leaves, detergents Interfered by citrus fruit Interfered by plastics, chemicals Interfered by citrus fruit, water treatment Interfered by biofilm 3 Water for Clinical Analysers Cuvette washing Tubing and probe rinsing Reagent and buffer reconstitution Dilution Water Baths 4 Clinical Analyzers Features and benefits of automation Diagnostic Instruments Precision optical systems for accuracy in testing Automatic sampling and dilutions modes Real time alerts to patient and QC failures Improved software alerts end user to mechanical failures Cost benefits Workflow efficiency and high speed through put Instrumentation targeted to reduce operating cost with more efficient technology Reduced operator interface 5 Assay Development Diagnostic Instruments Measuring chemical changes in the body for diagnosis, therapy and prognosis has resulted in new assay development Multiple method testing on a single analyzer Current research methodologies for infectious disease and tumor marker’s are moving from research labs in universities to the clinical laboratory Complex methodologies are being fully automated for more routine use 6 Unique Challenges for Medical Technologist Medical Technologist Verification of final clinical results to be accurate and precise are determined by Medical Technologist Clinical decisions are not solely made on the test result, but in conjunction with the patient’s history and symptoms Software alerts, QC reviews, calibration must all be within stated limits before results are released Troubleshooting instrument problems result in production delays, are costly and non-productive activities that must be performed and documented ➙ Try to avoid diagnostic instrument service because it is expensive 7 Reviewing Patient Results All analytical and pre-analytical factors must be reviewed and documented Medical Technologist must review all test results If results are flagged, troubleshooting the cause is necessary Diagnostic Instruments Quality Control Medical Technologist Patient Results 8 Troubleshooting procedures Sample handling procedures confirmed Quality control must be reviewed Assay Reagent issue Calibrator stability Mechanical Shifts and trends Peer group Previous data Diagnostic Instruments Quality Control Medical Technologist Patient Results Instrument malfunction Error codes If above solutions do not correct the erroneous result, further troubleshooting must identify cause before results can be released to physicians ➙ Delayed patient treatment. 9 Diagnostic Instruments Next Steps Water Quality NO Problem Assay Medical Technologist YES NO Mechanical YES Decontamination YES Problem solved Outside Source WHY ?? Water Quality 10 Water Quality Water Quality Quality results are dependent upon reliable instrumentation and known water quality Analytical factors need to be controlled and optimized to reduce the number of test failures, failed calibrations, and high blanks that can contribute to erroneous patient results Maintenance of high purity water system is essential to reliable results 11 Understanding Water Quality and Methodology Water should be considered a bulk reagent on any analyzer Water Quality The high purity water system is a separate unit, not monitored by diagnostic software on the clinical analyzer The unique properties of water if not processed and monitored can produce subtle changes in assay methods These changes in water quality can lead to erratic and inconsistent results The quality of water required or its impact on the testing method is often not considered until the purchase is complete 12 Diagnostic Dilemma Smaller sample size and reaction vessel are subjected Diagnostic Instruments Water Quality to harsher environment Inevitable build-up of biofilm in instruments, manifolds and tubing require more frequent decontaminations but Less and less time available for maintenance of the instruments Some sensitive assays can become contaminated with bacteria and ions Bacteria release enzymes and ions whose behavior is similar to the enzymes targeted in the assay method ➙ Increased need to monitor water quality as closely as any other instrument malfunction 13 Biofilm Formation Diagnostic Instruments Water Quality Organic Particles Surface Bacteria Time Biofilm may shed bacteria, pyrogens etc 14 Demonstration of ALP release from bacteria Diagnostic Instruments Water Quality Correlation between bacteria concentrations and levels of ALP in water Bacteria Strain (identification by 16S rDNA sequencing) Bacteria level (x 106 cfu/mL) ALP concentration (mUnit/mL) Sphingomonas paucimobilis 29.2 6.22 Caulobacter crescentus 9.7 9.95 Ralstonia pickettii 29.5 8.29 15 Diagnostic Instruments Detection methods Substrate-Phosphate Water Quality ALP + Pi UV-Visible pNPP Fluorescence Attophos Starbright MUP ELF Chemiluminescence CDP-Star (dioxetane) CSPD (dioxetane) Lumigen PPD AMPPD 16 Quality Control CLSI Water Quality Standards Water Quality New Standards released July 2006 (C3-A4 Vol. 26 No. 22) Nomenclature Type I,II,III has been replaced with purity types that provide more meaningful parameters CLRW (Clinical Laboratory reagent Water) replaces Type I,II for most applications IFW (Instrument Feed Water) allows instrument manufacturers to clarify specifications for their particular methods SRW ( Special Reagent Water) may be specified for specific applications when additional parameter are needed to insure water quality Autoclave and wash water will meet the requirements of previously classified Type III Complete review of the document should be done when considering new applications to insure the contaminants found in the source water do not become an issue 17 Water Contaminants Water: H2O …. and some other things Presence of contaminants Particles Gases Purification technologies Microorganisms H Ions H H Organics H 18 Protecting the Water Purification Unit: Pretreatment cartridge Due to the difference in water quality around the world, additional pretreatment cartridges are required. The cartridges provide protection and insure good performance of the reverse osmosis membrane The pretreatment packs include 0. 5 micron filter (1) to remove particles and activated carbon (2) to remove chlorine The activated carbon is impregnated with a small level of silver to prevent bacterial growth. Example of a pretreatment cartridge 19 What is reverse osmosis ? P P Feed Water Reject Permeate 20 Technology Insight: Electro-Deionization EDI module - Ion selective membranes - Ion exchange resins - Continuous current Reverse Osmosis Water 10 - 20 mS/cm A H+ + Anode Cl- C A Na+ Cl- Cl- Na+ OHNa+ - OH- H+ Cl- C Na+ Cl- Cathode Na+ Reject Product A - Anionic Membrane C - Cationic Membrane Resistivity: > 10 MW.cm TOC: < 30 ppb No need for regeneration 21 Filters – Bacteria Removal Screen 0.2 µm filters Designed for the removal of particles and microorganisms from liquids and gases. Use of PVDF membranes, provide high flow rates and throughputs, low extractables, broad chemical compatibility and the lowest protein binding of any membrane available. 22 Ultrafiltration Cut-off: 5 KDa to 20 KDa Removes bacterial by-products such as most proteins and macromolecules (e.g. endotoxins) Utilized for immunochemistry assays Immunoenzyme assays based on reporter enzymes (alkaline phosphatase, ALP) are sensitive to ALP released by bacteria Also filters bacteria 23 Storage CLRW water with a resistivity >10 megohm-cm cannot be stored because ionic and organic contamination will leach from the atmosphere and container materials in which it is stored. CLRW water should be used as it is produced Stored water is never as pure as when it is made Storage of water enhances bacterial contamination Containers need to be cleaned thoroughly between refilling. Carboys, tanks, bottles Notorious source of contamination since we often refill them without thoroughly cleaning them when they are emptied Some plastic materials out-gas polymers and plasticizers, and these end up in the water 24 Water Purification Unit Simplified flow schematic combining purification technologies Tank Pretreatment cartridge Feed water Reverse Osmosis cartridge Electrodeionization module Resistivity cell Pump To analyzer UV Germicidal Drain Ion exchange resins The electrodeionization module is not present in some purification units 25 Connecting the Water Purification Unit to the Clinical Analyzer Water is delivered in its purified state to a harsh environment within the chemistry analyzer bottle Water bottles inside analyzer are not frequently decontaminated Electronics, mechanical hardware, pumps all create heat within the analyzer cabinet, thus raising the interior temperature of the water bottle. Increased temperatures enhance the growth of bacteria and biofilm within the instruments manifolds and tubings. 26 Conclusions Water is a reagent. The quality of water has an impact on the testing method. 27