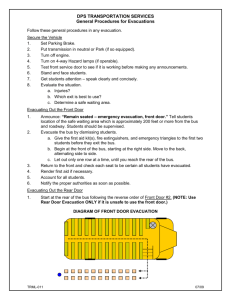

table of contents

advertisement