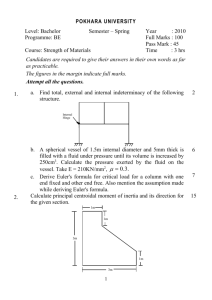

SoM-6.5

advertisement

Principal Stresses and Strain and Theories of Failure Strength of Materials Prof. A. S. PATIL Department of Mechanical Engineering Sinhgad Academy of Engineering, Pune Strength of Materials 1 3. Maximum Distortion Energy Theory (von Mises Criterion) • Failure occurs when the distortional energy associated with the principal stresses equals or exceeds the distortional energy corresponding to that for the yield strength of the material in uniaxial tension. • ductile material • based on a limiting energy of distortion (shear strains) • 0.5 ( (σ1 - σ2)2 + (σ2 - σ3)2 + (σ3 - σ1)2) < σyp2 Strength of Materials 2 Maximum Distortion Energy Theory (von Mises Criterion) For the three principal stresses; 1 u 1 1 2 2 3 3 2 1 2 2 2 1 2 3 2 1 2 3 2 1 3 2E Strength of Materials 3 After taking out the hydrostatic stress (ave=(1+2+3)/3) Now substitute 1, 2 and 3 with 1 ave , 2 ave , 3 ave 1 2 For plane stress; ud 1 1 2 22 3E 1 2 ud Y in an uniaxial tension test. 3E 1 2 Y 2 1 2 2 Strength of Materials 2 4 Graphical Representation of maximum distortion theory σ2 σ1 Strength of Materials 5 4. Maximum Strain Theory • By Saint Venant • Equivalent direct stress acting alone which produces strain equal to greater principal strain shall not exceed the safe limit. σ1 σ2 𝑒1 = − 𝐸 mE • Let f be the stress acting alone producing the strain 𝑓 σ1 σ2 𝑒1 = = − 𝐸 𝐸 Strength of Materials mE 6 Maximum Strain Theory f = σ1 − σ2 mE This stress f should not exceed the safe limit. Strength of Materials 7 NUMERICAL 1. Stresses induced at a critical point in a machine component made of steel are as follows: σ1 = 120 Mpa , σ2 = - 40 Mpa , τxy = 80 N/mm2 Calculate the factor of safety by: 1) Max. Shear Stress Theory 2) Max. Normal Stress Theory 3) Max. Distortion Energy Theory Take Syt = 380 N/mm2 Strength of Materials 8 • Given:σx = 120 Mpa , σy = - 40 Mpa , τxy = 80 N/mm2 Syt = 380 N/mm2 Solution :Principal Stress 1, 2 x y 2 1 2 x y Strength of Materials 2 4xy 2 9 • σ1 = 153.13 N/mm2 , σ2 = -73.14 N/mm2 • Maximum shear stress max max min 2 = 113.135 N/mm2 Strength of Materials 10 • Factor of Safety by:1) Maximum Shear stress theory: yt fos 1- 2 = 1.68 2) Maximum Normal stress theory: yt fos 1 = 2.48 Strength of Materials 11 3) Maximum Distortion Energy Theory:- 1 1 1 2 2 2 yt 2 fos FOS = 1.9 Strength of Materials 12 2. A bolt is under an axial pull of 24 kN together with a transverse shear force of 5 kN. Calculate the diameter if bolt using i) Max. principle stress theory ii) Max. shear stress theory iii) Strain energy theory Take, elastic limit of bolt material as 250 MPa and µ = 0.3. Factor of safety is 2.5 Strength of Materials 13 Given:d = diameter of the bolt in mm P = 24 kN , Shear force S = 5 kN σy = 250 N/mm2 FOS = 2.5 µ = 0.3 Solution:- 1, 2 x y 2 1 2 x y Strength of Materials 2 4xy 2 14 12000 13000 𝜎𝑛 = ± 𝐴 𝐴 𝜎1 = 25000 𝐴 𝜎2 = , Safe Stress = 𝜎𝑦 𝐹𝑂𝑆 1000 𝐴 = 100 N/mm2 Strength of Materials 15 1) Maximum principle stress theory 25000 𝐴 ≤ 100 A ≤ 100 d = 17.84 mm 2) Maximum shear stress theory 𝜎1- 𝜎2 = 𝜎𝑦𝑝 𝐹𝑂𝑆 25000 𝐴 - 1000 − 𝐴 = 100 ∴ 𝐝 = 𝟏𝟕. 𝟗𝟓 𝐦𝐦 Strength of Materials 16 Examples to solve 1. A solid circular shaft subjected to bending moment of 60 kNm and a torque of 15 kNm. Design the diameter of the shaft using. i) Max. principle stress theory ii) Max. shear stress theory iii) Max. strain energy theory Take µ = 0.28, yield strength of shaft is 225 MPa and factor of safety = 2.5 2. A square pin is required to resist a pull of 40kN. Derive a suitable section according to strain energy theory. Maximum tensile stress is 350 MPA and Poisson’s ratio is 0.3. Take factor of safety of 2.5 Strength of Materials 17 Numerical • A shaft is supported in a bearing 4 m apart and transmits 60 kW at 160 rpm. At 1.2 m from one bearing the shaft carries a pulley transmitting a load of 50 kN on the shaft. Find the suitable diameter for the shaft for each of the following cases. i) Maximum direct stress shall not exceed 120 N/mm2 ii) Maximum shear stress shall not exceed 60 N/mm2 Ans:- i) D= 133.2 mm ii) D= 134.5 mm Strength of Materials 18