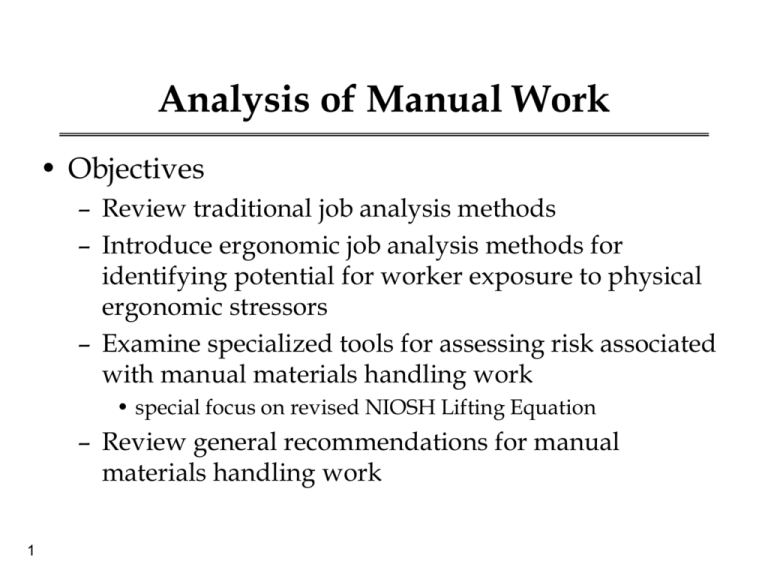

Analysis of Manual Work

advertisement

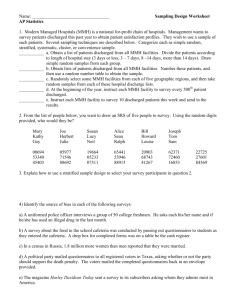

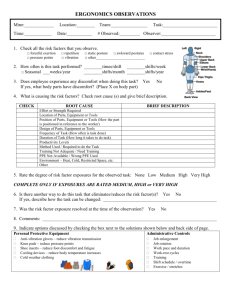

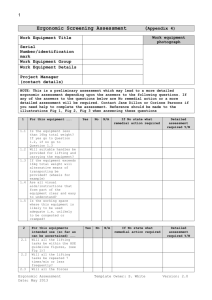

Analysis of Manual Work • Objectives – Review traditional job analysis methods – Introduce ergonomic job analysis methods for identifying potential for worker exposure to physical ergonomic stressors – Examine specialized tools for assessing risk associated with manual materials handling work • special focus on revised NIOSH Lifting Equation – Review general recommendations for manual materials handling work 1 Review traditional job analysis methods Describing Manual Work • Why would methods for describing manual work be useful? 2 Review traditional job analysis methods Job Analysis Traditional IE methods • Tools and procedures for describing certain aspects of a job • Taylor and the Gilbreths were pioneers • Methods: – Descriptive methods • ex: operation process charts, flow process charts – Predictive methods • ex: MTM, MOST - repetitive tasks – Assessment methods • ex: work sampling, time study 3 Review traditional job analysis methods Benefits of traditional analysis methods... • Description of manual work 4 Ergonomic job analysis Ergonomic Job Analysis* • A method for identifying and evaluating generic risk factors associated with work-related musculoskeletal disorders • Based on collection of data about a job, designed to address these questions: 5 – 1) Does performing the job expose a worker to any generic ergonomic risk factors? – 2) What aspects of the job cause or *Keyserling et al. (1991) Ergonomic job analysis Generic Ergonomic Risk Factors • Characterized by excesses in Intensity, Duration, and/or Frequency: – – – – – – 6 Force exertion Posture Contact stress Dynamics Vibration Temperature Ergonomic job analysis Aspects of a job that may result in exposure to generic ergonomic risk factors Methods Tasks Tools and Equipment Workers Work Environment 7 Organization Ergonomic job analysis Elements of Ergonomic Job Analysis • Preparation – team – equipment • Method – – – – – 8 Adverse health outcomes assessment Basic job documentation Identification of risk factor exposures Evaluation of risk factor exposures Exposure control Ergonomic job analysis Method - Adverse health outcomes assessment • Data sources: 9 Ergonomic job analysis Method - Basic Job Documentation 10 • • • • • • • • • • • Job analysis team members and date Uniquely identify job Describe worker(s) Describe work objectives Work schedule Production &/or work pace info Describe job rotation Sketch work station layout List tools and equipment List all handled parts and materials Describe work methods Ergonomic job analysis Method - Identification of risk factor exposures • Determine risk factors associated with each work element >>>>>>>>> Generic risk factors <<<<<<<< Work element A Description Contact stress…… Force Posture Thread wire through Y (based Y (pinch grip) Y (wire into fingertip) hole in insulator on gage) B………….. – risk factor checklist can be useful, but familiarity with job is essential • Determine risk factor exposure for total job 11 Ergonomic job analysis Method - Evaluation of risk factor exposures • Bases for evaluation of risk: – epidemiological data – company data – specialized tools • examples: – Lifting: NIOSH lifting equation, Michigan model, LMM, ... – Posture: RULA, OWAS, … – distal upper extremity: Strain Index (combines posture, force, etc) • After identification and evaluation, summarize findings 12 Ergonomic job analysis Method - Exposure control • Develop alternative solutions • Perform follow-up ergonomic job analysis to evaluate controls 13 Use of specialized tools in analysis of MMH tasks Analysis of Manual Materials Handling Tasks • Importance of MMH tasks relative to workplace MSDs – 1994 workplace stats: 529,741 injuries due to overexertion in lifting, pushing or pulling, holding, carrying or turning objects – low back region is the primary area of injury 14 Use of specialized tools in analysis of MMH tasks Injury Prevention Strategies • Task design • Worker selection • Worker training 15 Use of specialized tools in analysis of MMH tasks MMH Risk Factors Associated with Low Back Disorder/Low Back Pain* Lifting and force movements Heavy physical work Awkward postures Whole body vibration (in conjunction with lifting and awkward postures) Static work postures 16 * NIOSH, 1997 Use of specialized tools in analysis of MMH tasks MMH System • In analyzing a MMH task, consider the system characteristics…. – – – – worker material - container task - workplace work practices …and which characteristics might give rise to the risk factors mentioned previously 17 Use of specialized tools in analysis of MMH tasks Establishing Lifting Limits Revised NIOSH Equation • Bases: – Epidemiology: • injury rates for workers on jobs with LI>3 are quite high – Biomechanics: • 3400 N of disc compression – Physiology: • 2.2-4.7 kcal/min (task dependent) – Psychophysics: • acceptable to 75% of females, and 99% of males. 18 Use of specialized tools in analysis of MMH tasks Form of the NIOSH Equation Recommended weight limit (RWL) = LC * (HM * VM * DM * AM * FM * CM) where: LC: recommended maximum load, under optimal conditions and, all other factors are discounts to that maximum, to account for less-than-optimal conditions HM: accounts for horizontal distance from spine - as distance increases, RWL decreases VM: accounts for vertical height of start or end of lift - penalized if start or end varies from 75 cm, (about table/knuckle height) DM: accounts for vertical travel distance of load - penalized if distance exceeds 25 cm AM: accounts for lifting outside of the sagittal plane - penalized as move further away from sagittal CM: accounts for hand-handle coupling - poorer coupling results in reduction of RWL FM: accounts for rate of lifting - as rate increases, RWL decreases 19 Use of specialized tools in analysis of MMH tasks Revised NIOSH Equation Assumptions and Limitations • Assumptions: – – – – – – – – – smooth lifting (no acceleration) moderate sized object unrestricted lifting postures two-handed, various hand-load coupling steady lifting while standing favorable temperature main job is MMH, others require little energy good traction for feet, no foot movement same risk for lifting and lowering • Limitations: – Individual risk is not assessed (protective at the group level) 20 Use of specialized tools in analysis of MMH tasks Pushing and Pulling in MMH • Dangers: – overexertion – slipping • Important factors: – friction • shoe/floor • wheels – handle height – foot location 21 Use of specialized tools in analysis of MMH tasks Asymmetric Loading in MMH • Recommendation: – two-handed symmetric lifts • But asymmetry is more common: – one-handed handling – twisting or lateral bending of trunk • Problems with asymmetry: – capability decreases as: • stability decreases • greater reliance on one muscle instead of right-left pair 22 Use of specialized tools in analysis of MMH tasks Additional analysis tools for more complex MMH tasks • Shoaf et al equation - determines maximum predicted load for condition – accounts for push, pull, carry, lift – accounts for personal factors • Michigan model - determines % capable at every joint (determines weak link) – considers individual anthropometry – accounts for various postures throughout kinematic chain • Lumbar Motion Monitor model - determines LBD risk associated with task – considers trunk dynamics and moment of hand load 23 General recommendations for MMH work MMH job design recommendations Eliminate MMH if possible • If not possible, then implement administrative or engineering controls – Administrative controls: • – Engineering controls: • 24