Day 10 Thickening and Gelling Agents Milk and

Day 10

Thickening and Gelling Agents

Milk and Dairy Products

Words, Phrases, and Concepts

• Polysaccharides

• Thickening

• Gelling

• Type A gelatin

• Sheet or leaf gelatin

• Bloom rating

• To bloom gelatin

• Vegetable gum

• Amylose

• Amylopectin

• Starch granule

• Cereal starch

• Root starch

• Modified food starch

• Instant starch

• Gelatinization

• Starch retrogradation

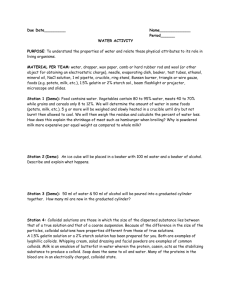

Introduction

To thicken or gel a food product:

– Add an ingredient that is already thick.

• Sour cream, cream cheese, jams and jellies, syrups, fruit purees.

• Besides thickening, these ingredients add color, flavor, and nutrients.

– Add an ingredient used exclusively for thickening and gelling.

• Gelatin.

• Vegetable gums.

• Starches.

– Form an emulsion. Example: heavy cream.

– Form a foam. Example: whipped cream.

– Add eggs.

Thickening and Gelling

Thickening occurs when water and other molecules or particles move around slowly.

Example: Pectin or other large molecules bump and loosely tangle.

Gelling occurs when water and other molecules or particles are prevented from moving around at all.

Example: Pectin or other large molecules bond or tightly entangle.

Thickening and Gelling

Almost any large molecule can thicken.

– Polysaccharides are very large molecules

• Made of many (poly) sugar molecules (saccharides) linked together.

Examples: Starch, vegetable gums.

– Proteins are very large molecules

• Made of many amino acids linked together.

Example: Gelatin.

– Many, but not all, molecules that thicken will gel when used at a high enough level.

• Cornstarch thickens at low levels, gels at high levels.

• Guar gum thickens at low levels, becomes gummy but does not gel at high levels.

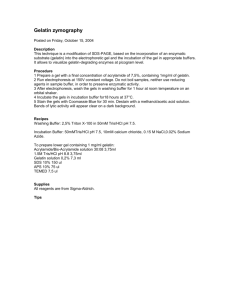

Gelatin

Gelatin

– Forms an appealing crystal clear gel.

Caution: gelatin forms lumps if not properly tempered into cold mixtures.

– Melts quickly and cleanly in mouth.

Caution: gelatin forms tough, rubbery gels if used at too high a level.

– Is an animal protein.

• Not allowed in strict vegetarian diets.

• Sources of gelatin:

– Pigskin (Type A gelatin).

– Cattle bones and hides (Type B gelatin).

– Fish (isinglass).

• Type A gelatin, from pigskin, is by far the most common; not allowed in kosher (Jewish) or halal (Islamic) diets.

Gelatin

Gelatin gels as it cools.

• Tiny strands slow, coil up, tangle, and stack up into fragile junctions.

• Water gets trapped within this three-dimensional web.

• Fragile gel is easily dissolved with body heat.

Gelatin

Gelatin (Type A) is produced in a series of steps.

1. Chopped cleaned pigskins are soaked in cold acid.

• Breaks down connective tissue: Rigid, ropelike collagen protein fibers are transformed into smaller invisible strands of gelatin.

2. Hot water is used for dissolving gelatin and extracting it from pigskins.

• Process is repeated up to six times.

• Each extraction occurs at a progressively higher temperature.

• As extraction temperature increases, quality of gelatin goes down.

• Gelatin solution is purified, concentrated, and formed into sheets or noodles.

3. Sheets or noodles are dried and ground into powder.

Gelatin

Sheet gelatin:

– Is also called leaf gelatin.

– Is made by further processing powdered gelatin.

• Powdered gelatin is redissolved then cast into a thin film.

– As with powdered gelatin, sheet gelatin is available in different grades, or Bloom ratings.

Bloom rating is a measure of gel strength.

– Most gelatin ranges from about 50 to 300 on the Bloom scale.

– The higher the Bloom rating, the firmer the gel and the faster it sets. Also,

• The lighter, clearer it appears and the milder it tastes.

• The shorter, less stringy the gel.

Gelatin

Bloom rating

– Of common powdered gelatin is about 230.

– Of sheet gelatin is often designated by the name of a precious metal.

• Silver and bronze sheet gelatin are most common types in North

America.

Notice the weight of the sheet changes with the Bloom rating. If a formula calls for ten sheets, use ten sheets, no matter the Bloom rating.

Gelatin

How to Use

1. Bloom gelatin first, so it is less likely to clump.

• To bloom gelatin means to add it to a cold liquid to hydrate.

• Use almost any cold liquid; water is most common.

Caution: Raw pineapple and kiwi juice contain an enzyme, a protease, that breaks down and liquefies gelatin.

Caution: Liquids high in acid, like lemon juice, can weaken gelatin, although they will not completely liquefy it.

• Wait 5 to 10 minutes, for gelatin to fully absorb water.

2. Heat the bloomed gelatin gently, or add to hot liquid, to melt.

Caution: Do not overheat, or gelatin could weaken.

Gelatin

Differences between powder and sheets

– Bloomed differently.

• Sheets are typically added to excess water, then removed and gently squeezed.

Example : Take care that water is room temperature or cooler, so sheets do not dissolve completely.

• Powdered gelatin is typically added to a measured amount of cold water.

– Measured differently.

• Sheets are typically counted.

– Easy to do with small amounts.

– With large amounts, easier to weigh.

• Powder is weighed.

Gelatin

Switching between different grades of sheet gelatin

– When counted, make a one-for-one substitution.

Example: If a formula calls for five gelatin sheets, use five sheets of any grade gelatin; manufacturer adjusts weight per sheet, to compensate for different gel strengths.

– When weighed, account for differences in Bloom ratings by adjusting weights.

Example: Instead of 100 grams of bronze sheets, use 76 grams of silver sheets:

100 grams ÷ 3.3 grams/bronze sheet = 30.3 sheets X 2.5 grams/silver sheet

Gelatin

Switching between sheet and powdered gelatin

– An approximate conversion is as follows:

17 sheets = 1 ounce (28 grams) gelatin powder.

– Conversion depends on actual Bloom rating of powdered gelatin.

• Always prepare a test batch to confirm that conversion works; adjust as necessary.

Note: water for blooming gelatin is generally listed in formulas that call for powdered gelatin but not for formulas calling for sheets bloomed in excess water.

Vegetable Gums

Vegetable gums

– Are polysaccharides that absorb large quantities of water.

– Some thicken only; some also gel.

• Are not gummy when properly used.

– Examples:

• Pectin.

• Agar.

• Carrageenan.

• Guar gum and locust bean gum.

• Gum arabic.

• Gum tragacanth.

• Xanthan gum.

• Methylcellulose.

Vegetable Gums

Pectin

– High in certain fruits: apples, plums, cranberries, raspberries, citrus peel.

• Can be made into jams and jellies without added pectin.

– Produces attractive clear gel, with clean flavor and pleasant mouthfeel.

– Can purchase pure pectin as dry powder.

– Requires proper amount of sugar and acid to gel.

– Uses: mirrors, glazes, jams and jellies, bakery fillings, fruit confections.

Vegetable Gums

Agar

– Also called agar-agar, or kanten.

– Extracted from red seaweed.

– Purchase as strands, flakes, or dry powder.

– To use: boil until dissolved.

• Strands are first soaked in water, to soften.

Vegetable Gums

Agar (cont.)

– Nicknamed the “vegetable gelatin.”

• Forms clear gels, similar to gelatin.

• Cannot be whipped as gelatin can.

• Used in place of gelatin whenever dietary or religious restrictions warrant its use.

• Much less agar is needed than gelatin: start with conversion of 8:1, or eight parts gelatin to one part agar.

– Uses: piping gels, gelled confections and desserts, for stabilizing icings and fillings, as a substitute for gelatin (in non-aerated products).

Vegetable Gums

Guar gum and locust bean gum

– Extracted from the endosperm of beans.

– Locust bean gum is also called carob gum.

– Uses

• In ice cream and frozen pasteurized egg whites, to thicken and prevent ice crystal growth.

• In cream cheese and sour cream, to thicken, add creaminess, and prevent separation of liquid.

Vegetable Gums

Xanthan gum

– From the fermentation of a microorganism.

– Forms a flexible film that traps air and leavening gases.

– Provides flexibility to doughs; helps them hold together.

– Main use in bakeshop: gluten-free baked goods.

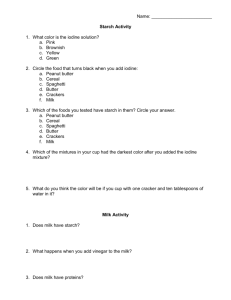

Starches

Starch molecules

– Polysaccharides consisting of many glucose units bonded together.

– Two types.

• Amylose; straight-chained.

• Amylopectin; branched.

Starches

Starch granules

– Small gritty particles tightly packed with starch molecules.

– Found in

• Cereal grains.

– Examples: corn, rice, wheat.

• Roots and tubers.

– Examples: potatoes, arrowroot, and yuca (also called cassava or manioc).

– Vary in size and shape, depending on the starch.

• Potato granules are relatively large and oval; cornstarch granules are much smaller and more angular.

– Grow larger as the plant ages.

• Starch molecules are arranged as concentric rings within the granule, much as growth rings form on a tree as it matures.

Starches

Different starches have different properties because of differences in

– Size and shape of granules.

– Amount of amylose/amylopectin or size of molecules.

Starches

Cereal starches

– Extracted from endosperm of corn, rice, wheat.

– Cornstarch is most common.

• Inexpensive and readily available.

• A general purpose starch.

• Compared to many other starches, is high in amylose.

• Has some disadvantages over certain other starches:

– Cloudy.

– Not stable in freezer.

– Has a cereal taste; masks flavors.

Starches

Root starches

– Extracted from the tubers (roots) of plants.

• Potato, arrowroot, yuca.

– In general, are lower in amylose and higher in amylopectin.

– Use instead of cornstarch:

• Where clarity, clean flavor, and a soft gel are desirable.

• In gluten-free baked goods.

– Gelatinize sooner than cornstarch, for less grittiness.

Starches

Tapioca is most common root starch.

– Extracted from yuca, also called cassava or manioc.

– Processed into pearls, for use in sauces and pie fillings.

• Require soaking, sometimes for hours or overnight; quick-cooking granules require only short soaking.

• Reduces stringiness.

Starches

Modified food starch

– Starch is treated with chemicals to modify its properties.

– Main reason for use: stability.

• Less likely to thin out when exposed to too much heat or acid.

• Less likely to tighten and weep when frozen.

– Any starch can be modified, but many modified starches are made from waxy maize starch.

– Some are cook-up starches and others are instant.

Starches

Instant starch

– Thickens and gels without heat.

– Most are also modified, for stability.

– Also called pregelatinized or cold-water swelling starch.

– To use: Slowly add to cold liquids, while whisking or stirring.

• If necessary, blend dry starch with about four parts sugar or other dry ingredient, to prevent clumping.

– Uses: for last-minute thickening; for heat-sensitive products.

Starches

Starch gelatinization

– Occurs when starch is heated in presence of water.

• Granules lose their orderliness and swell from large amounts of water moving in.

• Water becomes trapped inside swollen granules, causing liquids to thicken.

– Too much heat results in degraded granules and a loss of thickening.

Starches

For maximum thickening and gelling:

– Cook for the proper length of time.

• Follow formula’s method of preparation carefully.

• In general, cornstarch mixtures are boiled gently for two-three minutes.

– Need granules to swell and trap water but do not want granules to degrade.

Starches

Cook time will depend on:

– Type of starch.

• Root starches typically gelatinize sooner than cornstarch.

– Presence of tenderizers.

• Sweeteners and fats slow down the cooking of starch because they slow the swelling of granules.

• With formulas high in sugar, withhold half the sugar until after starch has gelatinized.

– Presence of acid.

• Acid speeds up the cooking of starch because it breaks apart starch granules and breaks down starch molecules.

• With formulas high in acid, reduce cook time, increase the amount of starch, or add acid after mixture is cooked and cooled. Or, use a modified food starch.

Starches

Starch molecules bond over time, once cooled.

– Process is called retrogradation.

– In creams and pie fillings,

• Gel shrinks and toughens.

• Weeping often occurs, where water squeezes out of tightening gel.

• Especially likely to occur:

– With cornstarch-based products.

– When products are frozen.

– In baked goods,

• Crumb stales, that is, it becomes dry, hard, and crumbly.

• Especially likely to occur

– With products made from lean doughs, such as baguettes.

– When products are refrigerated.

Functions of Thickening and Gelling Agents

Providing a thickened or gelled texture.

– Thickening and gelling are forms of structure building.

• Starch, in particular, contributes to the structure of baked goods.

– Increasing stability.

• Thickening and gelling agents are sometimes called stabilizers, meaning that they prevent undesirable changes from occurring in foods.

Examples: gelatin and whipped cream; guar gum and frozen egg whites .

Functions of Thickening and Gelling Agents

Providing gloss or sheen to sauces, fillings, and glazes.

– Many thickening and gelling agents form a smooth layer that clings to the surfaces of ingredients.

– Smooth layers reflect light in a way that provides gloss or sheen.

Example: mirror glazes on cakes, made with gelatin or pectin.

Additional Functions

– Softening and tenderizing baked goods.

– Absorbing moisture.

Storage and Handling

Store gelatin, gums, and starches covered.

– Prevents them from absorbing moisture and clumping.

To use: separate dry particles (gelatin, gum, or starch) before heating.

– Blend with other dry ingredients, such as granulated sugar.

• Rule of thumb: use about four parts sugar with one part dry starch.

– Blend with fat, such as butter or oil.

– Add first to cold water, to hydrate.

• Works with cook-up starches, gelatin, agar and many gums.

• Does not work with instant starches.

Words, Phrases, and Concepts

• Pathogenic microorganisms

• Pasteurization

• Homogenization

• Emulsion

• Casein

• Whey

• Lactose intolerance

• Cultured dairy products

• Lactic acid bacteria

Commercial Processes

• Pasteurization.

– Heat treatment to eliminate pathogenic (diseasecausing) microorganisms.

– Different methods:

• High-temperature, short-time (HTST); most common means.

• Ultra-high-temperature (UHT); also called ultrapasteurization.

– Longer shelf life but slightly different flavor.

Commercial Processes

• Homogenization.

– Prevents cream from separating and rising to top of milk.

– Milk forced through small openings:

• Breaks milk fat into tiny droplets.

• Forms a stable emulsion.

Effect of homogenization on milk fat in whole milk (a) unhomogenized, (b) homogenized

Commercial Processes

• Separation.

– Milk is spun fast in a separator; separates cream from milk.

• Separator is a type of centrifuge; works like a salad spinner.

• Cream is lighter, less dense; spins off from heavier milk.

Commercial Processes

The ability to separate out the fat from milk allows for a range of products with different milk fat contents.

Makeup of Milk

Milk is composed of:

– Mostly water.

– Milk fat and molecules dissolved in it, including:

• Small amounts of emulsifiers, carotenoid colors, rich dairy flavors.

– Milk solids not fat (MSNF), including:

• Protein, lactose (milk sugar), ash (minerals).

Makeup of Milk

Two main types of milk proteins:

– Casein proteins:

• Provide opaque whiteness to milk.

• Thicken and gel as they coagulate; easily coagulated with acids or enzymes.

– Important in the manufacture of cheeses, yogurt, sour cream.

– Whey proteins:

• In clear greenish liquid called whey.

• Form a film along pan bottoms and surface of heated milk; to prevent: add sugar to milk and stir as it heats.

Makeup of Milk

Lactose:

– Milk sugar.

• Provides slight sweet flavor to milk.

• A disaccharide; consists of glucose and galactose.

– Lactose intolerance: intestinal discomfort after consuming milk and milk products.

• Body does not contain enough of the enzyme lactase to break down lactose into glucose and galactose.

– Yeast are lactose intolerant, that is, they cannot ferment lactose.

Milk Products

Fluid Milk

– Classified by its fat content.

• Whole milk is highest in milk fat: 3.25% or higher.

– Best for freshest dairy flavor.

• Use in baked custards, cream pies, custard sauce, ice cream, pastry cream.

– Usually heated before added to yeast doughs.

Milk Products

Dry Milk

– Also called DMS: dry milk solids. Two types:

• High heat DMS; in yeast doughs and other baked goods.

• Low heat DMS; in ice cream, to increase milk solids.

– Made by removing most of the water from whole or fatfree milk.

• Fat in whole dry milk oxidizes easily to rancid off-flavor.

• Fat-free (nonfat) dry milk, NFDM, has a longer shelf life.

– Advantages over fluid milk: takes up less space and needs no refrigeration.

– To use: blend with dry ingredients or cream with butter or shortening.

Milk Products

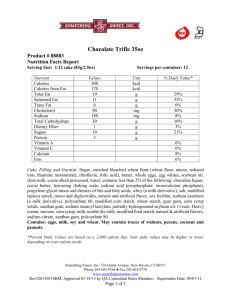

Cream

– Usually UHT pasteurized, for extended shelf life.

– Richer flavor, thicker consistency than milk.

– Heavy cream (36 – 40% milk fat) forms the most stable whipped cream.

– Light cream can be made by mixing equal parts heavy cream and whole milk.

Cream (cont.)

Milk Products

Milk Products

Evaporated and Sweetened Condensed Milks

– Purchased in cans; shelf stable.

– Low-fat and fat-free versions available.

– Both made by removing water from milk.

• Evaporated milk contains twice the milk fat and twice the MSNF as whole fluid milk.

• Sweetened condensed milk has additional water removed and contains added sugar.

– Are not interchangeable.

• Sweetened condensed is thicker, sweeter, denser; has more caramelized color and flavor. Can be used in Mexican flan.

– Uses: pumpkin pie, smooth fudge, caramel, as a cream substitute.

Milk Products

Cultured Dairy Products

– Are fermented products, made by adding live bacteria

“cultures.”

• Most common bacteria culture: lactic acid bacteria, which ferment lactose into lactic acid.

– Generally tolerated by those with lactose intolerance, because they are low in lactose.

– Includes:

• Cultured buttermilk.

• Yogurt.

• Sour cream.

• Crème fraîche.

• Clotted cream.

Milk Products

Cheeses

– Made by forming curds and separating out the liquid whey.

• Curds consist of coagulated casein proteins, with some liquid whey still trapped inside.

– Most are cultured dairy products; live bacteria produce the acid that coagulates the casein.

– Ripened (aged) or unripened (fresh, not aged).

– Most common in bakeshop: unripened cheeses.

• Cream cheese, Neufchâtel, baker’s cheese.

• Ricotta.

• Mascarpone.

• Quark.

Functions of Milk and Milk Products

Main Functions

– Increasing crust color.

• From Maillard browning of milk proteins and sugar (lactose).

– Delaying staling.

– Increasing crust softness.

• Bread made with milk will have soft rather than crisp crust.

– Blending flavors and providing richness in flavor.

– Providing fine, even crumb to baked goods.

– Forming a stable foam.

• Cream whips into foam, stiffened and stabilized by solid fat crystals.

• Milk proteins whip into foam; example: cappuccino froth, whipped evaporated milk.

Functions of Milk and Milk Products

Other Functions

– Aiding in the creaming of shortening.

• Dry milk solids only.

– Absorbing moisture.

• Adding DMS to doughs requires the addition, ounce for ounce, of additional water.

– Aiding in the coagulation of egg proteins.

• Custards made with water (or soy, almond milks) are not as firm as those made with milk.

– Providing moisture.

• Milk is mostly water (about 88% water).

• Heavy cream is over 50% water.

– Adding nutritional value.

Storage and Handling

All milk products absorb odors; cover properly.

• Fluid milk:

– Spoilage bacteria can grow and sour milk; discard.

– Light causes flavor changes, loss of vitamins.

• Cultured dairy products: have longer shelf life.

– Will become increasingly sour over time.

– Mold can grow; discard.

• Soft, unripened cheeses

– High in moisture and highly perishable (will mold).

• Nonfat DMS:

– Can clump; keep cool and dry, and sift, if necessary.

LABS

• All Groups:

• Panna Cotta

• Strawberry Sauce

• Pate choux

• Gr 3- Whip 1# Mascarpone

• Gr 4- Whip 1# Mascarpone/ 4 oz. heavy cream

Lab

• Panna Cotta- Amount of Gelatin

• Gr 1: 1 % powder

• Gr 2: ½ % powder

• Gr 3: 1 ½ % powder

• Gr 4: Leaf- 1% (1 leaf= 1.5 g powder)

Lab

• Strawberry Sauce 1 oz/pint

• Gr 1: Corn starch

• Gr 2: Arrowroot

• Gr 3: Potato starch

• Gr 4: Cake flour

• MOP: Make slurry with starch, 1 oz. sugar and 5 oz puree

• Bring puree to boil- add slurry- bring to boil- boil 2 minutes

Pate Choux

• Pg. 371

• Gr 1- Milk

• Gr 2- Water

• Gr 3- Milk; Butter

• Gr 4- Water, Butter