EPA New England

advertisement

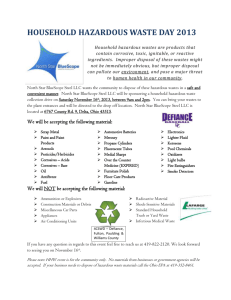

Hazardous Waste Management New England Marina Meeting March 30, 2006 U.S. Environmental Protection Agency (EPA) Region 1 New England 1 Where to look for Guidance EPA Office of Compliance Sector Notebook Project “Profile of the Water Transportation Industry”, September 1997, EPA/310-R-97-003 “Profile of the Shipbuilding and Repair Industry”, November 1997, EPA/310-R-97-008 Shipshape Shores and Waters- A Handbook for Marina Operators and Recreational Boaters, January 2003, EPA-841-B-03-001 www.epa.gov/owow/nps/marinashdbk2003.pdf 2 RCRA Components Subtitle C - Hazardous Waste Subtitle D - Solid Waste Subtitle I – Underground Storage Tanks Subtitle C – Cradle to Grave Control of Hazardous Wastes 3 RCRA Subtitle C Goals protect human health and environment from hazards posed by waste disposal, To ensure that wastes are managed in a manner that is protective of human health and the environment. To conserve energy and natural resources via waste recycling and recovery, To reduce or eliminate the amount of waste generated 4 Statutory Definition of Solid Waste ….any garbage, refuse, sludge from a waste treatment plant, water supply plant or air pollution control facility, and other discarded material, including solid, liquid, semisolid, or contained gaseous material... SOLID WASTE NEED NOT BE SOLID! 5 Statutory Definition of Hazardous Waste A “solid waste, or a combination of solid wastes, which because of its quantity, concentration, or physical, chemical, or infectious characteristics may: 1) Cause, or significantly contribute to an increase in mortality or an increase in serious irreversible, or incapacitating reversible, illness or 2) Pose a substantial present or potential hazard to human health or the environment when improperly treated, store transported, or disposed of, or otherwise managed.” 6 A Solid waste is hazardous if it: Exhibits any of the characteristics of a hazardous waste Has been named as a hazardous waste and listed as such in the regulations Is a mixture containing a listed hazardous waste and a non-hazardous solid waste Is a waste derived from the treatment, storage, or disposal of a listed waste 7 Characteristic Hazardous Wastes Ignitability Reactivity Corrosivity Toxicity (via TCLP) 8 Three Lists of Hazardous Wastes Non-specific Source Wastes Specific Source Wastes Commercial Chemical Products 9 IT IS YOUR RESPONSIBILITY !! As the Owner/Operator you must know all the waste streams you generate and which ones are Hazardous Wastes and, therefore, regulated. Do Hazardous Waste Determinations!! 10 EPA/Federal & State Regulations citation: 40 CFR Parts 260-299 authorized states and their regulations [equivalent or more stringent than feds] 11 HAZARDOUS WASTE DETERMINATIONS Generator’s responsibility Process knowledge Analysis MSDS Expiration dates Variability of waste streams Cross contamination 12 Waste Activity Notification and Generator Classification Large Quantity >1000Kg (2200#) ……………..…LQG (1 Kg Acutely Toxic Wastes) Small Quantity 100-1000Kg (220-2200#)………..SQG Conditionally Exempt SQG <100Kg (220#)…...CESQG Amount Generated =Classification with accumulation limits. [Volume and Time] [There are State Variations- see State Regulations] 13 Depending on Your Classification, There Are Requirements for….. Record keeping Housekeeping Accumulation Time Limits Emergency Preparedness Needs Employee Training 14 Specific Container Management Requirements for …… Satellite vs. Non-Satellite Storage Areas 15 MANAGEMENT REQUIREMENTS in CONTAINER STORAGE AREAS Labeling Dating Compatibility Aisle space Open/Closed Containers Condition of containers Ignitable waste special requirements 16 Satellite Storage….. At or near point of generation Under the control of the operator of the process Less than 55-gallons of wastes – total Labeled “Hazardous Waste” or other words to describe contents Keep containers closed, except when adding or removing 17 (Depending on Classification) CONTAINER STORAGE AREA INSPECTIONS The owner or operator must inspect areas where containers are stored, at least weekly, looking for leaks and for deterioration caused by corrosion or other factors. 18 Manifesting Wastes Requirements Key to Cradle to Grave Management 19 Land Disposal Restriction Notifications – Protect human health & environment – Minimize reliance on land disposal – Determine if wastes generated are restricted from land disposal. – Determine the appropriate treatability group (if any) for restricted wastes. – Determine if wastes meet treatment standards as generated. 20 HAZARDOUS WASTE TRAINING Initial training Annual refresher training Documentation of training program and employee training records Relevant to job duties performed Training program led by qualified staff document Job titles and Job descriptions RCRA Training is not OSHA or Emergency Response training. RCRA Training develops understanding of appropriate hazardous waste management practices. 21 PREPAREDNESS AND PREVENTION Facilities must be maintained and operated to minimize the possibility of a fire, explosion or release of hazardous waste or hazardous constituents. 22 CONTINGENCY PLAN o must be designed to minimize hazards to human health o o o o o and the environment from fires, explosions, or release of hazardous waste or hazardous waste constituents. must be carried out immediately. describe detailed response actions provide for arrangements with locals designate Emergency Coordinator and alternates identify emergency equipment o identify evacuation plans 23 PREPAREDNESS AND PREVENTION Alarm system Communication devices Extinguishers Adequate water supply Adequate aisle space In-place arrangements with locals [fire, police, hospitals] 24 UNIVERSAL WASTE Universal wastes are widely generated and widely recycled hazardous wastes. Management standards for these wastes are reduced to facilitate their recycling. 25 Types of UNIVERSAL WASTE Batteries Mercury containing thermostats Hazardous waste lamps state specific UWs 26 Universal Waste Requirements.. Containerized Labeled to describe content Dating Training Record keeping 27 RCRA Compliance Evaluation Inspection Outline Unannounced Most are multi-day Physical inspection of waste storage, generation points and processes, tour of operations and property 28 Inspections - continued Opening Conference the inspector may ask How many employees and shifts What is your generator status For explanation of processes, description of wastes and where generated Where wastes are stored- satellite and 90/180 day Inspector will explain how the physical inspection will proceed Inspector will request availability of documents for records review 29 Inspections (continued)… Documents for Record Reviews includes but is not limited to: training documents, contingency plans, shipping documents and LDRs, waste determination documentation, inspection logs, Biennial Reports, emergency preparedness information, import/export documentation 30 Inspections (continued) Close-Out Conference Ask for additional information. Review areas of concern from walkthrough and record review. Explain potential follow up. Give facility representatives an opportunity to comment or ask questions. 31 Post-Inspection Information Requests Possible Case Development Inspections Inspection Report Several months possible 32 Common Marina Wastes Paint and paint related wastes Aerosol cans Chemical stripping wastes Abrasive stripping wastes Equipment cleaning wastes Machine Shop wastes Engine Repair wastes Waste Oils, gear and lube oils 33 Common Marina Wastes Transmission fluid Waste fuel Welding wastes Fiberglass fabrication (solvents, resins, gelcoat wastes) Leftover raw materials/ Off-spec products Acids and alkalis Metal finishing wastes 34 Common Marina Wastes Pb/acid batteries Bilge water/bilge sludges Engine test tank waters Parts washer waste Rags Adhesive wastes 35 Common Marina Wastes Electronics wastes Pesticides and herbicides Compressed gas cylinders Filters- fuel, oil, paint booth Antifreeze (benzene) Dust collection system residues SEE LAST PAGE OF HANDOUT FOR MORE 36 Common Areas of Observed Violations Hazardous Waste Determinations Main Hazardous Waste Accumulation Area and/or Satellite Accumulation Area Container Mismanagement Open Containers Aisle space Secondary Containment Unmarked/Unlabeled Containers Incompatible Storage No or Inadequate Land Disposal Restriction (LDR) Notices 37 Common Areas of Observed Violations (continued) No or incomplete Hazardous Waste Manifests Inadequate Emergency Preparedness and Inadequate/Outdated Contingency Plan No or Inadequate Hazardous Waste Training No or inadequate In-house Inspections Storage > 180 Days, >90 Days w/o Permit 38 HW Determination Violations What we find... Mischaracterized or uncharacterized wastes; or Materials that are unused and pending disposal not characterized What we want... All wastes/materials characterized as soon as they are generated or when they are not going to be used 39 HW Determination Violations (continued) Because... Certain wastes have adverse affect on human health and/or the environment - that's why they're regulated. THE PERSON WHO GENERATES THE WASTE IS RESPONSIBLE FOR KNOWING WHAT IT IS!!! 40 Open Containers Violations What we find... Containers with no cover, no bung, or open funnel in bung What we want... All containers of hazardous waste closed unless materials are being added or removed Because... Materials can be easily spilled from an open container. Volatile materials may escape. 41 Unmarked/Unlabeled Container Violations What we find... Hazardous waste containers that have missing information/no information or are not dated What we want... Containers with labels that say the words "Hazardous Waste" and a description of the waste and the date when the waste started to accumulate (and sometimes more). 42 Unmarked/Unlabeled Containers (continued) Because... A properly labeled container assures that everyone, including workers and emergency responders, knows that there is a hazardous waste in the container and exactly what the waste is. Helps avoid mismanagement. 43 Unmarked/Unlabeled Containers (continued) Has caused wastes to be commingled Results in no one knowing what the container holds, for example: -person who knew has left the company -person who knows is on vacation when inspector arrives Can increase need for laboratory waste stream analysis for waste determinations 44 Satellite Accumulation Violations What we find... Hazardous waste drums being stored far from the place where the wastes are generated ...not under anyone's control ...more than 55-gallons What we want... At or near the point of generation and under the control of the operator, no more than 55gallons, and container meets management requirements 45 Satellite Accumulation Violations (continued) Because We don't want people walking long distances with uncontrolled quantities of hazardous waste We want someone watching over these containers. We don't want a lot of material hanging around. 46 Incompatible Waste Storage Violations What we find... Incompatible materials stored next to each other, or stacked on top on one another. What we want... Incompatible materials separated by a berm, dike, wall or other physical barrier. Because... KABOOM!!! 47 Hazardous Waste Training Violations Common Issue! Annual training conducted once and lapses Training is not relevant to duties performed Documentation is not maintained No plan on who should be trained and what they should be trained on Job descriptions not available or… 48 Hazardous Waste Training Violations (continued) Available, but no longer applicable for employee - For example: - personnel have rotated and job description no longer fits, or - job duties have changed and no longer match the job description Note: A bad training program will lead to poor waste management! 49 LDR Notices/Copies Violations What we find… Notices not completed at all or incomplete Copies are not maintained or available at the facility What we want… Copies of all fully completed notices maintained for 5 years. Because… It is important that all parties that manage the hazardous waste know that it must be treated before disposal. 50 Hazardous Waste Manifest Violations What we find… Photocopies maintained in lieu of actual records Completed signed copy not maintained (most important manifest document!) What we want… Copies of manifests maintained for 3 years. Copies of exception reports maintained. Because… This is the cradle to grave tracking system that ensures that hazardous wastes safely reach a designated facility. 51 Contingency Plan Violations What we find... No contingency plan Information in plan is old, incorrect telephone numbers or procedures; and Copies not sent to the appropriate parties. People listed in the plan have left Local officials have not been sent copies of the plan Emergency equipment descriptions and locations are missing or outdated Plan does not address required incidents, for example: - spills - fires - explosions - releases 52 Contingency Plan Violations (continued) What we want... Name and telephone number of facility person in charge of emergency response (plus back-up) Telephone numbers of local authorities (e.g., fire, hospital, police, DEP, NRC), response contractor Procedures on what to do in the case of a fire, flood, leak, spill, and for loading/unloading waste at your facility Lists, locations, and capability of emergency equipment; have it readily available and send copies to all local authorities Evacuation plan and evacuation routes 53 Contingency Plan Violations (continued) Because... It should be clear to all affected employees and anyone responding to an emergency what types of materials are at the facility, what to do, where to go, and who to call. 54 Weekly/Daily Inspection Violations What we find… No weekly/daily inspections/missed inspections Not all areas inspected Inspections/corrective actions not documented 55 Weekly/Daily Inspection Violations (continued) What we want… Inspections of satellite and main accumulation areas - weekly for containers - Daily for tanks Inspections of tanks- container management standards, leaking? or deterioration? Paper documentation for each area including comments and corrective actions taken Minimum for most states, except for MA ****(It’s ok to document a problem.) 56 Weekly/Daily Inspection Violations (continued) Because… It’s important to conduct a regular check to ensure that all management requirements are met and that no leaking or deterioration has occurred. 57 Storage for Greater than 90 or 180-Days What we find… Forgotten drums Non-compliant satellites Just didn’t ship What we want… Wastes regularly moved off-site in less than 90days or 180-days. Because… We don’t want large quantities of hazardous waste accumulating for long periods of time without additional precautions of a permit (i.e., closure plans and financial assurance). 58 EPA Enforcement Goals of Enforcement Environmental Protection Correction of Violations Deterrence Fairness – level playing field Punishment 59 Enforcement Response Informal Actions NOVs No penalties associated List violations Schedules for Return to Compliance 60 Enforcement Response Formal Administrative Orders Penalty Actions ($32,500/day/violation) Require Corrective Actions Requires Return to Compliance SEPs 61 Enforcement Response Civil Judicial Actions Referrals to DOJ Lawsuit in Federal District Court Can take several years to complete 62 Enforcement Response Criminal Actions Knowing, willful, or negligent acts Fines, imprisonment for individuals 63 Enforcement Response RCRA cases can range from $10K to multi-million dollars in penalties and require extensive corrective measures 64 Questions: Susann Nachmann 617-918-1871 Richard Piligian 617-918-1757 65