Top 10 Dumbest Things You Can Do in Operations Management

advertisement

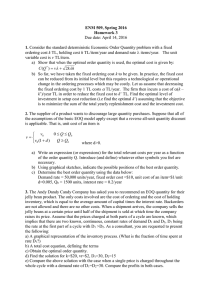

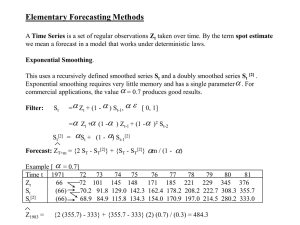

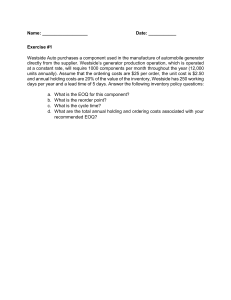

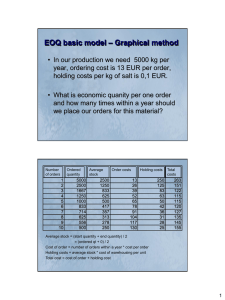

Top 10 Dumbest Things You Can Do in Operations Management 10. Forecast with a simple average of demand. 9. Ignore seasonal adjustment in forecasting seasonal data. 8. Forecast more than one step ahead with a straight-line trend. 7. Order every inventory item with the same frequency. 6. Use arbitrary ordering/holding costs in the EOQ model. 5. Apply the EOQ to dependent demand. 4. Monitor or evaluate product/service quality without a control chart. 3. Schedule service operations with arrival rate equal to service rate. 2. Schedule a project without the critical-path method. 1. Crash a task that is not on the critical path.