executive summary - Documents & Reports

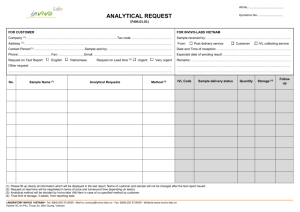

advertisement