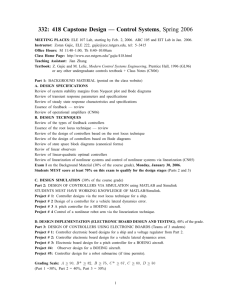

CHE517 Advanced Process Control

advertisement

CHE517

Advanced

Process Control

Prof. Shi-Shang Jang

Chemical Engineering Department

National Tsing-Hua University

Hsin Chu, Taiwan

Course Description

• Course: CHE517 Advanced Process Control

• Instructor: Professor Shi-Shang Jang

• Text: Seborg, D.E., Process Dynamics and

Control, 2nd Ed., Wiley, USA, 2003.

• Course Objective: To study the application of

advanced control methods to chemical and

electronic manufacturing processes

• Course Policies: One Exam(40%), a final

project (30%) and biweekly homework(30%)

Course Outline

1. Review of Feedback Control System

2. Dynamic Simulation Using MATLAB

and Simu-link

3. Feedforward Control and Cascade

Control

4. Selective Control System

5. Time Delay Compensation

6. Multivariable Control

Course Outline - Continued

7. Computer Process Control

8. Model Predictive Control

9. R2R Process Control

Chapter 1 Review of

Feedback Control Systems

•

•

•

•

•

•

•

•

•

Feedback Control

Terminology

Modeling

Transfer Functions

P, PI, PID Controllers

Block Diagram Analysis

Stability

Frequency Response

Stability in Frequency Domain

Feedback Control

Transmitter

Controller

Set point

Temp

sensor

Heat loss

stream

condensate

Examples:

• Room temperature control

• Automatic cruise control

• Steering an automobile

• Supply and demand of chemical engineers

Feedback Control-block

diagram

Manipulated

variable

error

+ Σ

Set point

Controller

disturbance

process

Controlled variable

-

Measured value

Sensor +

transmitter

Terminology:

• Set point

• Manipulated variable (MV)

• Controlled variable (CV)

• Disturbance or load (DV)

• Process

• controller

Instrumentation

Transmitter

Controller

Set point

Temp

sensor

Heat loss

stream

condensate

•

•

•

Signal Transmission: Pneumatic 3-15psig, safe longer time lags, reliable

Electronic 4-20mA, current, fast, easy to interface with computers, may

be sensitive to magnetic and/or electric fields

Transducers: to transform the signals between two types of signals, I/P:

current to pneumatic, P/I, pneumatic to current

Modeling

Q

Mass M

Cp

T

Q=UA(T-T0)

Rate of accumulation = Input – output + generation –

consumption

d

( MC PT ) Q UA(T T0 )

dt

At steady state : let T = TS and Q = QS 0 = QS – UA(TS - T0S)

Deviation variables : let T = TS+Td , Q = QS+Qd , T0 = T0s+T0d

Then :

d

MC P

dt

(Td ) Qd UA(Td T0d )

If system is at steady state initially Td(0) = 0

Transfer Functions

Laplace Transforming:

M Cp S Td(S) = qd(S) - U A (Td(S) – Tod(S))

Or

q d S

UATod S

Td S

SMC p UA SMC p UA

qd(S)

UA

MsC p UA

+

∑

+

1

Tod(S)

MsC p UA

Td(S)

Non-isothermal CSTR

F0

ρ0

CA0

T0

AB

rA = - KCA mol/ft3

T V ρ CA CB

steam

F

ρ

CA

T

K = αe-E/RT

condensate

• Total mass balance: d (V ) F0 F

dt

• Mass balance :

d

(V C A ) F0 C A0 F C A ( KC A )V

dt

d

• Energy balance : (V CPT ) F0CPT0 F C PT (Hr )( KC A ) UA(Ts T )

dt

• Initial conditions : V(t=0) = Vi , T(t=0) = Ti , CA(t=0) =

CAi

• Input variables : F0 , CA0 , T0 ,F

Linearization of a Function

F(X)

aX+b

X0 -△ X0

-△

0

X0+△

△

X

Linearization

f

dx

f x, u

x

dt

x x0

u u0

x x0

f ( x0 , u0 )

dxd

axd bud 0

dt

Laplace Transform

sxd s axd s bud s

or

xd ( s )

K

b

ud s s a s 1

f

u

x x0

u u0

u u0

Linearization of Nonisothermal CSTR

dVd

b11 F0, d b12 Fd

dt

dC A,d

a21Vd a22C A,d b11 F0, d b12 Fd

dt

dTd

a31Vd a32C A,d a33Td b31 F0, d b32C A, d b33Tsd

dt

i.e.

Vd 0

d

a

C

A

,

d

21

dt

Td a31

0

a22

a32

0 Vd b11 b12

0 C A,d b21 b22

a33 Td b31 b32

0 F0,d

b23 Fd AX ( s ) BU ( s )

b33 Ts ,d

F0,d

Vd

y 0 0 1 C A,d 0 0 0 Fd CX DU

Ts ,d

Td

Td s C ( sI A) 1 B D U ( s )

G p s Tsd s GL s F0,d ( s ) GL ' s Fd s

Common Transfer Functions

K=Gain; τ=time constant;

ζ=damping factor; D=delay

• First Order System

• Second Order System

CV ( s)

K

MV s s 1

CV ( s)

K

2 2

MV s s 2s 1

• First Order Plus Time Delay

CV ( s)

K Ds

e

MV s s 1

• Second Order Plus Time Delay

CV ( s)

K

2 2

e Ds

MV s s 2s 1

Transfer Functions of

Controllers

• Proportional Control (P)

m(s) = Kc[ e(s) ]

e(s)

m(s)

Kc

e = Tspt - T

• Proportional Integral Control (PI)

1

m( t ) K c e( t )

I

0 e(t)dt

t

1

m(s) K c e(s)

e(s)

Is

e(s)

K c (1

1

)

Is

m(s)

• Proportional-Integral-Derivative Control (PID)

1

m( t ) K c e( t )

I

m(s) K c

de

0 e(t)dt D dt

t

1

e(s) 1 Ds

Is

e(s)

K c (1

1

D s)

Is

m(s)

The Stability of a Linear

System

• Given a linear system y(s)/u(s)=

G(s)=N(s)/D(s) where N, D are

polynomials

• A linear system is stable if and only if

all the roots of D(s) is at LHS, i.e.,

the real parts of the roots of D(s) are

negative.

Stability in a Complex Plane

Im

Exponential Decay

with oscillatory

Purdy oscillatory

Exponential growth

with oscillatory

Fast Exponential

growth

Exponential Decay

Fast Decay

Slow Decay

Slow growth

Purdy oscillatory

Stable (LHP)

Unstable (RHP)

Re

Partial Proof of the Theory

• For example: y(s)/u(s)=K/(τs+1)

• The root of D(s)=-1/τ

• In time domain: τy’+y=ku(t)

• The solution of this ODE can be

derived by y(t)=e-t/τ [∫e1/τku(t)dt+c]

• It is clear that if τ<0, limt→∞y →∞.

Transfer functions in parallel

X(S)= G1(S)*U1(S) + G2(S)*U2(S)

X1(S)

U1(S)

X2(S)

G1(S)

X1(S)

+

Σ

G2(S)

U2(S)

X2(S)

+

X (S)

Transfer function Block

diagram

Tset

+

Kc

Σ

-

QS

control

1

MC P S UA

process

Measuring device

1

Proportional control

No measurement lags

Td

Tset

1

MC P S UA

1

1 KC

MC P S UA

KC

Td

Block Diagram Analysis

Xs

+

e

∑

-

Gc(S)

L(S)

GL(S)

m

GP(S)

Xm

X1

+

+

∑

Gm(S)

e = X s – Xm

m = Gc (S) e(s) = Gc e

X1 = Gp m = Gp Gc e

X = GL L + X1 = GL L + Gp Gc e

Xm = Gm X = Gm GL L + Gp Gc e

X = GL L + Gp Gc[Xs – Xm]

= GL L + Gp Gc [Xs] – Gp Gc [Xm]

=GL L + Gp Gc Xs – Gp Gc Gm X

G pG c

GL

X

L

Xs

1 G pG cG m

1 G pG cG m

X(S)

Stability of a Closed Loop

System

• A closed loop system is stable if and

only of the roots of its characteristic

equation :

1+Gc(s)Gp(s)Gm(s)=0

are all in LHP

Level System

dh

Fin Fout Fin k h

dt

Given a reference point Fin0 , h0

A

A

dhd

f

Fin Fin0 f h h0 Fin,d k hd

dt

Fin

h

2 h0

Laplacing

Ashd (s) ahd s Fin,d s

or

hd s

1

1/ a

K

Fin.d s As a A / a s 1 s 1

The jacketed CSTR

W

Set Point

TRC

FC

2A B

Tc

Wc

T, Ca

A Nonisothermal Jacketed CSTR

• (i) Material balance of species A

dC A W (C A f C A )

2

kCA

dt

V

• (ii) Energy balance of the jacket

dTc A(T Tc ) Wc (Tc Tw )

dt

M cCP '

Mc

• (iii) Energy balance for the reactor

2

dT W (T f T ) A(T Tc ) HkC A

dt

V

C PV

CP

• (iv) Dependence of the rate constant on

temperature

Q

k A0 exp(

)

T 273

Linearization of

Nonisothermal CSTR

• CV=T(t)

• MV=Wc(t)

• It can be shown that

Td s

K

3

Wc,d s as bs 2 cs 1

A Practical Example –Temperature

Control of a CSTR

Method of Reaction Curve

Process

output

Maximum slope

△C

D

Dead time

τ

Time constant

time

Ziegler-Nichols Reaction Curve

Tuning Rule

P only

PI

PID

Kc

/DKp

0.9/DKp 1.2/DKp

I

n.a.

D/0.3

D/0.5

D

n.a.

n.a.

0.5D

△C

D

τ

△m

D= 1

τ =13

k = -0.0202

Kc= -579.2079

τi =3.33

setpoint

Ziegler-Nichols Ultimate Gain

Tuning

Find the ultimate gain of the process

Ku. The period of the oscillation is

called ultimate period Pu

P only

PI

PID

Kc

Ku/2

Ku/2.2

Ku/1.7

I

n.a.

Pu/1.2

Pu/2

D

n.a.

n.a.

Pu/8

Measuring Controller

Performance

0

0

IAE y s y t dt et dt

ISE y s y t dt et dt

2

2

0

0

0

0

ITAE t y s y dt t et dt

Upper Limit of Designed

Controller Parameters of

PID Controllers

• Q: Given a plant with a transfer

function G(s), one implements a PID

controller for closed loop control,

what is the upper limit of its

parameters?

• A: The upper limit of a controller

should be bounded at its closed loop

stability.

Approaches

• Direct Substitution for Kc

• Root Locus method for Kc

• Frequency Analysis for all

parameters

An Example

+

-

○

Kc

1

( s 1)( s 2)( s 3)

1. Stability Limit by Direct

Substitution

• At the stability limit (maximum value of Kc

permissible), roots cross over to the RHP.

Hence when Kc=Ku, there are two roots

on the imaginary axis s=±iω

• (s+1)(s+2)(s+3)+Ku=0, and set s= ±iω,

we have (iω+1)(iω+2)(iω+3)+Ku= 0, i.e.

(6+Ku-6ω2)+i(11ω-ω3)=0. This can be

true only if both real and imaginary parts

vanishes: 11ω-ω3=0→ ω= ±√11 ;

6+Ku-6×11=0 →Ku=60

2. Method of Root Locus

Rlocus (sys,k)

k(12) ans =69.6706

3. Frequency Domain

Analysis

• Definitions: Given a transfer function

G(s)=y(s)/x(s); Given x(t)=Asinωt;

we have y(t) →Bsin(ωt+ψ)

• We denote Amplitude Ratio=AR(ω)

=B/A; Phase Angle=ψ(ω)

• Both AR and ψ are function of

frequency ω; we hence define AR

and ψ is the frequency response of

system G(s)

An Example

A sin(wt)

1

s 1s 2s 3

B = sin(wt+f)

Frequency Response of a

first order system

y(s)

K

A

G ( s)

; x(t ) A sin wt x( s )

x( s )

s 1

s w

A

K

y(s)

s w s 1

KA

y (t )

sin(wt f );f tan w

1 w

K

AR

1 w

f tan w

2

2

2

1

2

2

1

2

2

2

Basic Theorem

• Given a process with transfer function

G(s);

• AR(ω)=︳G(iω)︳

• φ(ω)=∠ G(iω)

• Basically, G(iω)=a+ib

AR a 2 b 2

f tan

1

b / a

Example: First Order

System

1

G (s)

s 1

1

1 i (w )

1

(w )

G iw

i

a ib

2 2

2 2

2 2

iw 1 1 w

1 w

1 w

1

AR a 2 b 2

1 2w 2

b

f tan 1 tan 1 w

a

Note that

lim AR 0

w

lim f 90

w

Corollary

• If G(s)=G1(s)G2(s)G3(s)

• Then AR(G)=AR(G1) AR(G2) AR(G3)

• φ(G)=φ (G1) +φ (G2)+φ (G3)

• Proof: Omitted

Example

K1

K2

G ( s)

G1 s G2 s

1w 1 2w 1

AR AR1 AR2

K1

1 w 1

2

2

K2

2

w 2 1

2

f f1 f2 tan 1 w 1 tan 1 w 2

Bode Plot: An example

G(s)=1/(s+1)(s+2)(s+3)

where db=20log10(AR)

Nyquist Plot

sys=tf(num,den)

NYQUIST(sys,{wmin,wmax}))

Nyquist Stability Criteria

• Given G(iω), assume that at a

frequency ωu, such that φ=-180° and

one has AR(ωu), the sufficient and

necessary condition of the stability of

the closed loop of G(s) is such that:

AR(ωu) ≦1

The Extension of Nyquist

Stability Criteria

• Given plant open loop transfer

function G(s), such that at a

frequency ωu, the phase angle

φ(ωu)=-180°. At that point, the

amplitude ratio AR=|G (ωu) |, then

the ultimate gain of the closed loop

system is Ku=1/AR, ultimate period

Pu=2π/ ωu.

Simulink Example

Response

0.165 0.5 s

GP

e

2.5s 1

D1.4

3.7-1.4=2.3

time

Simulink Example Continued

>> sys=tf(1,[1 6 11 6])

Transfer function:

1

---------------------s^3 + 6 s^2 + 11 s + 6

>> bode(sys)

wu=3.5

ARu=-38db

=10-38/20

=0.0162

Ku=1/ARu=80

Simulink Example Continued

1. Reaction Curve Approach:

KC=1.2/DKp=1.2*2.5/(0.5*0.165)=36;

I=D/0.5=1;D=D*0.5=0.25

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

0

1

2

3

4

5

6

7

8

9

10

Simulink Example Continued

1. Ultimate properties Approach:

Ku/1.7=80/1.7=47;I=Pu/2= 2* / 2wU =0.9;D=Pu/8=0.22