Process Selection and Design Presentation

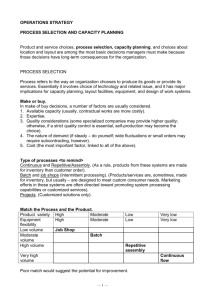

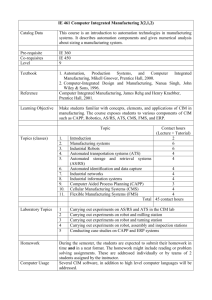

advertisement

Learning Objectives Process Selection and Design Dr. Richard Jerz 1 © 2012 rjerz.com • Explain the strategic importance of process selection. • Explain the influence that process selection has on an organization. • Explore process alternatives • Describe production and process technologies • Examine process analysis tools • Define some modern process technologies 2 © 2012 rjerz.com Process Strategy Process Selection and System Design Forecasting Capacity Planning Facilities and Equipment Product and Service Design Technological Change Layout Process Selection 4 • Key aspects of process strategy • Capital intensive – equipment/labor • Long term commitment • Technology • Effects • Cost • Process and product flexibility, adjust to changes • Design • Volume • Technology Work Design © 2012 rjerz.com • Efficiency 5 © 2012 rjerz.com Major Implications How Do We Produce Goods/Services Capacity planning Layout of facilities Equipment Design of work systems • • • • 6 • Make or Buy? • • • • • © 2012 rjerz.com 7 Available capacity Expertise Quality Considerations The nature of demand Cost © 2012 rjerz.com 1 Process Selection • Volume Product-Process Selection Batch • Expected output • Variety • How much Job Shop Repetitive • Flexibility • What degree Continuous 8 © 2012 rjerz.com 9 Process, Volume, and Variety 10 © 2012 rjerz.com Process and Characteristics 11 Process Technology Strategy • Technology and Innovation: The application of scientific discoveries to the development and improvement of products, services and operations processes. © 2012 rjerz.com © 2012 rjerz.com Kinds of Technology • Operations management is primarily concerned with three kinds of technology: • Product and service technology • Process technology • Information technology • All three have a major impact on: • Costs • Productivity • Competitiveness 16 © 2012 rjerz.com 17 © 2012 rjerz.com 2 Technology and Competitive Advantage • Innovations in Automation Technology • Automation: Machinery that has sensing and control devices that enables it to operate • Products and services • Fixed automation • Programmable automation • Cell phones • iPhone • Wireless computing • Examples • Process technology • Computer-aided design and manufacturing systems (CAD/CAM) • Numerically controlled (NC) machines • Robots • Flexible manufacturing systems (FMS) • Computer-integrated manufacturing (CIM) • Increasing productivity • Increasing quality • Lowering costs 18 © 2012 rjerz.com 19 Process Analysis Tools Crossover Charts: Select the Process with Lowest Cost • Crossover Chart – Shows which alternative is best at a production volume • Flow Diagrams - Shows the movement of materials • Time-Function Mapping - Shows flows and time frame • Value Stream Mapping - Shows flows and time and value added beyond the immediate organization • Process Charts - Uses symbols to show key activities 20 © 2012 rjerz.com • • • • How is cost determined? Accounting methods Engineering economics/financial analysis Resource consumption model (RCM) 21 Break-even (crossover) 22 © 2012 rjerz.com © 2012 rjerz.com Process Flow Diagram © 2012 rjerz.com 24 © 2012 rjerz.com 3 Process Chart 25 Time-Function Mapping © 2012 rjerz.com 26 © 2012 rjerz.com Modern Production Technologies Value Stream Map Machine technology Robots Vision system Process control, people-machine interfaces Flexible manufacturing systems (FMS) Automated storage and retrieval systems (ASRS) • Automatic identification systems (AIS) • Computer-integrated manufacturing (CIM) • • • • • • 27 © 2012 rjerz.com 28 Machine Technology © 2012 rjerz.com Robots Increased precision Increased productivity Increased flexibility Improved environmental impact • Reduced changeover time • Decreased size • Reduced power requirements • • • • 29 © 2012 rjerz.com 30 © 2012 rjerz.com 4 Robots Robotic Welding • Perform monotonous or dangerous tasks • Perform tasks requiring significant strength or endurance • Generally enhance consistency and accuracy 31 © 2012 rjerz.com 32 Vision Systems © 2012 rjerz.com Process Control - Example • Particular aid to inspection • Consistently accurate • Never bored • Modest cost • Superior to individuals performing the same tasks 33 © 2012 rjerz.com 34 Process Control © 2012 rjerz.com Flexible Manufacturing Systems (FMS) • Computer controls both the workstation and the material handling equipment • Enhance flexibility and reduced waste • Can economically produce low volume at high quality • Reduced changeover time and increased utilization • Stringent communication requirement between components 35 © 2012 rjerz.com 36 © 2012 rjerz.com 5 FMS Examples Automated Storage and Retrieval Systems (ASRS) • Automated placement and withdrawal of parts and products • Reduced errors and labor • Particularly useful in inventory and test areas of manufacturing firms 37 © 2012 rjerz.com 38 Automated Guided Vehicle (AGV) • Electronically guided and controlled carts • Used for movement of products Automatic Identification Systems • Barcode • RFID • • • • 39 © 2012 rjerz.com © 2012 rjerz.com Improved data acquisition Reduced data entry errors Increased speed Increased scope of process automation 40 © 2012 rjerz.com CIM Wheel (SME) Computer Integrated Manufacturing (CIM) • Extension of flexible manufacturing systems • Backwards to engineering and inventory control • Forward into warehousing and shipping • Can also include financial and customer service areas • Reducing the distinction between lowvolume/high-variety, and high-volume/lowvariety production 41 © 2012 rjerz.com 42 © 2012 rjerz.com 6 Technology in Services • Computers • Barcode & sensors (RFID) • Internet 43 © 2012 rjerz.com 7