DIESEL VS ELECTRIC TRACTION

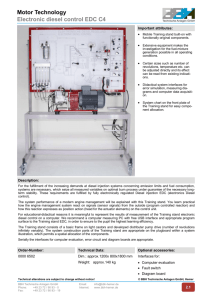

advertisement

Economies of TRACTION DIESEL VS ELECTRIC • How Competitive are the Diesels ? • Is there a need for further Electrification in Indian Railways ? Railway Electrification is justified on various Grounds Modernization Energy Efficiency Depleting Oil Reserves Savings in Foreign Exchange Marginally Capital intensive, but much cheaper operationally More Economical Enables higher speeds and improved throughput Higher hauling capability Eco-friendly How true is the above ? Electric Traction - 1881 After many decades of satisfactory performance, the steam engines were to give way to more modern locomotives. The year 1881 saw the birth of the first electric Railway run by a German Engineer Werner Van Siemens using both the rails to carry the current. Finding this a little too dangerous, Siemens soon adopted the overhead electric wires. Electric locomotives today raun on Rail roads in many countries. Diesel Traction - 1912 The diesel engine was invented in the year 1893, by a young German Engineer, called Rudolf Diesel. But it was only nineteen years later, that the first Diesel locomotive came into existence. Since then, diesel traction has grown from strength to strength. Over 89,000 Diesel locomotives have been built in the world so far, the General Motors, USA alone contributing to as many as 56,000 Locomotives. Superior Technology Diesel or Electric ? Diesel Traction is thus a far more recent technology, as compared to Electric traction. One reason why there are more diesels in the world than electric locos and why more and more are produced year after year. Railways in Europe and some other advanced countries had started Electrification many years before the modern Diesels came on the scene. In fact, Railways in modern economies like US, Australia, etc. are de-electrifying including Suburban services. Superior Technology Diesel or Electric ? - (ii) Diesel locomotive is in fact an Electric Locomotive carrying its own powerhouse. Today’s modern Diesel locomotives with 6 KMs of Electrical wiring is much more Electric than an Electric locomotive with 4 KMs of wire. Electric locomotive provides an easy means of drawing larger units of power from the OHE for the same axle load. Development of Technology for Low weight energy efficient engine and its controls delayed the advent of modern diesel locomotives. Superior Technology Diesel or Electric ? - (iii) Today, technological development in both tractions has levelled of. Diesel locos with Electric transmission have all the benefits of modern technology such as AC-AC transmission. And for the same weight, Diesel traction has 10% or higher load hauling capability. It is conceded that technology of high speed Passenger operation beyond 220 Kmph has advanced on Electric traction, but this is perhaps quite irrelevant to us today. World Railways - Status of Electrification Railway Percentage Electrified U.S.A. 0.9% Canada 0.1% Australia 9.6% China 15.6% France 44% India (BG) 44% Italy 59% Sweden 59% Austria 59% Amtrack (USA) 100% Source : Rail Business Report, 1999 Electrification on IR It is often said that Electrification on IR is hardly 24.5% of total network. The truth is Total Network includes BG, MG as well as NG and is 62759 KMs. Actual BG Route Kilometers are 44383 BG Running Track KMs are 62441 Electrified Running Track KMs - 27946 which is 44.8% of BG Running Track KMs. World’s Stock of Mainline Locomotives 27000 Electric Locomotives 86000 Diesel Locomotives North America (26%) Rest of the World (42%) North America (0%) Rest of the world (47%) Europea n Union (32%) Europea n Union (13%) China (10%) India Latin (5%) America (4%) China (`10%) India (10%) Latin Americ a (1%) Population of Diesel Locos in the World is 3.2 times that of the Electric locomotives (Source: World Bank Railway Database 2000) Electrification on IR (ii) Railway Electrification on the IR was taken up in a big way in the late 70s, as a knee jerk reaction to the 1974 oil crisis. Central Organisation for Railway Electrification (CORE) was created to speedily electrify the high density routes; this task has already been completed in the early 90s. While talking of 1980 Secretary’s report, we have blanked off Gujral Committee Recommendations and the falling crude prices in later years. It is felt that Electrification of Low density non-viable and uneconomic routes continues unabated, perhaps to sustain the organisation. Time has perhaps come, to pause and examine if the need for further electrification still persists. Energy Efficiency Sometimes Electric traction is perceived as more energy efficient, by wrongly computing the efficiency from the Overhead wire, in stead of from the Primary Source of Energy, viz., Coal / Oil (used in producing electricity in power houses) The energy efficiency of Traction should however be calculated right from the Primary source of Power, taking into account, losses occurring at every stage. (For example, in production of Electricity in Power houses and Transmission and Distribution) ENERGY EFFICIENCY (ii) ELECTRIC LOCO DIESEL LOCO Source : The Economics of Railway Traction by Dr. J. Majumdar (Mcgraw Hill & Co.) Overall Efficiency 1. Fuel 2. Theoretical efficiency of Diesel Cycle (for a volumetric compression ratio of 1:16) 3. Boiler efficiency (in electric operation: efficiency of steam power plant) 4. Indicated efficiency 5. Mechanical efficiency of diesel engine (auxiliaries included) 6. Efficiency of power transmission to axles 7. Theoretical efficiency of cycle in electric operation 8. Indicated efficiency and mechanical and electrical efficiency of the entire turbo-a.c. converter (auxiliaries included) 9. Efficiency of power transmission from power plant to substation 10. Efficiency of converter and of power transmission from substation input to current collector, return current losses included 11.Electro-mechanical efficiency of locomotive at the driving wheels, allowing for feed-water heating to 100 deg. C by exhaust stem. Energy Efficiency (iii) Mode of Traction Pass – Diesel Pass – Electric Goods – Diesel Goods – Electric Energy consumed per 1000 GTKM (AUTHORITY: ASS 1999-2000) 4.82 20.6 2.96 8.28 Energy consumed in KCAL Relative Energy Index 42252 66892 25948 26887 1.0 1.58 1.0 1.04 1 kg of HSD used in Diesel Traction = 10500 KCAL 1 KWH of Electricity requires = 2952 KCAL ALL India Average Heat Rate in KCAL / KWH AUTHORITY : CEA Figures The table proves that Electric traction as energy efficient is a myth Availability of Oil (Reserves) Will there be any Oil after 30 years ? ? ? Ever since Col. Blake discovered oil in 1857, this is the usual pessimistic refrain that we hear. Arthur Anderson/Cambridge Energy Research Associates reports: In 1970, the reserves were estimated to last 33.78 years In 1980, the estimate was 33 years despite increase in consumption by 30% In 1999, oil reserves were estimate to last 43 years despite increase in consumption by 43% Oil in India India is the least explored region for oil Well density per 100 Sq. Km India 20 World 100 In 1998, prognosticated hydrocarbon reserves in India were as high as 17 Billion tonnes that can last for 400 years at the consumption rate of 46 Million tonnes per year during that year. India consumes 2% of World’s oil, while Indian Railway uses only 1.7% of India ‘s Oil. (Source : TERI Year Books) Share of Railways in the consumption Others(7%) Power (4%) Railways (1.7%) Domestic (7%) Industry (19.6%) Road Transport (49.7%) Fertilisers (9%) Plantation/ Food (2%) Availability of Oil The Government is investing Rs.54 400 Crores in connecting the Golden Quadrilateral and diagonals by Super Highways. Almost every Automobile / Light Motor Vehicle Manufacturer continues to expand their production capacities. Fuel Cells A simple device uses Hydrogen from fuel combines with Oxygen and produces electricity. No noise, no smoke and no moving parts As per International Railway Journal of March 2000, Fuel Cell Trains shall be a reality by 2008. A breakthrough has already been achieved by BHEL, Hydrabad All Overhead wires will then become redundant !!! Diesel locos can be easily converted by replacing engine with fuel cell. Bio - Diesels Renewable fuels from bio sources include Ethanol Bio diesel Bio hydrogen Biogases As given by Dr.D.K.TULI, Chief Research Manager - IOC on 21-08-2002 Why Bio diesel is important for Railways ? Indian Rail has very large available land Bio diesel will help Railways to : Improve upon emission norms eventually reduce diesel cost redeploy surplus manpower contribute to environment protection Importance of Bio diesel Environment friendly Clean burning Renewable fuel No engine modification Increase in engine life Biodegradable and non-toxic Easy to handle and store Bio diesel process at IOC (R & D) Base Catalyzed transesterification of oil Raw Materials Used Rice Bran Oil Sun flower oil Mohuva Oil Rapeseed oil Japtropha oil Karanjia Oil Scale : 100 g to 60 Kg batch IOC R & D BIODIESEL PILOT PLANT The Indian Scene Annual Growth rate -8% compared to world average of 2% Oil pool deficit & subsidies Rs.16,000 Crores, Rs.18,440 Crores (1996-97) Current per capital usage of petroleum is abysmally low (0.1 ton / year) against 4.0 in Germany or 1.5 tons in Malaysia Even Malaysia’s figure would be beyond our paying capacity Our domestic production would meet only 33% of demand at the end of 10th plan and only 27% by 201011 Investment in Biofuels make strong Economic sense. Jatropha may be the Answer According to the Economic Survey (1995-96), Govt. of India, of the cultivable land area about 100-150 million hectares are classified as waste or degraded land Jatropha (Jatropha curcas, Ratanjyot, wild castor) thrives on any type of soil Needs minimal inputs or management Has no insect, pests & not browsed by cattle or sheep Can survive long periods of drought Propagation is easy Yield from the 3rd year onwards and continues for 25-30 years 25% oil from seeds by expelling 30% by solvent extraction The meal after extraction an excellent organic manure (38% protein, N:P:K ration 2.7:1.2:1) Photograph of Jatropha plant with seeds EU Initiatives on Biofuels Regulatory package COM-2001 / 547 containing action plan and directives 20% alternate fuels for gasoline and diesel by 2020 Major options biofuels, natural gas and biohydrogen Biofuels minimum 5.75% in 2010 Member states can give tax benefits Bio fuels to include Bio diesel, Bio ethanol, ETBE, Biogas. Objectives : Reduce dependency on imported oil Greenhouse gas reduction (8% Kyoto) Support agricultural sector Bio diesel Potential - Indian Railways An estimate Track length of 1,00,000 km If 50% tract available and 50 meters of both sides Approx. area 5000 sq..km considering an yield of 2 tons / ha Yield of oil crop 1 MMTPA Approx. Bio diesel potential 200-250,000 tones i.e. about 10% of the Railways’ diesel requirements Indian Oil as Partner in technology development The Railway Minister said that Railway Ministry and Indian Oil Corporation signed a memorandum of understanding for a pilot project for production of eco-friendly biodiesel for the Railways. Courtesy : The Hindu dt. 13th Feb.2003 Electric Traction -What it costs the Nation ? All figures are in MUs (millions of units) Total Demand of the Country Actual availability Shortfall Consumption of Railways in 2000-01 Avoidable Shortage inflicted by the Railways 507216 467400 26349 7308 27.7% Source : Central Electrical Authority (Figures for 2000-01) Electric Traction -What it costs the Nation ? (ii) Total Shortfall in Peak Load Capacity * Requirement of Railways ** Avoidable Capacity constraints caused by the Railways 10457 MW 5500 MW 54.1% * Source : Central Electrical Authority (Figures for 2000-01) ** Requirement as computed for 2800 Electric locos, assuming Loco Availability (85%), Load factor (60%) and T & D Losses (22%) etc. Every Diesel Loco of 4000 HP put on line adds to the Power Generation Capacity of the country by 3 MW Every Electric Loco of 6000 HP put on line Eats into the Power generation capacity by about 4 to 5 MW * Deprives 15000 Houses of Electric Power Adds to use of inefficient small DG sets by Industrial, Agricultural & Domestic sectors * Taking into account the Locomotive, Transmission and Distribution Losses. Electrify the Railways and Dieselise the Industry ?? In a country where 14.7% villages are yet to be electrified, can we afford to electrify Railways ? The Energy Policy should ideally aim at replacing inefficient use of Fuel Electrification replaces a highly efficient Turbo charged Railway Diesel locomotive with small sized high inefficient gen-sets resulting in higher consumption of HSD and pollution. Anticipated Drains from the Power production in future years, even with no further Electrification. Year Electric Energy required by IR (Million Units) 2001-02 7713 2006-07 9844 2011-12 12564 Assuming a 5% Growth / annum in Freight and Passenger Traffic over the 10th and 11th Plans and with same share of Traffic between Diesel and Electric Further Drain into the scarce Capital Resources At the end Additional of Plan Generation Capacity required by IR (MW) X 1520 XI 1939 Capital Cost required for Locos / Power Plant / T & D Network Rs.12760 Cr. Rs.16112 Cr. X Assuming a 5% growth / annum in Freight and Passenger Traffic over 10h and 11th Plans Optimum Utilisation of Energy Petroleum There is a lot of reluctance in the States for establishing any new coal-based Power Plants in view of the serious limitations like poor quality of coal with high ash and sulphur content, pollution of ash and dust, high cost of developing new coal fields, extreme shortage of water, etc,. Most of the Power houses set up in the country in the last five years and those in the pipe line are based on Petroleum products such as LNG, Diesel, Naptha, etc. Does Electrification save Foreign Exchange ? Electrification ends up draining the Foreign exchange, instead of saving it. The classic case is Ernakulam Trivandrum Electrification at Minus 29% rate of return, tapping Power from a Diesel Power station of Nallalam. Capital investment in Power plants is mostly by way of imported equipment. To Sum up, It is quite obvious that Electrification of Railways is leading to: Dieselisation of the Industry, Agriculture and Domestic Sector Increased Fossil Fuel Consumption and not Reduction Higher Outflow of Foreign Exchange and not savings for the Nation Is Electric Traction only Marginally Capital intensive ? Is Electric Traction only marginally Capital intensive ? The Nation pays dearly by spending our scarce Capital to create this vast infrastructure and to sustain it. On the Diesel traction, a modest engine is all that we require. Power Requirement of a 5000 HP Electric Locomotive Equivalent MW Capacity (Let us assume that Plant and Loco Load factors cancel each other) Transmission Losses 3.75 MW 10% (National Average 22%) 3.75 / 0.9 = 4.2 MW Rs.4.25 Cr. ** Generation Capacity required Current Cost of Power House / MW Cost of Distribution Network / Rs.4 Cr. MW Cost / MW of Power at the Rs.8.25 Cr. Loco Capital to be invested / loco 4.2 x 8.25 = Rs.34.65 Cr. Source : Data as published by CEA Electric Traction is prohibitively Capital intensive (Rs. In Crores) Loco Cost Cost of OHE per Loco Cost of Power House per Loco (refinery irrelevant) Cost of transmission / distribution system per loco Total Capital Cost Diesel 3.66 - Electric 3.79 3.25 17.85 16.80 3.66 41.69 Based on prices for the year 1999-2000 5 km of OHE per locomotive and Rs.65 lakhs /km Break-even Level as Assessed by various Committees Committee Year SAHAI NCAER RAJ Railway Board Directors Railway Board – Eds Railway Board – Eds 1963 1970 1978 1984 Break-even Level (GMT *) 6.06 – 6.91 13 – 18 29.6 – 37.5 31 – 46 1989 1996 34.9 49.72 * Gross Million Tonnes per Route KM / Annum Today, we are executing projects of Sections with 0 – 15 GMT !! Sections under Electrification recently Traffic densities on Sections under Electrification are far less than 49.7 GMT (Break-even level) Lucknow – Kanpur Kharagpur – Bhubaneshvar Ludhiana – Amritsar Ambala – Saharanpur 14 GMT 26 GMT 29 GMT 27 GMT GMT of Non-electrified sections on All India basis GMT > 49.72 40.0 – 49.72 30.0 – 40.0 20.0 – 30.0 10.0 – 20.0 5.0 – 10.0 < 5.0 % of RKM Nil 1.6% 6.7% 11.1% 31.8% 24.0 % 24.8% Justification for any more electrification thus does not appear to exist. Breakeven was given a Go By since no sections on IR in 1996 qualified for Electrification on 49 GMT basis and the CORE was facing a closure. If ROR should only be the criterion, can we de-electrify the low density routes already electrified ? If Oil prices come down, as it did from $36 in 1979 to $9 in 1998, can we attempt de-electrification of the entire country based on ROR ? Recommendations of Gujral Committee - 1990 For the period 1990-2005, Electrification of 2510 KMs recommended. Electrification recommended @ 214 Kms per year Sections specifically recommended for Not Electrifying already electrified. Actual Electrification done between 1990 and 2000 has been 5000 KMs which is double of what was recommended. Rate of Electrification is 2.33 times of what was recommended. Line Haul Costs The Operational Line Haul Costs for Diesel and Electric Traction are expressed in terms of the Line Haul Costs per 1000 GTKMs of Traffic carried. It has the following components. -Costs of Fuel, Stores, etc. -Repair, Maintenance and Operating Expenses. -Depreciation -Interest Anomalies in Line Haul Costs OHE Financing through Budgetary support (Applicable 7% Dividend) Capital-at-charge (Rs.4359 Crore *) of Electrification retained with CORE. Capital-at-charge of Zonal Railway kept low (Example-WR/43 Crore, SR/69.9 Crore since 1987, CR/120). Interest of full Capital-at-charge Rs.15 per 1000 GTKM ROR worked out for 36 years, slightly less than the OHE Codal life of 40 years to avoid Replacement costs getting reflected. IRFC Lease Hire Charge apportion to Diesel locos only (Example-ER) IRFC Lease Hire charge distributed in proportion of loco holding to the disadvantage of diesel traction where shunting locos also get included. * Source : 2001-02 (BE) Figure as per Budget Documents Explanatory Memorandum 2001-02 Line Haul Costs Proof of the Pudding is in the Eating !! Diesel Line Haul Cost on Non-electrified Railways (NE & NF) are significantly lower than that of Electrified Railways NE NF 46.48 62.10 65% Lower than IR Ave. 24% Lower than IR Ave. Line Haul Costs In any case, the Average Line Haul Cost derived from the High Density Electrified Routes cannot obviously be Extrapolated to justify the Electrification of Low Density Routes. Procedure for sanction of Electrification Projects Each Electrification Project will be justified on ROR which should exceed 14% with the DCF Method. In certain specific cases, Electrification will be justified on considerations of Operational flexibility Electrification of a single line section (Main Line) will normally not be considered. The ONLY Recommendation followed is to Do Away with Breakeven, due to obvious reasons. World Bank Appraisal Only Independent Appraisal of Two sections done in 1995 JHS-ET BallarshahVijayawada Projected ROR 23.4% 40.5% Actual ROR 9% 2% Wrong Assumptions: Speed of Goods trains Diesel in kmph Electric Maintenance cost in Diesel Rs. Per 1000 GTKM Electric Energy Cost (Rs.) Diesel Electric Assumed 24 Actual 28 36 3.3 29 7.69 2.2 2.8 / lit 0.4 / kwh 7.54 5.9 / lit 2.5 / kwh CAG Report No.9 of 2000 on FUEL MANAGEMENT DELHI - AMBALA - ROR Projected : 14.5% Actual : (-) 10.25% BINA - KATNI Full Diesel Operation Cost : 68.9 Crore Full Electric Operation Cost : 110.79 Crore Rate of Return (-) ve CAG Report 2000 For the Period 1994-95 to 1998-99 Total Working Expenses Fuel alone Steam Diesel Electric Whereas, Share of GTKM – Rs.87,057 Cr. Rs.21,772.9 Cr. Rs.149.31 Cr. Rs.8,590.38 Cr. (39.45%) Rs.13,033.21 Cr. (59.85%) Diesel Electric 46.17% 53.64% Railways have made no provision for energy meters in locomotives either to monitor the electric energy consumption or to work out the electricity consumed for electric traction of different classes of traffic. The apportionment of electricity consumed between goods and passenger services is being done on an estimated standard specific energy consumption (SEC) for passenger services. The SEC adopted was obviously erroneous. Sometimes, the adopted SEC for passenger traffic resulted in negative consumption for goods traffic. The figures, therefore, have no realistic basis. Electrification of the main routes picked up momentum in 1970s. By March 1999, 14,050 route kilometres were electrified at the cost of Rs.4,008.55 crores. It is imperative that a review is undertaken now for choice of traction with reference to the operational results of the electrification already done. Review by Audit of 2 electrified sections and a project completion report prepared by the World Bank in 1994 tend to indicate that the projected returns were significantly overstated and could not be achieved. Besides, the expected economy in cost of operation has not fructified having regard to the trend of international oil prices vis-à-vis the sharp rise in domestic electricity costs. Further in Indian conditions, uninterrupted electricity supply to Railways inevitably affects industry adversely. (Para 7) (v) Consumption of diesel/ electricity per 1000 GTKMs (BG) Sl. Period No. Diesel (Litres) Passenger Goods and and proportion proportion of mixed of mixed 3 4 5.33 3.33 5.30 3.20 5.15 3.15 5.39 3.12 5.27 3.12 1 2 1. 1994-95 2. 1995-96 3. 1996-97 4. 1997-98 5. 1998-99 Average for 5.29 the period 3.18 Electricity (KWH) Passenger Goods and and proportion of proportion mixed of mixed 5 6 20.26 8.88 19.98 8.88 19.89 9.02 19.82 8.85 19.75 8.51 19.93 8.82 Opportunity Cost of Investments in Electrification Electrified Route Current Cost Interest Cost @ 16% 15,398 KMs 10,000 Crores 1,601 Crores The interest cost alone can finance CIF value of the Total HSD consumed by IR The Capital Investment in Electrification can buy 2734 Diesel locos almost the same number that we have today *@ Average Current Price Rs.63 Lakhs per KM Load Haulability Conventional Locomotives 4000 HP WAG5 Adhesion 0.31 Starting TE 38t 1 in 100 2200 t 1 in 50 3150 t 3100 HP WDG2 0.36 40.5t 2750 t 3705 t Load Haulability Modern Diesel Vs Electic 6000 HP WAG9 Adhesion 0.37 Starting TE 47t 1 in 100 3205 t 1 in 50 4250 t 4000 HP WDG4 0.42 53t 3655 t 4840 t Average Freight Train Speeds - BG Year Diesel Electric 1960-61 22.2 19.5 1970-71 22.9 25.2 1980-81 21.3 22.8 1990-91 22.6 23.1 1995-96 22.5 23.8 1996-97 22.5 24.1 1997-98 22.7 24.7 1998-99 22.2 24.9 1999-00 22.6 24.8 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) Train KMs Goods Train Engine Hours (Goods) Wagon KMs Net Tonne KM (Goods) GTKM (Goods) GTKM (Goods) including eng. Wt. GTKM (Rev.) NTKM (Rev.) GTKM including wt. Of eng. X Avg. speed (Diesel) (9) ÷ (6) (Line 42 of the Report) Diesel 5,724,512 2,25,816 Electric 78,57,387 3,27,027 47,50,76,841 5,49,78,59,400 76,94,37,326 9,87,04,92,200 10,78,62,15,100 11,93,18,50,700 17,98,57,43,600 19,28,83,12,100 10,58,36,82,538 5,42,15,54,336 3,02,47,64,52,131 17,66,97,08,475 9,74,03,57,505 4,63,43,49,23,558 25.35 24.02 Courtesy : Traffic Accounts – Goods Analysis 2001-02 (BG) Study by LRDSS Conclusions HP to Load Ratio of 1.5 - Most beneficial & Cost effective. This, of course, pertains to sections near saturation. On Passenger dominant sections, HP to Load Ratio >2 for Diesel also. Further overpowering not recommended. - Benefit insignificant. On Single Line sections, gain under Electric traction is low. (Tract & Other reasons limit the speed improvement). HP to train load ratio is not a traction specific issue. Positive impact of Electric traction on Freight dominant double line sections where HP to trailing Load ratio is low. - 12 - 16% higher line capacity This recommendation of course is not traction specific but only HP specific. Environment Issues Contrary to popular perception, Electric traction is more polluting than Diesel traction. Power for Electric Loco comes from either Diesel based Power station with same level of pollution as Diesel loco Or from Coal based Thermal station whose “Green House” gases emission is 26% more than Diesel loco (UNDP Study) Electric Loco- Environment friendly - Is that really so ?? = 16 Tonnes of coal Ash per day One Electric Loco of 5000 HP requires 4.2 MW of Power. One MW of Power requires 10 Tonnes of Coal per day And at 40% Ash content, generates 4 Tonnes of Coal Ash per day. Source: Central Electricity Authority Annual Report 1998-99 Break Up Price of HSD Custom duty 10% Others 9% Marketing Margin 1% Product Price Adj 9% Excise Duty 13% Cess 7% CIF Cost 51% Price of HSD Oil Basic Price * Rs.14.54 per Litre (including Excise) Inclusive of Sales Tax & Freight the price ranges between Rs.15.12 to Rs.17.69 Average Issue Price Rs.16.25 per Litre * Authority : Board’s rate contract dt.12.1.2001 Is Electricity overpriced ? Railway Traction needs immune power, with no cuts, warranting duplication of Transmission and Distribution systems, which obviously comes at a Premium. Unlike HSD, Electricity is subsidised by waiving off Sales Tax and Excise, though it is an Economic Good manufactured and sold. Cost of Fuel & Electric Energy (Rs. Per 1000 GTKM) Year 94-95 95-96 96-97 97-98 98-99 99-00 Increase over 94-95 Pass. Diesel Elect. 39.30 55.95 38.52 63.45 41.40 74.98 52.02 81.78 52.38 86.31 57.31 90.43 46% 62% Goods Diesel Elect. 23.99 23.48 23.69 28.58 25.51 32.47 30.76 34.54 30.10 34.06 35.19 36.35 47% 55% Source: ASS Published by Ministry of Railways (1994-95 to 1999-2000) Conclusions Electric Vs Diesel debate is not an issue of Departmental dominance but Economic survival. Electrification of High Density Traffic Route (49.72 GMT and above) is not being questioned. There is no pressing need for electrifying remaining sections when Railways are facing Financial Disaster. A complete moratorium on Electrification should be place, as an immediate measure. CORE should be wound up. Work of ongoing projects should be executed only by the concerned Railway as is the case with projects of BG conversion, doubling of lines and other Engg. / S&T / Elect. Works, which also overlap on Multiple Railways.