Managing Production and Supply Chains

advertisement

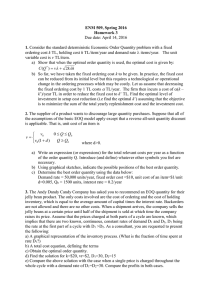

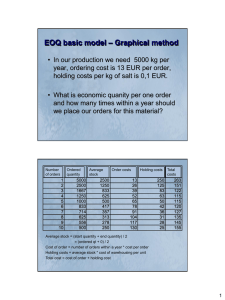

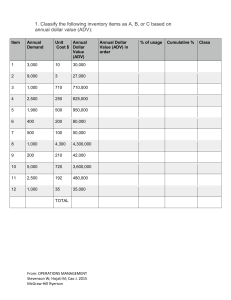

An introduction to the ProSim production management simulation A virtual company which manufactures & markets three products (X, Y, Z) Existing supply chain processes in place for key Marketing & Sales, Production Planning & Control, Purchasing & Payment You will manage the PP&C process Process redesign or supply chain restructuring are out of scope for now Inventory Throughput is the goal … or The Goal? How is this measured? What do we need information-wise to make Goal oriented decisions? What analysis or information systems based tools might help with the details and mechanics? Operating Cost What Visit ProSimPlanner Worksheet Where is the bottleneck? Maximum throughput? Assumptions regarding labor productivity, efficiency, and rejects Purchase cost? Make cost: • Labor (labor productivity?) • Machine time (machine efficiency?) • Materials (reject rate?) Products are produced based on weekly schedules Products are shipped at the end of each ‘month’ (i.e., every 4th week at the end of weeks 4, 8, 12, …) Last year’s monthly demand data are available Current month sales order base forecasts are adjusted weekly Master Production Scheduling (MPS) Materials Requirements Planning (MRP) For ‘simplicity’ we will only use workers 1 thru 9 this term; you can fire if you want but cannot hire (or re-hire). Parts demand? Ordering & setup costs? Holding & carrying costs? Classic EOQ conclusion? Materials demand? Ordering & setup costs? Holding & carrying costs? Classic EOQ conclusion? (watch time units – week, month, year?) Volume discounts? Adjusted EOQ conclusion? Quality control plan Facility maintenance plan True execution point – creating the weekly schedule Communicate plant managers and purchasing decisions Implement human resources recommendations Convert production planners estimates to actions It’s a deep looking pool but time to jump in and get started Complete the reading Prepare a forecast for products X, Y, Z and EOQ calculation for materials M (ProSimPrep1) Prepare a master production schedule for weeks 2 thru 9 (ProSimPrep2) Plan weeks 2 thru 4 (ProSimWk2 thru ProSimWk4) End of presentation