Standards - University of Adelaide

advertisement

AUTO-ID LABS

Standardisation in RFID

Alfio Grasso

Deputy Director, Auto-ID Lab, Adelaide

General Manager, RFID Automation

AutoLogistics & SCM 2005

1

Overview

AUTO-ID LABS

EPCglobal

Standards Development Process

Workgroups

Technical Standards

Hardware Action Group

Software Action Group

Standard’s Documents

ISO Standards

18000-1 to -7

Others

Regulatory Standards

FCC, ETSI, Australian 4W RFID licence

AutoLogistics & SCM 2005

2

AUTO-ID LABS

EPCglobal Standards Development Process

AutoLogistics & SCM 2005

3

EPCglobal structure

AUTO-ID LABS

EPCglobal Board

of Governors

GS1

Architectural

Review Committee

Business Steering

Committee

President,

EPCglobal

Technology

Steering Committee

Business Action

Group - CP

Software Action

Group

Work Groups

Work Groups

Business Action

Group - HLS

Work Groups

GS1 US

Staff

Auto-ID Labs

Public Policy

Steering Committee

Hardware Action

Group

Work Groups

AutoLogistics & SCM 2005

4

AUTO-ID LABS

Membership May 2005

End

Users

Asia

Jun-04

Solution

Providers

May-05

Solution

Providers

End

Users

Total

%

Increase

Total

7

14

21

21

86

107

410%

North America

48

84

132

177

168

345

161%

Europe

10

26

36

39

46

85

136%

Middle East & Africa

0

2

2

0

4

4

100%

Latin America

0

0

0

2

2

4

#DIV/0!

65

126

191

239

306

545

185%

Totals

AutoLogistics & SCM 2005

5

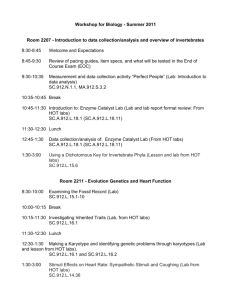

Working Groups

AUTO-ID LABS

Business Steering Committee (BSC)

Fast Moving Consumer Goods (FMCG)

Healthcare and Life Sciences (HLS)

Transport and Logistics (TLS)

Technical Steering Committee (TSC)

Hardware Action Group (HAG)

Software Action Group (SAG)

AutoLogistics & SCM 2005

6

AUTO-ID LABS

Standards Development Process

AutoLogistics & SCM 2005

7

AUTO-ID LABS

EPCglobal Workgroups

AutoLogistics & SCM 2005

8

AUTO-ID LABS

Fast Moving Consumer Goods

AutoLogistics & SCM 2005

9

AUTO-ID LABS

FMCG – Working Groups

Data Exchange

European Adoption Programme (EAP)

Pilot and Implementation (P&I)

Reusable Transport Items (RTI)

Strategic Planning

Tag and Inlay Standards

Asian Adoption Program (AAP)

AutoLogistics & SCM 2005

10

AUTO-ID LABS

DE - Charter

The objective of this group is to begin to begin

identifying the EXCEPTIONS to the simple Ship and

Receive process. These exceptions will be the

foundation for the track and trace business process

models. The charter of this group will be to explore

and document exception processes and defining

requirements needed of RFID technology to meet the

objective of streamlining the resolution of these

processes.

This group will also be tasked with identifying any

business process hurdles that come to light as a

result of their business process definitions, adding

some detail and consideration around these issues

and then passing them on to the Pilot &

Implementation Workgroup for final resolution and

documentation.

AutoLogistics & SCM 2005

11

DE - Deliverables

AUTO-ID LABS

Business Process Document

Identifying the EXCEPTIONS to the SHIP and

RECEIVE Process, the pain points that are a

result of these exceptions, and the requirements

of RFID technology to streamline the resolution

of these exceptions.

List of Business Process hurdles that need

further investigation and thought.

These should contain detailed descriptions of the

issues as well as any proposed process resolutions

(not technology) or technology requirements.

A summary of the issues/resolutions should be

forwarded to the Pilot & implementation group for final

resolution/documentation.

AutoLogistics & SCM 2005

12

EAP - Charter

AUTO-ID LABS

To help European business to extract maximum business

benefit from the use of EPCglobal technology as quickly as

possible and with minimum problems and without duplicating the

work of other EPCglobal or EAN.UCC work groups.

This will be done by

Agreeing and publicising common expectations of how EPCglobal

technology will be rolled out in Europe in order to avoid

incompatible approaches

Ensuring that European views related to EPCglobal are clearly

represented to EPCglobal and EAN.UCC standards and policy

groups.

Enabling EAP members to exchange information to assist in the

practical implementation and justification of RFID and EPCglobal

technology within Europe.

Lobbying and communicating with relevant organisations including

industry and consumer groups, government and other regulatory

authorities.

AutoLogistics & SCM 2005

13

AUTO-ID LABS

EAP - Deliverables

Technical Implementation

Business Processes

Radio Regulations

Business Case

Health and Safety

Privacy

Environmental Regulations

AutoLogistics & SCM 2005

14

AUTO-ID LABS

P&I Charter

The objective of the Pilot and

Implementation Working Group is to

provide end-user companies with

practical and timely information needed

as they prepare for RFID pilot and

implementation projects.

AutoLogistics & SCM 2005

15

P&I Deliverables

AUTO-ID LABS

First Set:

Implementation Guidelines

A five-phase EPC adoption framework with

implementation guidelines and lessons learned.

The five phases are Investigate, Experiment, Trial,

Pilot and Deploy.

Share Mechanism

Agreement by End Users to share certain levels of

information and process to elicit information

AutoLogistics & SCM 2005

16

P&I Deliverables Cont

AUTO-ID LABS

Second Set:

Vendor Profiles

A list of EPC/RFID solution providers with expertise on

hardware, software or services. The vendor list will be

segmented with brief description to help End User

companies find the services they need

Cost/Benefit Tutorial

A list of cost variables companies should consider as they

implement RFID projects. Designed like a checklist, this cost

list will enable companies to select the cost variables

applicable to their specific occasions or site conditions

Company Work Plan Template

A work plan template to illustrate key activities in every

adoption phase

AutoLogistics & SCM 2005

17

P&I Deliverables Cont

AUTO-ID LABS

Third Set:

Practice Briefing

Summarized technical white papers to help

explain specific implementation issues

KPI Directory

Listing of industry-accepted measurements

AutoLogistics & SCM 2005

18

AUTO-ID LABS

RTI - Charter

The overall aim of the WG is to ensure EPC

tagging will support the efficient management

of RTIs across the supply chain and provide

clear links with product tracking requirements

associated with the movements of assets.

A number of the objectives are linked to ongoing work with other EPCglobal WGs.

Wherever possible dialogue will be

established with those WGs to ensure

consistency of approach and shared learning.

AutoLogistics & SCM 2005

19

RTI - Scope

AUTO-ID LABS

Defining the concept of Returnable Transport Item

Ensure all possible equipment types relevant to the

Consumer Goods Sector are included in the WG scope

Confirm and validate existing GS1 standards for RTI

codification and the relevant EDI messaging

schemas underpinning the efficient management of

equipment and product flows

GRAI /GIAI

Validate the existing code numbering standards for

identifying returnable assets and components are sufficient

to meet the needs of efficient asset management

EDI messaging for RTI management

Review and validate existing proposals for RTI (and

product) tracking. This will build on from the prior

work of EAN member organizations and International

Council for RTI (IC-RTI).

AutoLogistics & SCM 2005

20

RTI – Scope Cont

AUTO-ID LABS

Converting to EPC tagging

Validate that Tag Data Standard V1.1 meets the

requirements for RTI tagging and is consistent

with existing GS1 standards, above.

Asset & Product Tracking

Determine business guidelines for the

synchronised tracking of assets (GRAI)

alongside of products (SSCC).

This may include:

Development of requirements for the possible encoding

of GRAI and SSCC into a single tag.

Alternative use of separate asset and unit load tags for

tracking purposes

AutoLogistics & SCM 2005

21

RTI – Scope Cont

AUTO-ID LABS

Non-unique coding

Develop guidelines for the use of identical tags for

a single RTI (e.g. returnable plastic crate, RPC),

designed to enhance readability.

EPC Data Exchange

Propose amendments to existing EPC data

exchange schemas to include the tracking of RTIs

as an optional, but integral part of overall EPC

data exchange for key supply chain processes

Future RTI tagging requirements

Develop user requirements for tag functionality

specific to the future needs of RTI applications

(e.g. read/write, temperature and trauma sensing)

AutoLogistics & SCM 2005

22

RTI - Deliverables

AUTO-ID LABS

Guidelines:

EPC application for the management of

RTIs and product tracking

AutoLogistics & SCM 2005

23

SP - Charter

AUTO-ID LABS

Ensure that the EPCglobal Strategic Work Plan is

aligned with End User business priorities

Provide collaborative, focused interaction between

EPCglobal End Users and EPCglobal on the work and

priorities of the overall Action Groups.

Capture requirements and prioritize the critical path

elements needed to support End User implementations of

EPC and the EPCglobal Network.

Recommend the Strategic Work Plan priorities to the

Business Steering Committee

Provide visibility into the prioritization and Work Plan

process

Facilitate a process to assess the delivery of

EPCglobal Strategic Work Plan elements and

evaluate the effect of changes

AutoLogistics & SCM 2005

24

SP - Deliverables

AUTO-ID LABS

EPCglobal Strategic Work Plan that illustrates

critical path Network elements.

Objectives/Requirements

Prioritization

Scope, Schedule, Resources, etc….

Work Plan Change Management process

Process to facilitate communication to and from

EPCglobal End-User community and workgroups

Regular meetings with the Business Steering

Committee to present results and status of

Strategic Work Plan

Miscellaneous research and deliverables requested

by the Business Steering Committee

Glossary of terms

AutoLogistics & SCM 2005

25

AUTO-ID LABS

T&I - Charter

The objective of this WG is to create a Tag

and Label Standard specification to enable

silicon RFID chip, inlay, tag, RFID printer, and

RFID applicator manufacturers to standardize

their product offerings to meet the end user

requirements described in the RFID Usability

Requirements.

The goal of the Working Group is to complete

the necessary documentation for the Tag and

Label specification to conform to EPCglobal

requirements.

AutoLogistics & SCM 2005

26

T&I Key Objectives

AUTO-ID LABS

Deliver a specification for standard label

sizes.

Review of RFID Usability document.

Review existing label standards EAN/UCC,

GSMP EPCTDT.

Define user requirements for label sizes.

Make recommendation for standardize

sizes.

Develop standard label size specification.

AutoLogistics & SCM 2005

27

T&I Key Objectives Cont

AUTO-ID LABS

Deliver a specification for standard Inlay

locations.

Define no print areas.

Determine if a no print area is possible, if it is,

define the most acceptable location for the user

community and create a specification.

Printer/reader Applicator requirements.

Determine the Printer/Reader and applicator

antenna location requirements in combination with

1.1 above. If an optimum location can be

determined, seek consensus and publish a

specification.

Maximum Height of inlay in print areas.

AutoLogistics & SCM 2005

28

T&I Key Objectives Cont

AUTO-ID LABS

Maximum Height for no print areas.

Standardize inlay sizes.

Other topics TBD

Additional Topics TBD…. Some may be too

proprietary to standardize.

Chip pad formats

Chips sizes

Strap designs

Antenna design requirement for chips, i.e.

Capacitance and resistance, etc.

AutoLogistics & SCM 2005

29

T&I Key Objectives Cont

AUTO-ID LABS

Identify the process and format for

adding future tag and labels standards

as new requirements occur.

Review the possible requirements for tag

and labels standards in other industry

sectors apart from Retail/CPG that may

potentially become users of EPC

technology.

Develop a process for adoption of new

inlay and label standards.

AutoLogistics & SCM 2005

30

T&I Key Objectives Cont

AUTO-ID LABS

Environment and Safety issues of tag design

and disposal.

Review the possible requirements for tag and

labels with corrugated manufacturers for control

of waste products in recycling of paper

Quantify and make recommendations on material

usage and effect to the environment.

Evaluate existing packaging standards and label

requirements for use of heavy metals such as

copper, aluminium and silver. (used in antenna

fabrication)

Other medical and safety issues regarding tag

and inlay materials for child safety, toxicity, etc.

AutoLogistics & SCM 2005

31

AUTO-ID LABS

T&I - Deliverables

Tag and Label Standard V 1.0

document

Appendix to describe guidelines

Appendix for process & template of

future scheme requirements.

AutoLogistics & SCM 2005

32

AAP - Charter

AUTO-ID LABS

To help Asian business to extract maximum business benefit

from the use of EPCglobal technology as quickly as possible

with minimum problems and without duplicating the work of

other EPCglobal or EAN.UCC work groups.

This will be done by:

Obtain agreement on standards adoption by EPCglobal members

in the region and publicize common expectations of how EPCglobal

technology will be implemented in Asia in order to avoid conflicting

approaches

Ensure that Asian views related to EPCglobal and user

requirements in the region are clearly represented to EPCglobal

and EAN.UCC standards and policy groups.

Enable AAP members to exchange information to assist in the

practical implementation and justification of RFID and EPCglobal

technology within Asia.

Communicate with relevant organizations including industry and

consumer groups, government and other regulatory authorities.

Attract adoption of EPCglobal standards from key entities in the

region.

AutoLogistics & SCM 2005

33

AAP - Deliverables

AUTO-ID LABS

Four meetings per annum

including presentations, demonstrations and

information exchange for AAP participants.

A clear statement of a common approach to

EPCglobal roll out in Asia which covers:

Technical Implementation

Business Processes

Radio Regulations

Privacy

AutoLogistics & SCM 2005

34

AUTO-ID LABS

Healthcare and Life Sciences

AutoLogistics & SCM 2005

35

AUTO-ID LABS

HLS – Working Groups

Strategy

Policy

Process

Information

Technology

Research

AutoLogistics & SCM 2005

36

AUTO-ID LABS

Strategy – Charter/Objectives

Develop and manage the execution of a Strategic

Work Plan, designed to coordinate and prioritize

the activities of Work Groups within the HLS BAG.

Provide specific input to EPCglobal Technical and

Business Action Groups, and other standardssetting bodies, as appropriate, regarding the

requirements for

standards, policies, and agreements

between and among trading partners and regulatory

bodies

in the extended healthcare and life sciences supply chains

as related to the application and use of RFID technology in

general, and the EPCglobal Network,

specifically, to track, trace and authenticate articles of

commerce.

AutoLogistics & SCM 2005

37

Strategy Charter Cont

AUTO-ID LABS

The development of specific Use

Cases, and Scenarios, which describe

(i) the route traversed by articles of

commerce and

(ii) business interactions involved at each

node of the supply chain,

focused initially on compliance with

international laws and regulations, State

pedigree laws and US FDA guidelines

AutoLogistics & SCM 2005

38

Strategy Charter Cont

AUTO-ID LABS

The development of specific Use Cases, and

Scenarios, which describe

(i) the route traversed by articles of commerce and

(ii) business interactions involved at each node of

the supply chain,

focused on elements that may include

enhancing supply chain efficiencies,

improving care provider efficiencies and effectiveness,

and

enhancing the patient/consumer experience, compliance,

and safe usage.

AutoLogistics & SCM 2005

39

Strategy - Deliverables

AUTO-ID LABS

Prioritized list of Use Cases and Scenarios,

accompanied by detailed recommendations

A Strategic Work Plan that includes the

following:

Objectives/Requirements

Priorities

Deliverables

Scope, Schedule/Timeline, Resources, etc….

Work Plan Change Management process

AutoLogistics & SCM 2005

40

Policy – Charter/Objectives

AUTO-ID LABS

The objective of the HLS Policy

workgroup is to

promote the adoption of RFID and EPC

technology

within the healthcare supply chain

by developing opportunities for the

enabling regulations, guidelines and

mandates

to be enacted, promoted or enforced

through existing industry channels of

communication and bodies of influence.

AutoLogistics & SCM 2005

41

Policy - Deliverables

AUTO-ID LABS

Detailed, well-documented reports

identifying which areas of regulatory

compliance, public policy, privacy, security,

patient and consumer education, and

business policy

A Policy Work Plan that includes the

following:

Objectives/Requirements

Priorities

Deliverables

Scope, Schedule/Timeline, Resources, etc….

Work Plan Change Management process

AutoLogistics & SCM 2005

42

AUTO-ID LABS

Process – Charter/Objectives

Develop the business processes that

will outline the key EPCglobal HLS

BAG use cases and define the

underlying process descriptions

Development of specific Use Cases

The scope of the Use Case includes all

nodes beginning at the point of

Pharmaceutical Packaging and ending at

the decommissioning at the Hospital or

Retail Pharmacy.

AutoLogistics & SCM 2005

43

Process - Deliverables

AUTO-ID LABS

Detailed RFID enabled supply chain Use

Cases and Scenarios, Process description,

flows and information maps

A Process Work Plan that includes the

following:

Objectives/Requirements

Priorities

Deliverables

Scope, Schedule/Timeline, Resources, etc….

Work Plan Change Management process

AutoLogistics & SCM 2005

44

AUTO-ID LABS

Information – Charter/Objectives

The Objective of the HLS Information

WG (IWG) is to recommend information

business requirements and related

process for the Healthcare and Life

Sciences supply chain for use cases.

AutoLogistics & SCM 2005

45

Information - Deliverables

AUTO-ID LABS

Documents describing

Information Access API Specification.

Numbering Systems.

Data Retention.

Data Synchronization and Data Validation

Data Ownership, Visibility, and Sharing.

Data Security and Privacy

EPC Number Assignment

AutoLogistics & SCM 2005

46

AUTO-ID LABS

Technology Charter/Objectives

The objective of the Technology

Working Group (WG) is to serve as a

technical resource to the other work

groups inside the HLS Business Action

Group.

AutoLogistics & SCM 2005

47

Technology - Deliverables

AUTO-ID LABS

Prioritized list of Use Cases and Scenarios,

accompanied by detailed recommendations

for action by EPCglobal Technical and

Business Action Groups regarding

development of appropriate Technology.

A Technology Work Plan that includes the

following:

Objectives/Requirements

Priorities

Deliverables

Scope, Schedule/Timeline, Resources, etc….

Work Plan Change Management process

AutoLogistics & SCM 2005

48

AUTO-ID LABS

Research – Charter/Objectives

Develop requirements for further research as defined and prioritized

by the Healthcare and Life Sciences Business Action Group

Strategic Planning Working Group.

Review and summarize the existing research on the effect of RF on

products, humans, and the environment.

Survey the major stakeholders in pharmaceutical applications of

RFID technology on the research they have performed, the areas in

which research is continuing, and their willingness to share results.

Coordinate with academic RFID thought leaders to assess the state

of the art in RFID research, including MIT, Michigan State, and the

University of Adelaide, Australia.

Examine and summarize research on the effect of Cold Chain on

RFID technology.

Review research concerning the effect of sterilization procedures on

tag performance.

Determine plausible scenarios and timelines for sensor technology

development.

AutoLogistics & SCM 2005

49

AUTO-ID LABS

Research - Deliverables

Annotated survey results showing RFID industry

research snapshot.

Backgrounder document on the state of the art in

RFID research.

Gap assessment of critical research not yet done or

not yet publicly available.

Documents summarizing public use cases on the

effect of RF on product, humans, and the

environment. Special consideration will be given to

the effect of RFID on liquids and biologics.

Summary documents on the implications of using

RFID in Cold Chain and Sterilization environments,

again based on use cases in the public domain.

AutoLogistics & SCM 2005

50

AUTO-ID LABS

Transport & Logistics

AutoLogistics & SCM 2005

51

AUTO-ID LABS

Transport & Logistics (NEW)

AutoLogistics & SCM 2005

52

AUTO-ID LABS

Hardware Action Group

AutoLogistics & SCM 2005

53

AUTO-ID LABS

HAG – Working Groups

Class 1 Generation 2 (Work completed)

Gen 2 Testing & Certification

Joints Requirements Group for Item

Level Tagging

Others planned

AutoLogistics & SCM 2005

54

AUTO-ID LABS

Software Action Group

AutoLogistics & SCM 2005

55

AUTO-ID LABS

SAG Working Groups

Reader Protocol

Reader Management

Filtering and Collection

ONS

Security

Tag Data Translation

EPCIS

EPCIS Phase 2

Tag Data Standards

AutoLogistics & SCM 2005

56

AUTO-ID LABS

Future Working Groups ?

Automotive

Aerospace

Electronics

Biologics

AutoLogistics & SCM 2005

57

AUTO-ID LABS

EPCglobal Technical Standards

Hardware Action Group

Software Action Group

AutoLogistics & SCM 2005

58

Push

Sharing

EPCIS

EPCIS

Accessing

Accessing

Application

Application

Firewall

Partner

Partner

Accessing

Accessing

Application

Application

EPCIS Query Interface

EPCIS

EPCIS

Repository

Repository

EPCIS Capture Interface

Security

AUTO-ID LABS

EPCglobal network: roles and

interfaces

EPCIS

EPCISCapturing

Capturing

Application

Application

Capture

Business

Xactions

& F&C Events

F&C Interface

F&C

F&CMiddleware

Middleware

Systems

Mgmt

Reader Protocol / Mgmt Interface

Reader

Reader

Tag Protocol (Gen2) / Tag Data Std

2004 EPCglobal

Push

Sharing

• Green boxes

represent Specs.

• Blue boxes

represent roles, not

necessarily discrete

components

Tag

Tag

AutoLogistics & SCM 2005

59

AUTO-ID LABS

Hardware Action Group

C1G2 – Completed

Testing and Certification

Requirements Item Level Tagging

AutoLogistics & SCM 2005

60

AUTO-ID LABS

HAG - Mission

Define the interfaces between

hardware components (primarily

RFID tags and readers) in the

EPCglobal Network

AutoLogistics & SCM 2005

61

AUTO-ID LABS

C1G2

AutoLogistics & SCM 2005

62

C1G2 Features

AUTO-ID LABS

Tag must be able to communicate from 860 MHz to 960

MHz

Tags must understand 3 different modulation schemes

Double Sideband Amplitude Shift Keying DSB-ASK

Single Sideband Amplitude Shift Keying SSB-ASK

Phase Reversal Amplitude Shift Keying PR-ASK

Coding is by Pulse Interval Encoding (PIE)

T=>R data rates 40, 80, 160, 320 and 640 kbits

Selection

Access & Kill Passwords

EPC up to 256 bits

Dense reader channelised signalling

AutoLogistics & SCM 2005

63

AUTO-ID LABS

Interrogator/tag operations and

tag state

Reader

Tags

State

Select

Ready

Arbitrate

Reply

Inventory

Acknowledged

Open

Secured

Access

Killed

AutoLogistics & SCM 2005

64

Inventory

AUTO-ID LABS

Reader Talks First

Sets up communication parameters, defines a round

Round Size (Q value), slots are numbered from 0 to 2Q-1

Tags select a slot within a round to offer a reply

Tag States

Ready

Arbitrate

Reply

Acknowledge

Open

Secured

Killed

AutoLogistics & SCM 2005

65

Replies

AUTO-ID LABS

Single Tag Reply

Interrogator

Select

CW

Query

Tag

CW

RN16

T4

T1

Collided Reply

Interrogator

Ack

CW

Query

T2

QueryRep

NAK if EPC

is invalid

Invalid ACK

QueryRep

Ack

CW

CW

No

Reply

QueryRep

No

Reply

RN16

RN16

T1

NAK

T2

T1

CW

Collision

Detected

Tag

QueryRep or

QueryAdjust

if EPC is valid

PC + EPC + CRC16

No Reply

CW

QueryRep

T2

T1

T3

T1

AutoLogistics & SCM 2005

T2

T1

T3

66

Query

QueryRep

QueryAdjust

AUTO-ID LABS

Power-up & ~killed

Slot

Counter

NEW ROUND

CMD: Query [mismatched

inventoried or SL flags]

Reply: None

slot

CMD: Select

Action: Return to ready

Reply: None. Note 1

CMD: Query

Action: New round

Reply: Note 3

CMD: All other

Action: Remain in ready

Reply: None

Ready

NEW ROUND

CMD: Query [slot > 0 & matching

(inventoried & SL) flags]

Reply: None

Arbitrate

CMD: QueryRep, QueryAdjust [slot <> 0]

Reply: None

NEW ROUND

CMD: Query [slot = 0 & matching

(inventoried & SL) flags]

Reply: New RN16

CMD: QueryAdjust, QueryRep [slot=0]

Reply: New RN16

CMD: Select

Action: Return to ready

Reply: None. Note 1

CMD: Query

Action: New round

Reply: Note 3

CMD: All other

Action: Return to arbitrate

Reply: None.

CMD: None within time T2

Action: Return to arbitrate

Reply: None.

Reply

CMD: ACK [valid RN16]

Reply: PC, UII, CRC-16

CMD: QueryAdjust [slot = 0]

Reply: New RN16

CMD: ACK [valid RN16]

Reply: PC, UII, CRC-16

CMD: Req_RN [invalid RN16]

Reply: None

Acknowledged

CMD: Req_RN [valid RN16] & {access password = 0}

Reply: Handle

CMD: Req_RN [valid RN16] &

{access password <> 0}

Reply: handle

CMD: Select

Action: Return to ready

Reply: None. Note 1

CMD: Query

Action: New round

Reply: Notes 2, 3

CMD: QueryRep, QueryAdjust

Action: Return to ready

Reply: None. Note 2

CMD: All other

Action: Return to arbitrate

Reply: None.

Open

CMD: Access [valid handle & valid access password]

Reply: handle when done

Secured

CMD: Kill [valid handle & valid nonzero kill password]

Reply: handle when done

Power-up & killed

CMD: ACK [valid handle]

Reply: PC, UII, CRC-16

CMD: Req_RN, Read, Write, Lock, BlockWrite, BlockErase

Reply: See state-transition tables

CMD: Kill [valid handle & kill password = 0]

Reply: Error code

CMD: Kill, Access [invalid handle]

Reply: None

Killed

CMD: ACK [valid handle]

Reply: PC, UII, CRC-16

CMD: Req_RN, Read, Write, Lock, BlockWrite, BlockErase

Reply: See state-transition tables

CMD: Kill [valid handle & kill password = 0] or [invalid handle]

Reply: Error code

CMD: Access [valid handle & valid access password] or

[invalid handle]

Reply: handle when done

CMD: All

Reply: None

NOTES

1. Select: Assert/deassert SL or set inventoried to A or B.

2. Query: AB or B A if the new session matches the prior session; otherwise no change to the inventoried flag.

QueryRep/QueryAdjust: AB or B A if the session matches the prior Query; otherwise, the command is invalid and ignored by the Tag.

3. Query starts a new round and may change the session. Tags may go to ready, arbitrate, or reply.

AutoLogistics & SCM 2005

67

AUTO-ID LABS

Testing & Certification

AutoLogistics & SCM 2005

68

HAG - T&C

AUTO-ID LABS

UHF Gen 2 Testing and Certification

Working Group

Approved by EPCglobal legal counsel - 24 March

2005

Objectives/Charter

Review Gen 2 Certification Test Plans for RF and

Protocol Testing currently being developed by

MET Labs and its partner, CETECOM Spain.

Provide technical feedback on UHF Gen 2

Certification Test Plans via comment matrices.

Actively resolve all technical feedback through

comment resolution process.

AutoLogistics & SCM 2005

69

AUTO-ID LABS

T&C Deliverable

Comment resolution matrix for

METLabs Certification Test plan

AutoLogistics & SCM 2005

70

Activities

AUTO-ID LABS

Conformance Trade Marking

Compliance Specification Sheet

Owned by EPCglobal

Vendor Neutral

Keyed to TID, so system can pull compliance information from

the EPC Network

Testing philosophies

RF Interface

Connector or radiated

Interoperability

Compatible

Parameter Matrix

EPC compliant devices will have a matrix identifying what

parameters were tested

AutoLogistics & SCM 2005

71

T&C - Working Documents

AUTO-ID LABS

Protocol Requirements

Requirements of test equipment for C1G2 and measurement

requirements of both, interrogators and tags, for testing

operating procedures and commands in the Tagidentification layer

RF Requirements

Requirements of an RF test system for testing the physical

interactions, i.e. the signalling layer of the communication

link between C1G2 Interrogators and Tags

Protocol

Protocol test system for testing operating procedures and

commands of the data link layer of a layered network

communication

Design Interoperability

Test system for the operating procedures for testing end-toend functionality between two communicating RFID devices

AutoLogistics & SCM 2005

72

AUTO-ID LABS

Requirements - Item Level Tagging

AutoLogistics & SCM 2005

73

Requirements Group

AUTO-ID LABS

New Group, established in July 2005

Initial Membership limited to

10 members from Fast Moving Consumers Group,

10 members from Healthcare & Life Sciences

Group

10 members from HAG

A member of the Auto-ID Labs

A member of the Architecture Review Committee

(ARC)

AutoLogistics & SCM 2005

74

AUTO-ID LABS

Proposed Charter

To develop requirements for an Item-Level Tagging Specification

including but not limited to

a) Minimum and maximum tag read and, if appropriate, write range

b) Minimum and maximum tag read and, if appropriate, write rate

c) Security requirements including general type, encryption

strength, and key management

d) Privacy features, including consideration of worldwide

regulations

e) Memory features, including size and organization

f)

Read and write reliability

g) Complete description of physical operating environments

common in the handling of individual items in the supply chain –

needs to reflect environments for both HLS and FMCG supply chains

h) Other requirements and expectations as decided by the JRG

AutoLogistics & SCM 2005

75

AUTO-ID LABS

Software Action Group

AutoLogistics & SCM 2005

76

AUTO-ID LABS

SAG - Mission

The definition of software interface and

other standards both within the

EPCglobal Network elements and

between these and other elements of

enterprise systems distributed over a

number of enterprises and geographies.

AutoLogistics & SCM 2005

77

AUTO-ID LABS

Working Groups

Filtering and Collection

Reader Protocol

Reader Management

Object Name Service (ONS)

EPCIS (Information Services)

Security

TAG Data Translation

EPC Information Services Phase 2

Tag Data Standards

AutoLogistics & SCM 2005

78

AUTO-ID LABS

AutoLogistics & SCM 2005

79

Filtering and Collection

AUTO-ID LABS

Charter

Create a specification for a software

application programming interface (API),

associated data specifications, and

reporting mechanisms, through which

clients may obtain filtered, aggregated tag

read data from a multiplicity of tag read

sources.

AutoLogistics & SCM 2005

80

F&C Deliverables

AUTO-ID LABS

Application Level Event Specification (ALE):

Filters and Counters (normative document)

Report:

Recommendation of future standards

Recommendations for topics to be addressed by

follow-on WGs to this one

Use case coverage

Identification of use cases addressed by the

specification, and not addressed by the specification.

Prototyping and acceptance test plan.

Certification and compliance requirements.

AutoLogistics & SCM 2005

81

Reader Management

AUTO-ID LABS

Charter

Define a set of standard functions that enable

configuration, provisioning, monitoring, and alarm

notification of individual RFID readers. It will

leverage the standard communication protocol

defined by the Reader Protocol Working Group

where applicable. This set of standard functions

will provide a baseline for management

operations, will be extensible for future revisions,

and will provide the ability to accommodate vendor

specific extensions.

AutoLogistics & SCM 2005

82

RM Deliverables

AUTO-ID LABS

Reader Management Specification

(normative document) defining:

Standard objects that need to be managed

by all RFID readers.

Set of operations that can be performed on

the objects.

Extensible object model.

AutoLogistics & SCM 2005

83

Reader Protocol

AUTO-ID LABS

Charter

Define the protocol specification for

exchanging data and commands between

hosts and readers, supporting functions

such as reading tags, writing to tags, and

killing tags.

AutoLogistics & SCM 2005

84

RP Deliverables

AUTO-ID LABS

Reader Protocol Specification v1.0

(normative document as outlined in the

charter)

Report:

Working Group Report On IP

Prototyping and Acceptance Test Plan

Certification and Compliance requirements

AutoLogistics & SCM 2005

85

AUTO-ID LABS

Object Name Service

Charter

Complete outstanding work concerning the

Object Name Service. This includes bringing

the "Object Name Service 1.0" document to

the Standard Specification level within the

EPCglobal standards development process. In

addition to the base protocol specification, the

group will also specify an application

programming interface (API) for issuing ONS

queries and an operational guidelines

document that outlines industry best practices

for the operation of DNS infrastructure.

AutoLogistics & SCM 2005

86

ONS Deliverables

AUTO-ID LABS

ONS 1.0 Specification:

Alignment with the published version of the Tag Data Standards

and the namespaces and DNS encoding of those namespaces. It is

important to note that there is a normative dependency between

this document and the final publication of the Tag Data Standards.

Alignment of the NAPTR records Service field with the protocol

element of the EPCglobal Network.

Update of all content to be consistent with the new EPCglobal

standards development process

ONS API Specification

A document that outlines the API for interfacing to an ONS resolver

and returning the output

ONS Operational Recommendations

A document that references guidelines developed by external

standards bodies for the proper use of DNS infrastructure.

Future Issues List for consumption by the TSC

A short list of future items that the working group identifies as

possibly needing future development.

AutoLogistics & SCM 2005

87

Security

AUTO-ID LABS

Charter

Deliver a set of recommendations to provide a

security framework to ensure different levels (i.e.

‘low, ’medium’, ‘high’) of consumer information

privacy, data authentication, integrity for both

wireless and wired data transmissions, and mutual

business confidence for collaborative business

trading networks

Re-charter, so that Security WG can develop

the EPCglobal Certificate Profile that will be a

normative document.

AutoLogistics & SCM 2005

88

Security Deliverables

AUTO-ID LABS

Data Security Recommendations

Consumer Privacy Practice

Recommendations

Report:

Working Group Report On IP

AutoLogistics & SCM 2005

89

Tag Data Standards

AUTO-ID LABS

Charter

The objective of this WG is to extend the

current TDS specification to enable it to

cope with potential issues associated with

the expansion of subscribers, particularly

to other sectors of industry.

Provide guidance/methodology as an

extension to the current TDS specification,

to address issues that are expected to

arise, see next few slides.

AutoLogistics & SCM 2005

90

Alpha-numeric handling.

AUTO-ID LABS

There are many existing coding schemes

that require the use of alpha-numeric

coding (such as GRAI and DoD/UID).

EPCglobal need to address the use of

alpha-numeric coding for the specification.

AutoLogistics & SCM 2005

91

EAN.UCC Codes

AUTO-ID LABS

Define pure identification form of URI for

current EAN/UCC codes.

Current TDS 1.1 specification defines the

URI form presupposing the physical

limitation of tag, such as bit length.

TDS need to define the pure identification

form of URI stated in TDS 1.1, based on

the actual and current EAN/UCC coding.

AutoLogistics & SCM 2005

92

Transition management.

AUTO-ID LABS

TDS need to identify requirements and

document methods to enable smooth

transitions to current TDS specifications

from prior tag data white papers

specification published in the Auto-ID

Center period.

AutoLogistics & SCM 2005

93

Manufacturer transit codes.

AUTO-ID LABS

TDS need to identify the requirements of

the tag manufacturers to encode “transit”

codes that make tags unique at the time of

initial sale, and provide guidelines and

methodology to address such requirements.

AutoLogistics & SCM 2005

94

Non-unique encodings.

AUTO-ID LABS

TDS need to identify the requirements of

non-unique encodings, such as “non-serial

ID” and longer bit tags which store more

than one identifier (e.g. pallet tags which

have both a GRAI and an SSCC encoded

in one physical tag) or use of two identical

tags for single object to enhance readability,

and provide guidelines and methodology to

address the use of these encodings.

AutoLogistics & SCM 2005

95

AUTO-ID LABS

ISO

The requirement of synchronization /

incorporation of ISO data standard

structure to EPC TDS specification.

AutoLogistics & SCM 2005

96

AUTO-ID LABS

New Format

Identify and document the required

correction and enhancement to the

current TDS specification, in particular

to make greater use of tables and

diagrams and less use of prose-based

descriptions.

AutoLogistics & SCM 2005

97

Future Formats

AUTO-ID LABS

Identify the process and format for future tag

data standard scheme requirements.

The requirement of tag data in other industry

sectors apart from Retail/CPG that may potentially

become users of EPC technology.

What kind of data standard is required by Class 2

tag and beyond? In particular, will the fast filter

value or even the header (which identifies tag

length / numbering scheme) need to be

programmed into the user-writeable part of the tag

memory?

AutoLogistics & SCM 2005

98

AUTO-ID LABS

TDS Deliverables

Tag Data Standard V 2.0 document

Appendix to describe guidelines

Appendix for process & template of

future scheme requirements.

AutoLogistics & SCM 2005

99

Tag Data Translation

AUTO-ID LABS

Charter

Develop the necessary specifications to express

the current Tag Data Standards encoding and

decoding rules in an unambiguous machinereadable format, which will allow any component

in the EPC Network technology stack to

automatically convert between the binary and tagencoding and pure-identity URI formats of the

EPC as appropriate. The motivation is to allow

components flexibility in how they receive or

transmit EPCs, to reduce potential ‘impedance

mismatches’ at interfaces in the EPC Network

technology stack. Reference implementations of

software that demonstrate these capabilities will

also be developed.

AutoLogistics & SCM 2005

100

AUTO-ID LABS

TDT Deliverables

Specifications for an XML data table

(simultaneously both human-readable and

machine-readable) to represent the formatting

structure of the various numbering schemes

defined in the Tag Data Standards specification.

Specifications of an API for a software conversion

engine or other software that uses the XML data

table to obtain access to updated versions of the

data tables, by means of which it can update its

processing rules, to support additional numbering

schemes in the future.

AutoLogistics & SCM 2005

101

AUTO-ID LABS

TDT Deliverables Cont

Specifications for a standard language or

data type by which applications or any

component of the EPC Network technology

stack can express the preferred

representation of EPC, which should be

input/output from that component.

A reference implementation of the XML data

table, which is consistent with the current

specification of EPC Tag Data Standards.

AutoLogistics & SCM 2005

102

AUTO-ID LABS

TDT Deliverables Cont

Specifications for a software conversion

engine which is able to convert between

the various EPC representations (raw

tag information, tag-encoding URI, pureidentity URI) and ideally also the native

representations in the numbering

schemes, which are included in the Tag

Data Standards.

AutoLogistics & SCM 2005

103

AUTO-ID LABS

TDT Deliverables Cont

A reference implementation of the

conversion engine, which uses the data

table to update its processing rules.

Note that the engine is not required to

parse the original XML data table for

each conversion operation.

Implementations may choose to store

these rules in database tables or

generate programming code based on

the XML table.

AutoLogistics & SCM 2005

104

AUTO-ID LABS

TDT Deliverables Cont

Relevant additional coding schemes for

other industry sectors should also be

considered in the design of the table

and the computational/processing

functions required of the conversion

engine, in order that the core

functionality of the engine anticipates

and supports their future inclusion.

This may also include support for

alphanumeric coding schemes.

AutoLogistics & SCM 2005

105

EPCIS

AUTO-ID LABS

Charter

Produce an informative description of alternative

interfaces (at a functional, not technical

implementation level) for capturing, securing, and

accessing EPC-related data, with supporting data

model abstractions (metamodels) as appropriate

to serve as input to BAG WGs to help them see

"what's possible" as they consider Use Cases that

leverage EPCIS. Present these informative

interface descriptions to the EPCglobal community

including the Architectural Review Committee

(ARC) for technical direction and the BAG for

business direction.

However, Activities suspended to form and

work on EPCIS Phase 2.

AutoLogistics & SCM 2005

106

EPCIS Deliverables

AUTO-ID LABS

An informative description of alternative

interfaces as defined to include:

Supporting data model abstractions (meta

models) as appropriate for understanding

Identification of use cases addressed by

the interfaces, and not addressed by the

interfaces

Recommendations for topics of follow-on

Working Groups

Assumptions about interactions with other

EPCglobal specifications and work groups

AutoLogistics & SCM 2005

107

EPCIS Phase 2

AUTO-ID LABS

Charter

The initial Working Group has completed a concise,

preliminary functional description of EPC IS in the form of a

slide presentation, and presented that description to BAG.

The initial Working Group is also in the process of writing a

more complete, user-level informative document, which,

when delivered, will end the initial working group.

This new EPCIS Working Group is chartered both to

continue user level requirements gathering and

documentation, and to create technical specifications within

a narrowly defined set of objectives. The motivation for

limiting the scope of this WG to a narrowly defined set of

objectives is to expedite the specification writing and

consensus building process.

AutoLogistics & SCM 2005

108

AUTO-ID LABS

Scope of EPCIS2

EPC IS version 1.0 will address Data Capture by providing an

interface specification for representing and transferring

operational events in an EPC network that may include both

basic EPC data and be augmented with business level

transaction identifiers and other additional information.

EPC IS version 1.0 will address Data Query by providing an

interface for querying EPC IS information from compliant

systems.

Access Control and Authentication will be addressed, to the

extent that it is possible, by citing existing well-established

industry practices for Internet B2B commerce. Access Control

specifications will be created for dimensions that are particular

to EPC IS, in the context of pair-wise information sharing

between trading partners having a pre-established relationship.

AutoLogistics & SCM 2005

109

AUTO-ID LABS

Scope Cont

All specifications will seek to adopt the layered

approach already adopted by the Reader Protocol,

Reader Management, and Filtering & Collection

Working Groups, in which services are described

abstractly through a neutral notation such as UML,

with bindings to specific message syntax and

transport specified separately.

In addition, EPCIS specifications will seek to cleanly

separate the specification of data from operations

upon data.

The only binding of the abstract service descriptions

provided in this version of specifications will be a

binding to a web services framework, using WSDL

and XSD.

AutoLogistics & SCM 2005

110

EPCIS2 Deliverables

AUTO-ID LABS

Version 1 of an EPCIS Application Protocol

Interface specification covering data capture

and data query.

Non-normative Report:

Recommendation for areas to be considered by

future Working Groups.

Non-normative Report:

Use case coverage: Identification of use cases

addressed by the specification, and not

addressed by the specification.

Prototyping and acceptance test plan.

AutoLogistics & SCM 2005

111

AUTO-ID LABS

Graphical Illustration of roles

AutoLogistics & SCM 2005

112

Tag Data Standards

AUTO-ID LABS

An Example of How GTIN Integration Could Work With the EPC

Illustrative Example (EAN-13): 12 34567 89012 8

EAN - 13

0

1

2

3

4

5

6

Company Prefix

7

8

9

0

1

2

8

Item Reference Check Digit )

1 2 3 4 5 6 7 8 9 01 28 >

8

1 2 3 4 5 6 7

EPC:

3

1234567

Header EPC Manager Number

9

0

1

2

8

Remove

Check Digit

89012

0000000123456

Object Class Number

Serial Number

GTIN

AutoLogistics & SCM 2005

113

AUTO-ID LABS

Tag Data Translation

AutoLogistics & SCM 2005

114

AUTO-ID LABS

ONS

AutoLogistics & SCM 2005

115

EPC Event Layers

AUTO-ID LABS

R

R

Enterprise

App

EPCIS

“at time T, the association of the following case tags to

the following pallet tag was created at palletizer #3”

Palletizer

(Operational App)

“between the time the case crossed the first beam and the

second beam at location L, the following tag was read”

ALE

RFID

“Middleware”

Reader Protocol

Reader

dozens of individual tag read events from specific

antenna

Reader

AutoLogistics & SCM 2005

116

AUTO-ID LABS

EPCIS Concepts

AutoLogistics & SCM 2005

117

AUTO-ID LABS

Possible Retailer Implementation

Enterprise-wide Repository

EPCIS

Query

Trading partners

EPCIS

EPCIS Capture

Retail Store

Dist Center

Retail Store

Rdr

Mware

App

AutoLogistics & SCM 2005

118

Capture Application

AUTO-ID LABS

Manufacturer

Retailer

Dist Ctr

Tagging

Station

Palletizer

Dist Ctr

Dock

Portal

Dock

Portal

Rack

Store

Dock

Portal

Backroom

Receipt

Impact

Doorway

Operational Apps

Commission Observe

Observe

Aggregate

Observe

Shipment

Observe Observe

Receipt Putaway

Observe

Shipment

Observe

Disaggregate

Observe

Restock

EPCIS Events

AutoLogistics & SCM 2005

119

AUTO-ID LABS

EPCglobal Standards

Up to date as of 29 July 2005

AutoLogistics & SCM 2005

120

HAG Standards

AUTO-ID LABS

Ratified Standards

C1G2 V1.0.9

C1G2 Conformance V1.0.2

Working Documents

C1G2 V1.1.0

Testing & Certification

Protocol Requirements

RF Requirements

Design Interoperability

Protocol

AutoLogistics & SCM 2005

121

SAG Standards

AUTO-ID LABS

Ratified Standard

Tag Data Standards V1.27

Proposed Specification

The Application Level Events (ALE) Specification,

Version 1.0

Candidate Specifications

EPCglobal Object Name Service (ONS) 1.0

Tag Data Translation Version 3 June 2005

LCWD to Candidate Specification

Reader Protocol 1.1

AutoLogistics & SCM 2005

122

SAG Standards Cont

AUTO-ID LABS

Last Call Working Draft

Reader Management 1.0

TDS V1.3

Working Drafts

ALE Futures

ALE Compliance

Security Working Drafts

ALE V2

EPCIS V6

Reader Protocol V1

Reader Management V2

ONSV2

Security Survey

Security White Paper

EPCglobal Certificate and Certificate Validation Profile

EPCIS Service Binding Interfaces to Backend Applications

AutoLogistics & SCM 2005

123

SAG Standards Cont

AUTO-ID LABS

Working Drafts

EPCIS

EPCIS-User Definition

EPCIS_Web Services Definition Language

EPCIS

ContainmentProfile.doc

AS2 Vs WebServices for EPCIS.doc

EPCIS Phase 2

EPC Information Services User Definition

EPC Information Services

TDS V2.0

ONS Compliance

AutoLogistics & SCM 2005

124

AUTO-ID LABS

ISO Standards

AutoLogistics & SCM 2005

125

AUTO-ID LABS

RF Regulations

Regulators

Classify RFID as Industrial, Scientific and

Medical use

ISM bands

125-134 kHz (ISO 18000-2)

13.56 MHz or HF (ISO 18000-3)

433 MHz (ISO 18000-7)

860 to 960 MHz or UHF (ISO 18000-6)

2.45 GHz (ISO 18000-4)

5.8 GHz (no ISO standard)

AutoLogistics & SCM 2005

126

Other RFID Standards

AUTO-ID LABS

ISO_IEC_18000-1

Reference architecture and definition of parameters to be standardized

ISO_IEC_TR_18001

Application requirements profiles

ISO_IEC_18046

RFID Tag and Interrogator Performance Test Methods

ISO_IEC_TR_18047-2

Test methods for air interface communications below 135 kHz

ISO_IEC_TR_18047-3

Test methods for air interface communications at 13,56 MHz

ISO_IEC_TR_18047-4

Test methods for air interface communications at 2.45 GHz

ISO_IEC_TR_18047-6

Test methods for air interface communications at 860 to 960 MHz

ISO_IEC_TR_18047-7

Test methods for air interface communications at 433 MHz

ISO_IEC_19762

Harmonised Vocabulary

ISO_IEC_24710

Elementary Tag Licence Plate functionality, for 18000-2 to 18000-7

AutoLogistics & SCM 2005

127

Other Relevant ISO Standards

AUTO-ID LABS

ISO_IEC_15418

EAN/UCC Application Identifiers and Fact Data Identifiers and Maintenance

ISO_IEC_15424

Data Carrier Identifiers (including Symbology Identifiers)

ISO_IEC_15434

Transfer syntax for high capacity ADC media

ISO_IEC_15459-Parts 1,2 & 3

Unique identification of transport units

Part 1: General

Part 2: Registration procedures

Part 3: Unique Item Identification for Supply Chain Management

ISO_IEC_15961

Data protocol: application interface

ISO_IEC_15962

Data protocol: data encoding rules and logical memory functions

ISO_IEC_15963

Unique identification for RF tags

AutoLogistics & SCM 2005

128

AUTO-ID LABS

EPCglobal submission to ISO

EPCglobal submitted C1G2 V1.0.9 to ISO

PDAM to 18000-6 issued 26 Feb 2005

Preliminary Draft Amendment

C1G2 will be 18000-6 Type C

PDAM Ballot Resolution Meeting

Singapore, 7 June 2005

174 comments resolved

New FPDAM released

15 July 2005

FPDAM Ballot resolution Meeting

Klagenfurt, Austria, 30 November 2005

AutoLogistics & SCM 2005

129

AUTO-ID LABS

Regulatory Standards

AutoLogistics & SCM 2005

130

AUTO-ID LABS

UHF

The UHF tags will be able to be read by readers

operating within 860 – 960 MHz range.

The readers will be restricted to a small subset of this

range depending on where in the world they are

being operated.

There are also regulations on the amount of power

emitted by the readers depending on where the

readers are being used.

Therefore, a tag may be applied to an item and

shipped anywhere in the world, but a reader has to

be specifically set up for the region or country

Latest update on UHF from ISO WG4

AutoLogistics & SCM 2005

131

AUTO-ID LABS

Map of the ITU regions

AutoLogistics & SCM 2005

132

ITU Region 1 (EU and Africa)

EN300-220 & EN302-208

AUTO-ID LABS

CEPT countries

869.4 - 869.65 MHz : 500mW erp : DC<10%

865.6 - 867.6 MHz : 2W erp : LBT

South Africa

869.4 - 869.65 MHz : 500mW erp

915.2 - 915.4 MHz : 8 W eirp

Note: all of the above operate in < 250kHz

channels

AutoLogistics & SCM 2005

133

ITU Region 2 (Americas)

AUTO-ID LABS

FCC Part 15.247

USA, Canada and Mexico

902 - 928 MHz : 4W EIRP FHSS, 500kHz

wide channels permitted – relaxed

emission requirements within the whole

band.

Central & South America

Generally similar to North America but

varies from country to country.

AutoLogistics & SCM 2005

134

ITU Region 3 (Asia)

AUTO-ID LABS

Australia

918 - 926 MHz : 1W EIRP

920 – 926 MHz : 4W EIRP

Experimental

Strict conditions apply

New Zealand

864 - 868 MHz : 4W EIRP

Elsewhere in Asia

Generally follow CEPT some exceptions below

China 917 to 922 2W ERP

Hong Kong 865-868 2W ERP & 920-925 4W EIRP

Japan 952 - 954 MHz : 4W EIRP (licensed)

Malaysia 919-923 MHz, 2W ERP

Singapore 866-869 MHz 0.5W ERP & 923-925 2W ERP (licence)

South-Korea 910 – 914 MHz

Taiwan 922-928 1W ERP (indoor) 0.5W (outdoor)

AutoLogistics & SCM 2005

135

AUTO-ID LABS

Australian 4W RFID licence

AutoLogistics & SCM 2005

136

Experimental Licence

AUTO-ID LABS

The original licence for RFID

1W EIRP, 918 to 926 MHz

Experimental 4W EIRP Licence

Granted to GS1 Australia

12 July 2005

Operates from 920 to 926 MHz

Only licence that will be granted

Statistics needed to determine

possible interference to

Vodaphone

Receiver base station at 915 MHz

AutoLogistics & SCM 2005

137

AUTO-ID LABS

GS1 Contact

For details contact Fiona Wilson

fwilson@gs1au.org

AutoLogistics & SCM 2005

138

AUTO-ID LABS

Conclusions

AutoLogistics & SCM 2005

139

Conclusions

AUTO-ID LABS

Many RFID related Standards Published

Many people working on those standards

> 1500 people within EPCglobal workgroups

EPCglobal standards are ratified ONLY after artefacts have been

validated

EPCglobal working on both Technical & Business Standards

Security is a big focus

Multi-vendor support for the standards

Conformance documents being published/developed

UHF band opening up

Many GS1 countries already have band allocations

Australia well placed (2nd best in the world)

4W EIRP

12 by 500 kHz wide channels

Auto-ID Lab, Adelaide

Australasian Adoption Research Initiative

RFID Automation

AutoLogistics & SCM 2005

140

AUTO-ID LABS

Questions

AutoLogistics & SCM 2005

141

AUTO-ID LABS

Further Information

Alfio Grasso

Deputy Director

Auto-ID Lab, Adelaide

General Manager

RFID Automation

University of Adelaide

Web: www.rfidautomation.org

Email : alf@rfidautomation.org

Ph: (08) 8303 6473

Mob: 0402 037 968

AutoLogistics & SCM 2005

142