Catalyst Fundamentals

advertisement

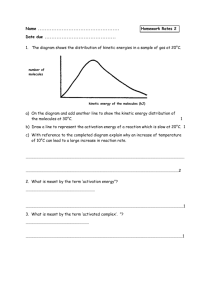

Catalyst Fundamentals 朱信 Hsin Chu Professor Dept. of Environmental Eng. National Cheng Kung University 1 1. The Basics: Activity and Selectivity Catalyst A material that increases the rate of a chemical reaction while itself not undergoing any permanent change Complete oxidation example (nonselective) Pt C2 H 4 3O2 2CO2 2H 2O The adsorption of C2H4 and O2 onto the catalyst Pt provides a chemical shortcut → reaction at lower temperatures Partial oxidation example (selective) 1 VO C2 H 4 O2 CH 3CHO (aldehyde) 2 Next slide (Fig. 1.1) Activation energy 2 5 2 Both the net enthalpy (△H) and net free energy (△G) are unaffected by the presence of the catalyst. (and consequently the equilibrium constant (Ke)) The catalyst influences selectivity by preferentially lowering the activation energy for a particular step in the reaction sequence and increases the rate at which this step proceeds. e.g., V2O5: The reaction path leading to the formation of the aldehyde product is favored because it has a lower activation energy than the complete combustion to CO2 and H2O. Pt: The opposite is true. In catalytic air pollution control: All the processes utilize solid heterogeneous catalysts through which gaseous reactants pass. 4 2. Dispersed Catalyst Model The number of reactant molecules converted to products in a given time is directly related to the number of catalytic sites available to the reactants. → Maximize the number of active sites by dispersing the catalytic components (Pt, Fe, Ni, Rh, Pd, CuO, PdO, CoO, etc.) onto a surface High surface area, porous oxide particles (carriers): Al2O3, SiO2, TiO2, SiO2-Al2O3 combinations, activated carbon, etc. Next slide (Fig. 1.2) Pt catalyst dispersed on a high surface area Al2O3 carrier 5 The internal surface of the Al2O3 in rich in surface OH– groups, depending on the type of Al2O3 and its thermal history. These OH species, represent sites upon which one can chemically or physically bond a catalytic substance. The higher the catalytic surface area, the higher the rate of reaction for a process controlled by kinetics rather than mass transfer. The rate is influenced by the hydrodynamics of the fluid flow, the pore size and structure of the carrier, and the molecular dimensions of the diffusing molecule. 7 3. The Steps in Heterogeneous Catalysis catalyst A B (1) Reactant A → outer surface of the carrier containing the catalytic sites Bulk molecular diffusion rates vary approximately with T3/2 Typical activation energy, E1=2-4 kcal/mol (2) Reactant A → internal catalytic sites Pore diffusion process varies approximately with the square root of k, the rate constant for the chemical conversion reaction. Activation energy, E2, is approximately one-half that of a chemical reaction or about 6~10 kcal/mol. (3) Reactant A chemisorb onto the catalytic site Chemisorption rates generally follow exp (-E3/RT). E3, activatin energy for chemisorptions , is typically greater than 10 kcal/mol. 8 (4) Catalytic surface reactions involve chemisorbed A → B Reaction rates follow exp (-E4/RT). Activation energy, E4, is typically grater than 10 kcal/mol. (5) Product B must desorb from the site Desorption rates follow exp (-E5/RT). Activation energy, E5, is typically greater than 10 kcal/mol. (6) Product B diffuse through the porous network Kinetics are similar to step 2. (7) Product B diffuse into the bulk gas Kinetics are similar to step 1. Next slide (Fig. 1.3) Rate-controlling steps versus temperature profile 9 4. The Arrhenius Equation A simple first order reaction rate = kCA k: rate constant CA: concentration of the reactant A Arrhenius Equation Ea k k0 exp RT ln k ln k0 Ea 1 R T k0: proportional to the number of active sites Next slide (Fig. 1.4) Arrhenius plot 11