Principal Stresses and Strain and Theories of Failure

advertisement

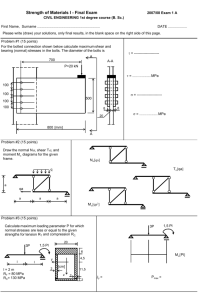

Principal Stresses and Strain and Theories of Failure Strength of Materials Prof. A. S. PATIL Department of Mechanical Engineering Sinhgad Academy of Engineering, Pune Strength of Materials 1 6.4 THEORIES OF FAILURE • To predict elastic failure under any conditions from the behavior of materials in a simple test. • Different theories for different materials and parameters that are considered. 1. Maximum Principal Stress Theory 2. Maximum Shear Stress Theory 3. Maximum Distortion Energy Theory 4. Maximum Strain Energy Theory Strength of Materials 2 1. Maximum principal stress theory • • • • • Maximum principal stress = Yield Stress Rankine brittle materials based on a limiting normal stress σ1 = σyp 1 x y 2 yp 1 2 x y Strength of Materials 2 4xy 2 3 2. Maximum Shear stress theory • Failure occurs when maximum shear stress in complex stress system is equal to the value of maximum shear stress in simple tension. • Tresca, Guest, Coulomb • ductile Material • based on the concept of limiting shearing stress Strength of Materials 4 Maximum Shear Stress Theory (Tresca Criterion) In a tension specimen: max max min 2 The diameter of the Mohr circle = For Plane Stress: 1 (3=0) Y 2 Y max y 2 s y y 1, 2 have same signs. 1 2 Y Strength of Materials 1, 2 have opposite signs. 5 Graphical Representation The boundaries of the governing equation is represented by inclined parallel lines . Material will reach its elastic limit when point (σ1, σ2) falls outside the hexagonal region Strength of Materials 6 NUMERICAL 1. Stresses induced at a critical point in a machine component made of steel are as follows: σx = 120 Mpa , σy = - 40 Mpa , τxy = 80 N/mm2 Calculate the factor of safety by: 1) Max. Shear Stress Theory 2) Max. Normal Stress Theory Take Syt = 380 N/mm2 Strength of Materials 7 • Given:σx = 120 Mpa , σy = - 40 Mpa , τxy = 80 N/mm2 Syt = 380 N/mm2 Solution :Principal Stress 1, 2 x y 2 1 2 x y Strength of Materials 2 4xy 2 8 • σ1 = 153.13 N/mm2 , σ2 = -73.14 N/mm2 • Maximum shear stress max max min 2 = 113.135 N/mm2 Strength of Materials 9 • Factor of Safety by:1) Maximum Shear stress theory: yt fos 1- 2 = 1.68 2) Maximum Normal stress theory: yt fos 1 = 2.48 Strength of Materials 10 Numerical 2. A bolt is subjected to an axial pull of 8 kN and a transverse shear force of 3 kN. Determine the diameter of the bolt required based on i) Maximum principal stress theory ii) Maximum shear stress theory Take elastic limit in simple tension =270 N/mm2 Poisson’s Ratio = 0.3. Adopt a factor of safety = 3 Strength of Materials 11 • Solution:Safe axial tensile stress = f = 270/3 = 90 N/mm2 Direct stress on bolt section = 8000/A N/mm2 Shear stress on bolt section = 3000/ A N/mm2 Where ‘A’ is cross sectional area of bolt i) Maximum principal stress theory x y 1 2 x y 4xy 2 1, 2 2 2 Strength of Materials 12 2 4000 1 8000 3000 1 4 A 2 A A 2 9000 N / mm 2 90 N / mm 2 A - Safe axial tensile stress 𝜋𝑑2 A= 4 ∴ 𝑑 = 11.28 𝑚𝑚 = 100 Strength of Materials 13 • Maximum shear stress theory 𝜎1 = 𝜎2 = 4000 5000 9000 + = N/mm2 𝐴 𝐴 𝐴 4000 5000 1000 =N/mm2 𝐴 𝐴 𝐴 Maximum shear stress 1 2 5000 max N / mm 2 2 A Strength of Materials 14 • Safe shear stress = 5000 𝐴 90 2 = 45 N/mm2 = 45 ∴ 𝐴 = 111.11 mm2 d = 11.89 mm Strength of Materials 15